Method for reinforcing measurement precision of substrate structure coordinate

A high-precision, coordinate technology, used in measuring devices, optical devices, instruments, etc., can solve problems such as the influence of measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

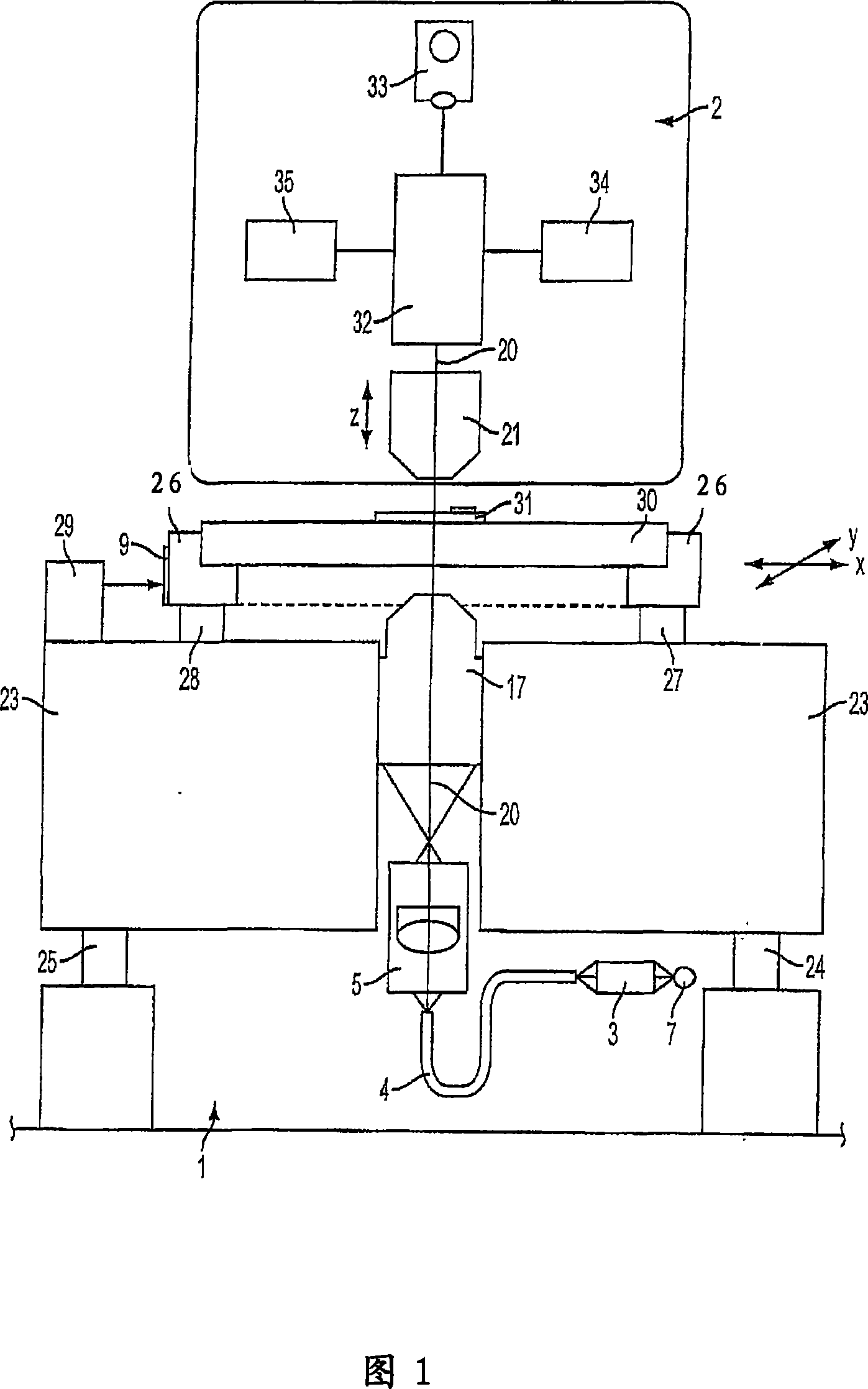

[0050] A coordinate measuring device of the type shown in FIG. 1 has been explained in detail in the introductory part of the description.

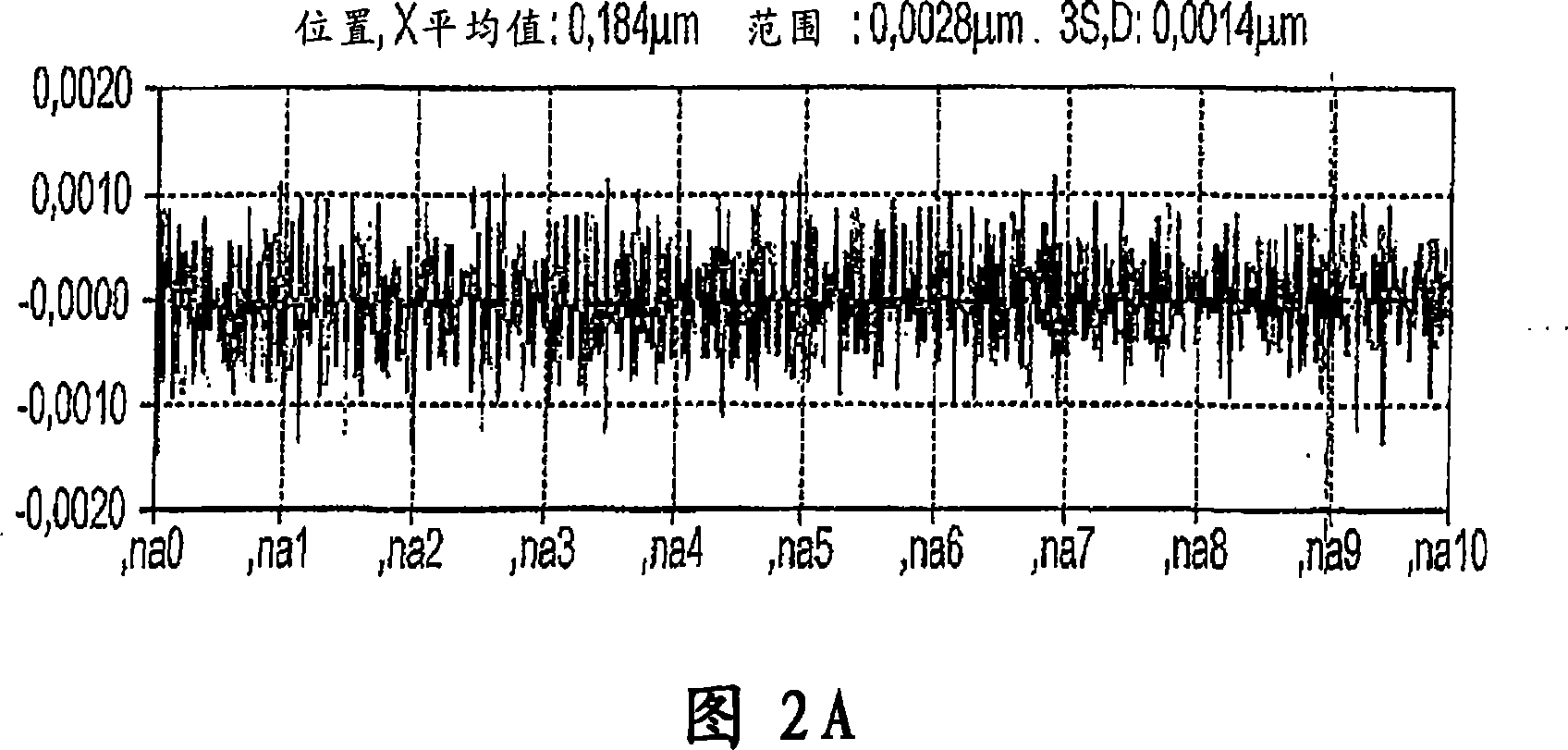

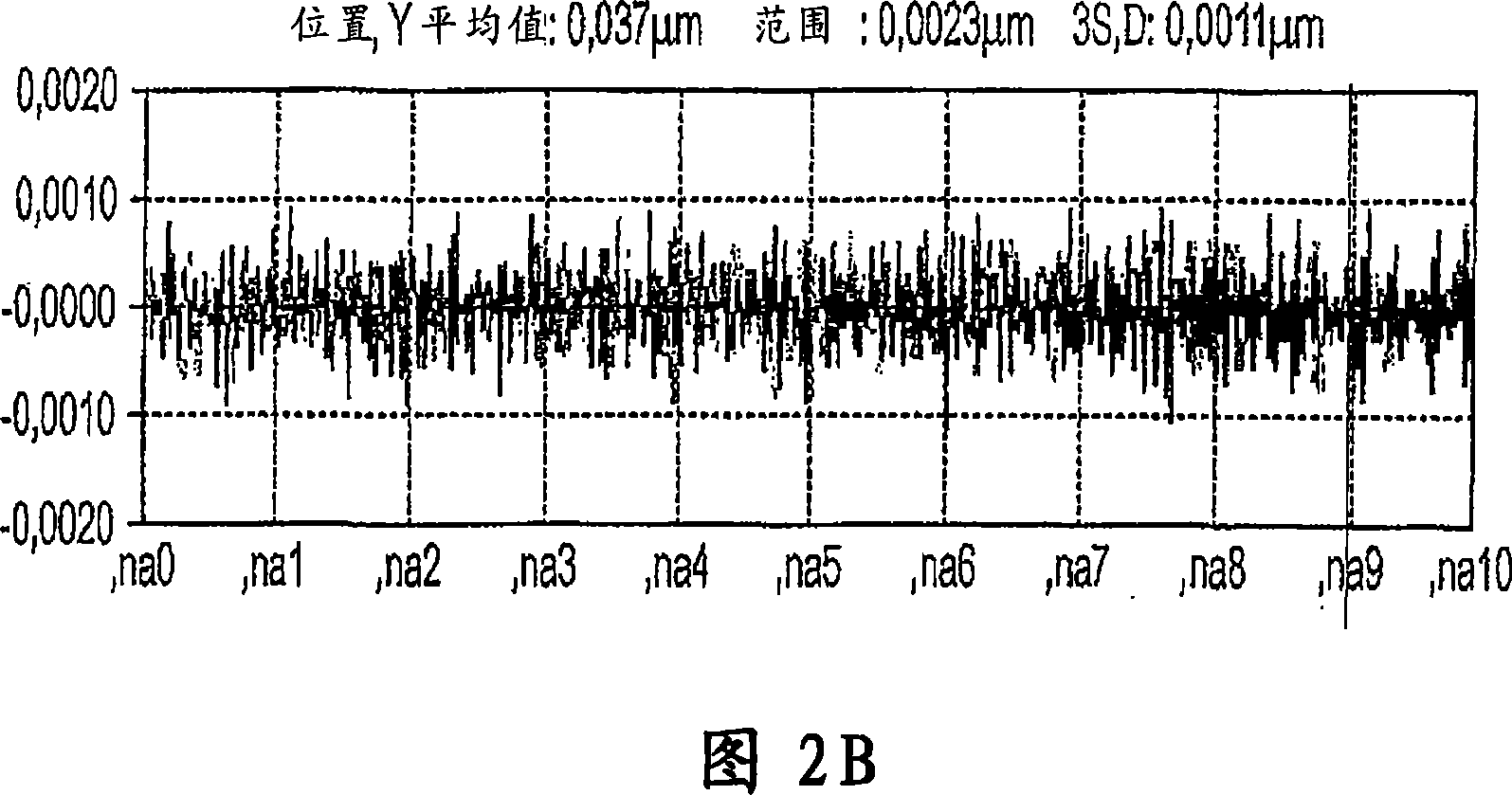

[0051] The repeatability or reproducibility of this coordinate measuring device is usually determined in the factory by measuring a 15x15 point measurement grid (measurement area 6 inches, 152x152 mm). The value of three times the standard deviation (3σ) is usually determined after 20 measurements of the coordinates obtained in the X and Y coordinate directions. This maximum value of three times the standard deviation is indicative of repeatability and thus machine performance.

[0052] If measurements are made locally on defined mask positions (i.e. without traversing the X / Y measurement stage in this case), then this is an indication of short-term reproducibility (here, 20*100 measurements*4 seconds = 2.2 hours). This measurement gives an indication of the repeatability over a short period of time (so-called needle test).

[0053] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com