Sealing device

A technology of sealing device and mounting part, which is applied in the direction of engine sealing, rotating parts against centrifugal force, bearings, etc., which can solve the problems of increasing sliding torque, sliding loss of auxiliary lip 55d, curling, etc., and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Embodiments of the present invention will be described below with reference to the drawings.

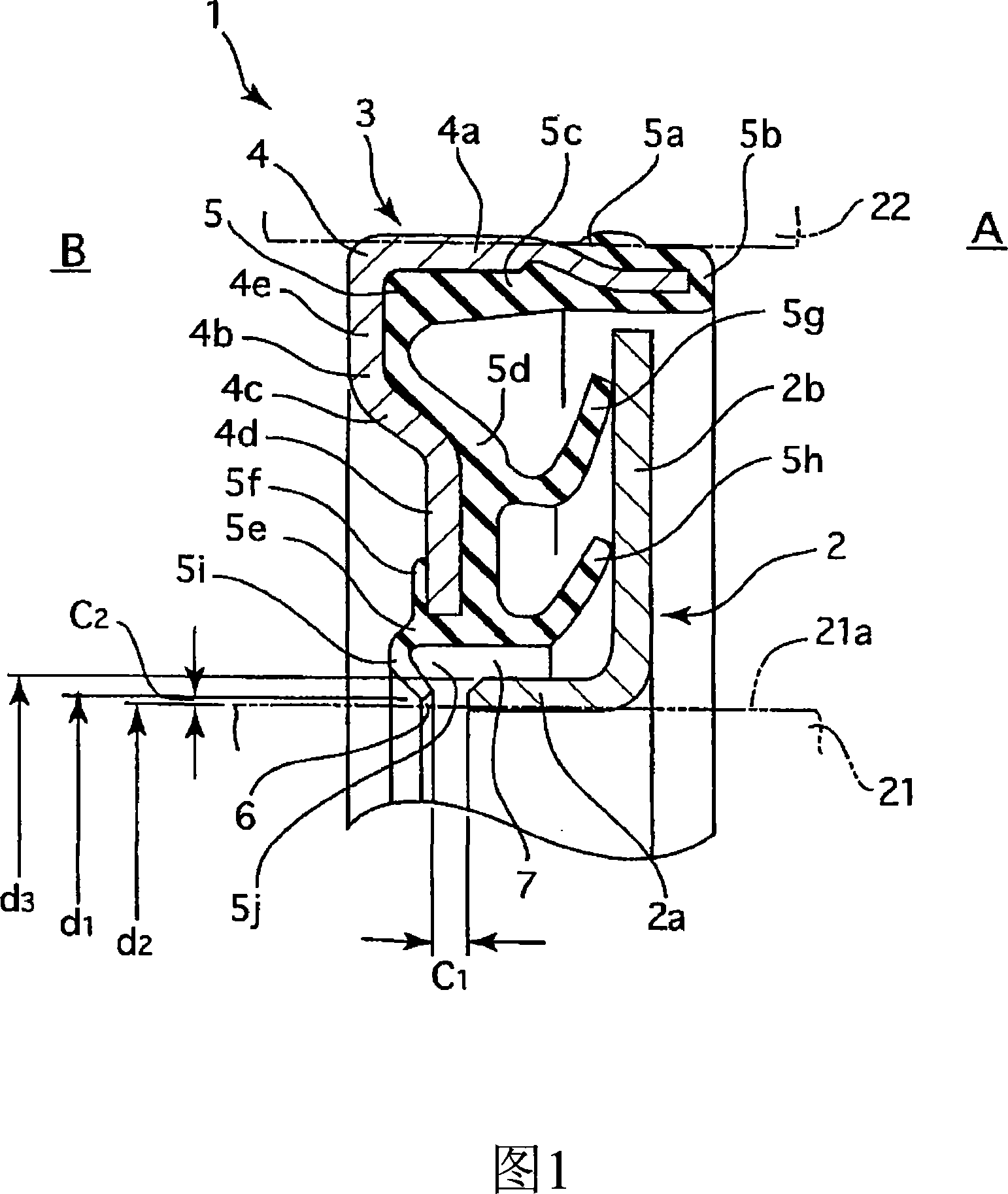

[0057] Fig. 1 shows a cross-sectional view of main components of a sealing device 1 according to an embodiment of the present invention. The sealing device 1 described in this embodiment is used as a wheel hub bearing seal in the field of automobiles, and has the following structure.

[0058] That is, the sealing device (packing seal) 1 has an oil slinger 2 and a lip member 3, the former being mounted on and rotating with a bearing inner ring 21 as one of two parts which rotate relatively, And the latter is mounted on the bearing outer ring 22, which is the other of the two parts, which is tightly attached to the oil deflector ring 2 and can slide freely. The spherical body (rotating body, not shown in the figure) of the bearing is on the left side of the figure of the sealing device 1, so the right side in the figure is the bearing exterior A, and the left side is the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com