fuel injector assembly

A fuel injector and injector technology, applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve the problems of affecting performance, damage, separation, etc., to save materials, eliminate bending moments, and save manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

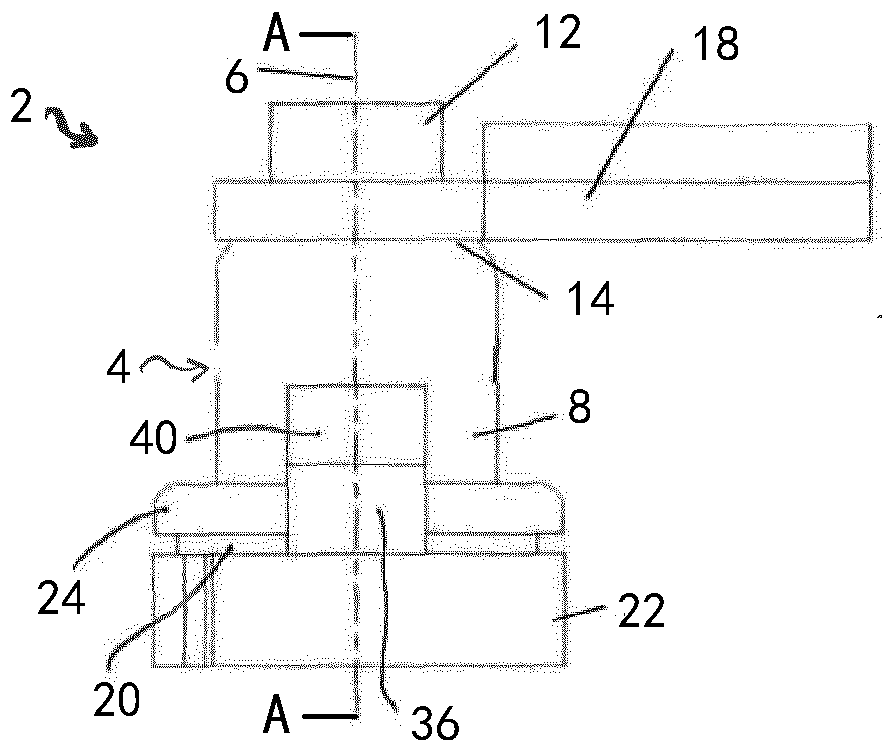

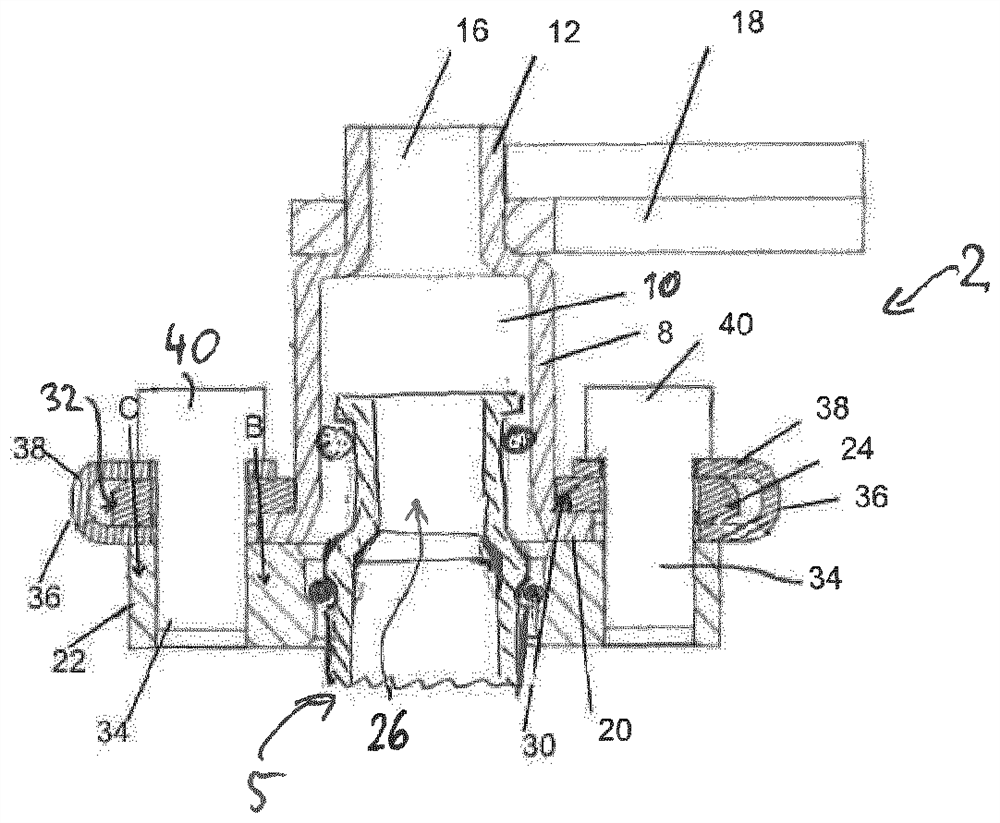

[0030] now refer to figure 1 , shows the injector cup assembly 2 having the fuel injector cup 4 formed from sheet material as a single piece. The fuel injector cup 4 is substantially cylindrically formed about an axis 6 . The fuel injector cup 4 has a main body portion 8 containing a fuel injector 5 ( figure 1 Not shown in ) the volume 10 of the fuel inlet port. As shown, at the outer upstream end of the injector cup, the injector cup 4 has a coaxial tubular stub 12 having a reduced outer diameter relative to the diameter of the main body portion 8 to form an annular shoulder 14 . The stub contains a fuel inlet port 16 to which a fluid tube (not shown) is connected to provide a hydraulic connection between the volume 20 and a fuel source, typically in the form of a common rail (not shown) .

[0031] At the end of the volume in the injector cup 10 opposite the stub 12 , the volume in the injector cup 10 opens to receive the inlet end of the fuel injector 5 .

[0032] now a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com