Desalination apparatus and method

A kind of equipment and desalination technology, applied in chemical instruments and methods, water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of uneconomical production cost, expensive, heavy infrastructure cost, etc., and achieve minimum environmental impact the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

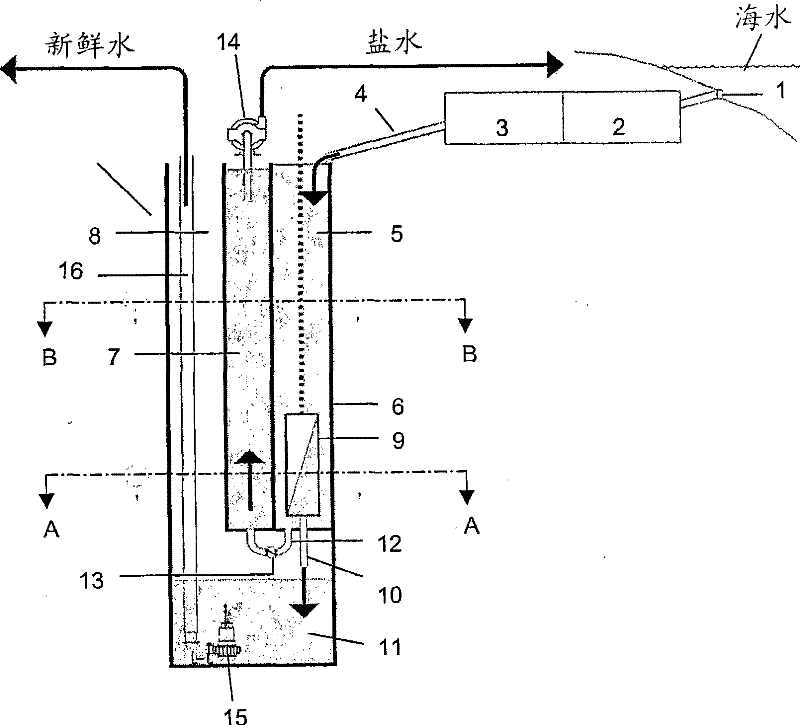

[0070] The present invention will be described in detail with reference to preferred embodiments. The desalination facility is located close to the sea to easily draw seawater for desalination, preferably using a gravity flow method.

[0071] Preferred embodiments of the present invention will be described by way of illustration only and not limitation. refer to figure 1 , the seawater inlet 1 is located at a sufficient depth below mean sea level to ensure that the lowest sea level is higher than the seawater inlet when the tide is lowest. The seawater flows to the seawater filtration system 2 by gravity. Established systems for filtering seawater known in the art are employed to ensure that the seawater is filtered to remove solid particles in order to produce the "cleanest" quality possible by applying existing commercially available technology. Such techniques will not be described herein.

[0072] Next step Before the seawater enters the reverse osmosis step, according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com