Polyether ester elastic fiber and fabrics and clothes made by using the same

A technology of elastic fiber and polyether ester, applied in the field of polyether ester elastic fiber, which can solve the problems of comfort limitation and non-practicability of polyether ester elastic fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

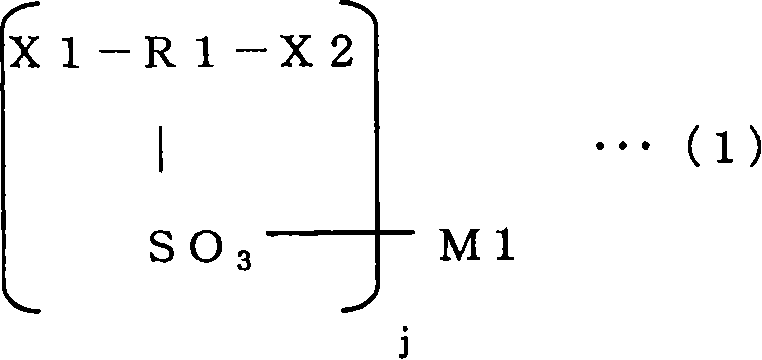

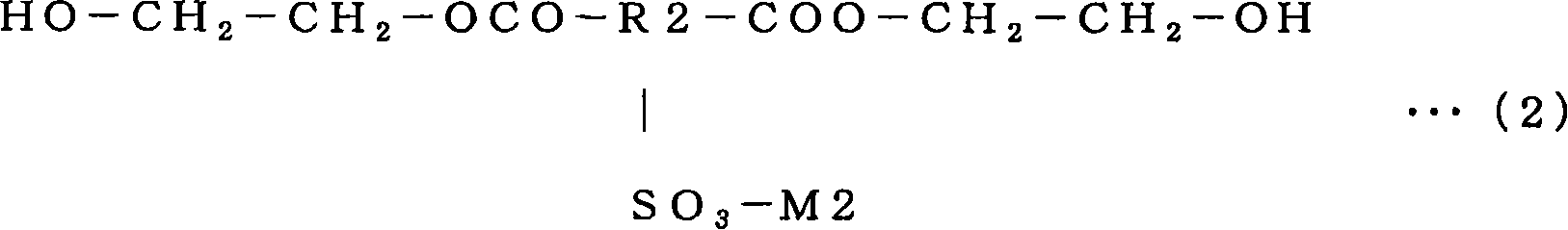

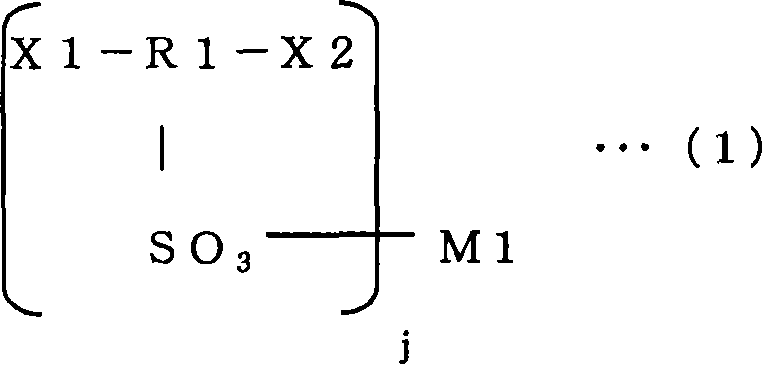

Method used

Image

Examples

Embodiment 1

[0096] 100 parts by weight of dimethyl terephthalate and 23 parts by weight of 40% by weight of sodium 3,5-bis(β-hydroxyethoxycarbonyl)benzenesulfonate in ethylene glycol solution (5.0 moles relative to the total acid content) %), 113.4 parts by weight of polyoxyethylene glycol (number average molecular weight 4000), 73.5 parts by weight of 1,4-butanediol (1.4 mole multiples of all acid components) and 0.4 parts by weight of tetrabutyl titanate catalyst were added to In the reaction tank, the transesterification reaction was carried out at an internal temperature of 200°C. When about 80% of the theoretical amount of methanol is distilled out, 0.4 parts by weight of the above-mentioned hindered phenol compound (4) is added, and then the temperature is increased and the pressure is reduced to start the condensation polymerization reaction. In the polycondensation reaction, the pressure reached 30mmHg in about 30 minutes, and then reached 3mmHg in 30 minutes, and then reacted under a...

Embodiment 2

[0101] Except having used polyoxyethylene glycol (number average molecular weight 2000) instead of polyoxyethylene glycol (number average molecular weight 4000), it carried out similarly to Example 1, and obtained the elastic fiber with an intrinsic viscosity of 1.16. The results are shown in Table 1.

Embodiment 3

[0103] Except changing the copolymerization ratio of polyoxyethylene glycol (number average molecular weight 4000) to make the weight ratio of hard segment / soft segment 60 / 40% by weight, the same procedure as in Example 1 was carried out to obtain an intrinsic viscosity of 1.12 Polyetherester elastic filament. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com