Method for eliminating pinch of jaw opening for fetching coil of cold rolled steel strip

A technology of cold-rolled strip steel and strip steel, which is applied in the field of eliminating the folding jaws of cold-rolled strip steel coils, and can solve the problems of inability to meet the needs of coiling steel strips with different thicknesses, affecting the quality of steel coils, stainless steel coils, and insufficient lengths, etc. problem, to achieve the effect of low cost, convenient operation, and elimination of horizontal folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

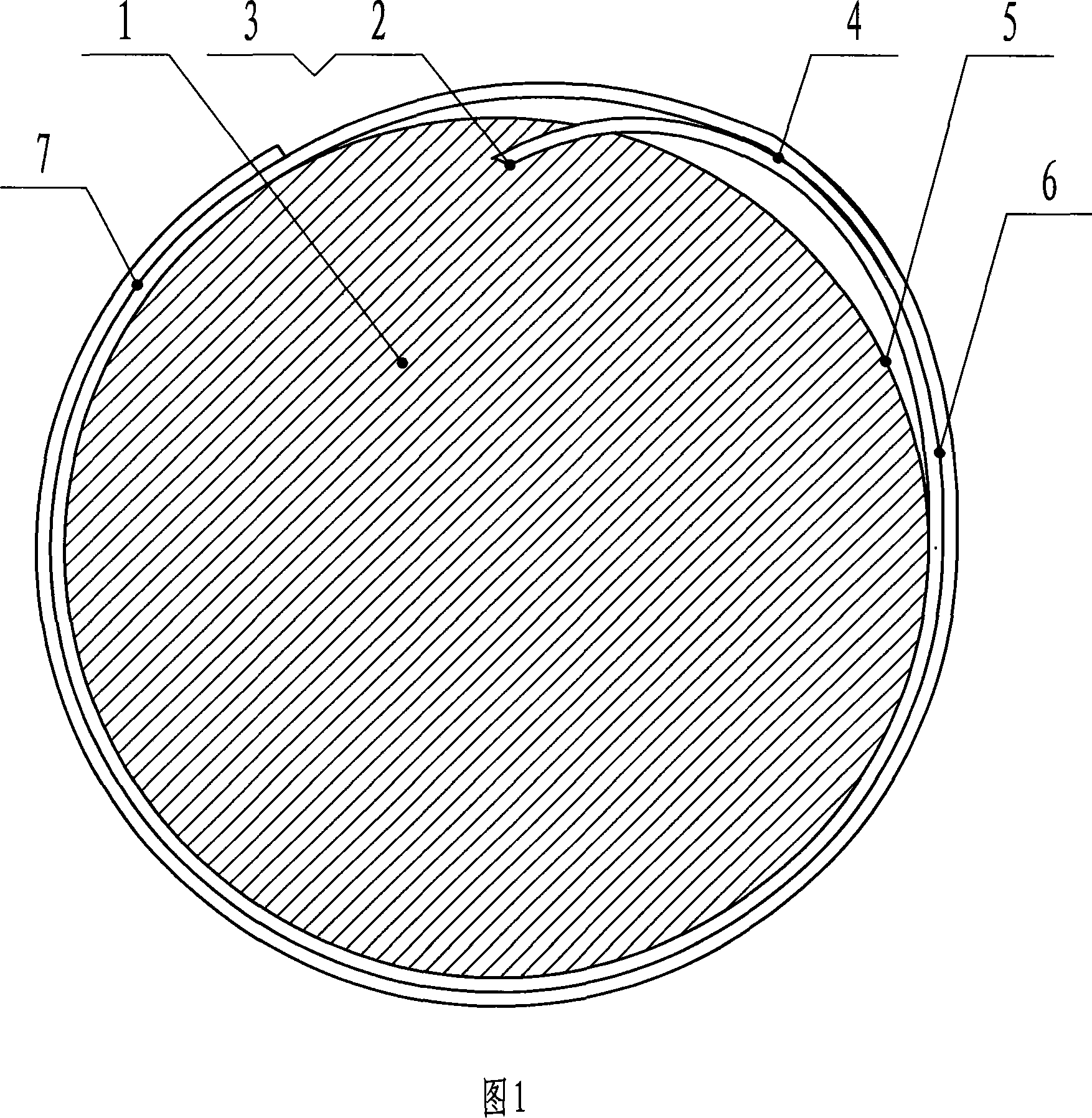

[0038] The coiler used in this embodiment is the coiler produced by SUNDWIG, Germany. The diameter of the reel 11 when it is expanded is Ф610mm, the circumference is 1916mm, and the width is 1400mm. The strip steel 9 coiled is OCr18Ni9 stainless steel, and the thickness is 3mm .

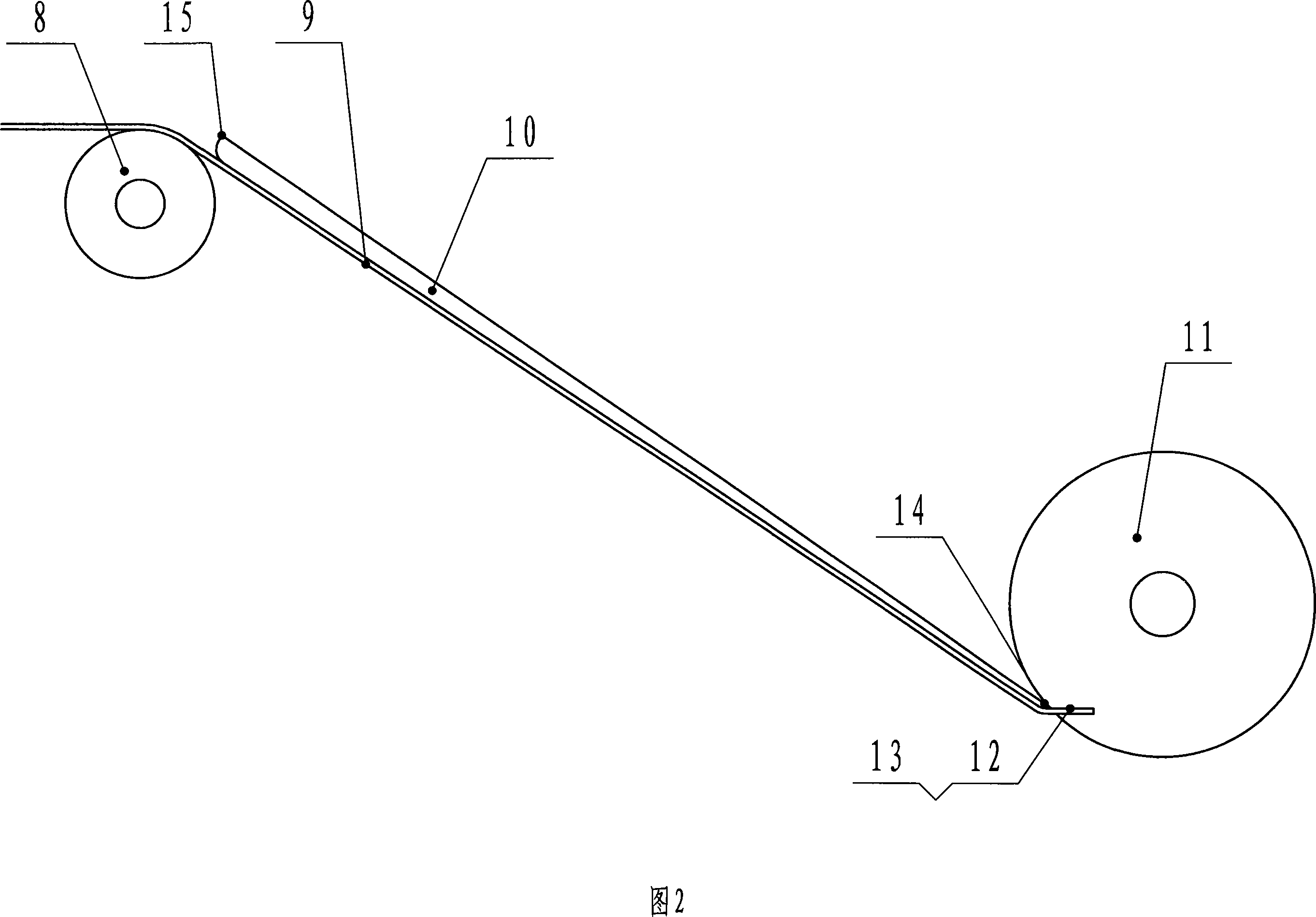

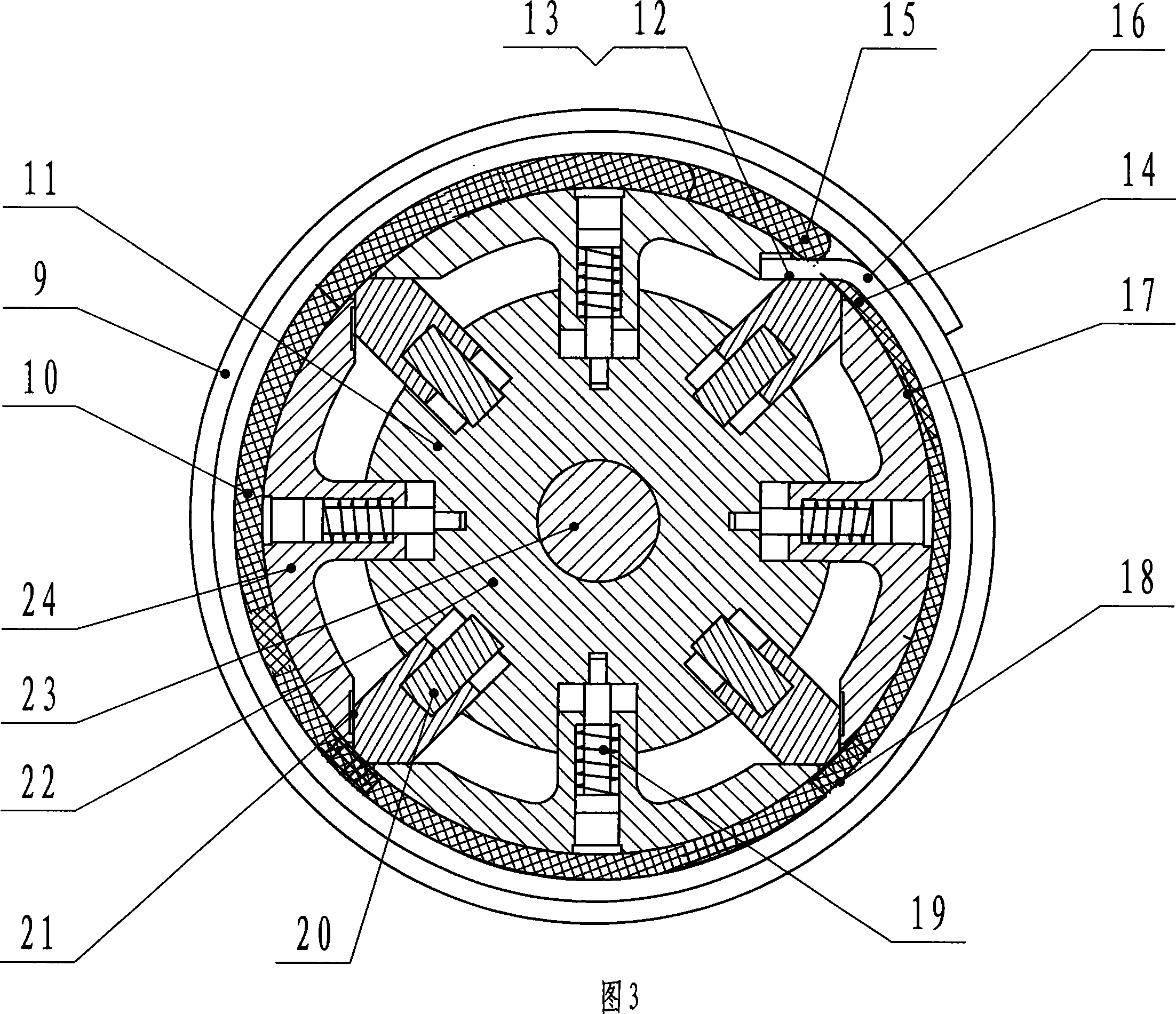

[0039]Referring to Fig. 2 for the coiling step of the present embodiment, the insertion end 13 of the strip steel 9 is pulled out from the guide roller 8 of the rolling mill, inserted into the jaw 12 of the reel 11, and then the elastic pad 10 is laid on the guide roller 8 and the clamp. On the strip steel 9 between the openings 12, the thin end 14 of the elastic pad 10 is next to the jaw 12, and the thick end 15 of the elastic pad 10 is on the top. In the present embodiment, the thick end 15 is close to the guide roller 8, and then starts The reel 11 of the coiler makes the reel 11 rotate counterclockwise to coil the steel strip 9, and forms an elastic lift 16 on the right side of the jaw 12 in Fig....

Embodiment 2

[0042] The coiler used in this embodiment is the coiler produced by Spain FAGOR. The diameter of the reel 11 when it is expanded is Ф610mm, the circumference is 1916mm, and the width is 1400mm. The strip steel 9 coiled is 430 stainless steel and the thickness is 2.0mm. mm.

[0043] Referring to Fig. 4 for the coiling step of this embodiment, the insertion end 13 of the strip steel 9 is pulled out from the guide roller 8, inserted into the jaw 12 of the reel 11, and then the elastic pad 25 is laid on the guide roller 8 and the jaw 12 On the strip steel 9 between, the thin end 27 of elastic liner 25 is down, is 470mm apart from jaw 12, and the thick end 26 of elastic liner 25 is on, then starts the reel 11 of coiler, makes reel 11 Rotate counterclockwise to coil the steel strip 9, (you can also start the reel 11 of the coiler to make the reel 11 rotate 90° and then pad the elastic liner 25) and form an elastic warp on the right side of the jaw 12 in Fig. 5 Start 28, when reel 1...

Embodiment 3

[0046] The coiler used in this embodiment is a coiler produced by SUNDWIG, Germany. The diameter of the reel 11 when it is expanded is Ф610mm, the circumference is 1916mm, and the width is 1400mm. The strip steel 9 coiled is OCr18Ni9 stainless steel with a thickness of 1.5 mm.

[0047] The coiling step of the present embodiment can refer to Fig. 4, and the insertion end 13 of strip steel 9 is pulled out from guide roller 8, is inserted into the jaw 12 of reel 11, and then elastic liner 25 is laid on guide roller 8 and jaw On the strip steel 9 between 12, the thin end 27 of elastic liner 25 is down, be 400mm apart from jaw 12, the thick end 26 of elastic liner 25 is on, start the reel 11 of coiler then, make reel 11 anticlockwise rotation coiling strip steel 9, and form elastic upturn 28 on the right side of jaw 12 among Fig. 6, while reel 11 coils strip steel 9, elastic liner 25 is also rolled into circle, Roll between the fan-shaped plate outer surface 17 of the reel 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com