Marker with penetrater

A technology for marking and tools, which is applied in the field of marking tools with liquid cores, can solve the problems of liquid leakage of marking tools, easy deformation and rupture of sealing rings, etc., and achieve the effect of preventing dripping, avoiding dripping, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

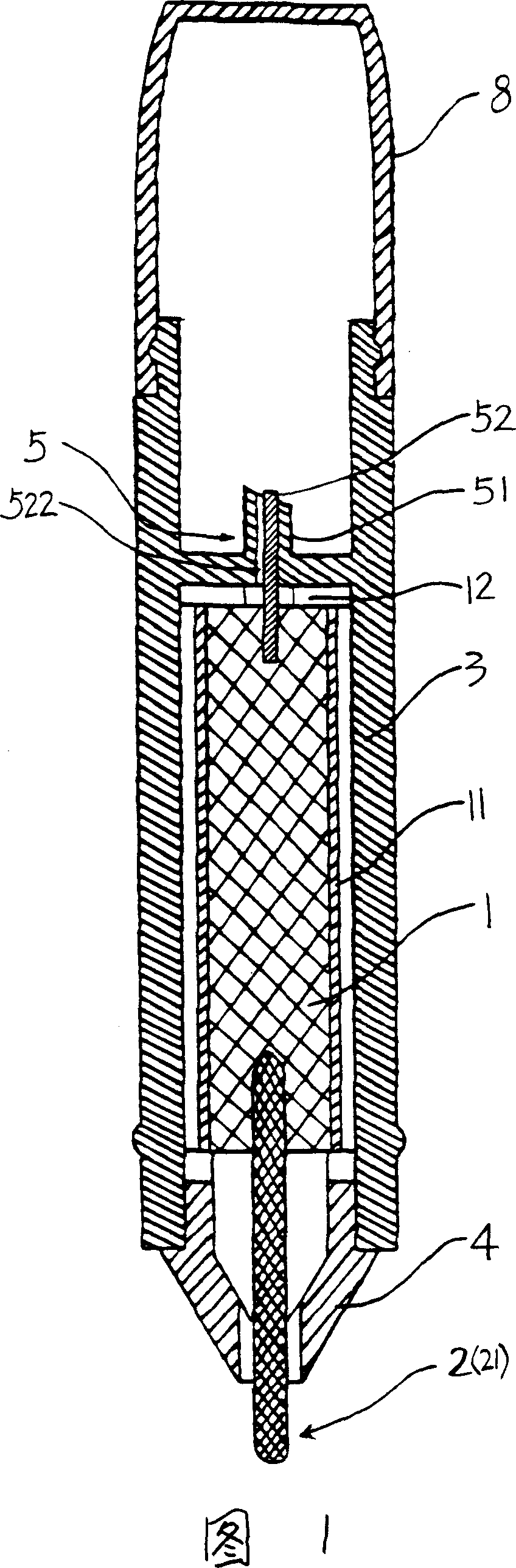

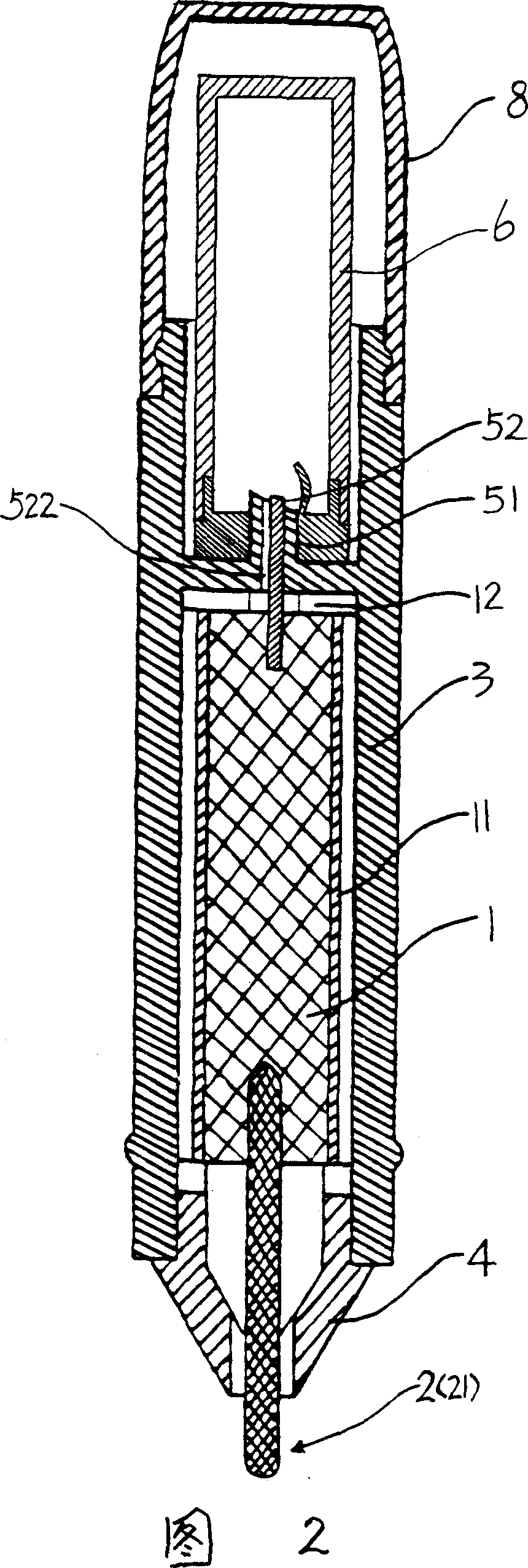

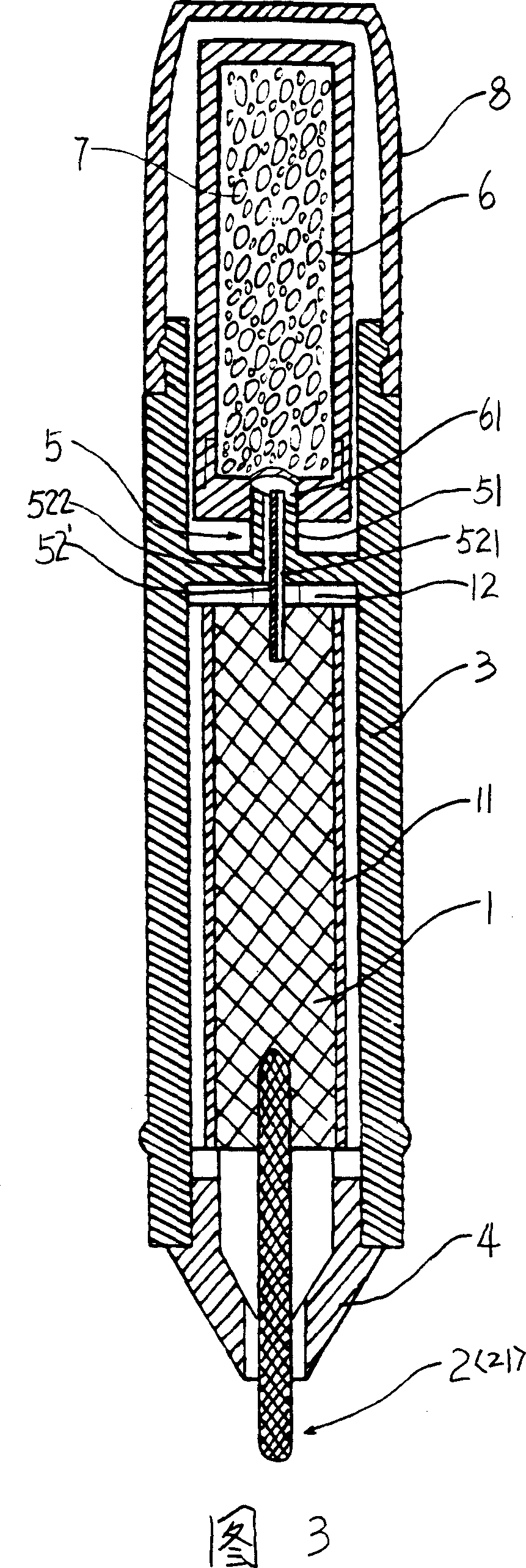

[0044] The present invention is a marking tool with an opening device, which includes: a liquid-containing core 1 for absorbing and storing marking ink (writing ink), and a marking nib 2 for applying marking ink (writing ink) Overlay on the marking (writing) medium, housing 3 for protecting the liquid-containing core 1, fixing sleeve 4 for fixing the marking tip 2, at least one ink reservoir with marking ink is arranged outside or inside the marking tool device 6, an opening device 5 is arranged above the liquid-containing core 1, which is used to open and guide the ink reservoir 6 with marking ink, so as to continuously provide marking ink to the marking nib 2, greatly extending the marking time. The service life of the tool, the structure is simple and reasonable, and the cost is low, and at the same time it effectively prevents and avoids the phenomenon of dripping.

[0045] Referring to Fig. 1, an opening device 5 is provided above the liquid-containing core 1, and the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com