Expansion type flow gel profile controlling water shutoff agent

A technology of profile control and water plugging agent and gel, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of insufficient formation plugging, poor salt resistance and temperature resistance, and short delayed crosslinking, etc., to achieve Increase the water absorption expansion multiple, increase the salt resistance and temperature resistance, and increase the effect of delayed crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Mix the solution concentration of 0.12% of polymer polyacrylamide (molecular weight: 23-25 million) with 0.4% of boron modified phenolic resin delayed crosslinking agent, control the gel reaction temperature to 80°C, and the pH value of the solution system to be 7.5.

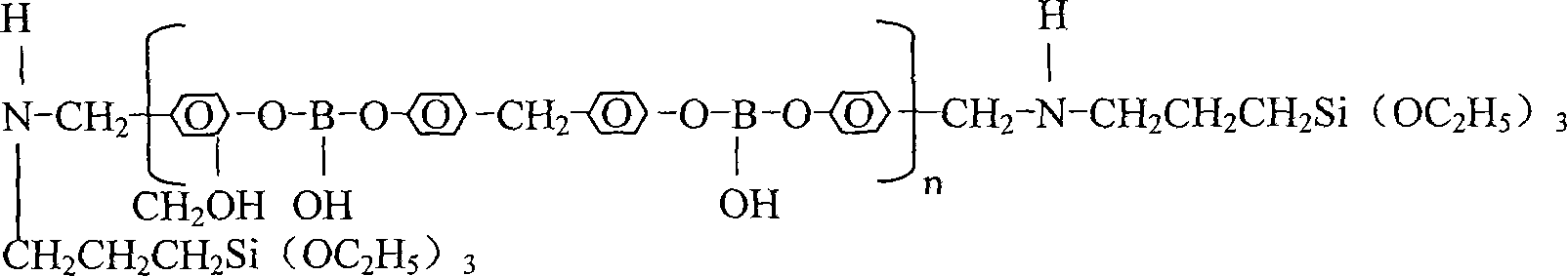

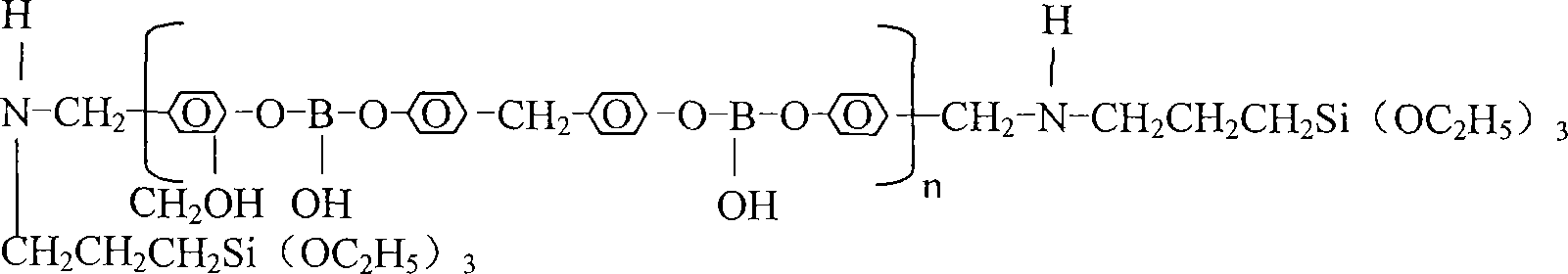

[0015] Wherein the boron modified phenolic resin delayed crosslinking agent processing and preparation process is as follows:

[0016] 1. Feed according to the molar ratio of phenol and formaldehyde 1:5.2, first add phenol, then add caustic soda according to 0.8% of the total amount of pure phenol and formaldehyde, and control the temperature at 50°C for 15 minutes.

[0017] 2. Add 80% of the total amount of formaldehyde, and control the temperature to react for 40 minutes under the conditions of 55°C and ph=9. At this time, the reaction solution was light red.

[0018] 3. Add caustic soda according to 0.2% of the total amount of pure phenol and formaldehyde, then add the remaining 20% formaldehyde, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com