Dryer and the control method of the same

A control method and drying machine technology, which can be applied to household clothes dryers, clothing dryer equipment, textiles and papermaking, etc., and can solve problems such as reducing fan speed, reducing drying performance, and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

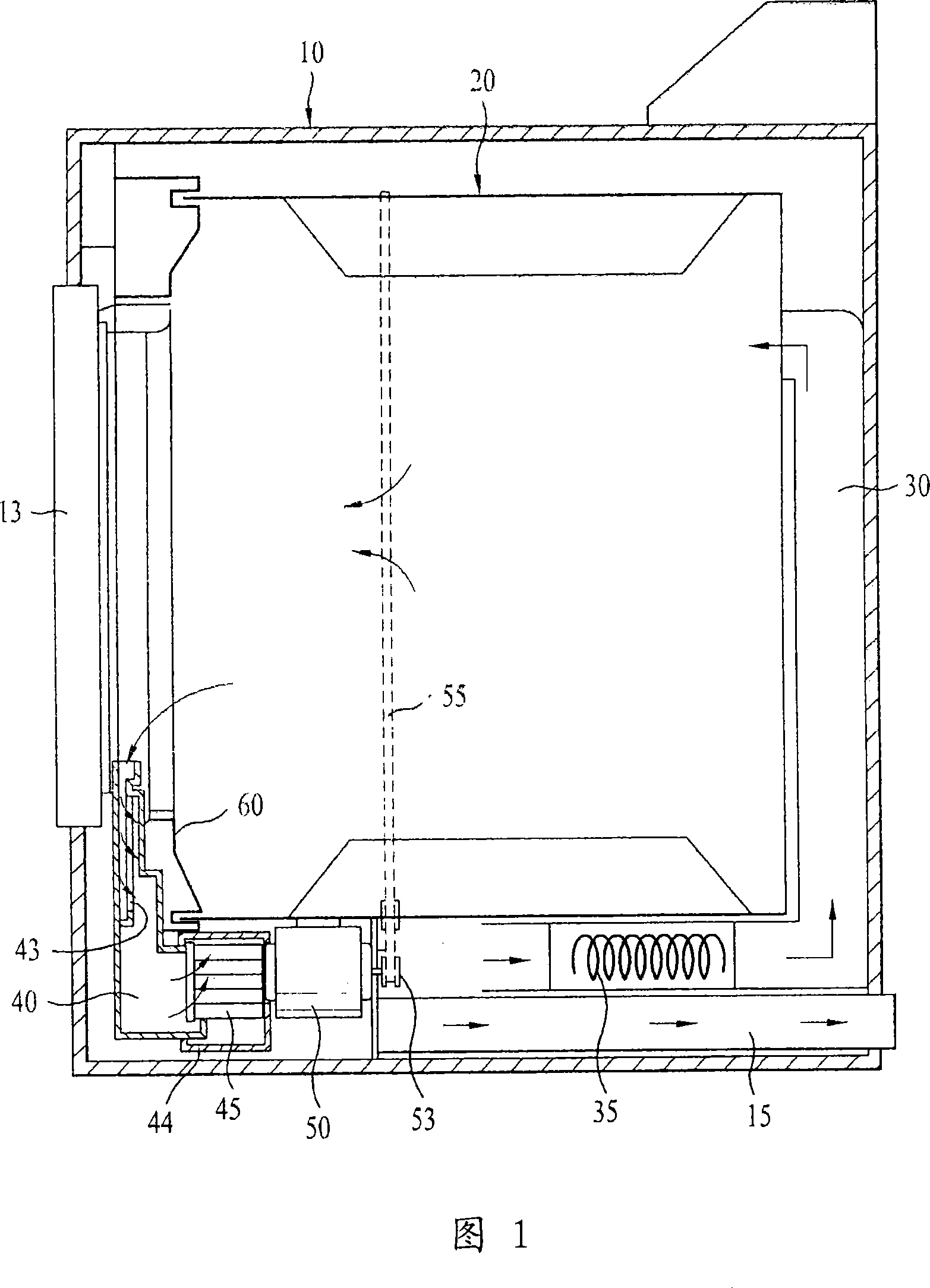

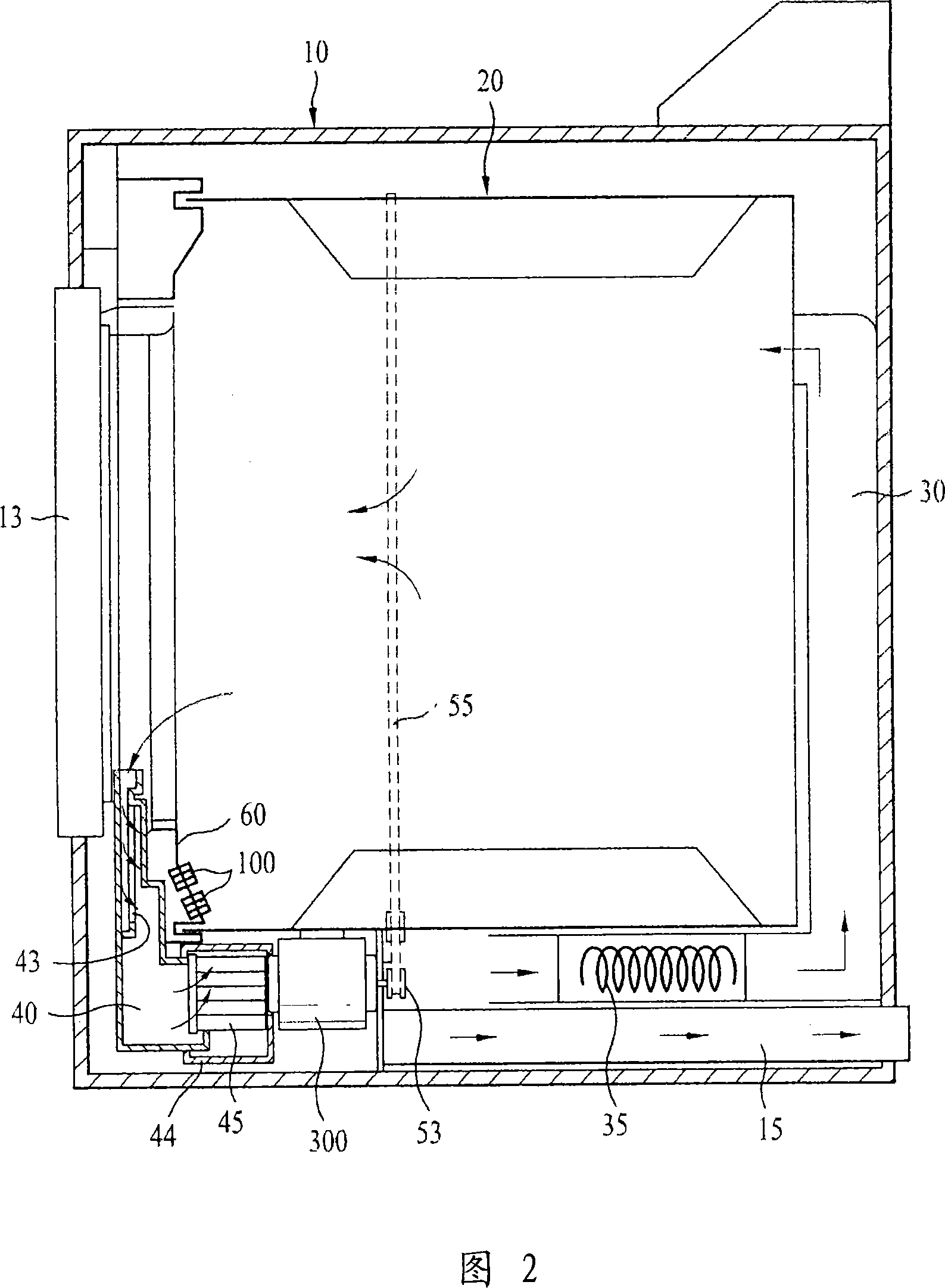

[0035] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

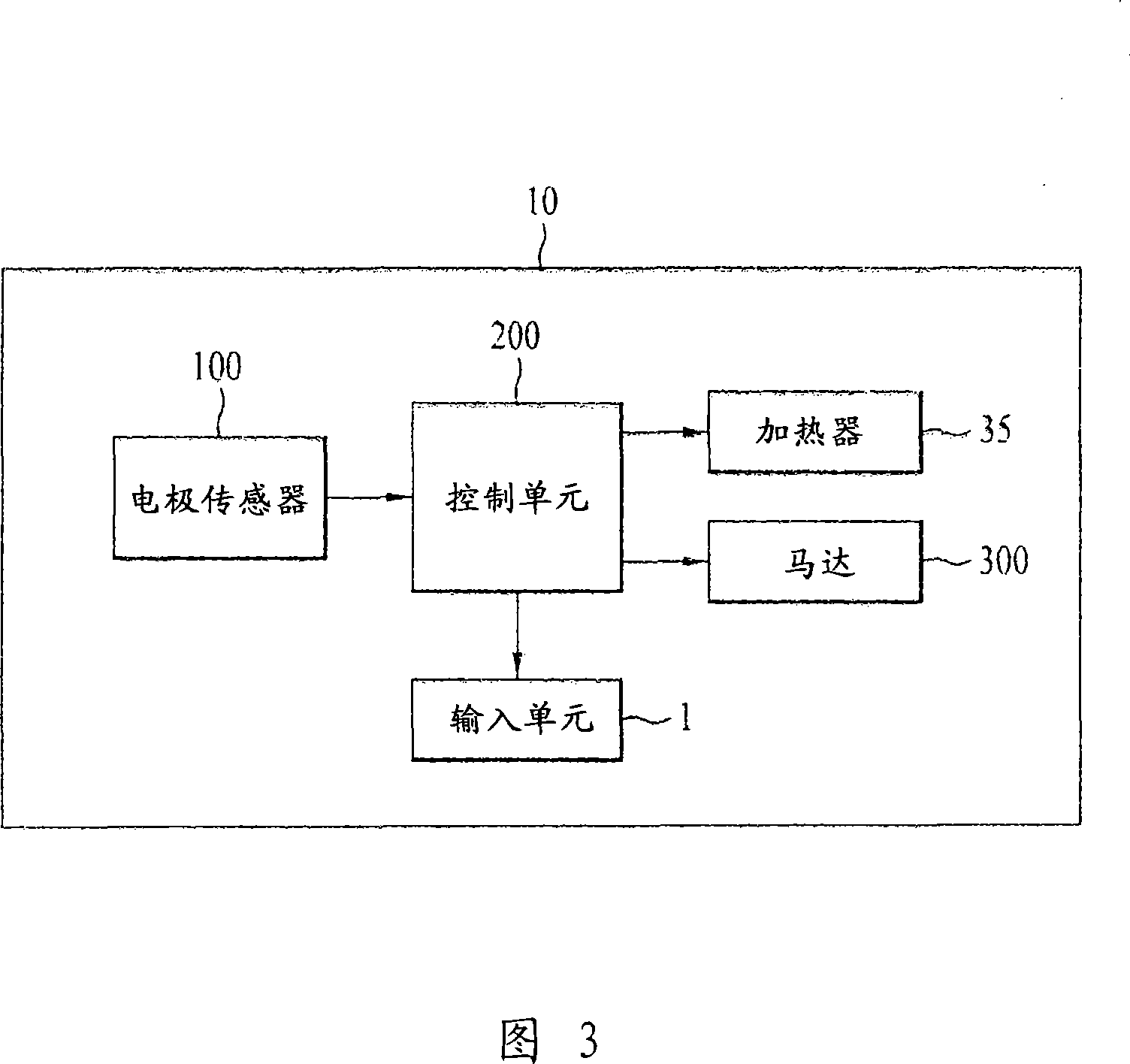

[0036] Fig. 2 is a longitudinal sectional view showing the exhaust type dryer according to the preferred embodiment of the present invention; Fig. 3 is a block diagram showing the control system of the dryer according to the preferred embodiment of the present invention; Fig. 4 is A flowchart showing a procedure for controlling a dryer according to the invention.

[0037] Referring to FIGS. 2 and 3 , the dryer includes a drying drum 20 , a drying drum support 60 , a sensing device, a driving unit, and a control unit 200 . Wherein the drying drum 20 is rotatably fixed on the main body 10 to dry the dry objects in the main body 10; the drying drum bracket 60 is positioned at the front side of the drying dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com