Method and device for connecting each storage battery plate into plate stack and inserting the said plate stack into storage battery case

A battery box and insertion box technology, applied in lead-acid battery, lead-acid battery construction, secondary battery and other directions, can solve problems such as production capacity limitation and difficult adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

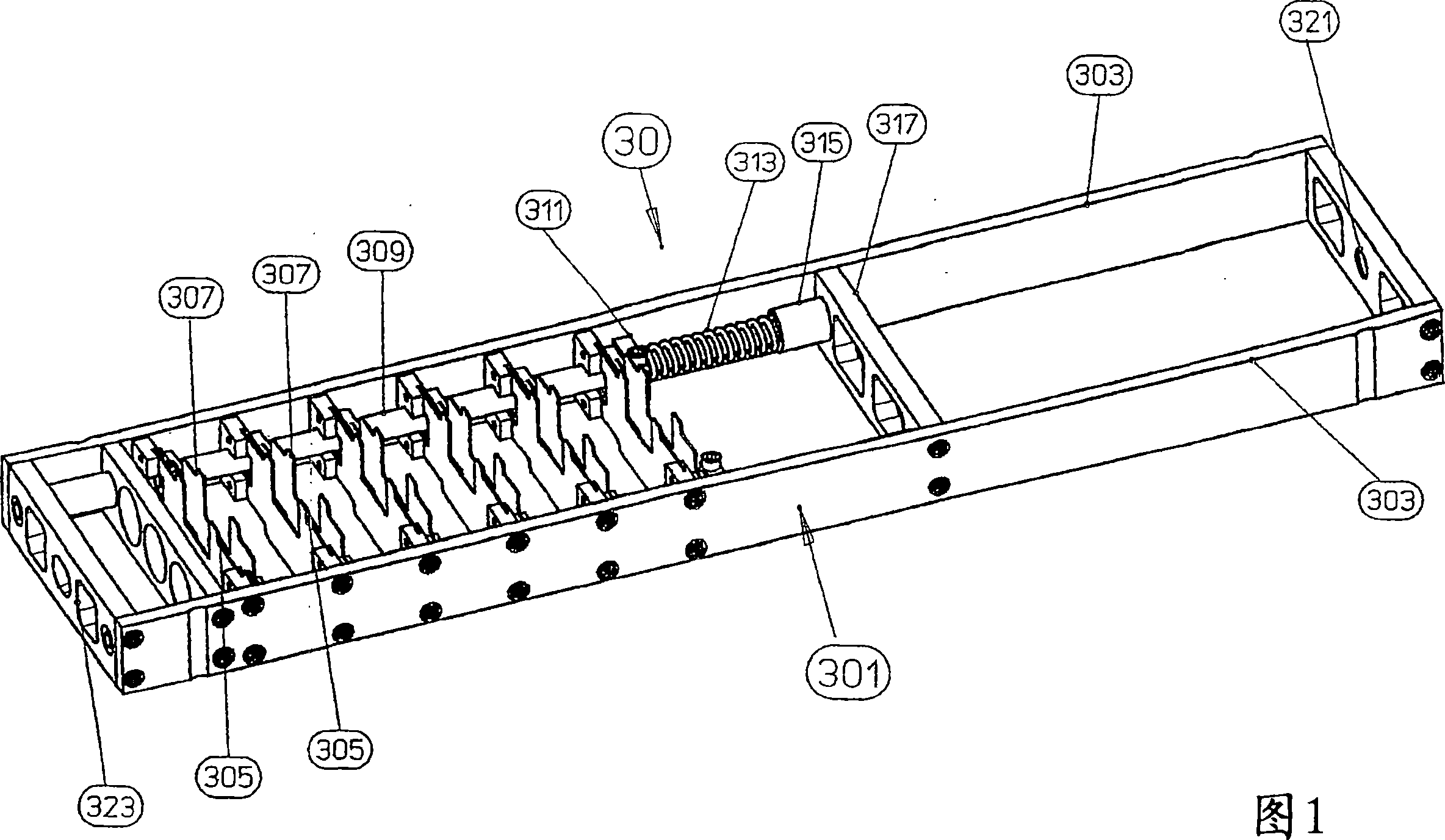

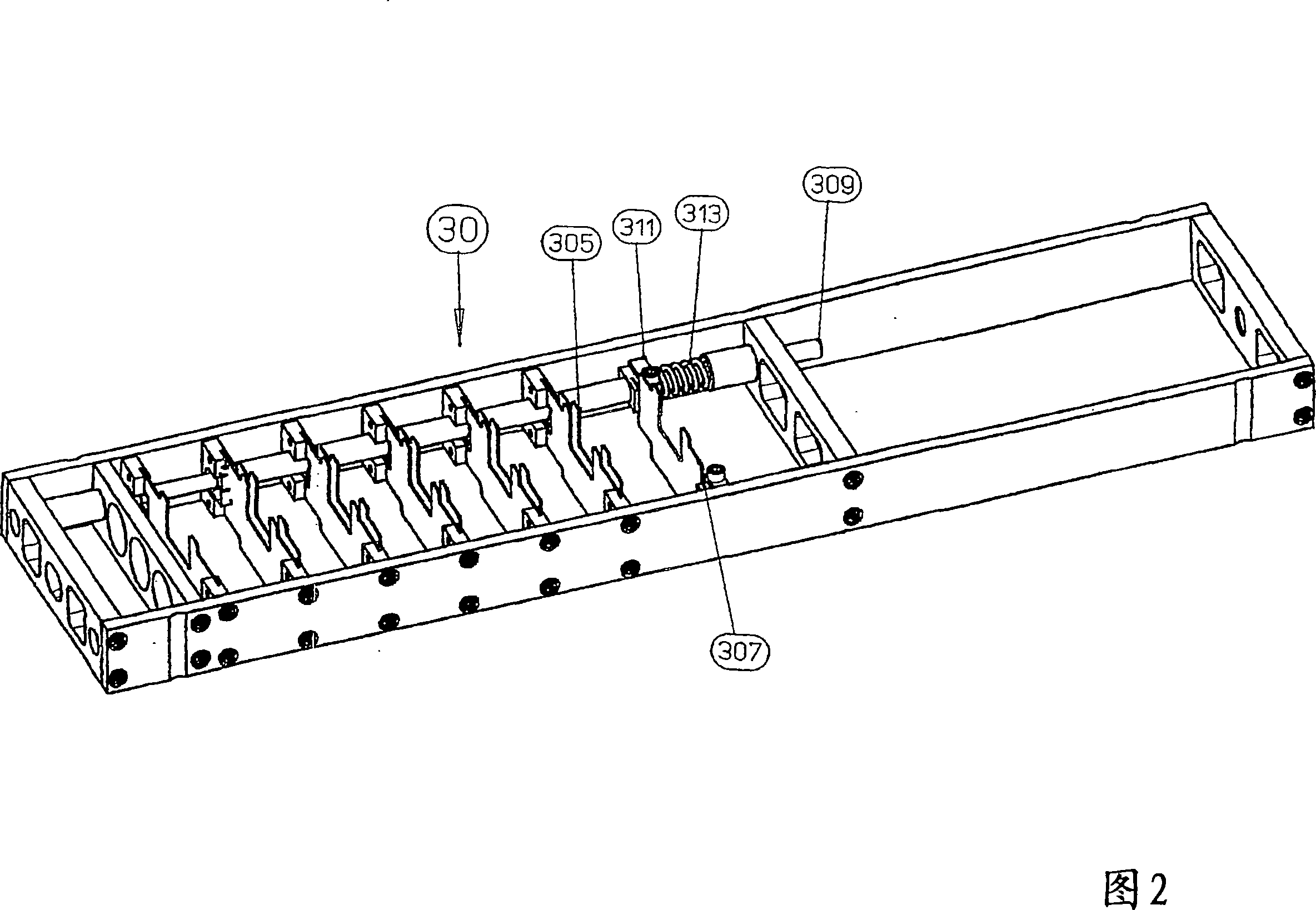

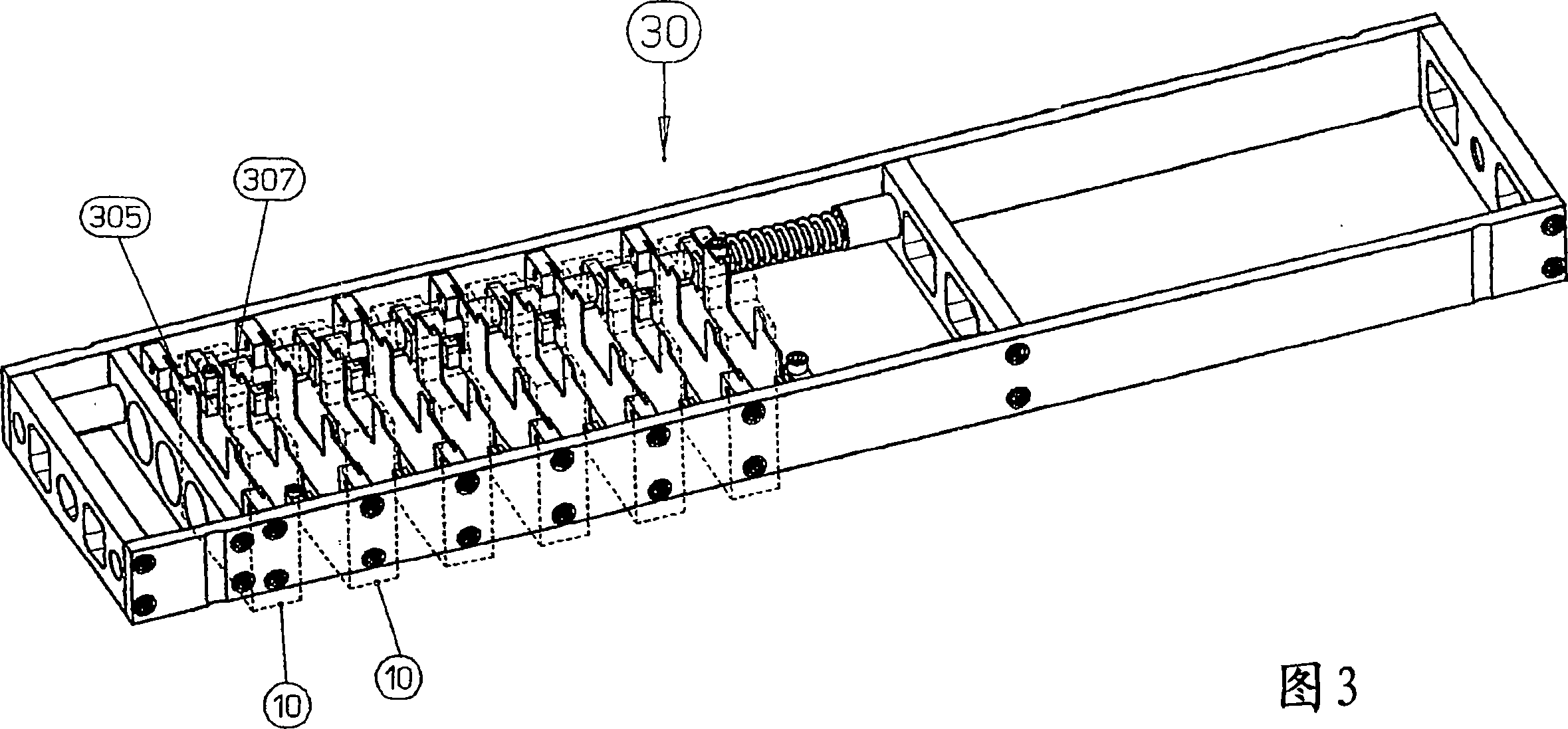

[0149] FIG. 53 schematically shows a plate stack 10 consisting of accumulator plates—alternately anode plates and cathode plates—in which lugs 12 of the anode plates are arranged in the region of a (front) narrow side. In the region located behind, the lugs 14 of the cathode plate are arranged. As mentioned above, the cathode or anode plates are inserted into a magazine made of separator material.

[0150] The lugs 12 of the individual anode plates are connected to each other by a bridge 16 . Likewise, the lugs 14 of the individual cathode plates are connected to one another via a cast bridge 8 . It is also shown in Fig. 54 that an upwardly protruding flange 17, 19 is respectively provided on the bridging portions 16 and 18 connecting the lugs 12, 14 of the cathode plates and the anode plates to each other, and they are used to connect the batteries to each other. Ends 24 connect stacks of adjacent cells 22 within a battery box 20 .

[0151] The plate stack 10 is arranged i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com