Inversive steering gear of water-jet type watercraft

A steering device, water jet technology, applied in the direction of steering with jets, etc., can solve the problems of long time, prone to shipping accidents, unable to stop the ship immediately, etc., and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

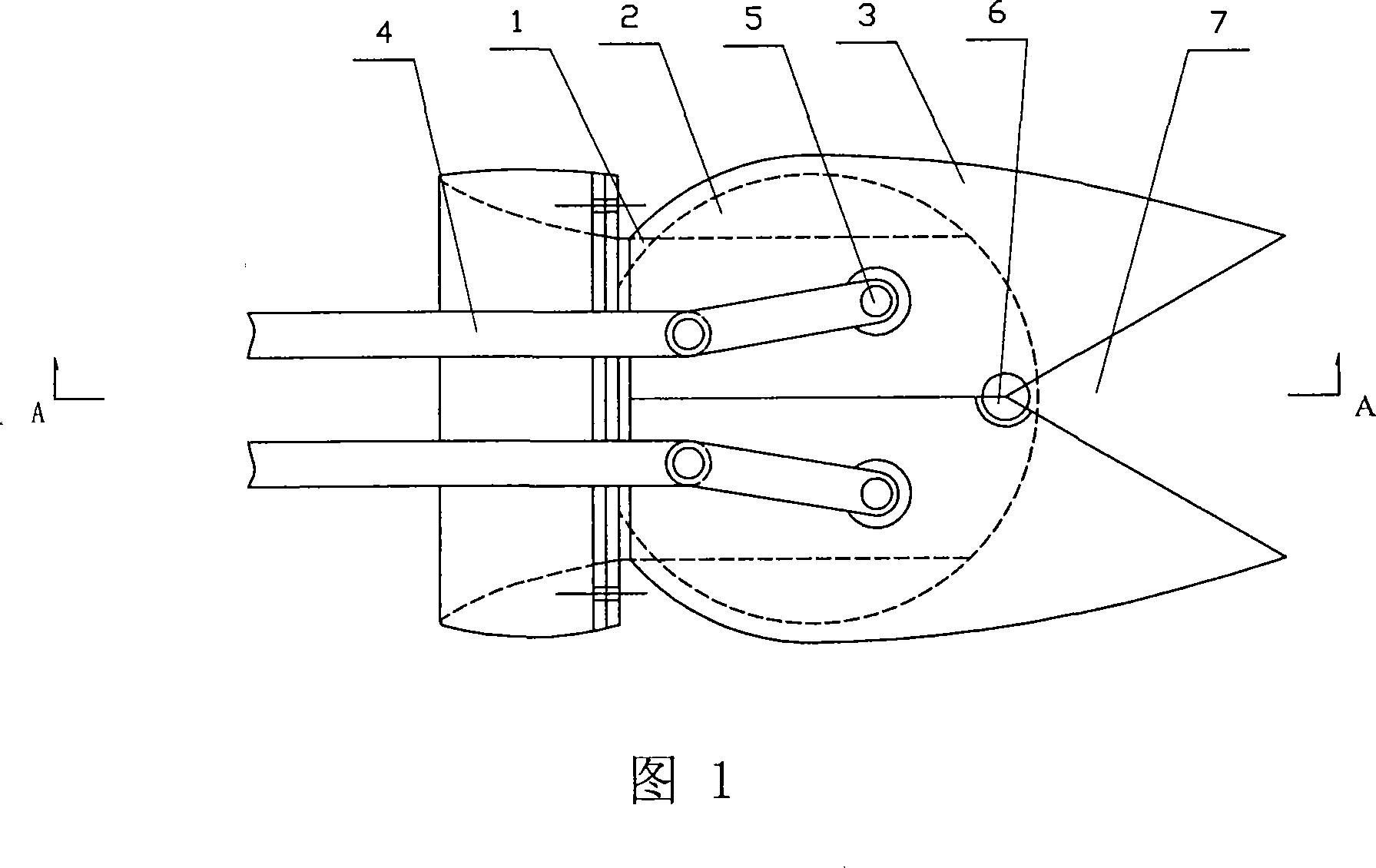

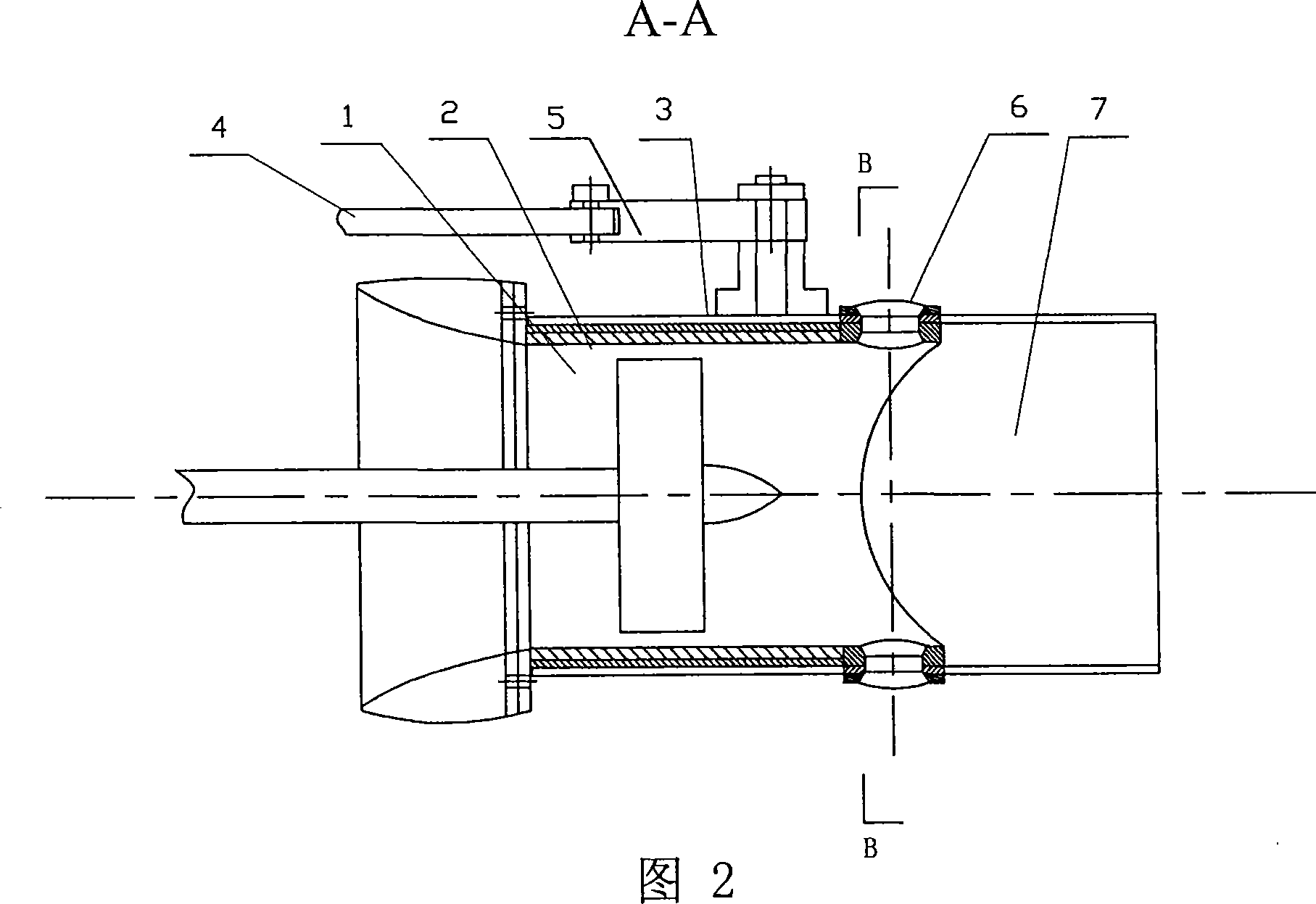

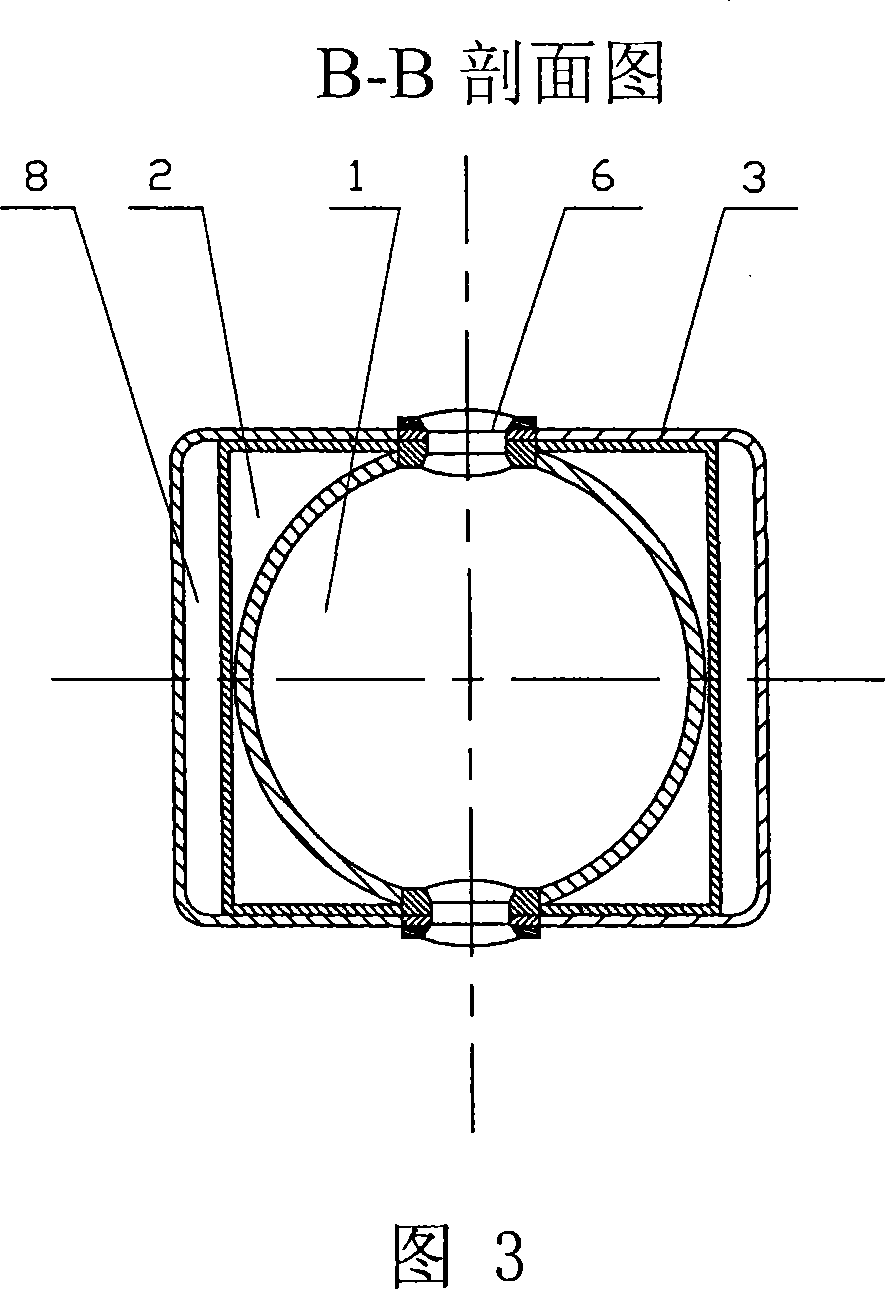

[0010] As can be seen from FIGS. 1 to 3 , the present invention includes a propeller conduit 1 , a cylinder 2 for reverse flow guidance, two cooperating guide covers 3 , a hydraulic drive rod 4 , and a connecting rod 5 . The front end of the propeller duct 1 is connected to the ship, and the rear section radially penetrates the cylinder 2 to the cylinder surface of the cylinder. The upper and lower surfaces of the two wind deflectors 3 are fixed on the upper and lower surfaces of the cylinder 2 by the pivot pin 6 . Located on the same vertical line drawn by the central line of the propeller guide tube, the two shrouds are rotated around the two shaft pins 6 of the same axis. The space between the two shrouds 3 and the cylindrical surface of the cylinder 2 is a reverse flow guide channel 8, which is used for spraying the water in reverse direction when the two shrouds are closed. The two wind deflectors 3 are respectively equipped with a connecting rod 5, and the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com