Simple mattress strung with ropes

A technology for a mattress and a mesh frame, applied in the field of mattresses, can solve the problems of difficulty in mass production, complex production process, long time and labor, etc., and achieve the effect of saving labor and working time, simple production process, and saving steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

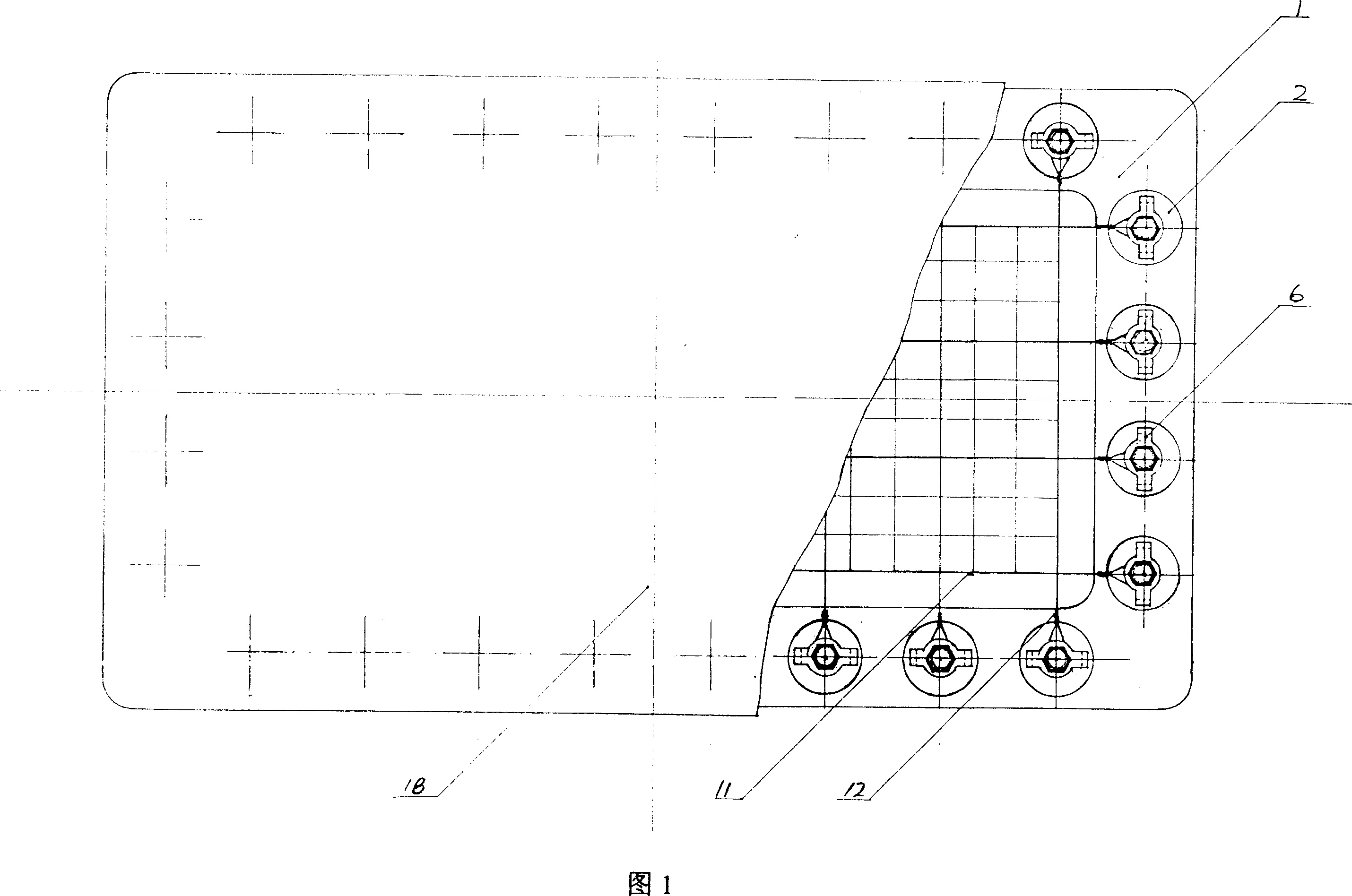

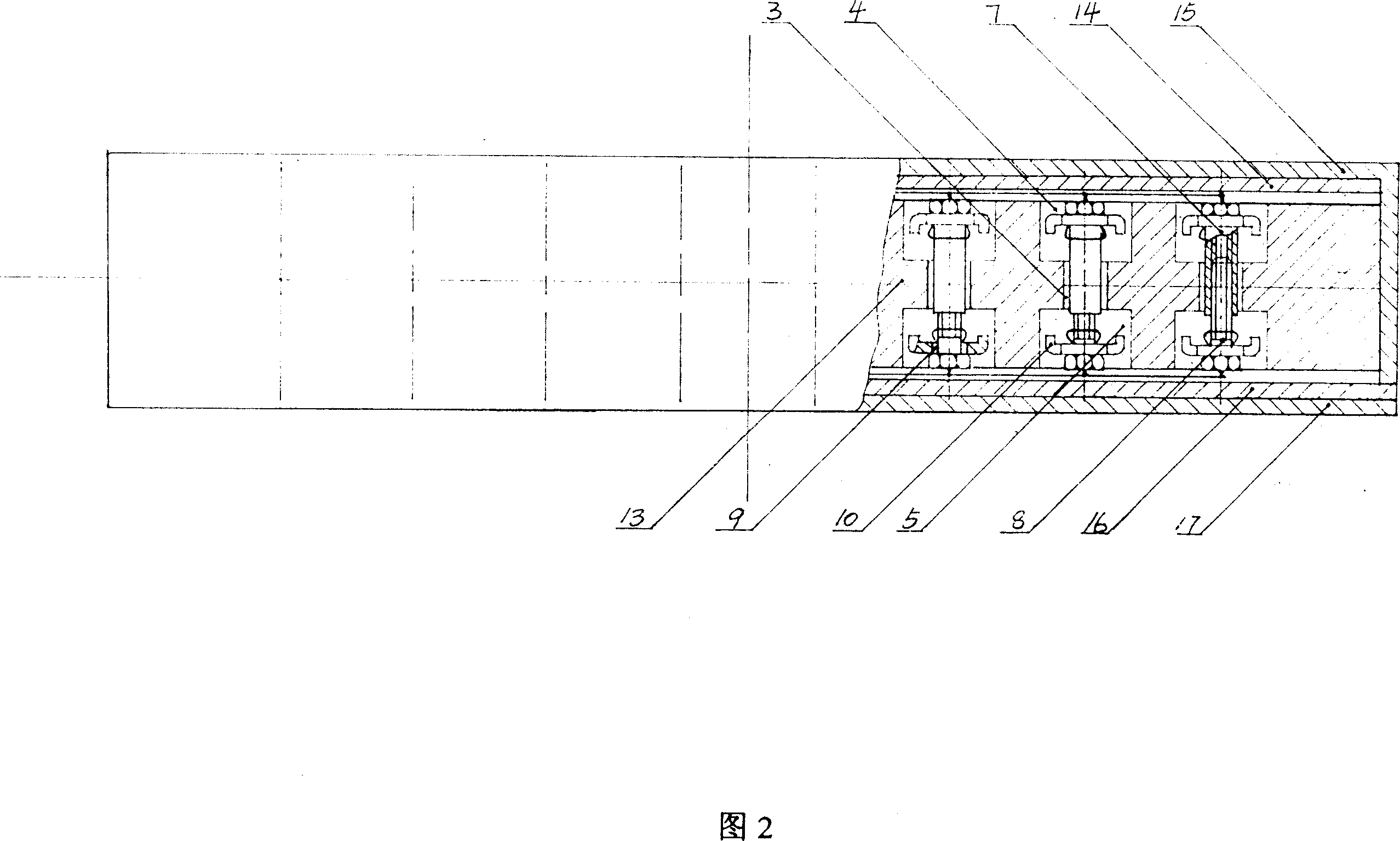

[0009] As shown in the figure, rows of through holes (2) are vertically drilled on the rectangular frame (1). The macropores A (4) and macropores B (5) are interconnected and formed. Screw sleeves (7) and screw rods (8) respectively covered with rope hooks (6) are installed in the through holes (2), and the screw sleeves (7) and screw rods (8) are connected to each other through threads, wherein the rope hooks (6) For watch shape, circular hole (9) is arranged in the middle, and strip (10) on both sides rolls inward into a concave shape. Spread the woven rope net (11) on the upper and lower sides of the rectangular frame (1) respectively, and connect the rope ends (12) on the two sides of the rope net (11) with the screw sleeves installed in the through hole (2) respectively. (7) is connected with the screw rod (8), and the rope ends (12) on the rope nets (11) on both sides are respectively fixed on the screw sleeve (7) and the screw rod (8) with a rope hook (6), and then tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com