Focal plane shutter for digital cameras

A technology of focal plane shutter and digital camera, which is applied in the field of focal plane shutter, and can solve the problems that the hook part cannot return to the original shape, the engagement part and the engaged part cannot be well engaged, and deflection occurs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

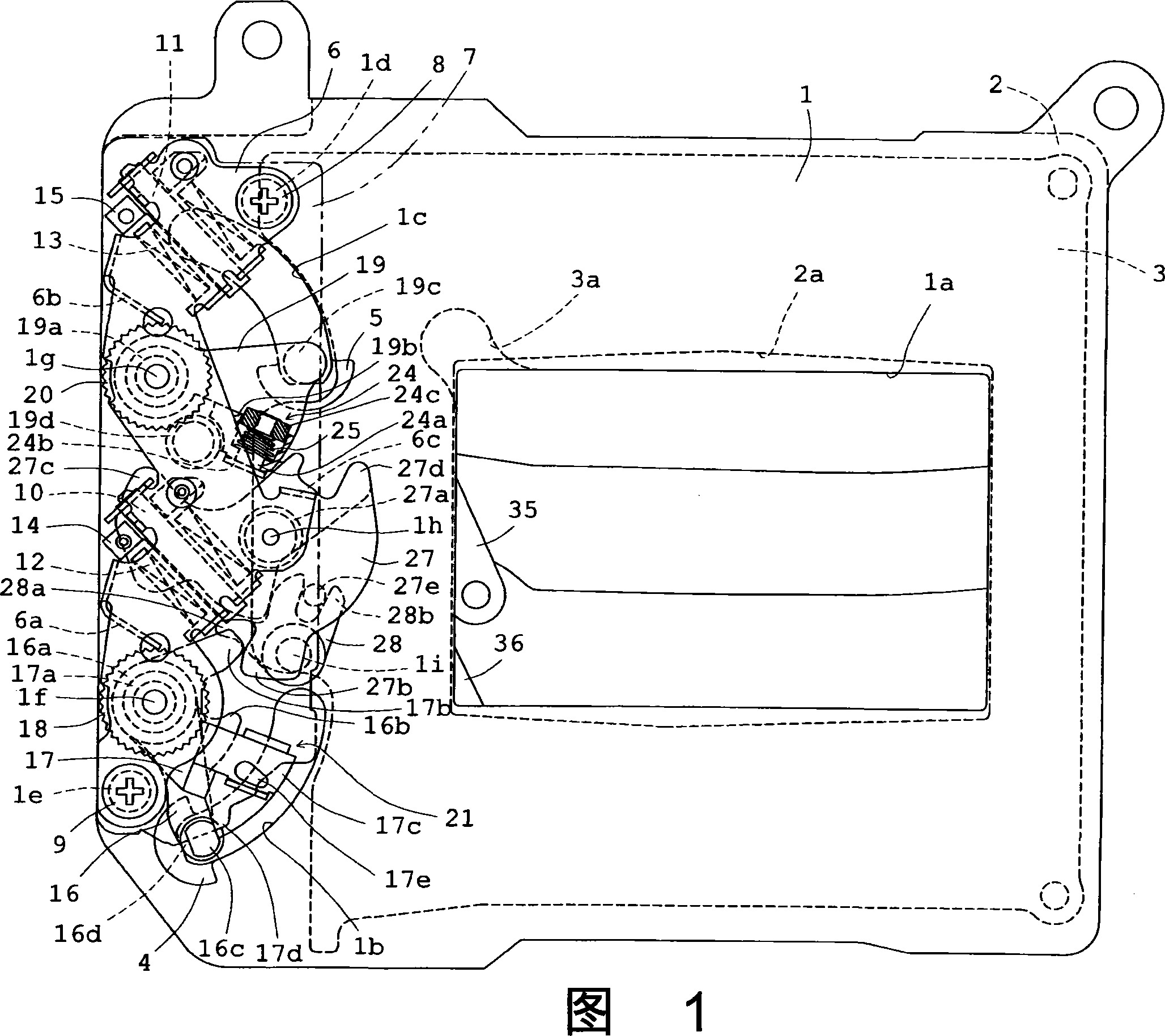

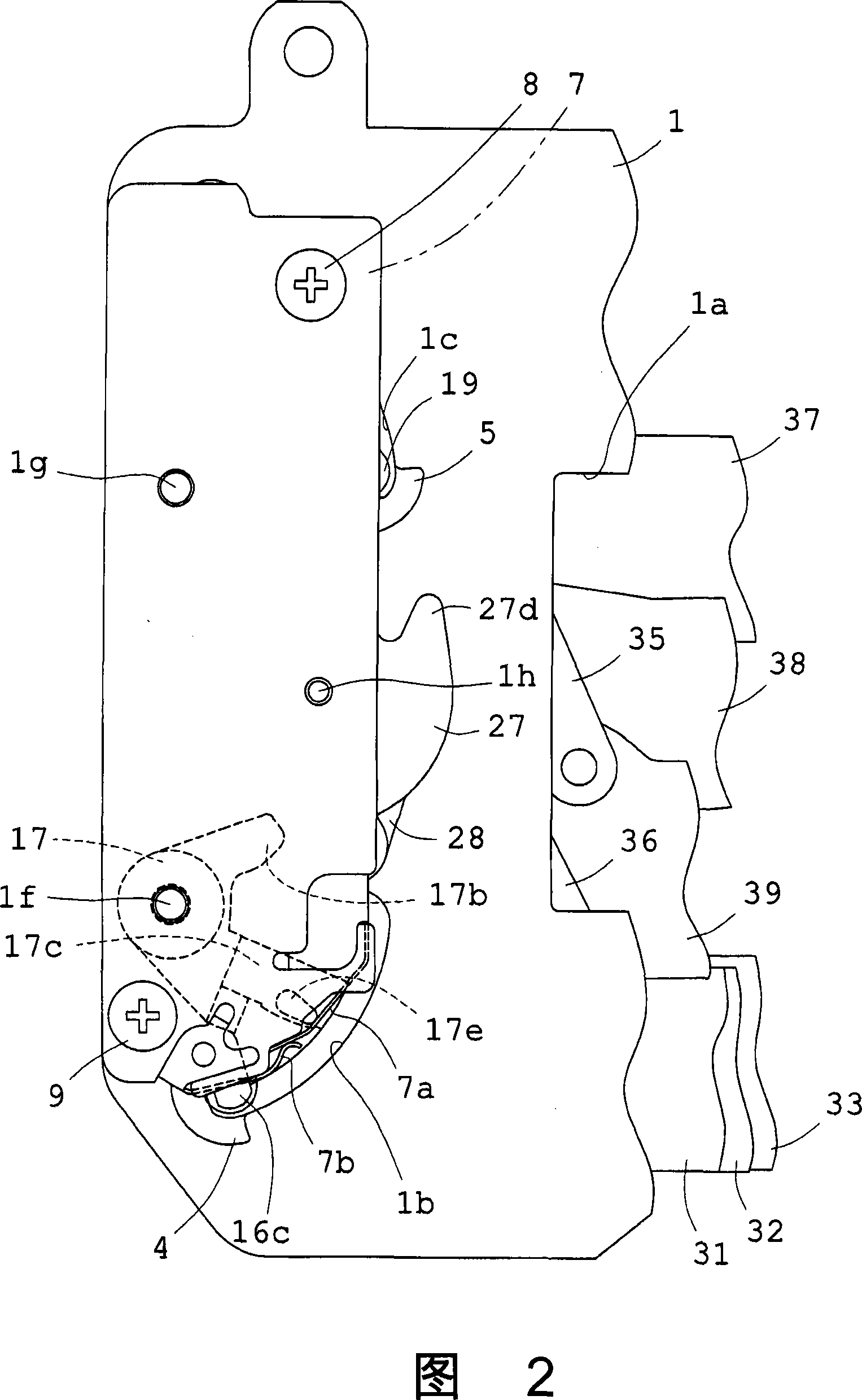

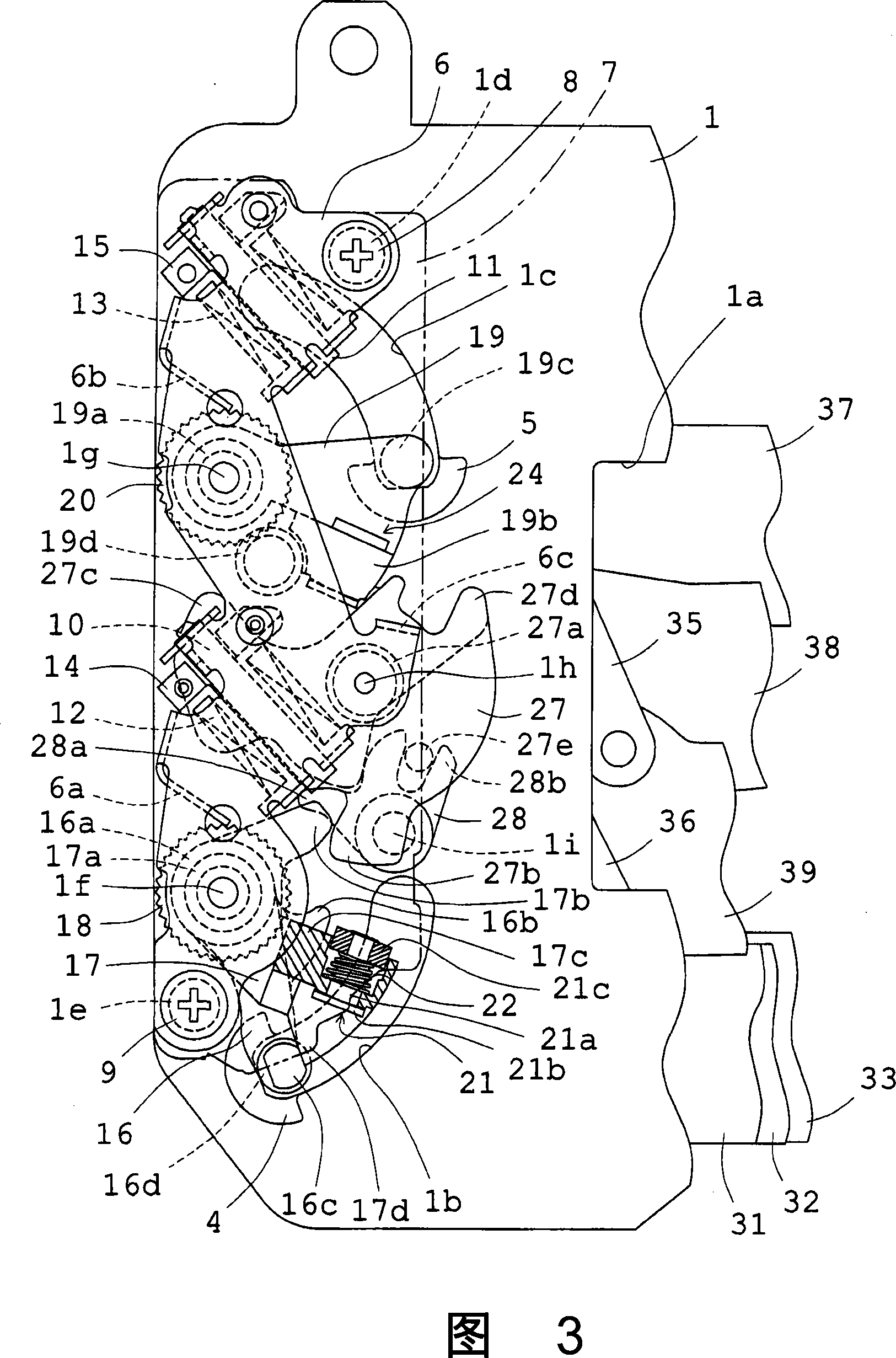

[0034] Fig. 1 is a plan view from the side of the subject in the state of being installed in the camera, and the outline of the printed circuit board is indicated by a two-dot dash line to easily show the state of the constituent members immediately after the exposure operation . FIG. 2 is an enlarged plan view of a part of FIG. 1 , and is shown for understanding a printed circuit board and a switch mechanism mounted thereon. FIG. 3 is a partially enlarged plan view similar to FIG. 1 . Fig. 4 is a cross-sectional view, seen from the right side of Fig. 2 and Fig. 3 , showing the overlapping relationship of constituent members for easy understanding. FIGS. 5 to 11 are plan views showing only main components necessary for explaining the operation of the components shown in FIG. 3 . FIG. 5 is the same as FIG. 3 and shows the state immediately after the exposure operation is completed. FIG. 7 shows the state of the setting operation performed from the state of FIG. 6 . Fig. 8 s...

Embodiment 2

[0074] Embodiment 2 will be described below. Like FIG. 3 , FIG. 13 is a plan view showing the state immediately after the exposure operation, but the mounting portion 17c of the second driving member 17 for the front blade is not cut and shown. In addition, FIG. 14 is a cross-sectional view seen from the right side of FIG. 13 to make the overlapping relationship of the constituent members easy to understand. In addition, in the structure shown in FIG. 2 used in the description of Example 1, the suppression member 28 is removed and used for description of this Example. In addition, the above-mentioned FIG. 12 used in the description of the operation of the first embodiment is also used in the description of the operation of the present embodiment. In addition, most of the constituent members of the present embodiment are the same as those of the first embodiment described above. Therefore, in FIG. 13 and FIG. 14 , the same members and the same parts as in the first embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com