City underground integral drainpipe construction method

A drainage pipe and integrated technology, which is applied in the construction of integral urban underground drainage pipes, can solve the problems of deformation or diversion of other pipe networks, difficulties in cement pipes, weak points of pipes at joints, etc., so as to eliminate the hidden danger of rusting. , The effect of improving the resistance to internal compression and eliminating engineering hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

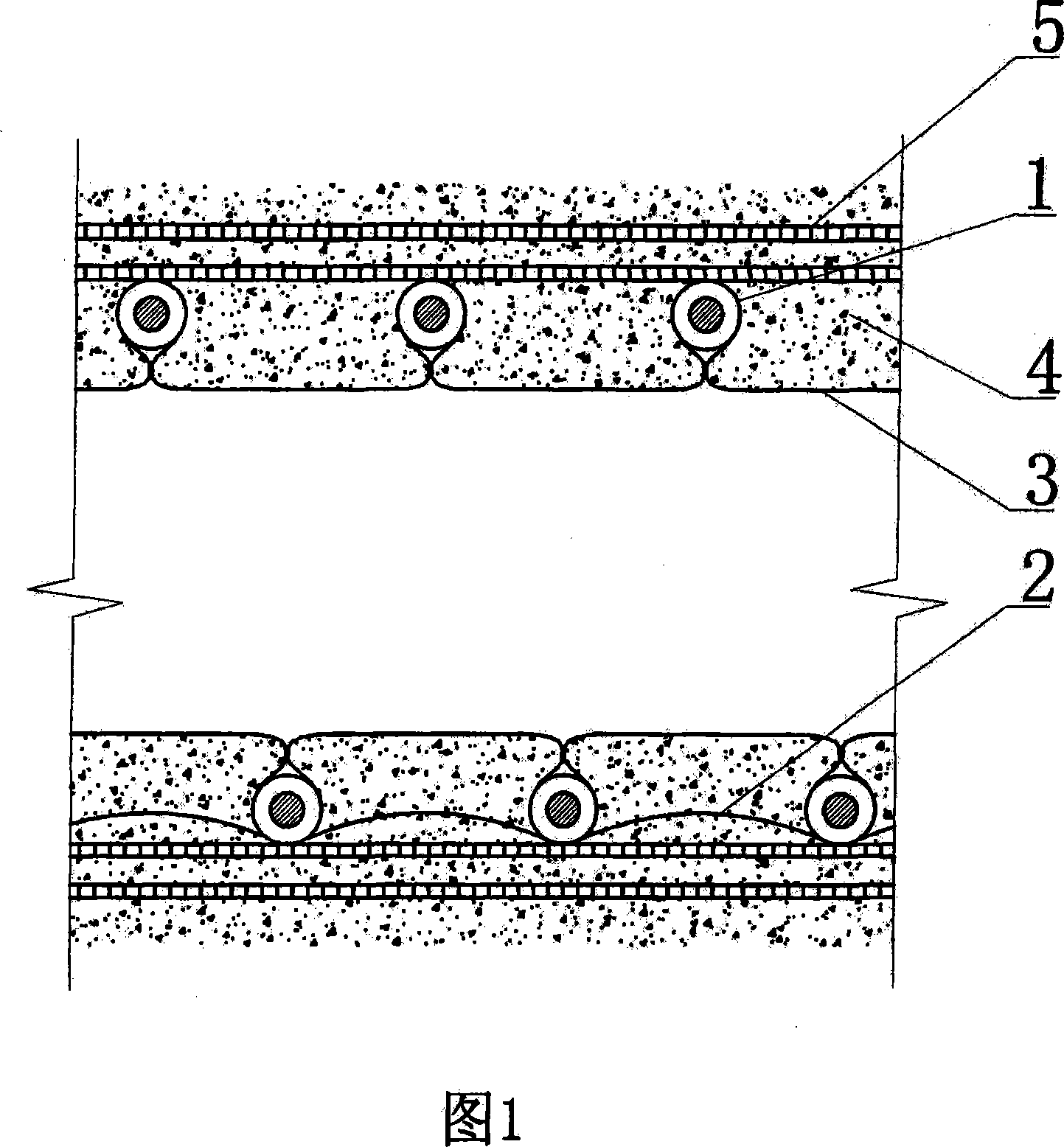

[0016] After the completion of the underground earthwork excavation, clean up and arrange the heights of all the entry points involved in the drainage of this pipeline, the joint points with the same pipeline network, and all obstacles in this pipeline, and ensure that all raised points are lower than In the case of each water inlet, the general direction of the drain pipe must have a gradual transition from high to low. The skeleton of the drain pipe is composed of a spiral steel core plastic strip, distance control rope, polypropylene woven cloth and steel wire mesh. The core plastic bar outer layer plastic is selected polyethylene plastic, and its thickness is 1 / 4 of steel core diameter, and steel core then is made of steel wire rope, and steel core plastic bar forming method carries out by known molding process with plastic extruder. The ratio of the diameter of the steel core plastic strip to the diameter of the spiral tube is 1:50, and each adjacent ring of the spiral tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com