Cooling storage

A storage room and storage room technology, which is applied to the field of cooling storage rooms, can solve the problems of complicated installation workability, poor workability, and difficult positioning of cooling units, and achieve the effects of easy installation work, improved installation workability, and cost realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

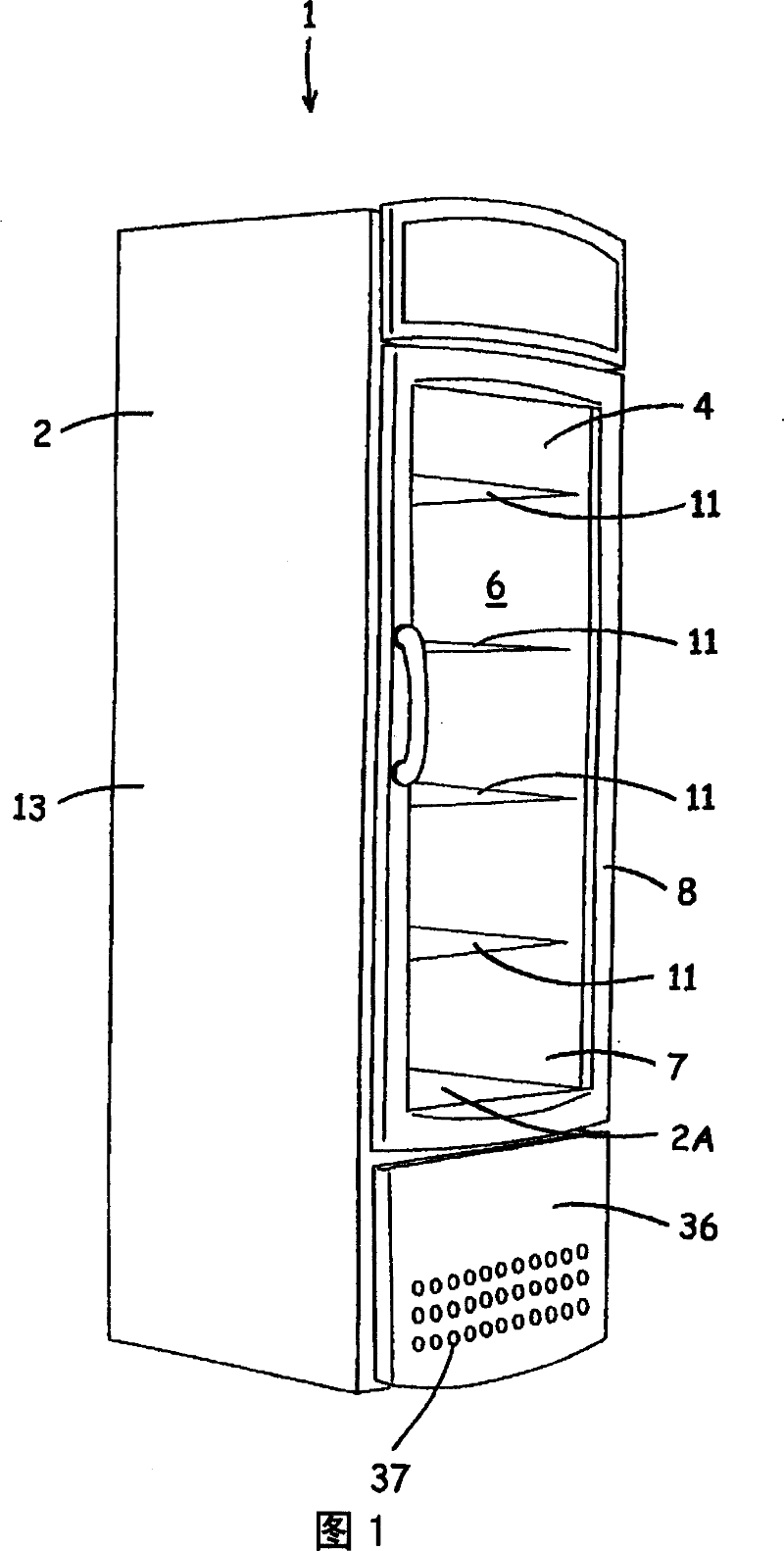

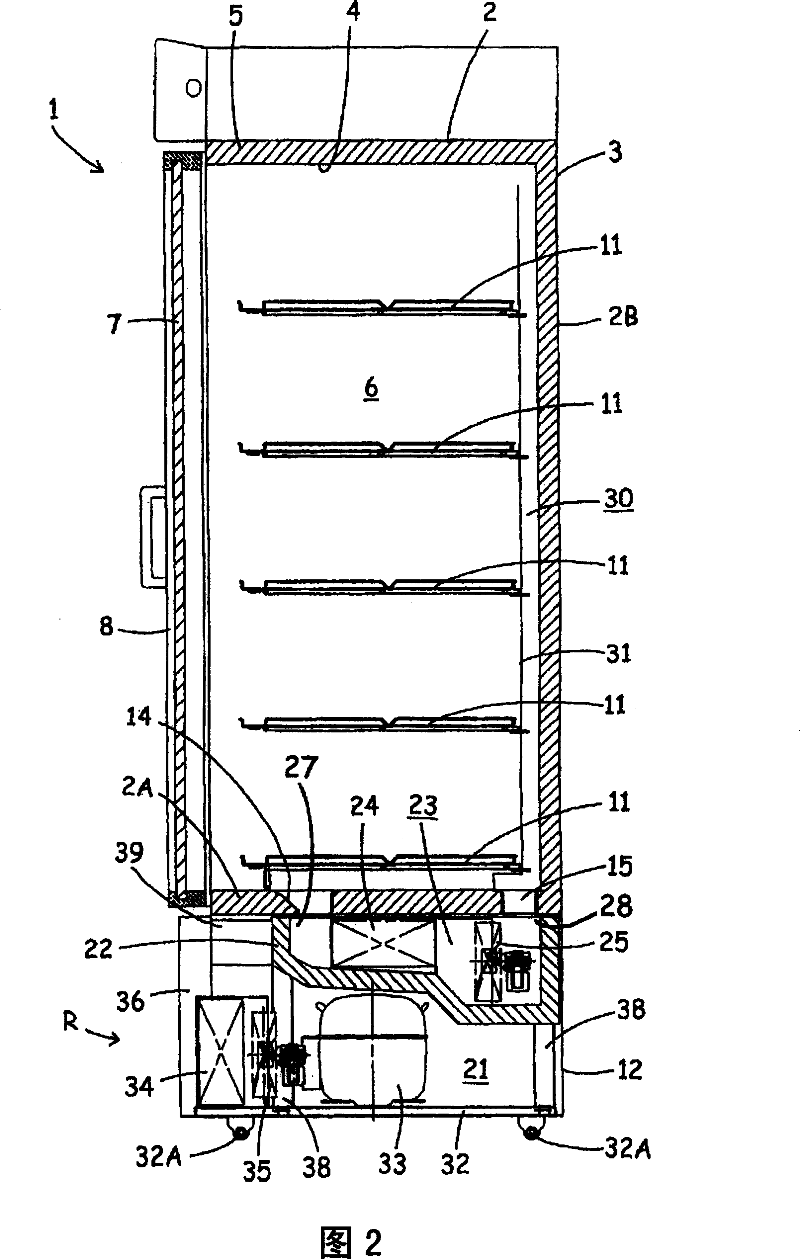

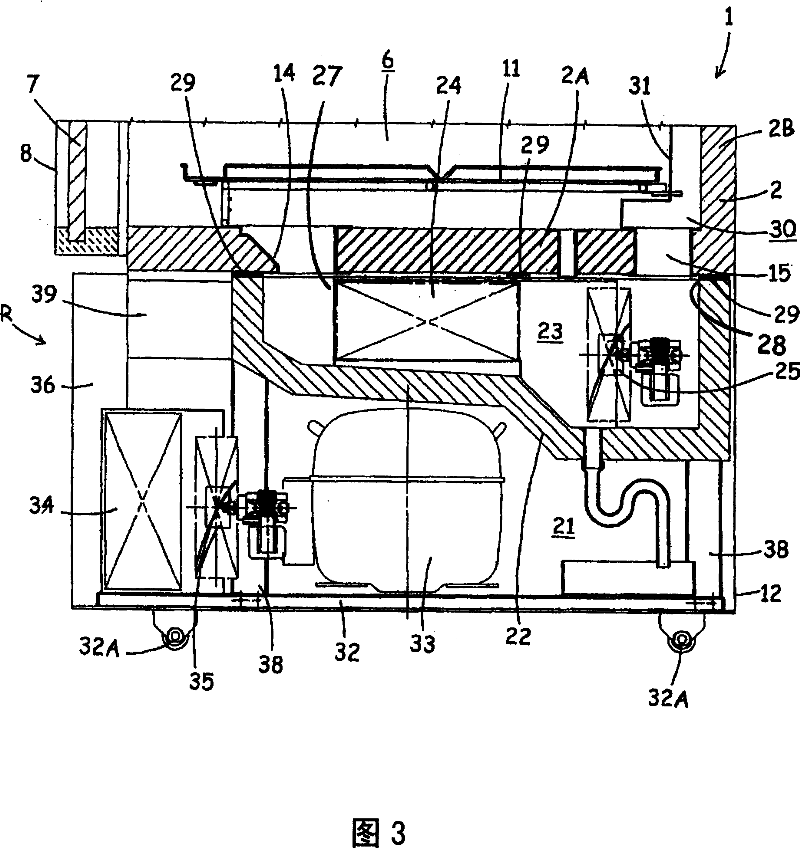

[0035] Hereinafter, cooling storage 1 according to the embodiment of the present invention will be described in detail based on the drawings. Fig. 1 is a perspective view of a cooling storage 1 to which the present invention is applied, Fig. 2 is a longitudinal sectional side view of the same cooling storage 1, and Fig. 3 is an enlarged longitudinal sectional side view of the lower part of Fig. 2 .

[0036] The cooling storage 1 of the present embodiment has a main body constituted by a rectangular heat insulating box 2 with an open front. The heat insulating box 2 is composed of an outer box 3 made of steel plate having an opening at the front, an inner box 4 having an opening at the front, and a heat insulating material 5 filled between the inner and outer boxes 3 and 4 with foam. In addition, a store room 6 with an open front is formed in the heat-insulating box 2 . The store room 6 is open at the front and is closably closed by a door 8 provided with glass 7 through which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com