Polypropylene resin composite for filling hollow shaping product and preparation method thereof

A polypropylene resin and composition technology, which is applied in the field of filled polypropylene resin composition for hollow molding and its preparation field, can solve the problems that it is difficult to uniformly disperse inorganic fillers, the impact strength is difficult to meet the requirements of falling shelves, and it is difficult to form thin-walled containers. problems such as stability and rapidity, to achieve the effect of good toughness, low thermal expansion coefficient and low shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

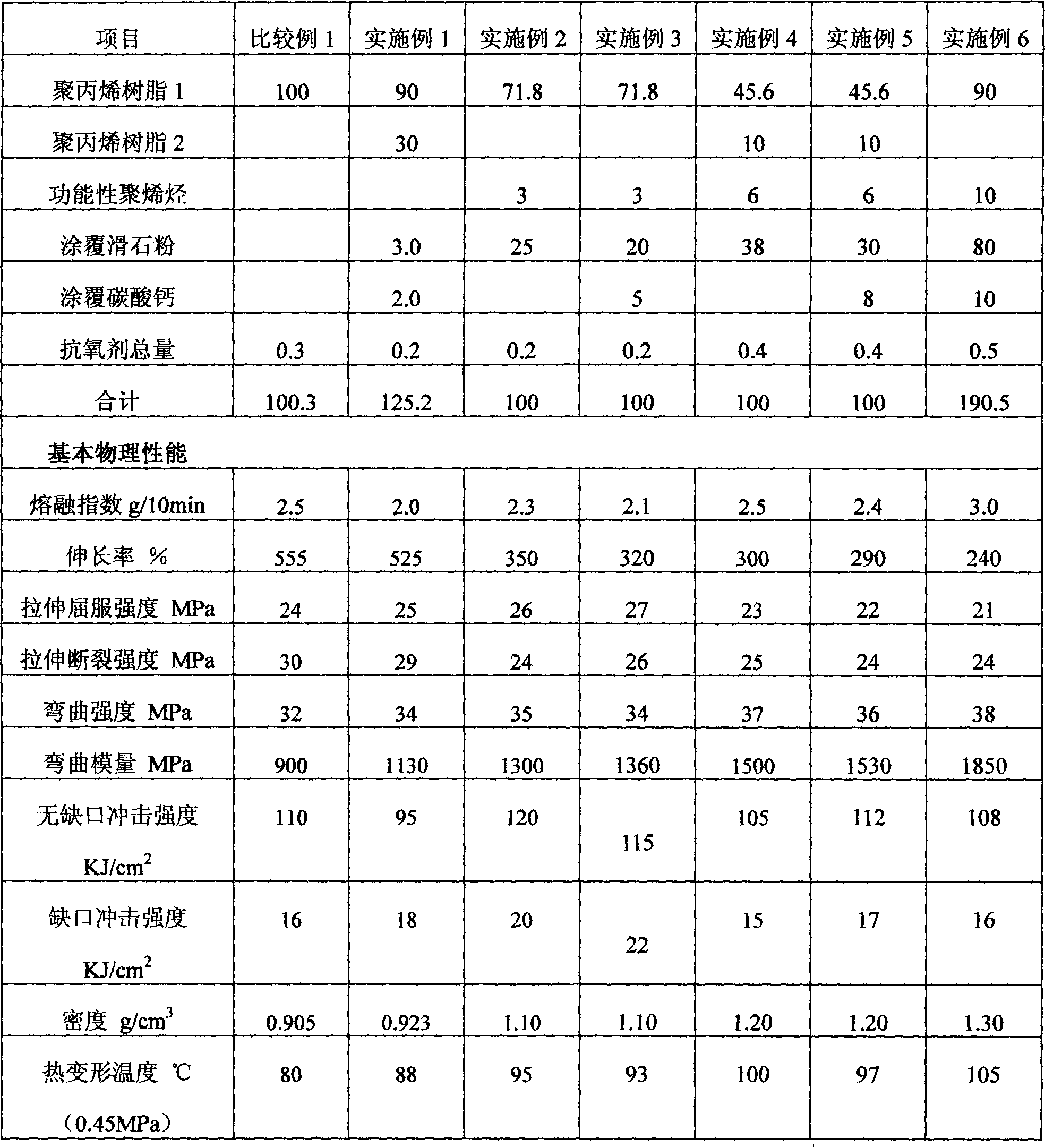

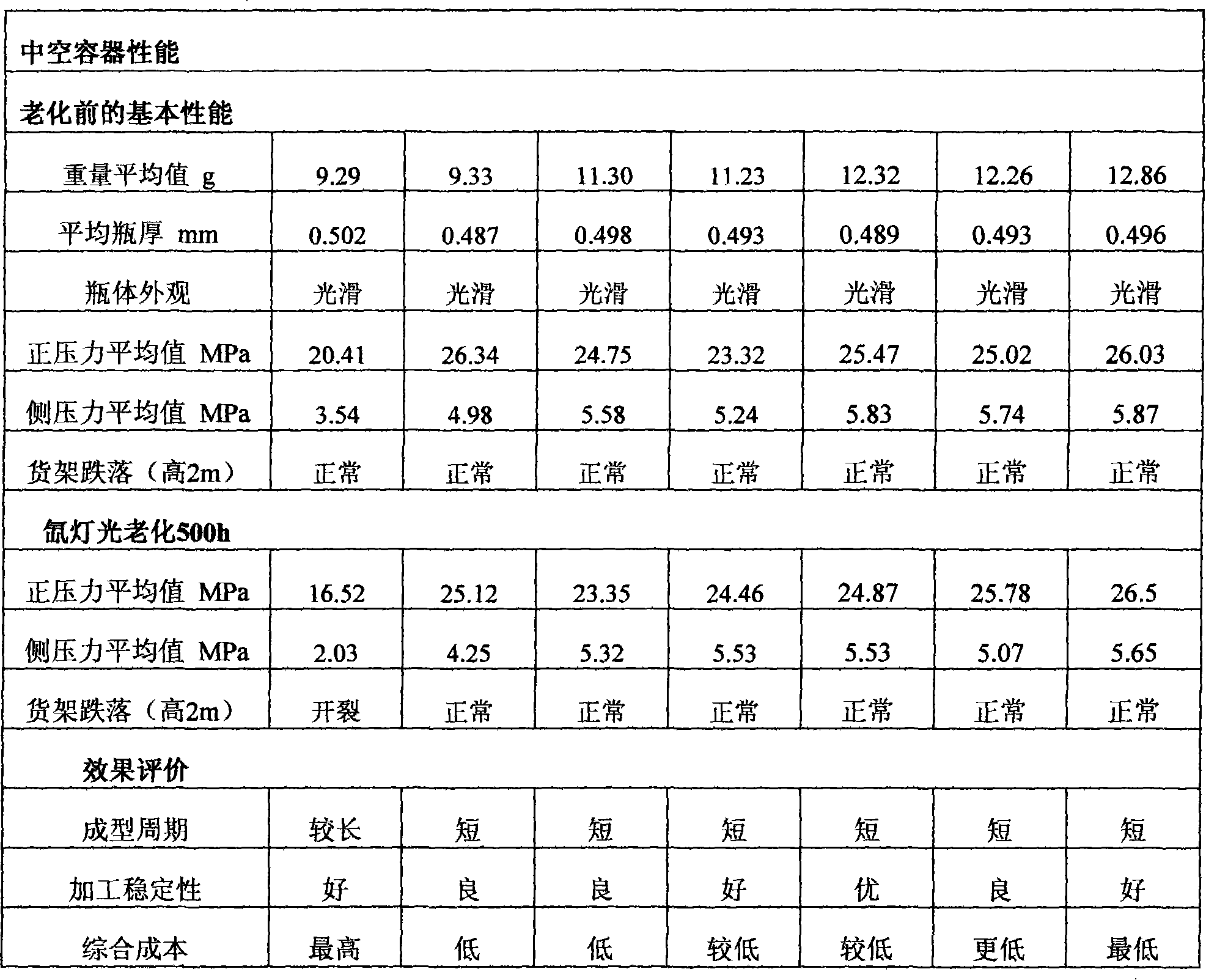

Examples

Embodiment 1

[0041] (1) First use the surface modifier γ-glycidyl etheroxypropyl trimethoxysilane KH-560 to carry out surface coating treatment on talc powder (particle size: 8.0 μm) in a high-speed mixer to obtain coated talc powder , the consumption of surface modifier is 0.4% of talcum powder total amount. The treatment process conditions are as follows: the rotation speed is 1000r / min, the treatment temperature is 130°C, and the treatment time is 10min.

[0042] Surface modifier stearic acid is used in a high-speed mixer to carry out surface coating treatment to calcium carbonate (particle size is 10.0 μm) to obtain coated calcium carbonate, and the consumption of surface modifier is 3.0% of the total amount of calcium carbonate. The treatment process conditions are as follows: the rotation speed is 1500r / min, the treatment temperature is 90°C, and the treatment time is 30min.

[0043] (2) According to the weight ratio shown in Table 1, 90 parts by weight of impact copolymer polypropy...

Embodiment 2

[0046] (1) Pretreatment of inorganic fillers. Use the surface modifier γ-aminopropyltriethoxysilane KH-550 in a high-speed mixer to carry out surface coating treatment on the inorganic filler talc powder (particle size is 5.0 μm) to obtain coated talc powder, surface modifier The dosage is 0.5% of the total amount of talcum powder. The treatment process conditions are as follows: the rotation speed is 1500r / min, the treatment temperature is 115°C, and the treatment time is 15min.

[0047] (2) according to the weight ratio shown in table 1, the polypropylene resin 1 (PP1) of 71.8 weight parts is impact copolymerized polypropylene, and the ethylene content of impact copolymerized polypropylene is 8% (mass content), melt index is 2.5g / 10min (230 ℃, 2.16kg), the functional polyolefin of the maleic anhydride grafted polyethylene of 3 weight parts (active group content is 0.4%, melt index is 2.0g / 10min (230 ℃, 2.16kg )), 25 parts of coated talcum powder, 0.2 parts by weight of ant...

Embodiment 3

[0050] (1) Use surface modifier γ-aminopropyltriethoxysilane KH-550 to carry out surface coating treatment to talcum powder (particle size is 5.0 μ n) in high-speed mixer to obtain coated talcum powder, surface modification The consumption of agent is 0.8% of talcum powder total amount. The treatment process conditions are as follows: the rotation speed is 1500r / min, the treatment temperature is 115°C, and the treatment time is 15min.

[0051] Coated calcium carbonate (with a particle size of 8.0 μm) was surface-coated in a high-speed mixer with the surface modifier isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate to obtain coated carbonate. Calcium, the amount of surface modifier is 0.4% of the total amount of calcium carbonate. The treatment process conditions are as follows: the rotation speed is 1500r / min, the treatment temperature is 105°C, and the treatment time is 15min.

[0052] (2) According to the weight ratio shown in Table 1, 71.8 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com