Back light module unit and LCD device

A technology of backlight module and liquid crystal panel, applied in optics, nonlinear optics, instruments, etc., can solve the problem of high production cost of reflector grounding, and achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

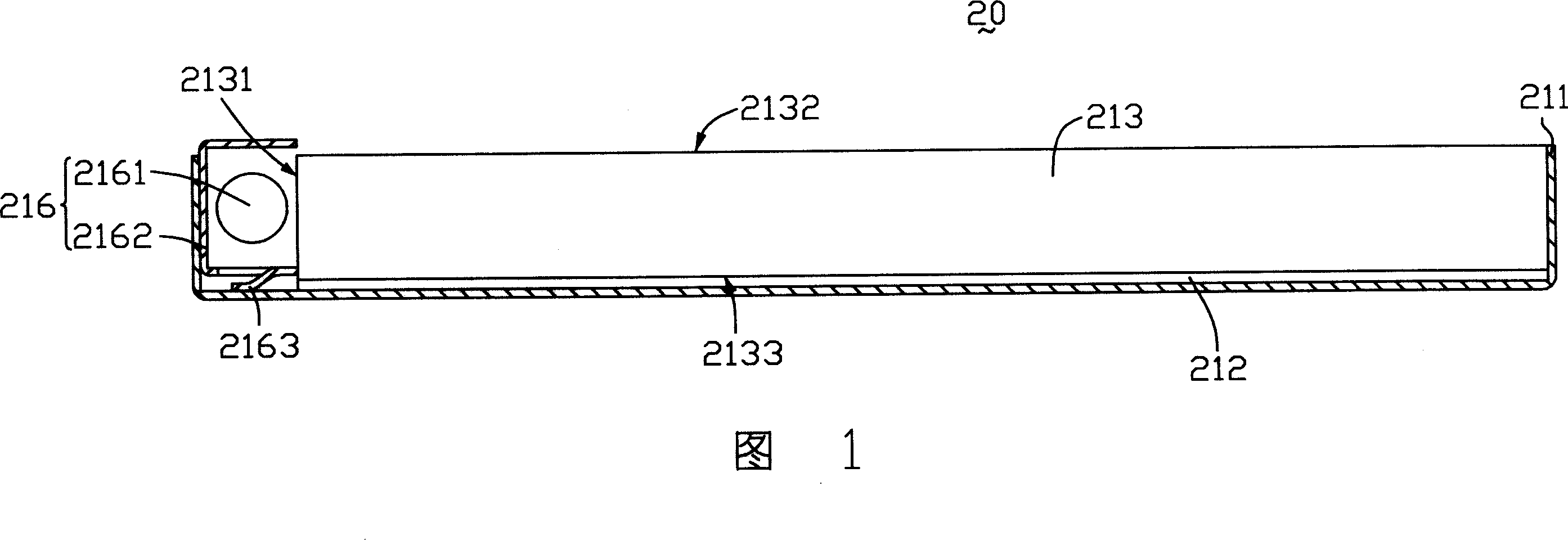

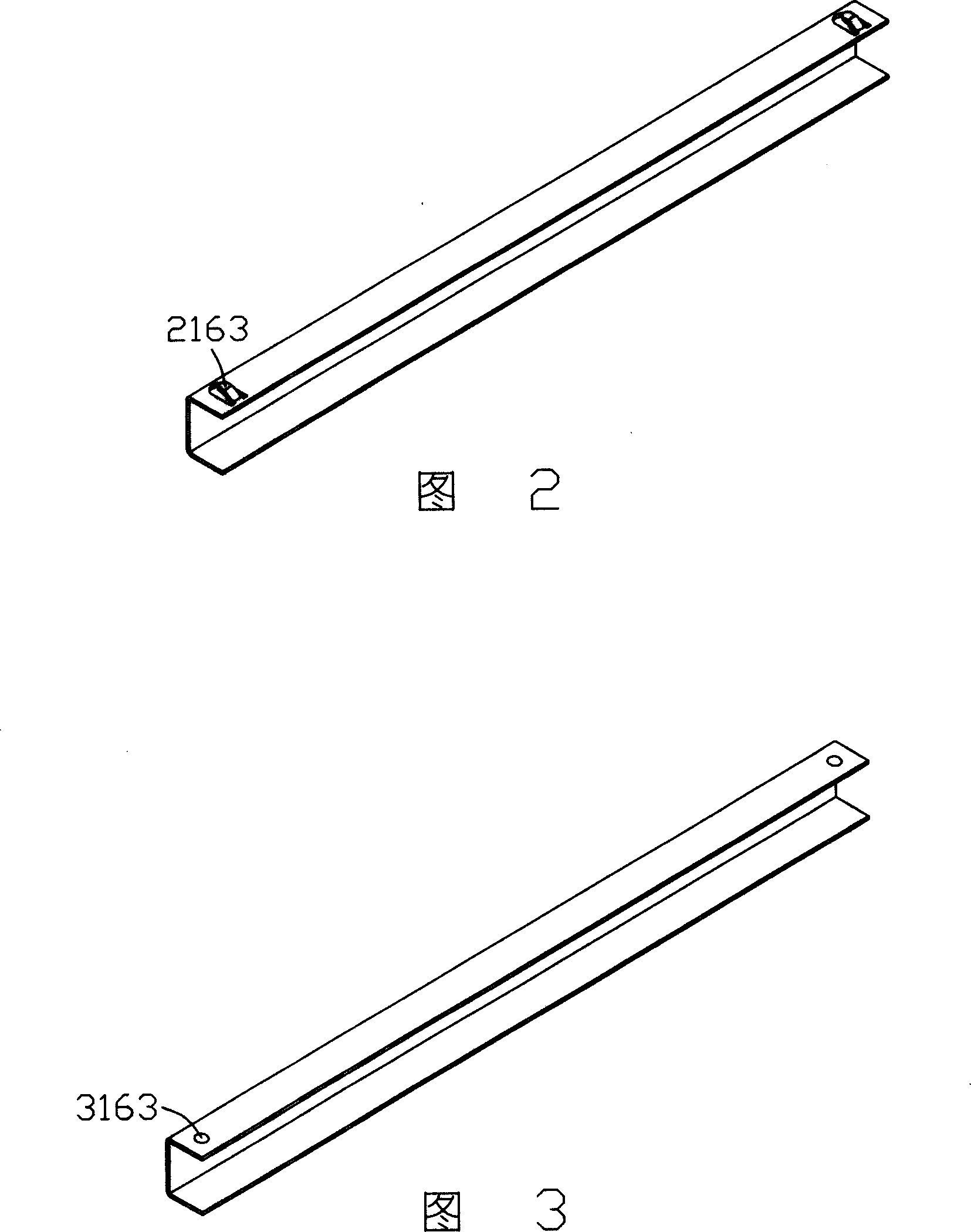

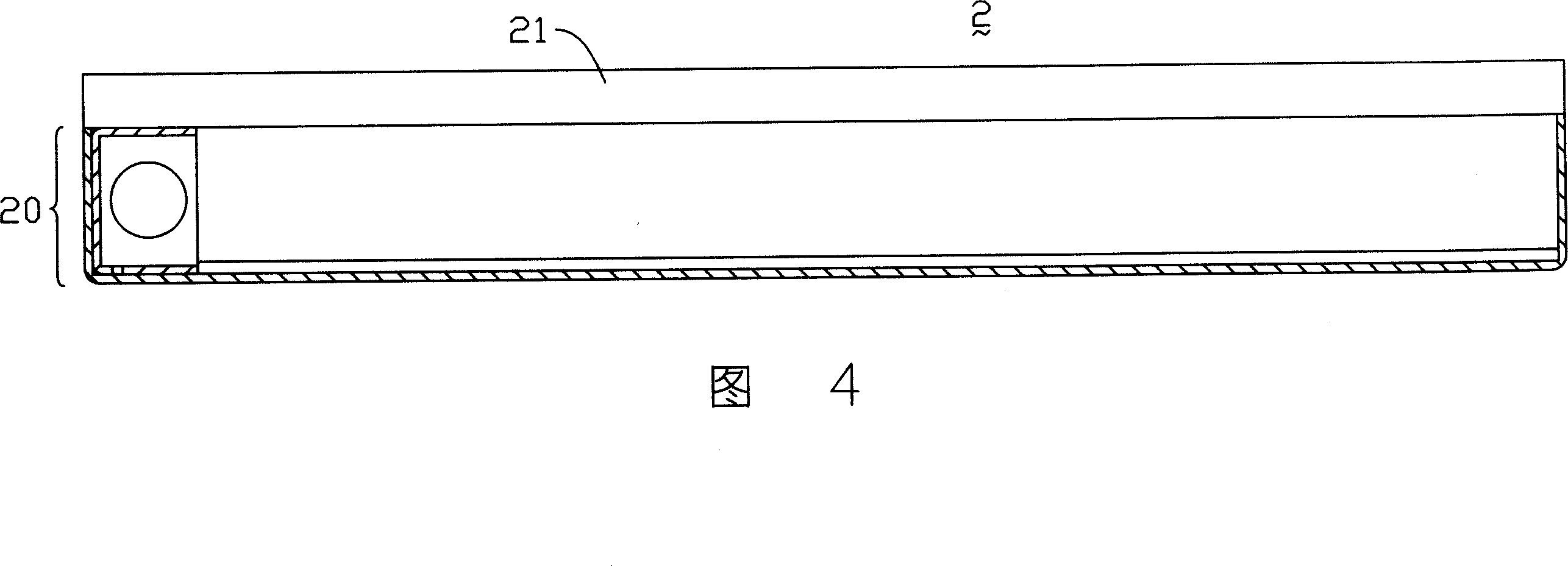

[0014] The backlight module 20 of the present invention is shown in Figure 1, and the backlight module 20 includes a back frame (bottom bezel) 211, a reflector 212, a light guide plate 213 and a lamp group 216, and the lamp group 216 includes a The lamp tube 2161 and a lamp reflector 2162 are integrally formed with elastic pieces 2163 on the bottom surface of the reflector 2162 .

[0015] The light guide plate 213 includes a light incident surface 2131 , a light exit surface 2132 intersecting the light incident surface 2131 , and a bottom surface 2133 opposite to the light exit surface 2132 .

[0016] The lamp tube 2161 is in the shape of a strip, and it is arranged opposite to the light incident surface 2131. The reflector 2162 accommodates the lamp tube 2161. The reflector 212 is arranged on the bottom surface 2133 of the light guide plate 213. The back frame 211 accommodates the plate 212 , light guide plate 213 and lamp tube group 216 . The reflector 2162 is electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com