Bicycle five-way assembly

A bicycle and component technology, applied to bicycle accessories, bicycle racks, vehicle components, etc., can solve problems such as poor reliability, complexity, and difficult connection, and achieve the effects of easy translation, fast installation, and less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

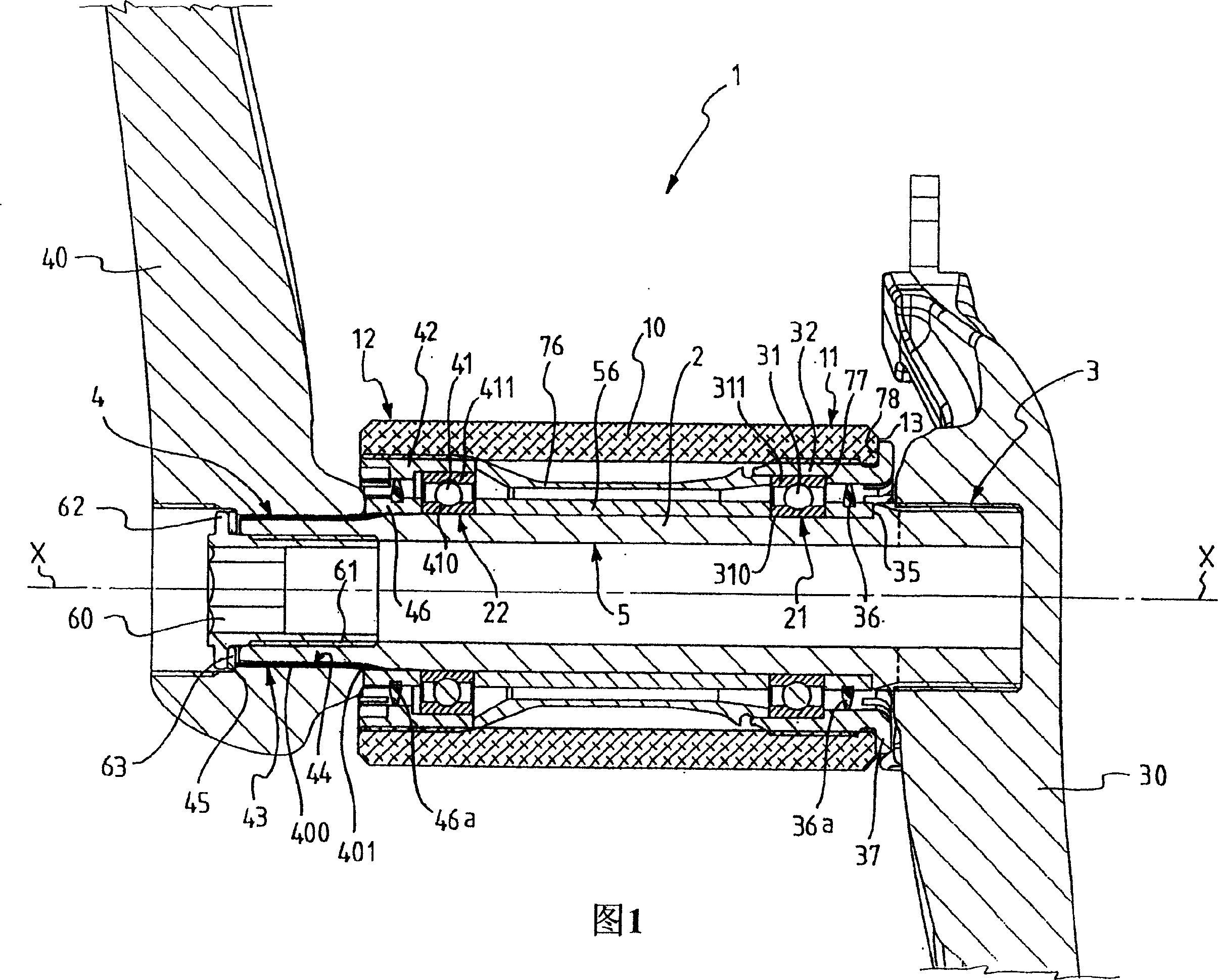

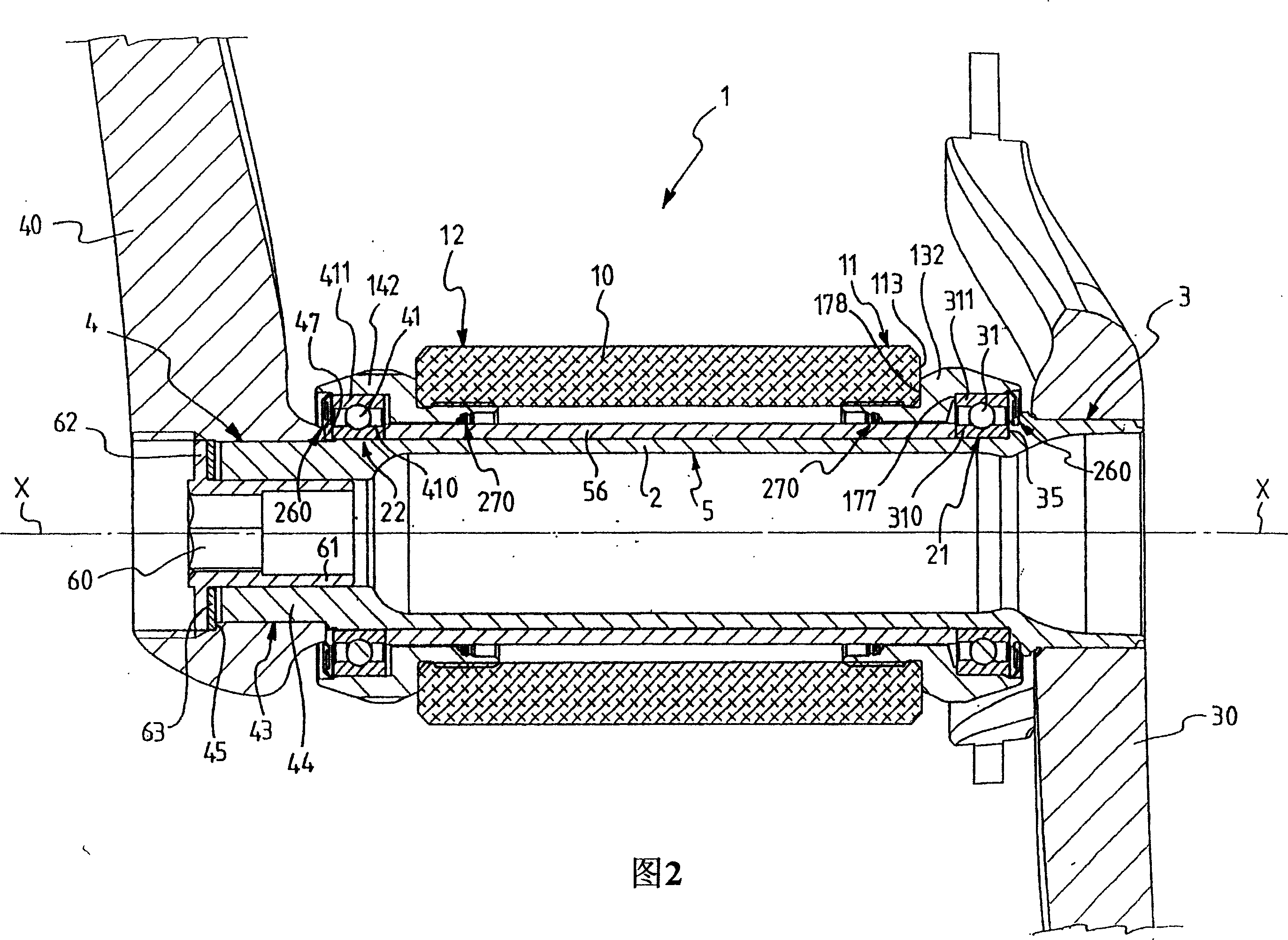

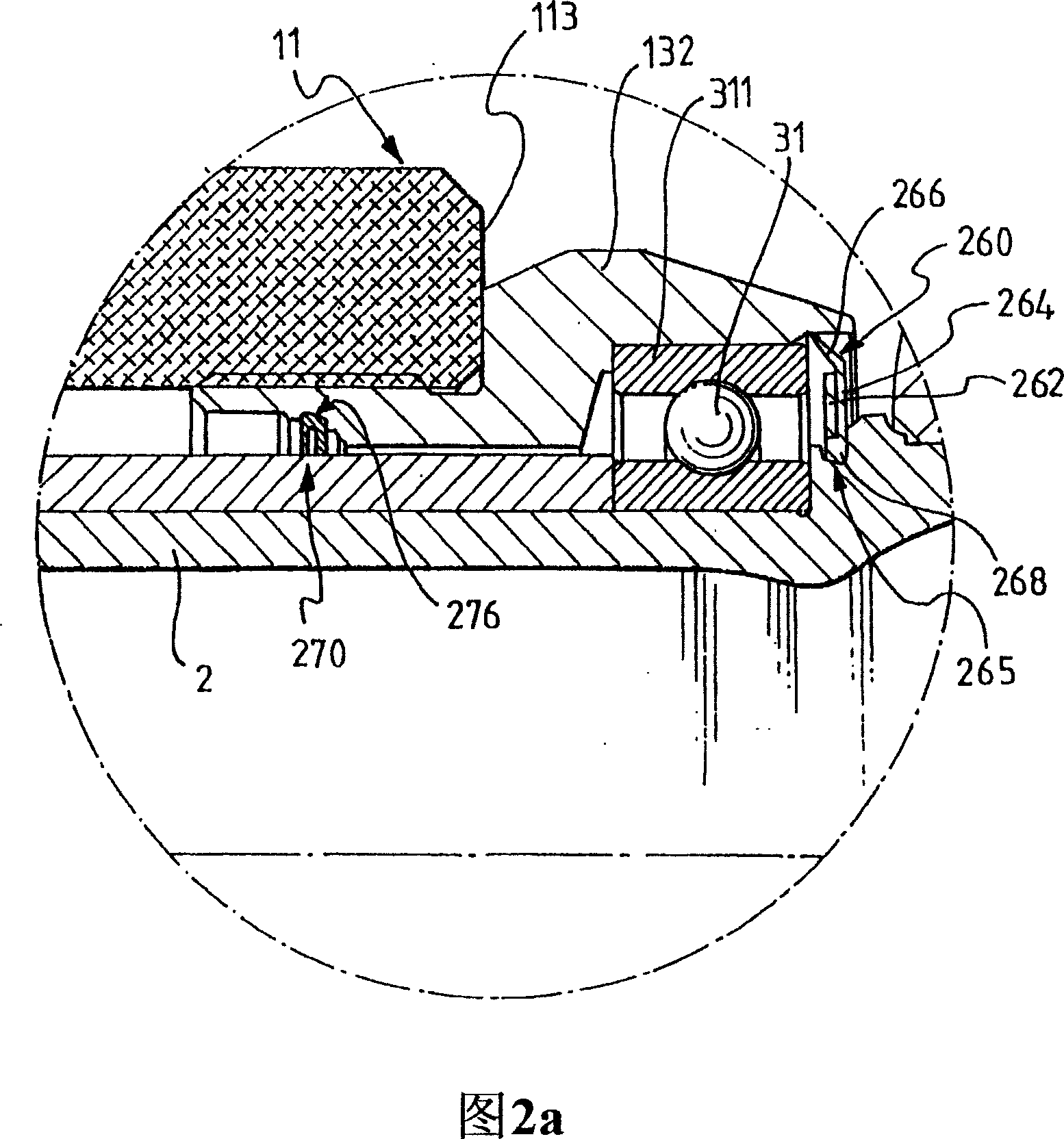

[0106] Referring to FIG. 1 , there is indicated a bicycle bottom bracket assembly according to a first embodiment of the present invention.

[0107] The assembly 1 comprises a shaft 2 having a longitudinal axis X-X extending in a predetermined direction. The shaft 2 comprises opposite end portions 3 and 4 on the right and left, respectively, with which a right crank arm 30 and a left crank arm 40 are associated, respectively.

[0108] The axle 2 is rotatably supported in an axle box 10 suitably provided in the bicycle frame by interposing right bearing 31 and left bearing 41 suitably inserted on the axle 2 between the axle 2 and the axle box 10 . The axlebox 10 is substantially cylindrical and extends along a longitudinal axis intended to coincide with the axis X-X of the axle 2 when the axle 2 is housed in the axlebox 10 .

[0109] In the particular embodiment illustrated in Figure 1, the bearings 31 and 41 are ball bearings, but other types of bearings suitable for ensuring...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap