Horizontal downward-adjusting type mechanical rolling machine

A level-down, plate rolling machine technology, applied in the field of plate rolling machines, can solve problems such as poor processing, assembly, disassembly and maintenance, uneven power distribution, mechanical damage, etc., to achieve convenient assembly, disassembly and maintenance, balanced force, avoid damage or The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

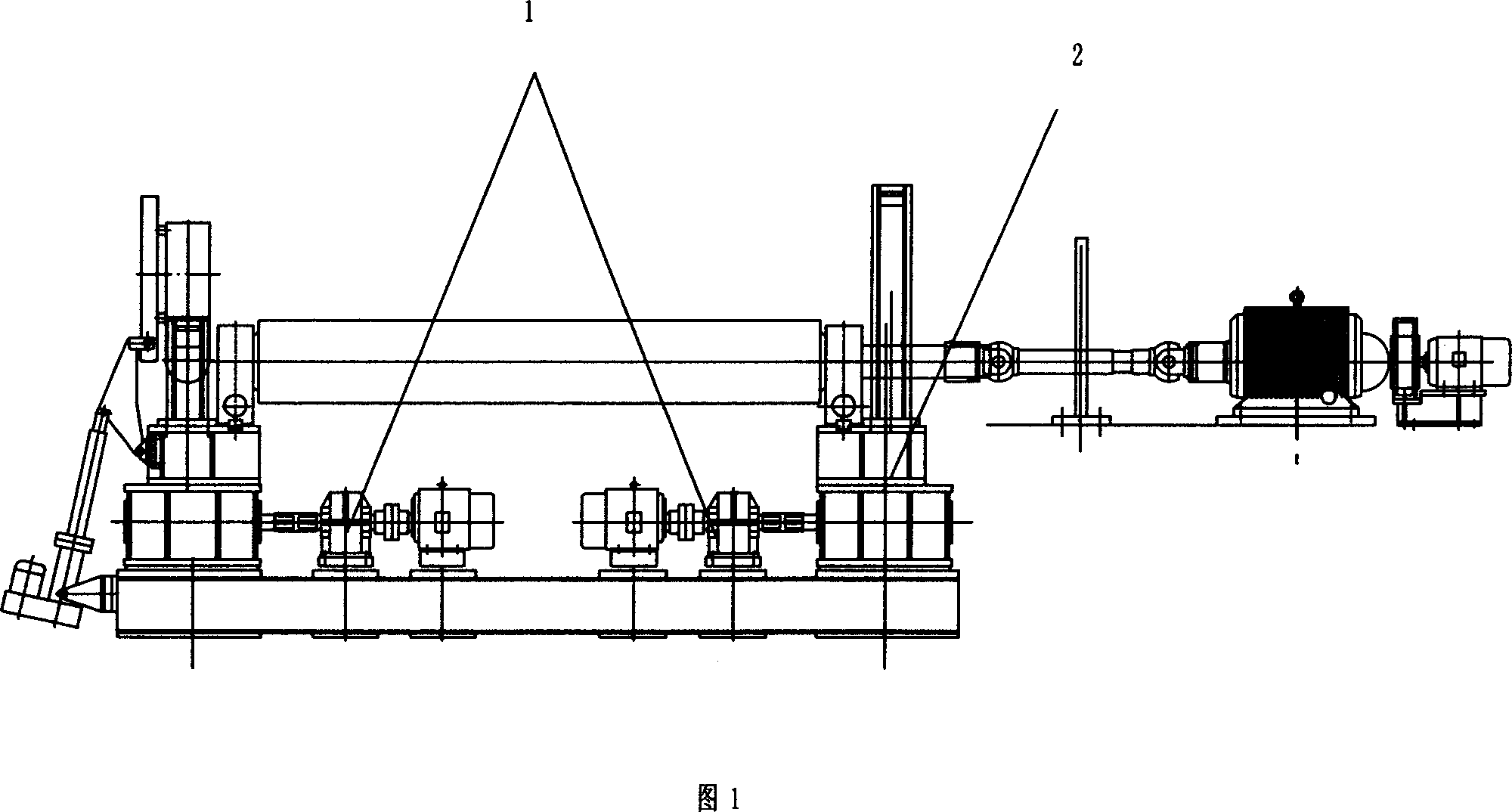

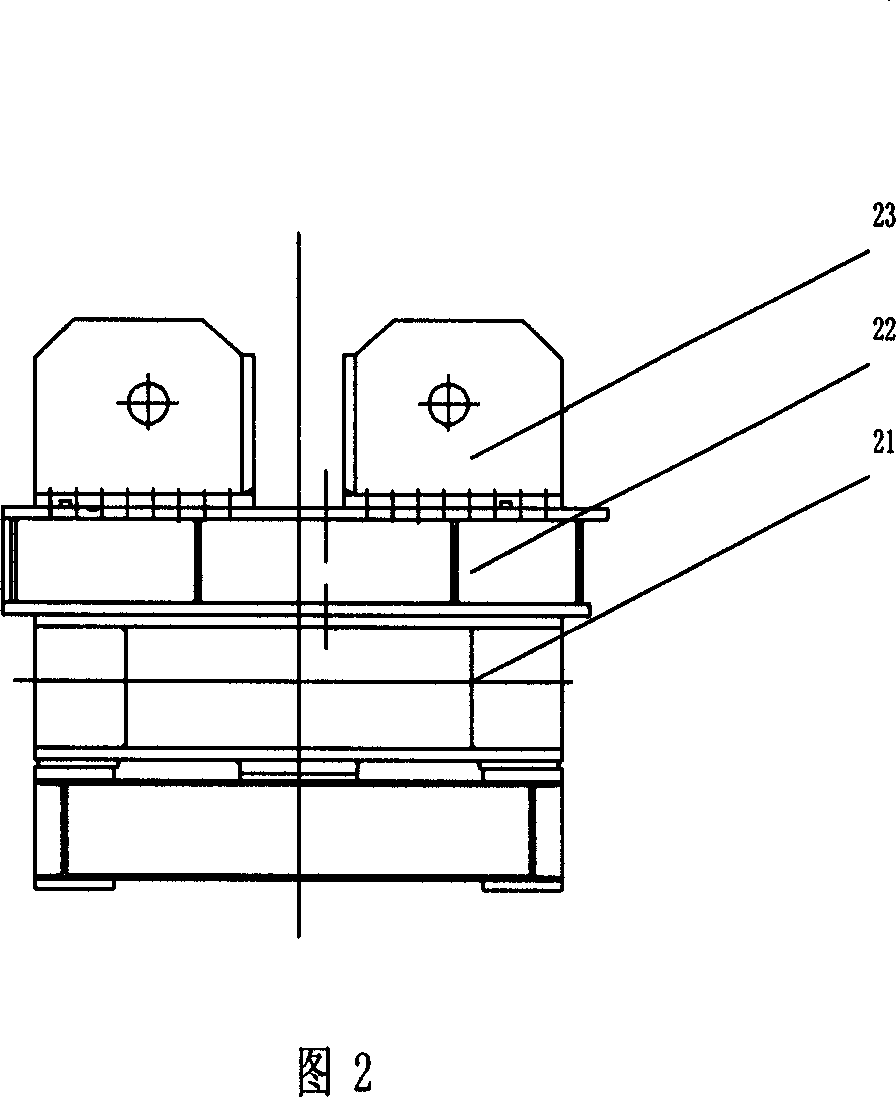

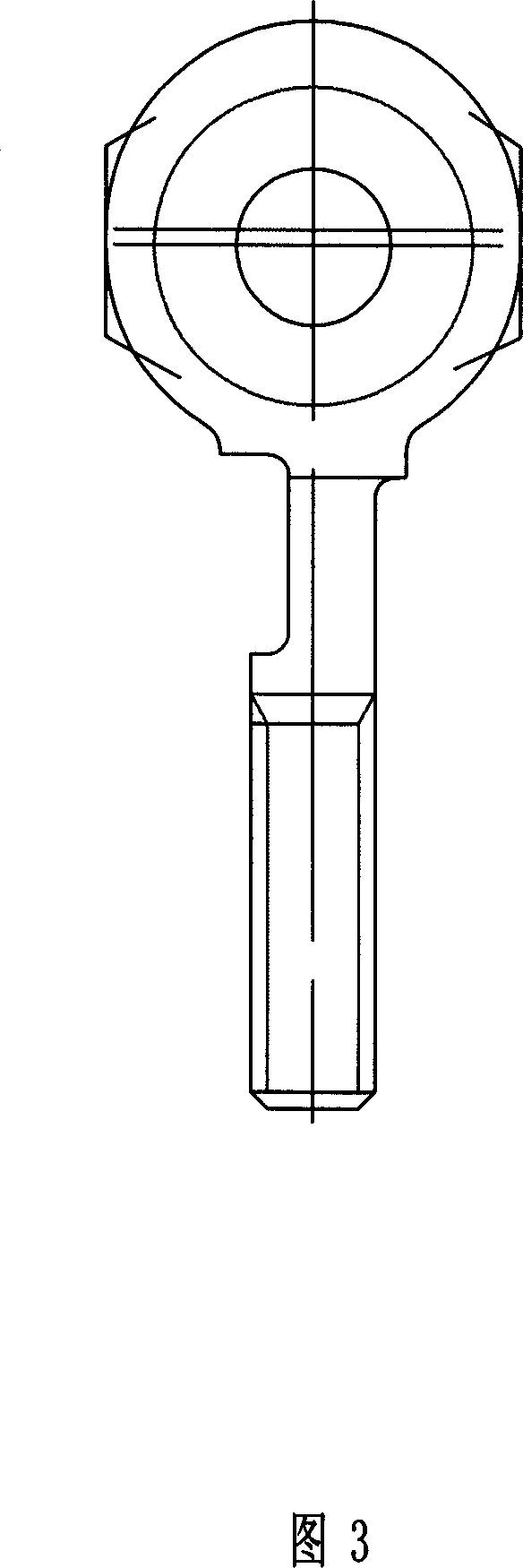

[0012] The present invention will be further described below in conjunction with the accompanying drawings. The invention discloses a horizontal down-adjustment mechanical plate rolling machine, which includes a driving device 1 and a frame 2. As shown in Figure 1, the driving device is equipped with a set at each end of the plate rolling machine, and is connected to the left and right machine respectively. The transmission mechanism in the frame is connected; as shown in Figure 2, the lower half of the frame is an independent box 21 that can accommodate the transmission mechanism, its lower end is fixedly connected with the chassis, and the upper half of the frame is installed on On the independent box body, the frame is equipped with connecting rods that cooperate with the transmission mechanism, as shown in Figure 3 and Figure 4, the connecting part of the rod part of the connecting rods and the seat is concave. The connecting tie rod of the present invention can also be ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com