1-3.5T gap buffer lift oil cylinder with one-way valve at cylinder bottom

A technology for lifting cylinders and one-way valves, which is applied to lifting devices, fluid pressure actuating devices, etc., can solve the problems of reducing the stability of hydraulic parts, reducing the working area of hydraulic oil, and being unfavorable for forklifts to work. Good for heat balance, lower hydraulic oil temperature, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

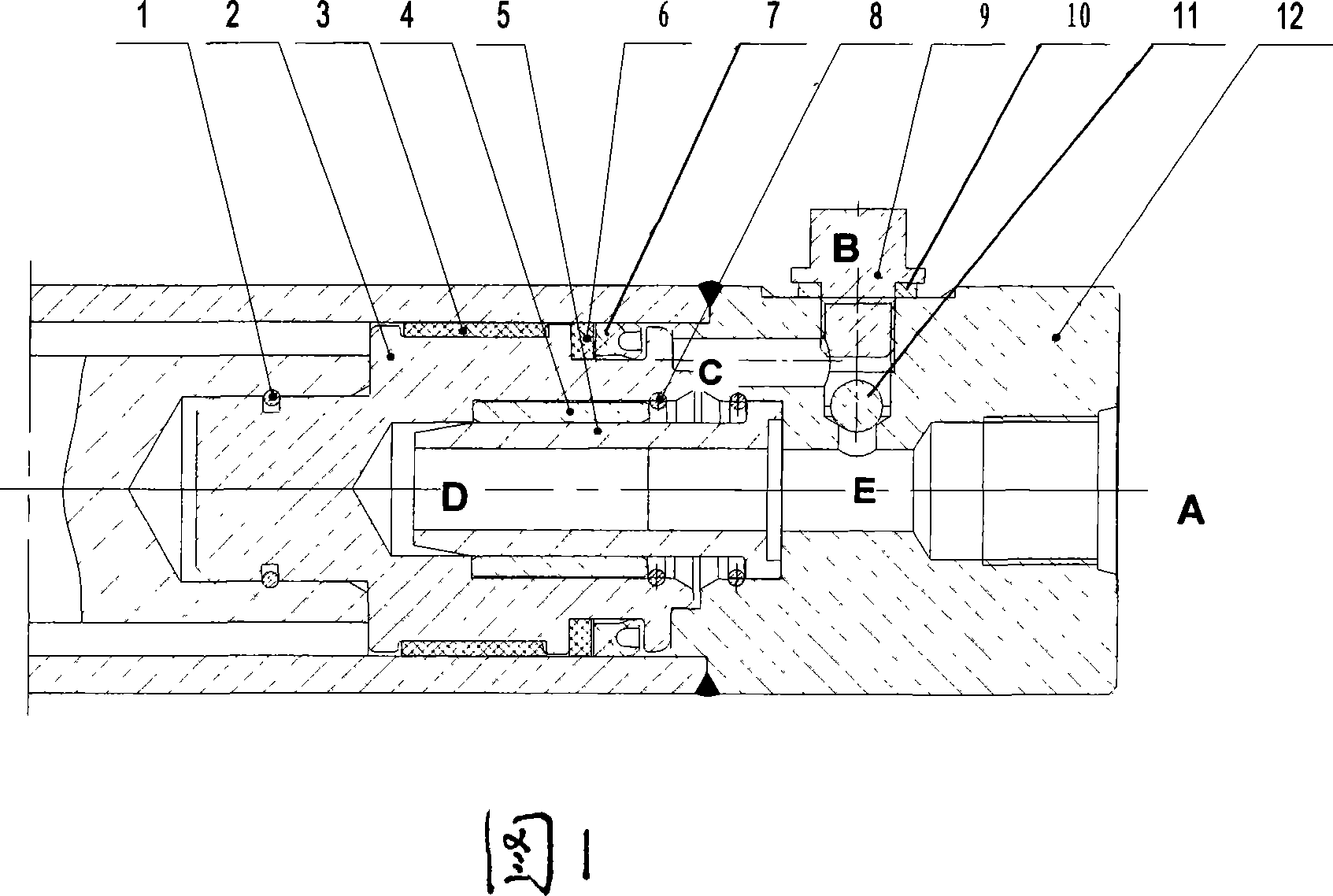

[0017] The 1-3.5T gap buffer lifting cylinder with cylinder bottom check valve includes cylinder body, piston 2, spool 5 and cylinder bottom 12. The spool 5 is located in the spool hole corresponding to the piston 2 and the cylinder bottom, and the spool 5 corresponds to the oil passage at the bottom of the cylinder 12, the piston 2 is set with a piston steel wire retaining ring 1, the support ring 3, a U-shaped sealing ring 6 and a retainer 7, and the valve core 5 is set with a copper sleeve 4 and a steel wire retaining ring 8, see picture 1.

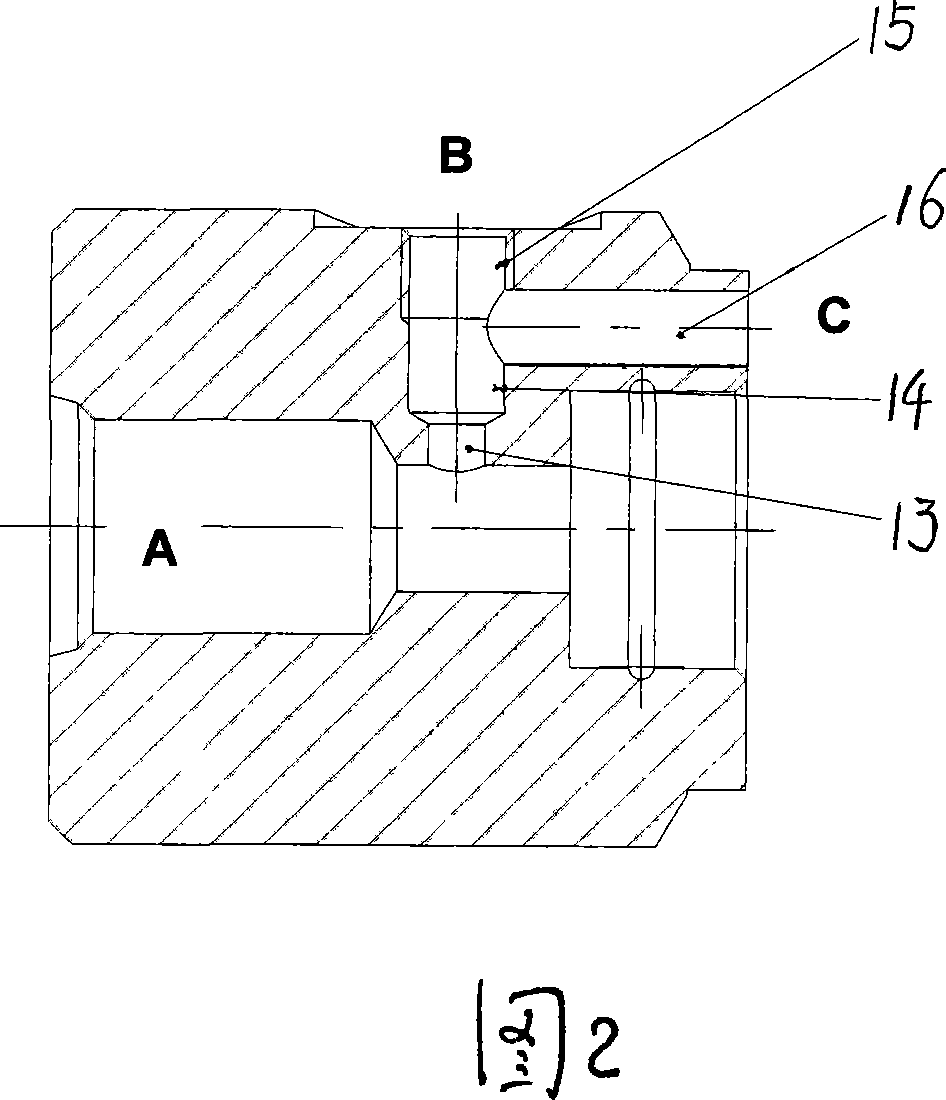

[0018] There is a small through hole 13 radially on one side of the oil passage at the bottom of the cylinder 12, the small through hole 13 is coaxially connected to the steel ball hole 14 and the threaded hole 15, perpendicular to the steel ball hole 14, and a cylinder bottom 12 with a piston 2 Corresponding to the bypass oil channel 16 at the bottom, the steel ball 11 is fitted in the steel ball hole 14 to act as a one-way valve, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com