Diaphragm chuck

A diaphragm type and chuck technology, applied in chucks, manufacturing tools, mechanical equipment, etc., can solve problems such as complex production and inaccurate processing of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

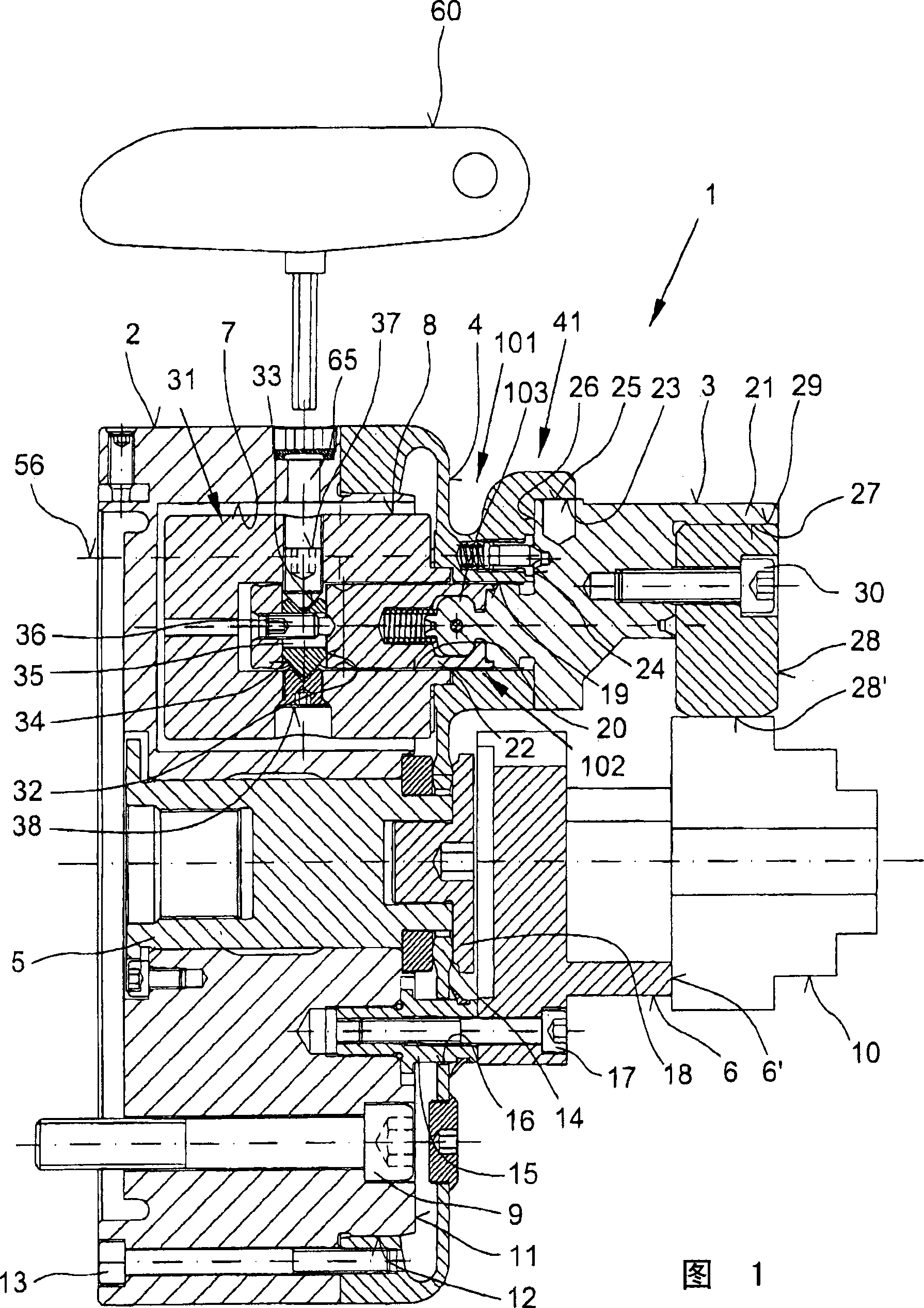

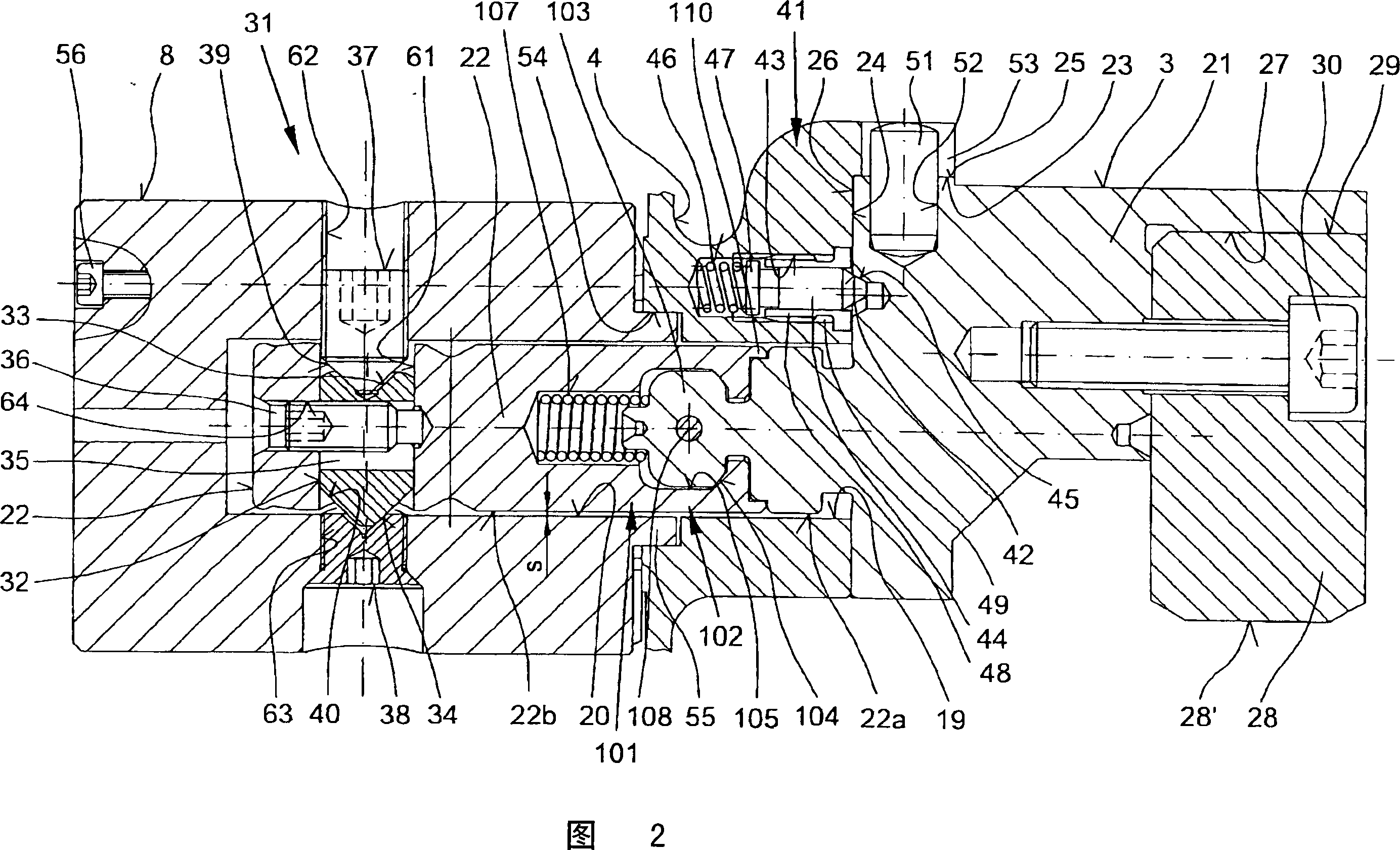

[0022] Diaphragm chuck shown in Fig. 1 is denoted by numeral 1, it is specially used for clamping high-quality workpiece 10, such as a gear, and is mainly composed of jaws 3 inserted into chuck body 2, and jaws 3 function On the workpiece 10 , the workpiece 10 is in driving connection with a deformable membrane 4 made of metallic material on a front face 12 attached by bolts 13 to recesses 12 in the exterior of the chuck body 2 .

[0023] For actuating the diaphragm 4 a centrally arranged actuator 5 is provided, into which an adjustable pull rod is screwed via a servo (not shown) on the end face remote from the jaw 3 . At the other end of the actuator 5 the diaphragm 4 with the crown collar 14 is clamped by the disc 18 .

[0024] In addition, counterweights 8 are inserted into the grooves 7 penetrating into the chuck body 2 facing the jaws 3, and these counterweights 8 counteract the centrifugal force generated by the jaws 3 when the diaphragm chuck 1 rotates , and the jaw 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com