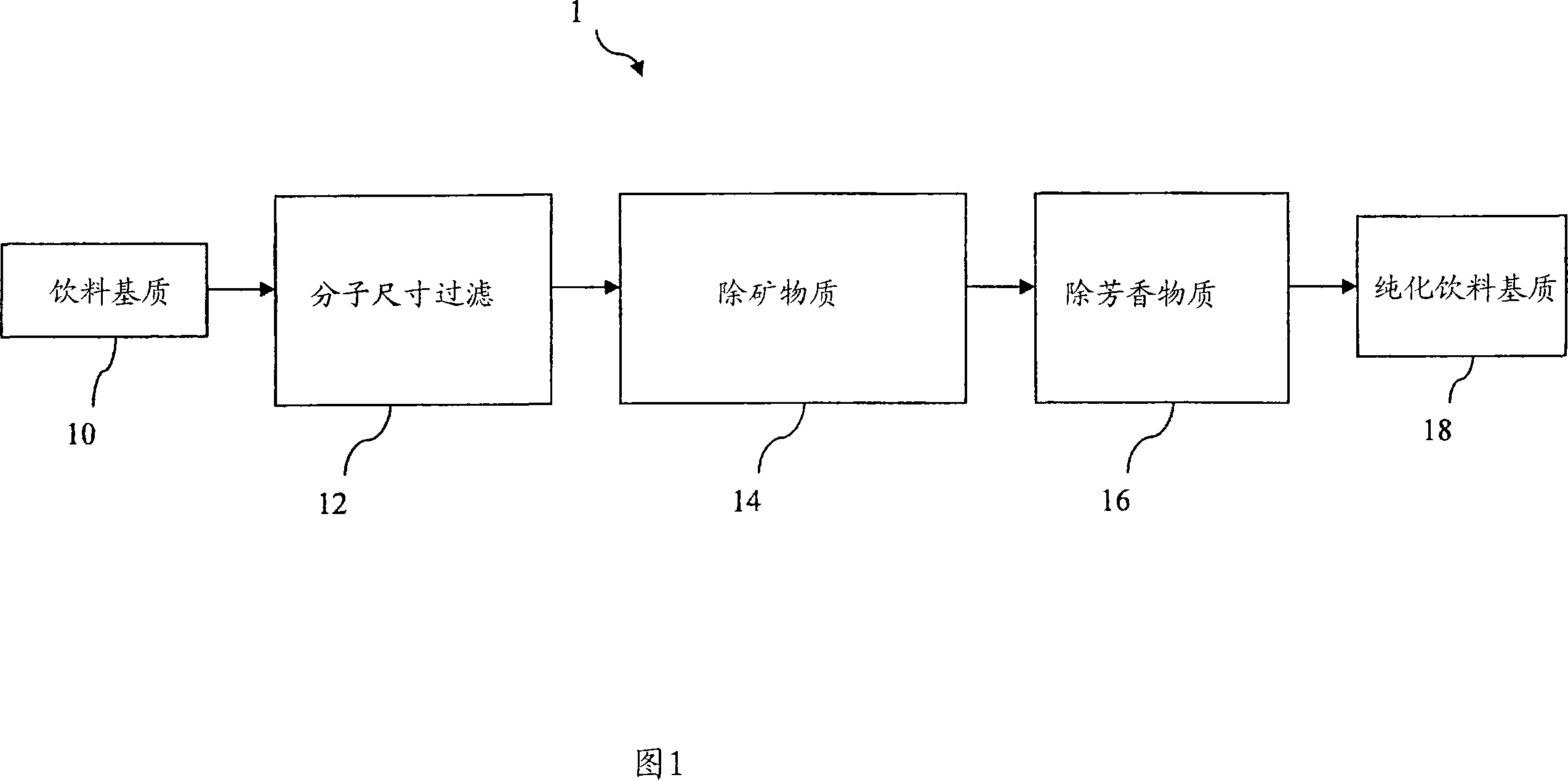

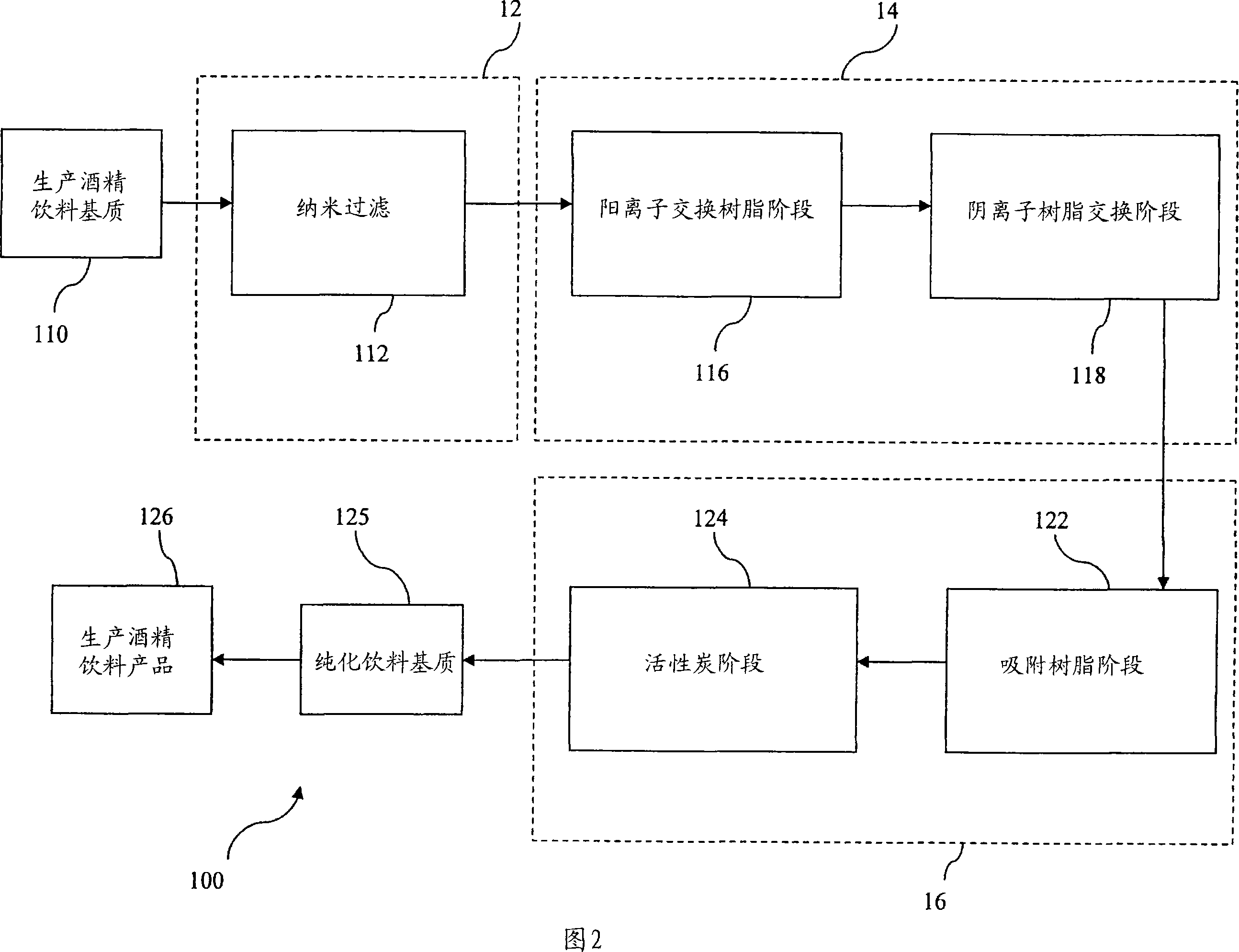

Purified beverage products and processes for making the same

A beverage and process technology, applied in the field of high-purity alcohol beverage base products, can solve problems such as adverse effects of fermentation and/or brewing beverage products during storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] The following table shows an example of an alcoholic beverage base, and analyzes the various compounds and their characteristics in each step of the above-mentioned filtration process according to the present invention.

[0063] Enter

raw material

Nano

After filtering

Cationic

after exchange

anion

after exchange

adsorption

after resin

activity

after charcoal

ABV 1

11.35

11.24

11.12

11.21

11.08

11.06

ABW

9.03

9.01

8.92

8.98

8.83

8.87

calories

248.60

223.60

218.30

216.29

204.16

216.87

solid

2.15

0.55

0.32

0.33

0.27

0.31

pH

3.75

3.87

4.81

4.56

5.59

4.17

R.I. 3

1.34

1.33

1.34

1.34

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com