Resin guardrail

A resin and guardrail technology, applied in the direction of roads, road safety devices, roads, etc., can solve the problems of no shock absorption device, impact, corrosion, etc., to achieve the effect of ensuring the vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

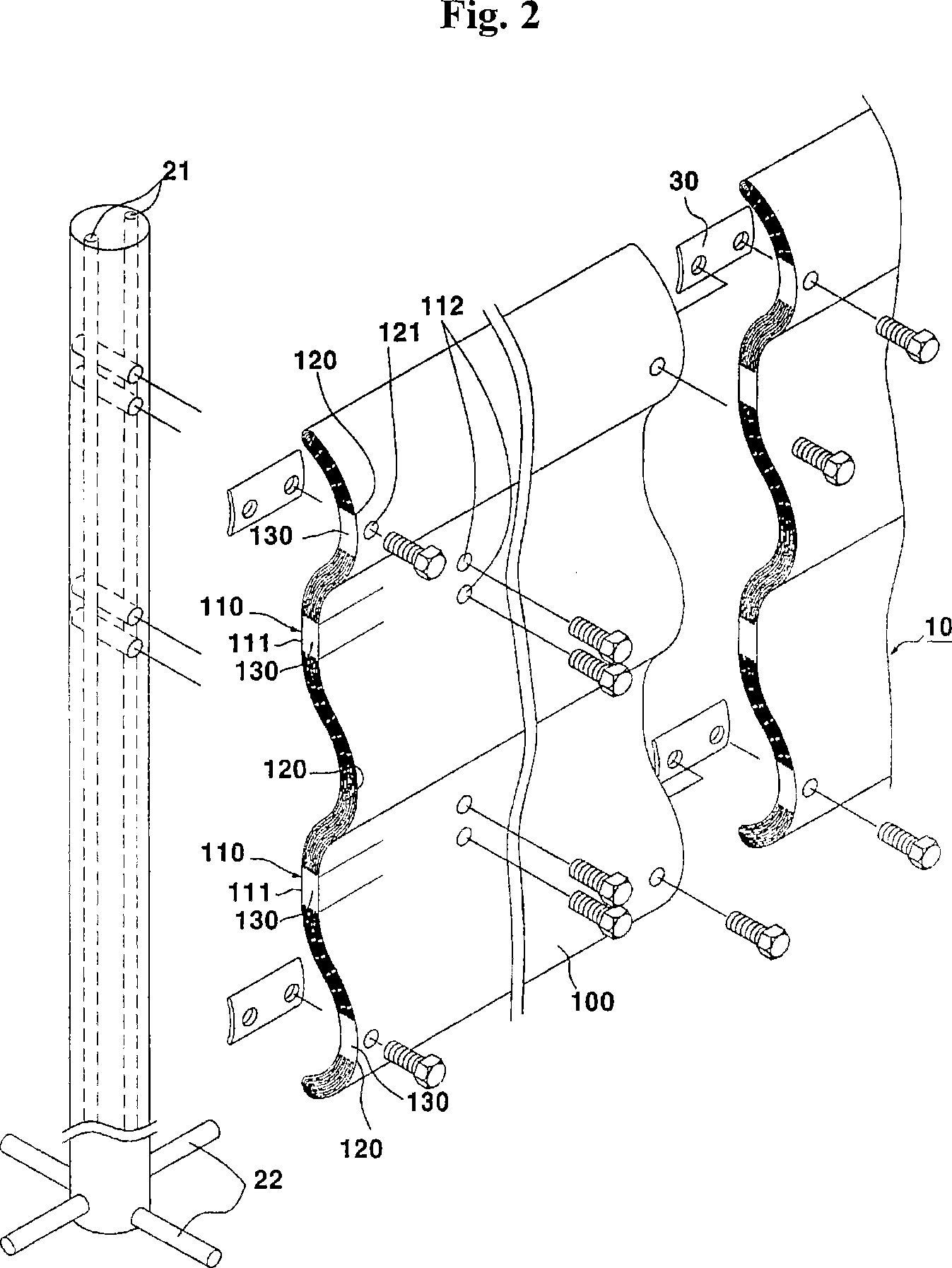

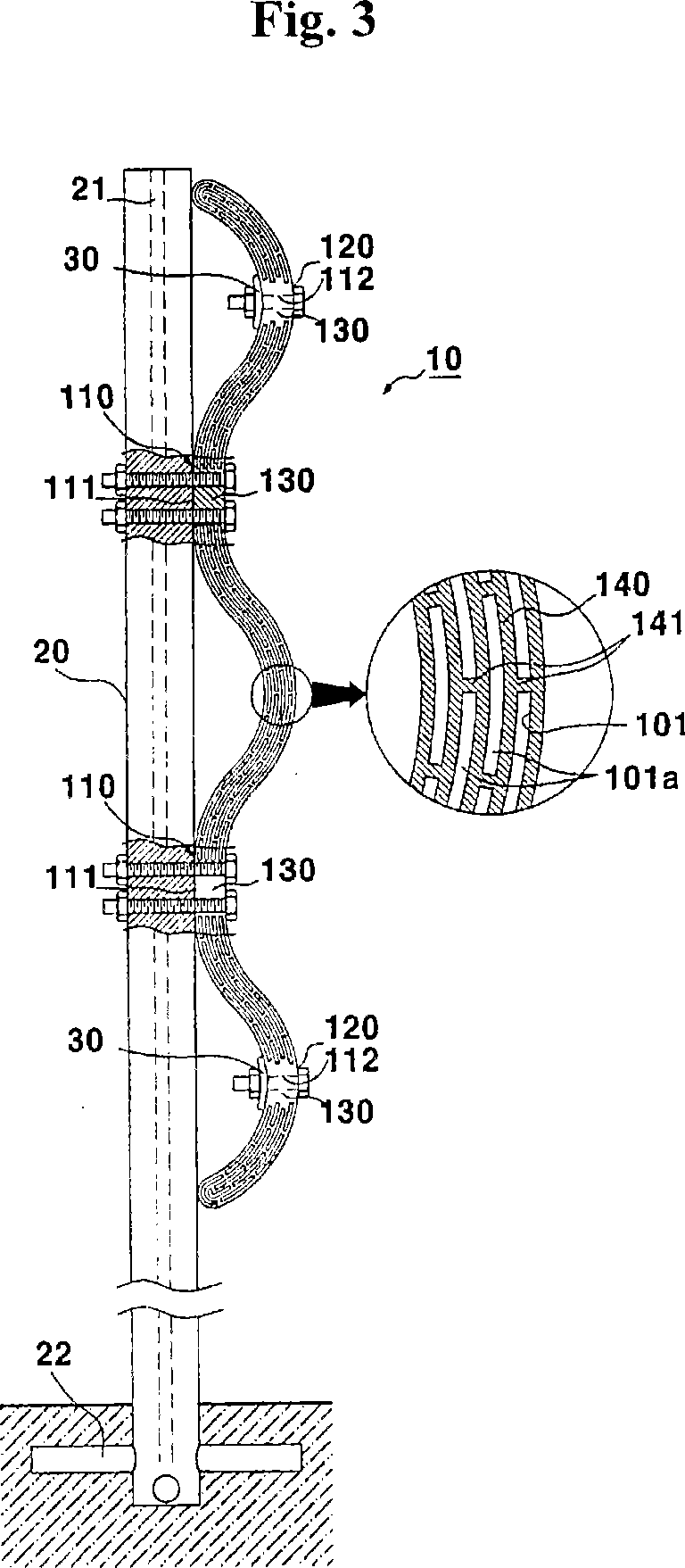

[0023] The preferred embodiment of the present invention will be described in detail below with reference to Fig. 2 and Fig. 3 of the accompanying drawings.

[0024] As described above, the guard sheet, which is the main part of the guardrail, is made of resin and has the following structure for increasing strength (weakness of resin), and can be produced by molding.

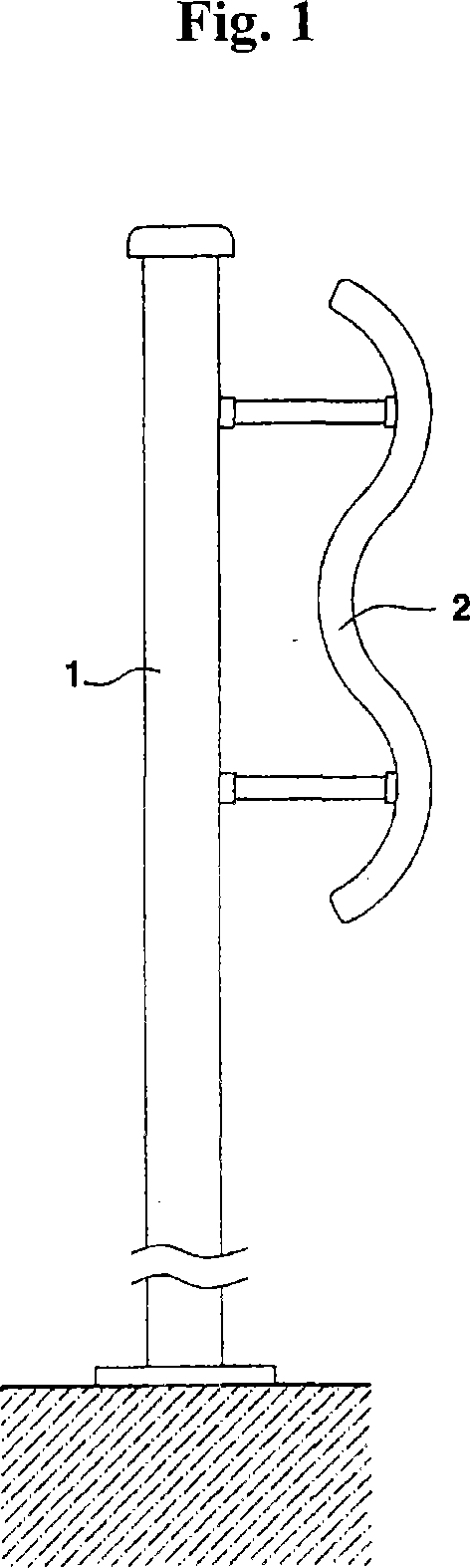

[0025] That is, the guardrail includes pillars, a plurality of protective sheets engaged with the pillars, and connectors for connecting the protective sheets to each other, and each of the protective sheets 10 has a hollow plate-shaped base 100 . The base has an overall corrugated cross-section with one or more rearwardly protruding rear ridges 110 and one or more forwardly protruding frontal ridges 120 .

[0026] Each of the rear spines 100 includes a flat portion 111 . One or more first fastening holes 112 are formed on the flat portion 111 for fastening the protective sheet to the pillar 20 by screws. Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com