Camera module and portable electronic device

A technology of a camera module and a processing device, which is applied in the field of photography, can solve the problems of time-consuming focusing operation and step motor out-of-step, and achieve the effect of shortening the focusing time and reducing out-of-step.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

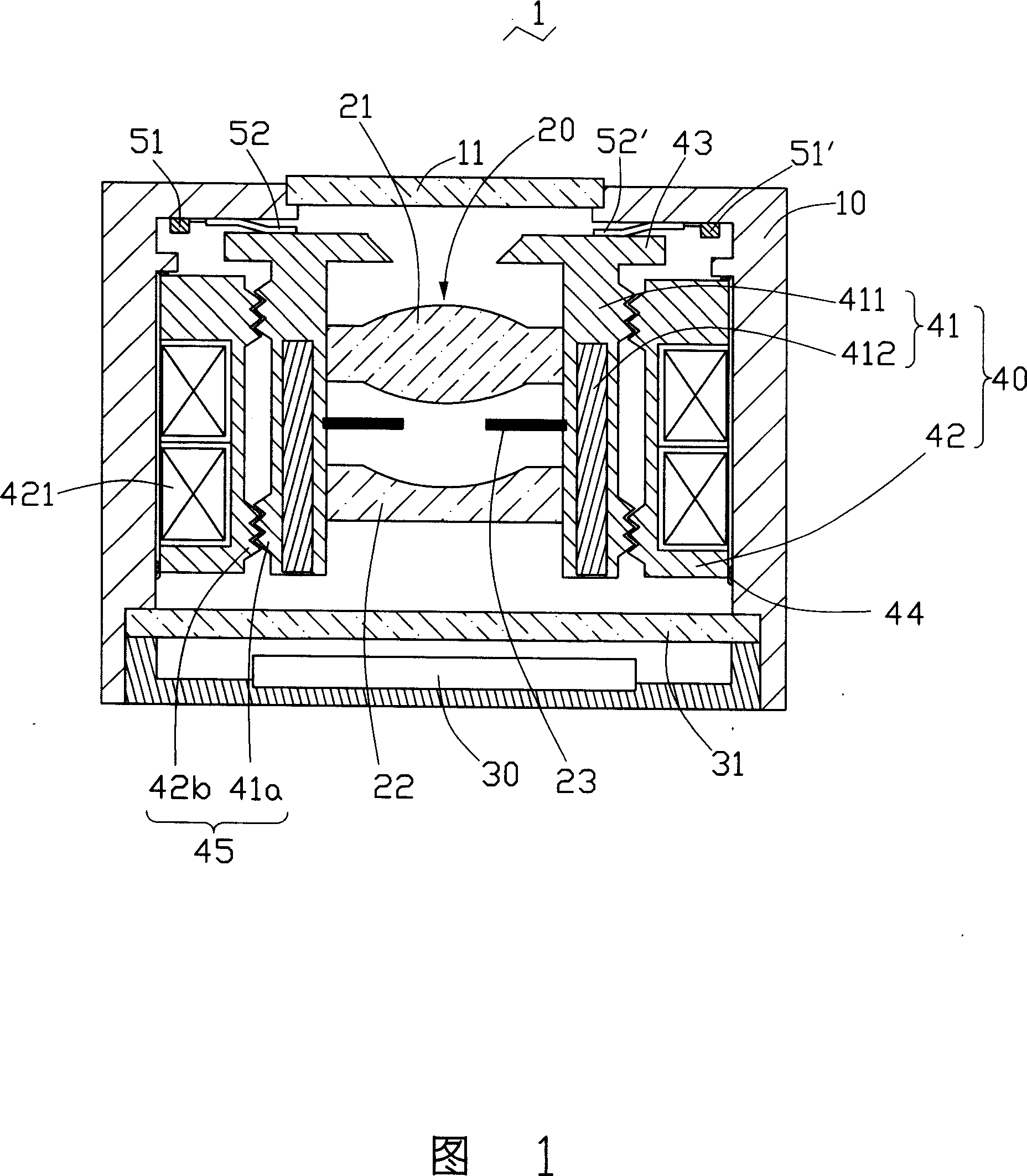

[0016] Referring to Fig. 1, the camera module 1 provided for the first embodiment of the present invention includes a lens group 20, a lens housing 10, a photosensitive chip 30 and a lens driving device for driving the lens group 20 to move 40.

[0017] The lens set 20 includes one or more lenses. In this embodiment, the lens set 20 includes two lenses 21 , 22 , and an aperture 23 is provided between the two lenses 21 , 22 . The lens group 20 is disposed in the lens housing 10 .

[0018] The lens housing 10 is provided with an opening in the direction of the optical axis of the lens group 20 , so that light can enter the lens group 20 . In order to prevent dust and other sundries from entering the camera module 1 , in this embodiment, a transparent plate 11 is provided at the opening.

[0019] The photosensitive chip 30 is arranged on the side opposite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com