Long size element for suspending ceiling

A ceiling and long ruler technology, applied in building components, buildings, ceilings, etc., can solve problems such as the reduction of durability strength, and achieve the effect of reducing painting operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

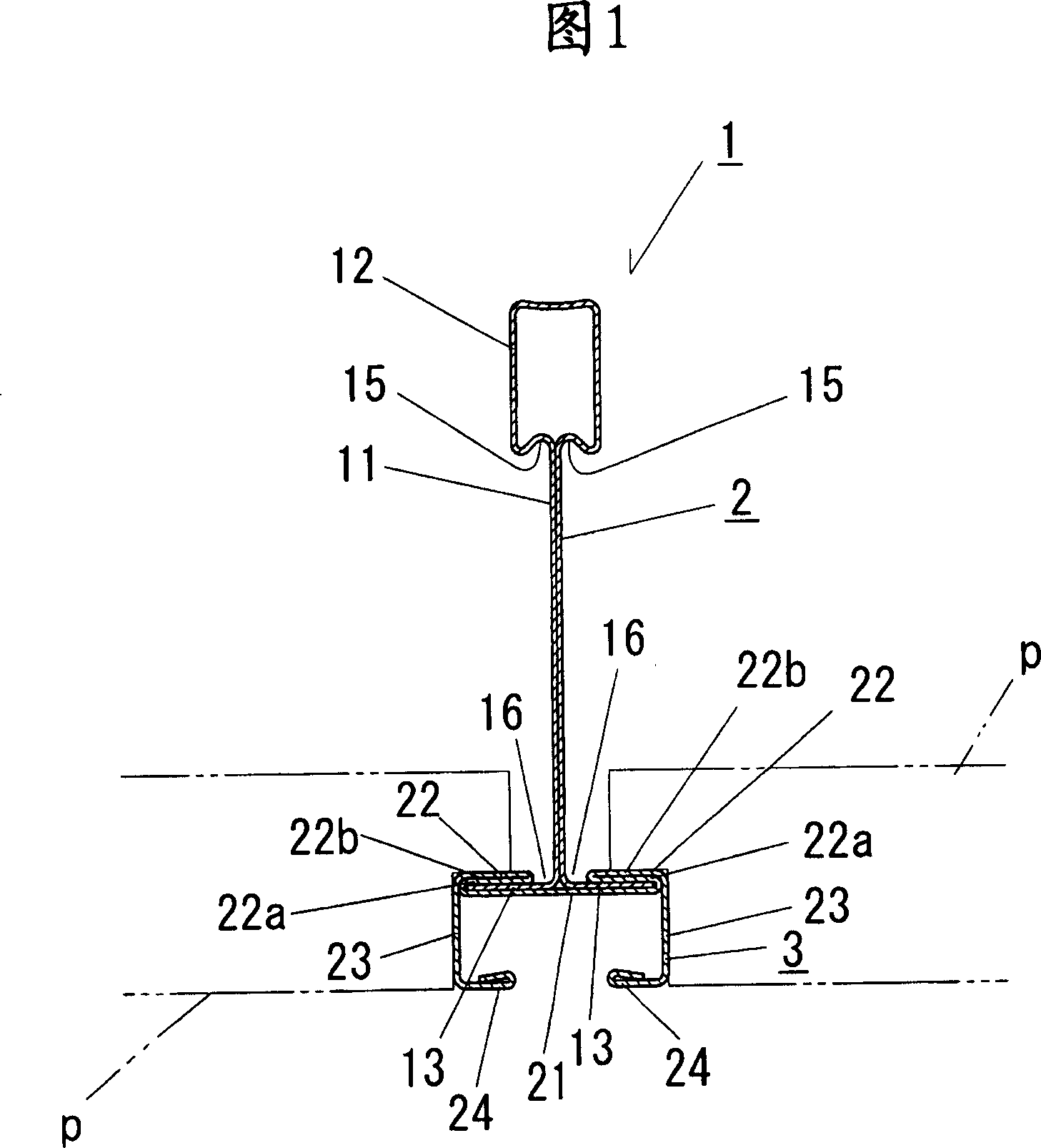

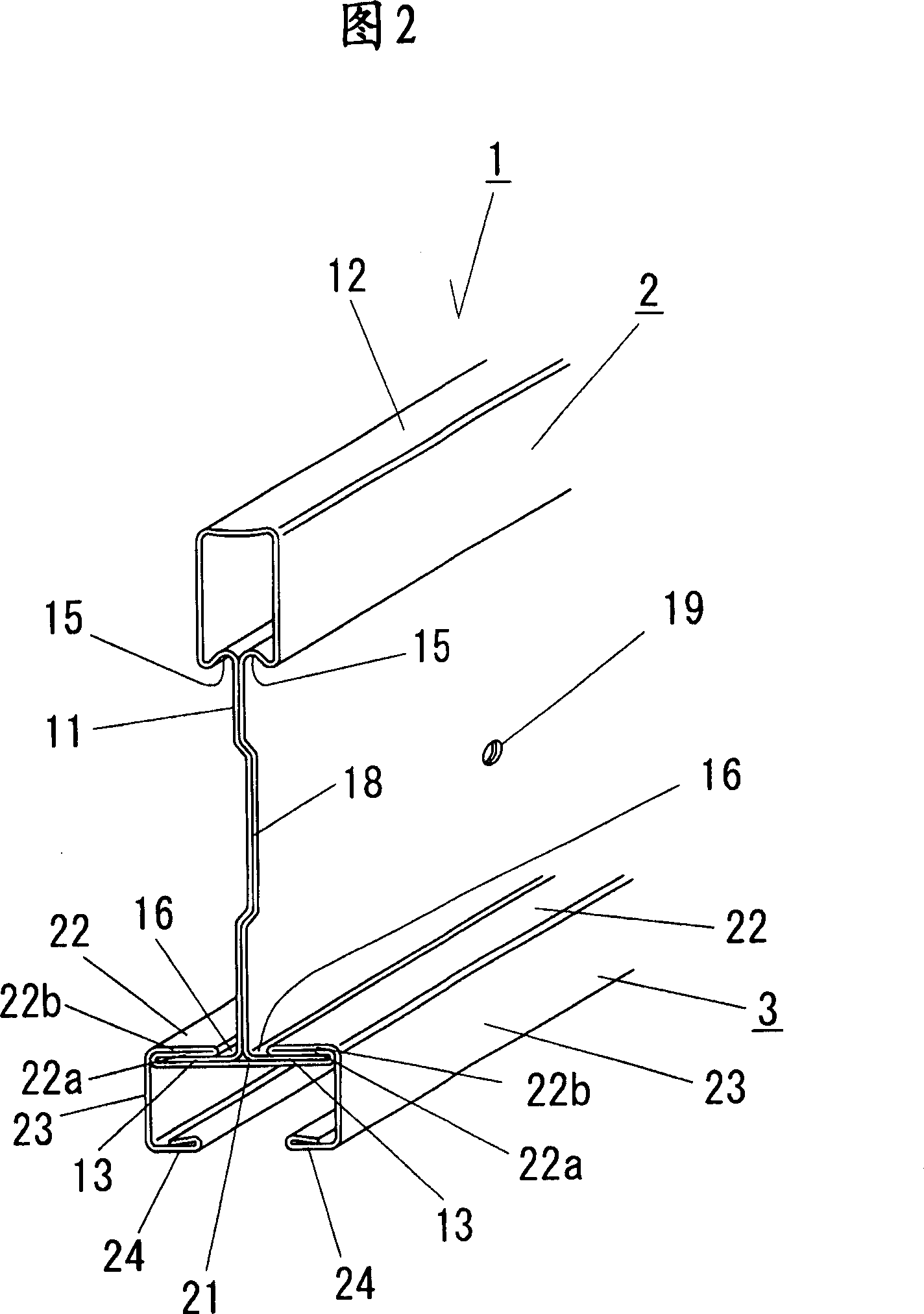

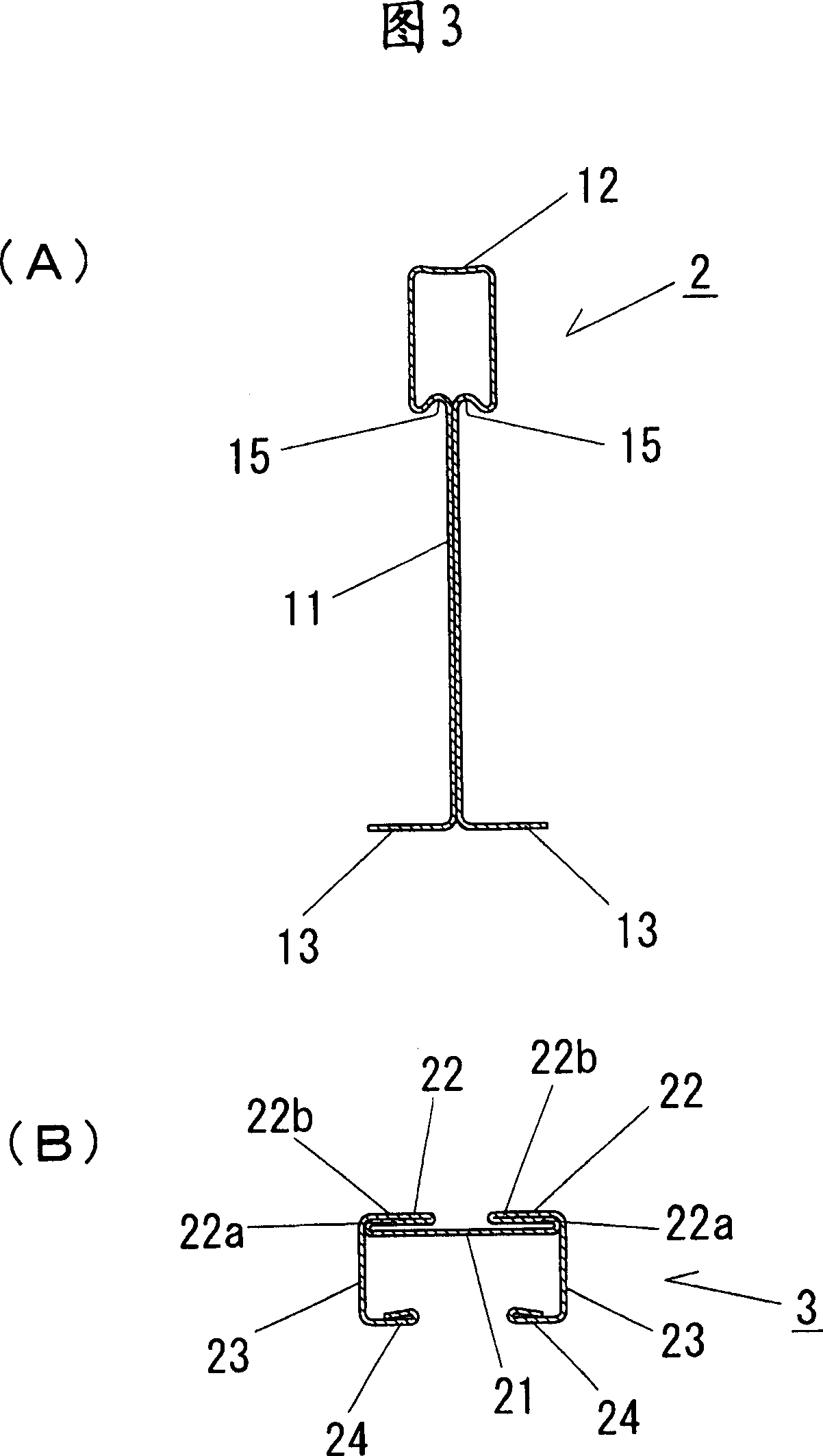

[0055] As shown in Figures 1 to 3, the elongated member 1 for suspending the ceiling of the first embodiment is integrally formed by combining a suspending rod 2 with an inverted T-shaped section and a locking beam 3 with a U-shaped section.

[0056]The above-mentioned suspension rod 2 is formed of a long substantially rectangular steel plate, and its cross-sectional shape is mirror-symmetrical with respect to the center line. The suspension bar 2 is processed into an inverted T-shaped cross section by stamping a steel plate, and is composed of a locking raised portion 12 , a vertical side portion 11 , and horizontal engaging portions 13 , 13 . Here, the vertical side portion 11 is formed by stacking steel plates so that both sides of the longitudinal center line are partially back-to-back, and formed into two plates in the vertical direction. The locking protrusions 12 respectively extend from the upper ends of the two plates constituting the vertical side portion 11, and are...

no. 2 example

[0092] As shown in Figures 13 to 15, the elongated member 101 for suspending the ceiling of the second embodiment is integrally formed by combining a suspending rod 102 with an inverted T-shaped section and a locking beam 103 with a substantially U-shaped section. . The suspension rod 102 is the same as the above-mentioned first embodiment, and is formed by bending a substantially rectangular steel plate through roll forming, and consists of a locking raised portion 12, a vertical side portion 11, and a horizontal engaging portion 113. , 113 constitute.

[0093]Here, the horizontal engaging portions 113, 113 are bent and formed with ribs protruding upward (on the side of the locking raised portion 12) along the longitudinal direction at a position having a predetermined interval in the horizontal direction from the lower end of the vertical side portion 11. Section 115, 115. The rib 115 of the horizontal engaging portion 113 is bent into a mountain-shaped cross-section protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com