Evaporator

An evaporator, refrigerant technology, applied in the direction of evaporator/condenser, indirect heat exchanger, heat exchanger type, etc., can solve the problem of small heat transfer area, reduced heat exchange performance, refrigerant flow parts and separated fins The assembly of the chip components is troublesome and other problems, so as to achieve the effect of improving heat exchange performance, improving emission performance and good heat exchange performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

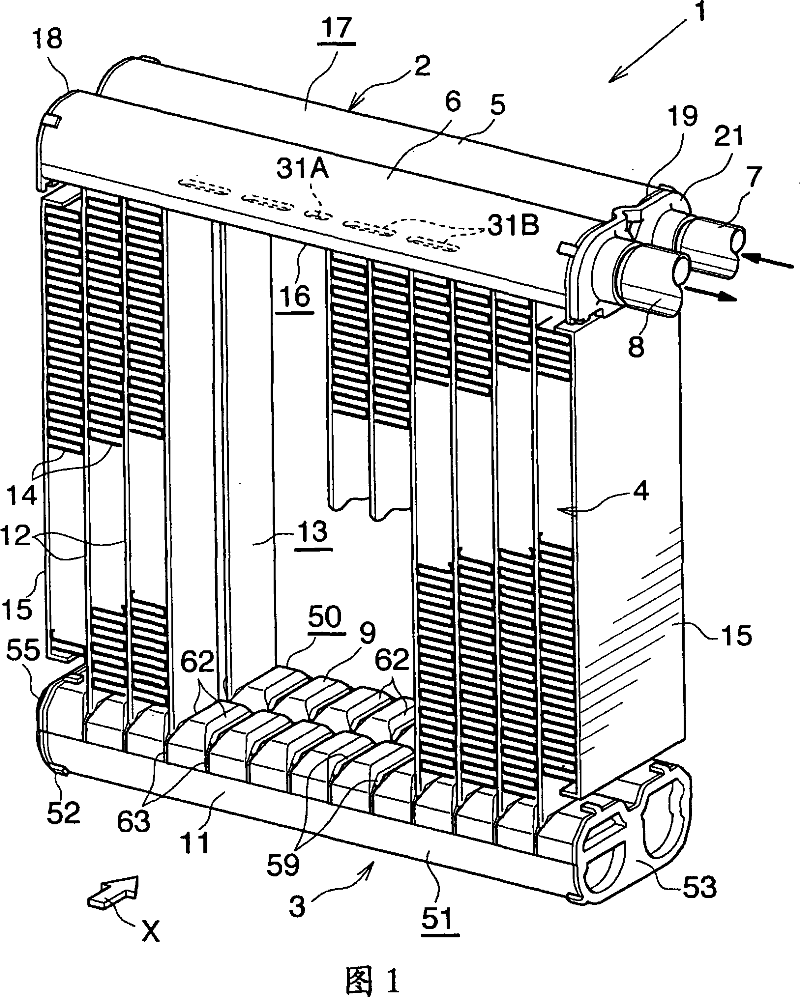

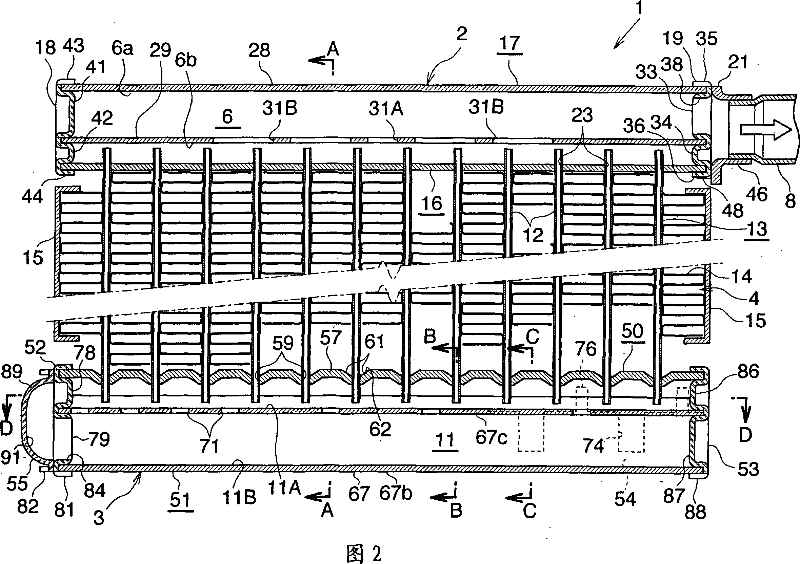

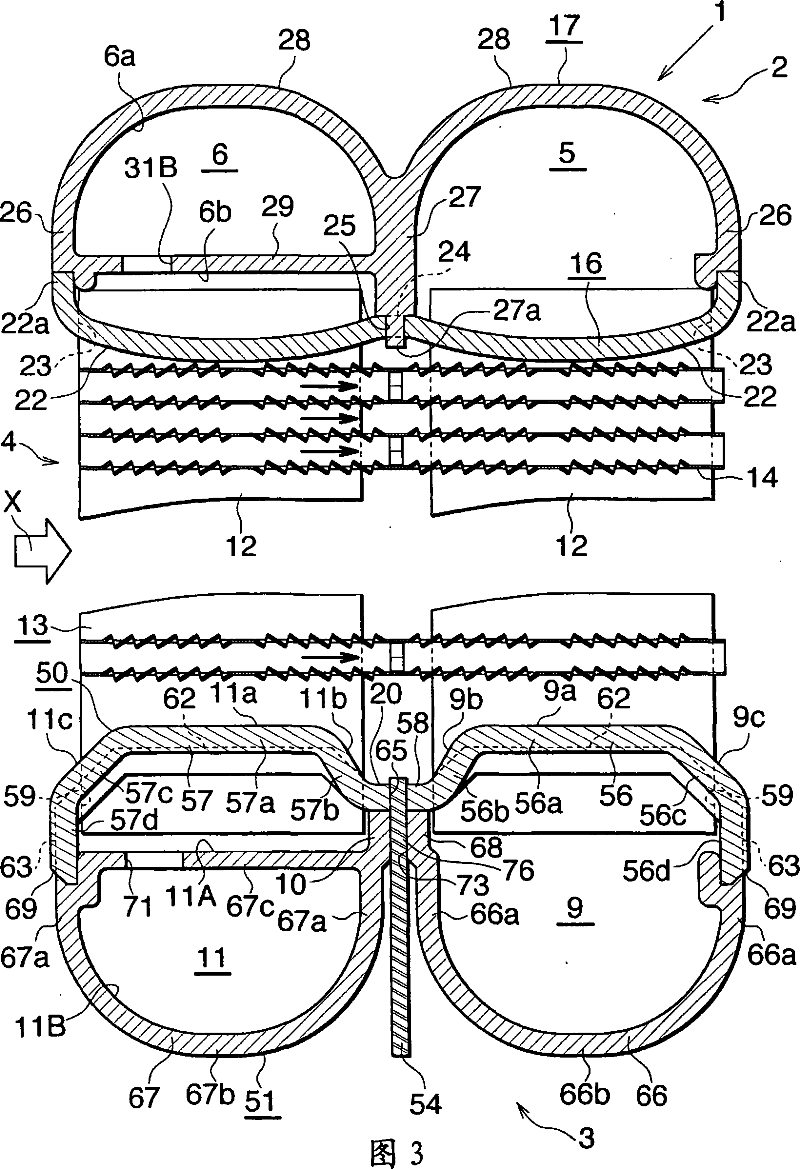

[0065] 1 to 10 show this embodiment.

[0066] 1 to 3 show the overall structure of the evaporator, and FIGS. 4 to 10 show the structure of the main part of the evaporator. Figure 11 shows how the refrigerant flows in the evaporator.

[0067] In Figures 1 to 3, the evaporator (1) for a car air-conditioning unit using a refrigerant containing chlorofluorocarbons includes a refrigerant inlet-outlet box (2) made of aluminum and a refrigerant turning box (3) made of aluminum. ), the boxes (2) and (3) are vertically separated from each other, and also include a heat exchange core part (4) disposed between the boxes (2) and (3).

[0068] The refrigerant inlet-outlet box (2) includes a refrigerant inlet header portion (5) on the side toward the front (downstream side with respect to the air flow direction), and a refrigerant inlet header portion (5) on the side toward the rear (downstream side with respect to the air flow direction). The upstream side of the refrigerant outlet heade...

Embodiment 2

[0113] This embodiment is shown in FIG. 12 .

[0114] In the corrugated fin (14) of the evaporator of Embodiment 2, except for the cutout (95) and the inward protrusion ( 96), a notch (95) and an inward protrusion (96) are also formed on the front protruding portion (140) of the corrugated fin (14) protruding forward beyond the front end of the front flat tube (12).

[0115] Other structural features are the same as those of the evaporator (1) of Embodiment 1.

[0116] In the evaporator of Embodiment 2, when condensed water is generated on the surface of the corrugated fins (14), a part of the condensed water flows downward through the openings between the louver plates (94). In addition, condensed water flows toward the junction between the flat tube (12) and the crest portion (14a) and trough portion (14b) of the corrugated fin (14) under the action of surface tension, and collects on the junction. . Condensed water accumulated on the junction between the flat tube (12) a...

Embodiment 3

[0118] This embodiment is shown in FIG. 13 .

[0119] In the corrugated fins (14) of the evaporator of Embodiment 3, instead of the cutouts (95) and the inward protrusions ( 96), a notch (95) and an inward protrusion (96) are formed on the front protruding portion (140) of the corrugated fin (14) protruding forward beyond the front end of the front flat tube (12).

[0120] Other structural features are the same as those of the evaporator (1) of Embodiment 1.

[0121] In the evaporator of Embodiment 3, when condensed water is generated on the surface of the corrugated fins (14), a part of the condensed water flows downward through the openings between the louver plates (94). In addition, condensed water flows toward the junction between the flat tube (12) and the crest portion (14a) and trough portion (14b) of the corrugated fin (14) under the action of surface tension, and collects on the junction. . Condensed water accumulated on the junction between the flat tube (12) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com