Tail yarn holding device of spinning machine

A technology of holding device and spinning machine, applied in textile and paper making, etc., can solve the problem of not being able to shorten the length of tail yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

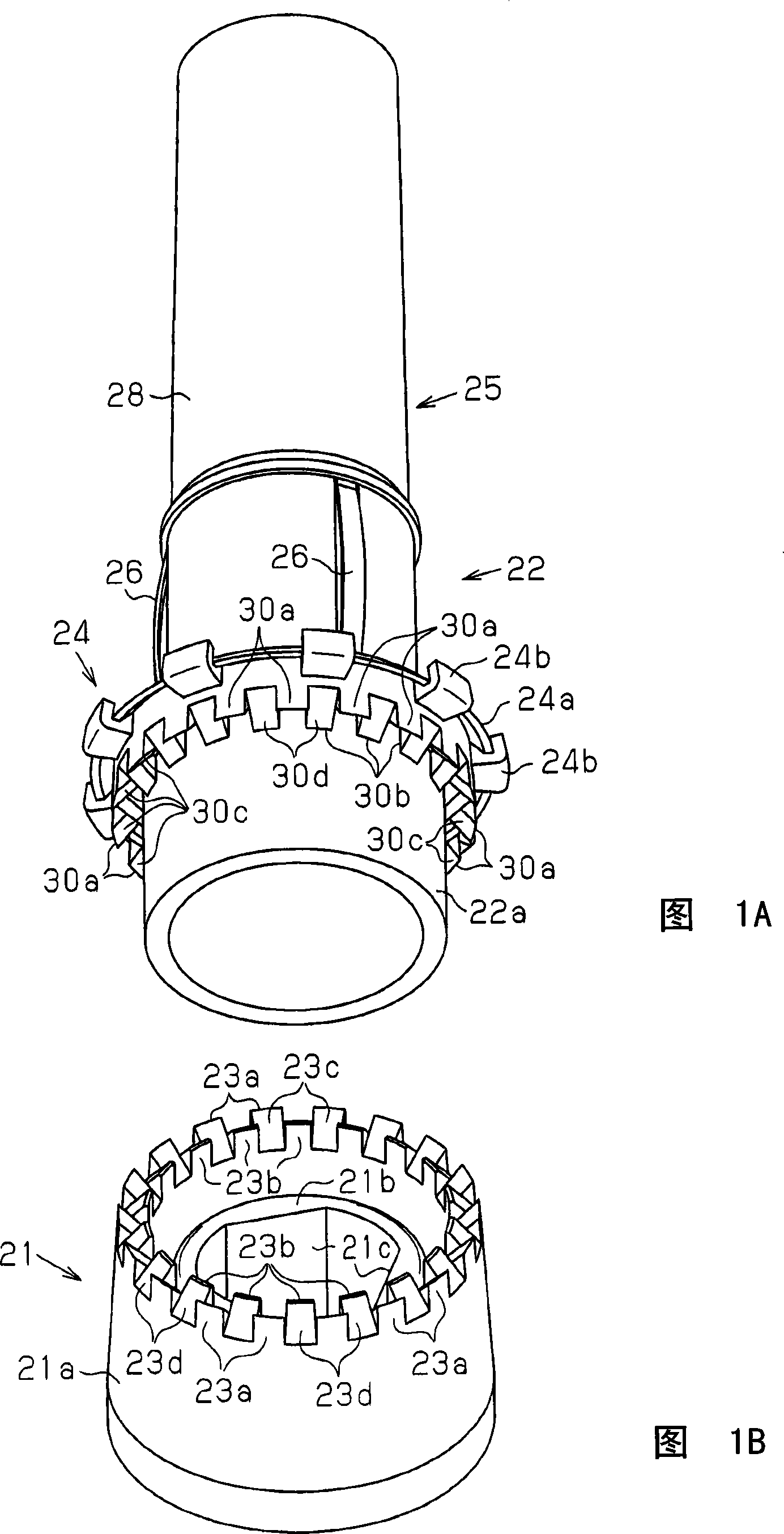

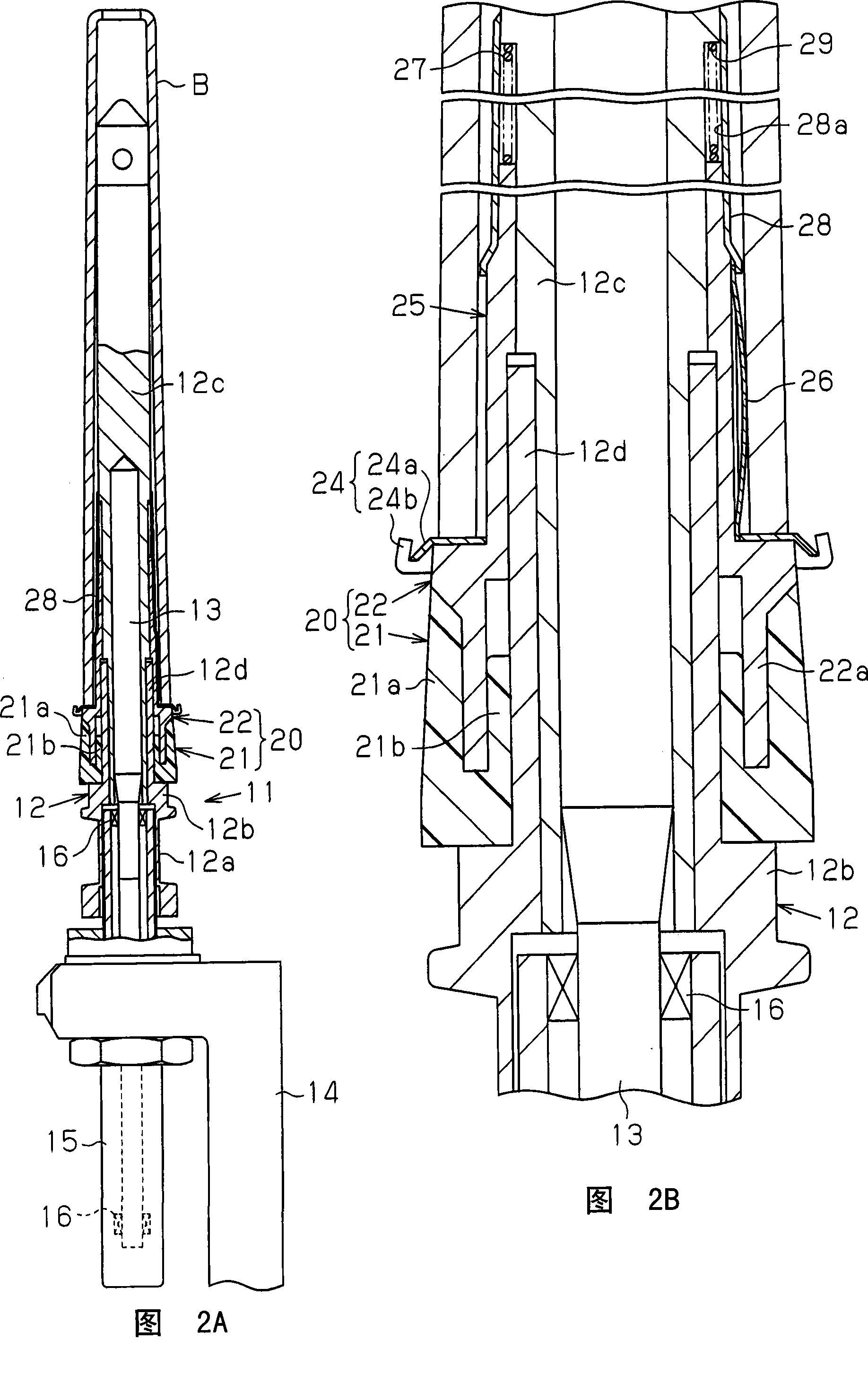

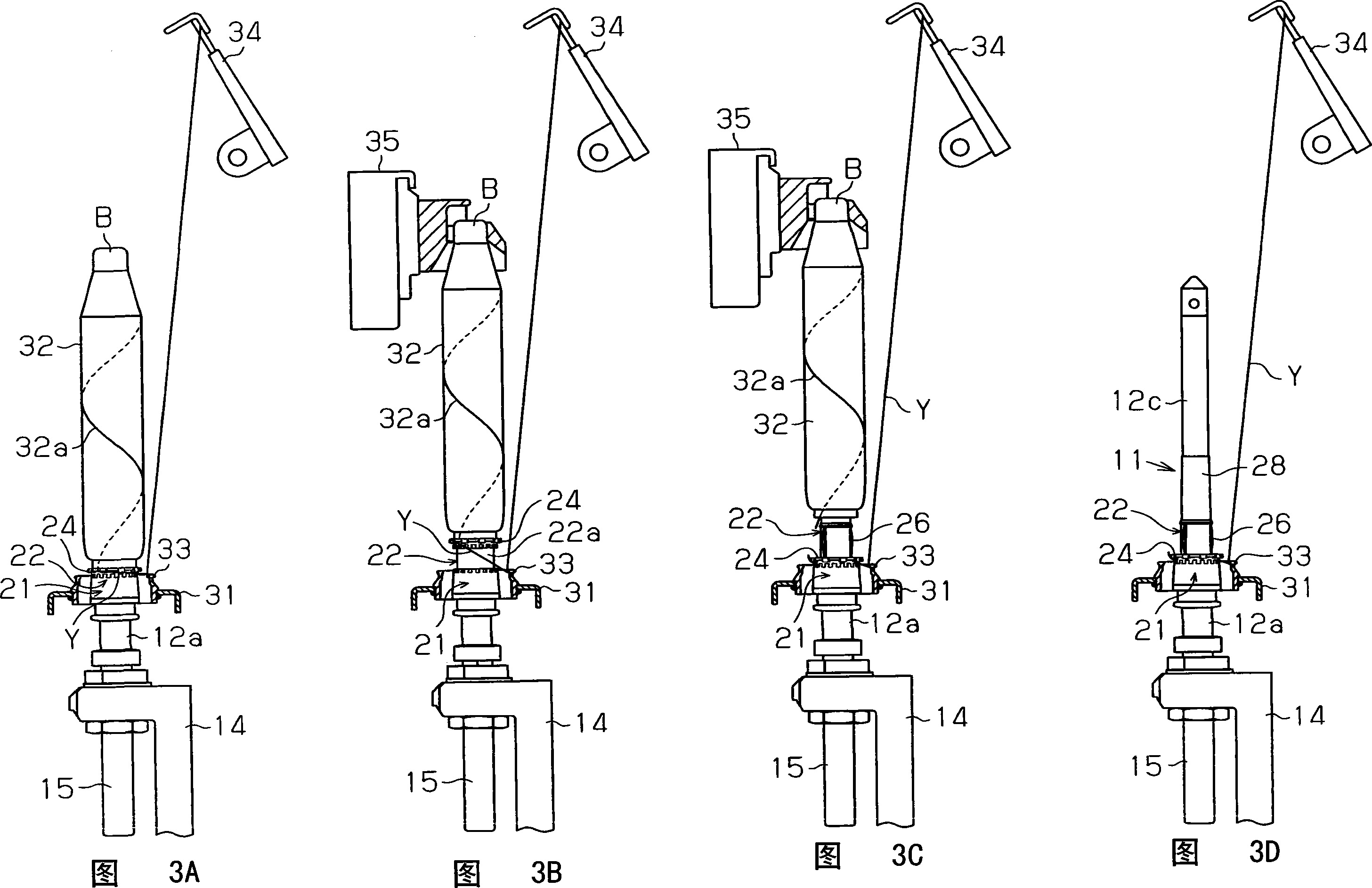

[0017] A ring spinning frame according to an embodiment of the present invention will now be described with reference to FIGS. 1A-4B.

[0018] As shown in FIG. 2A, the spindle 11 has a blade portion 12 and a spindle shaft 13. As shown in FIG. The spindle shaft 13 is rotatably supported by a spindle foot 15 fixed to a lower dragon bar 14 with a bearing 16 . The blade portion 12 has a foot 12b and blades 12c. The foot 12b has a belt engaging the portion 12a, and the blade 12c is fitted to the upper portion of the foot 12b. The bobbin B is connected to the blade 12c. Spindle 13 is a molded insert with blade 12C.

[0019] The foot 12b has a mounting member 12d on the upper portion. A tail yarn holding part 20, which functions as a tail yarn holding device, is installed on the mounting part 12d. The tail yarn holding part 20 includes an annular lower holding part 21 and an annular upper holding part 22 . In this embodiment, the lower grip member 21 is formed of an elastic bod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap