Door drive mechanism, especially revolving door drive mechanism

A drive device and door drive technology, applied in door/window fittings, power control mechanisms, switches with brakes, etc., can solve the problem that the door torque distribution cannot be optimized, increase the effective piston area, and reduce the working pressure. , The effect of avoiding the load of mechanical structural components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

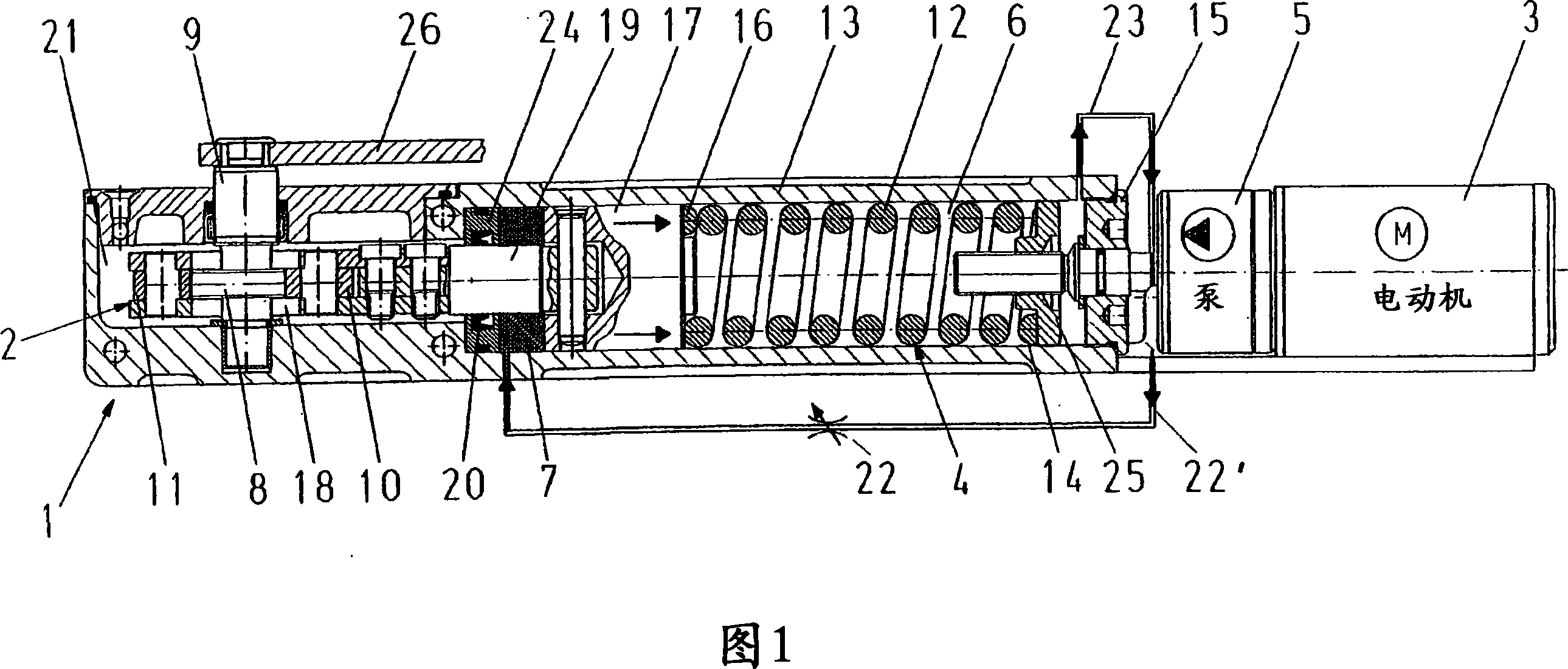

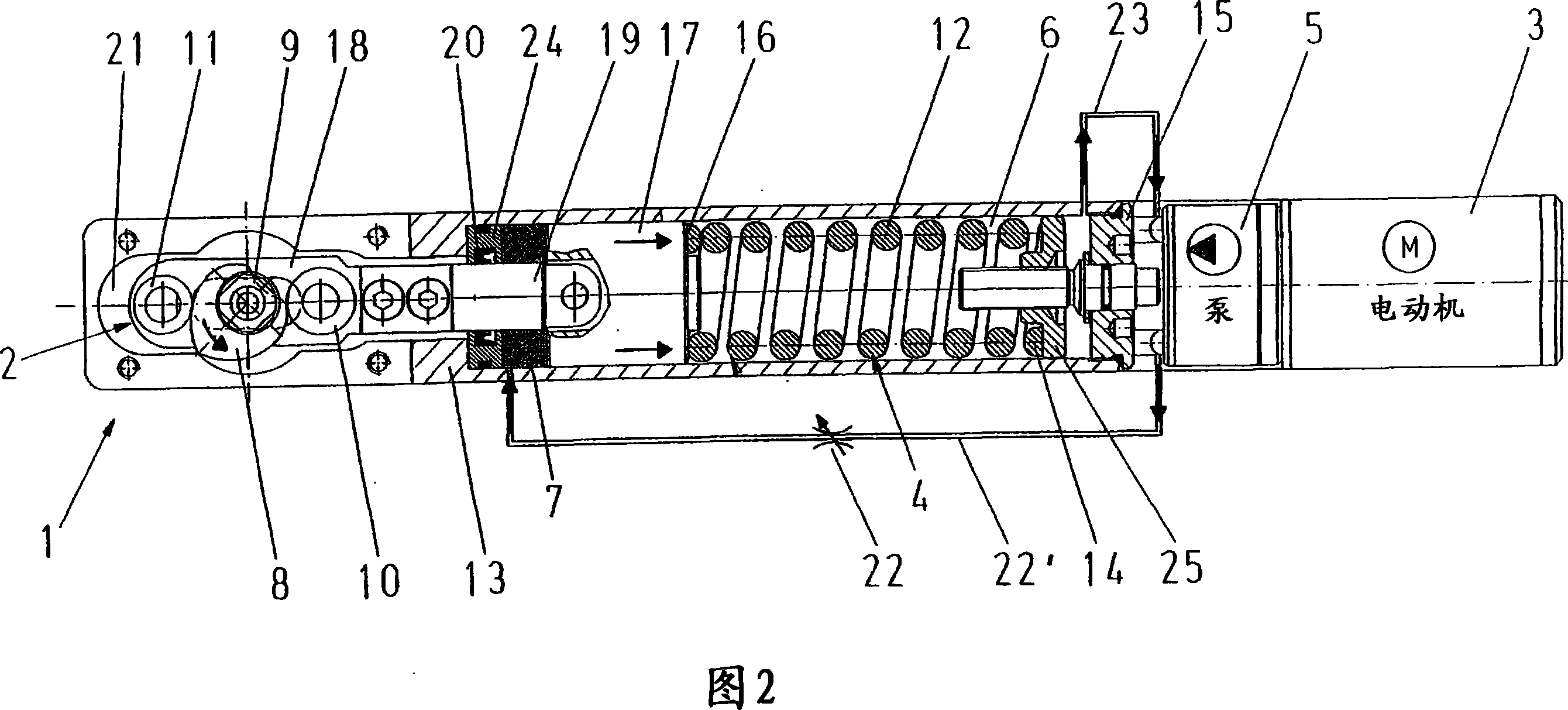

[0018] FIG. 1 shows a door operator 1 according to the invention, which can be designed in particular as a revolving door operator. The door operator 1 has a drive unit 2 which can be connected via an output shaft 9 to a door (not shown in FIG. 1 ), for example via a lever 26 and a slide rail with a sliding block. The drive unit 2 is arranged in a housing 13 .

[0019] Furthermore, the door operator 1 has an electric motor 3 and a spring accumulator 4 arranged in the housing 13 , which is connected to the electric motor 3 and the drive unit 2 .

[0020] As shown in FIGS. 1 and 2 , the electric motor 3 is drivingly connected to a hydraulic pump 5 . In the described embodiment, the electric motor 3 and the hydraulic pump 5 are installed on the casing 13 , but they can also be flanged separately or combined on the casing 13 . The electric motor 3 is hydraulically connected via a hydraulic pump 5 and a first hydraulic line 22 ′ to a pressure chamber 7 which is associated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com