Apparatus and method for making product having various shapes

A technology of equipment and products, which can be used in household utensils, manufacturing tools, clay products, etc., and can solve problems such as difficult to make pottery utensils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

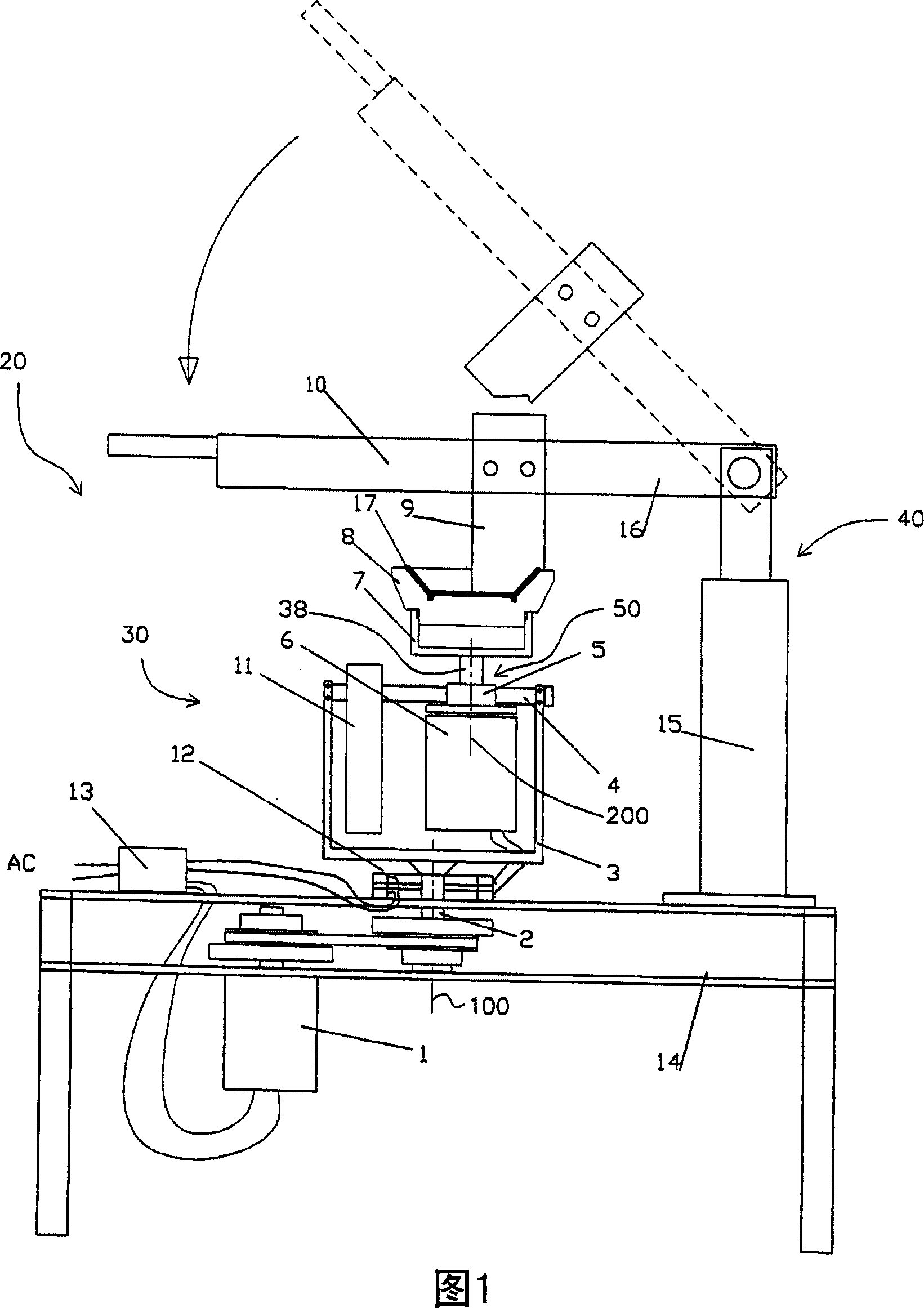

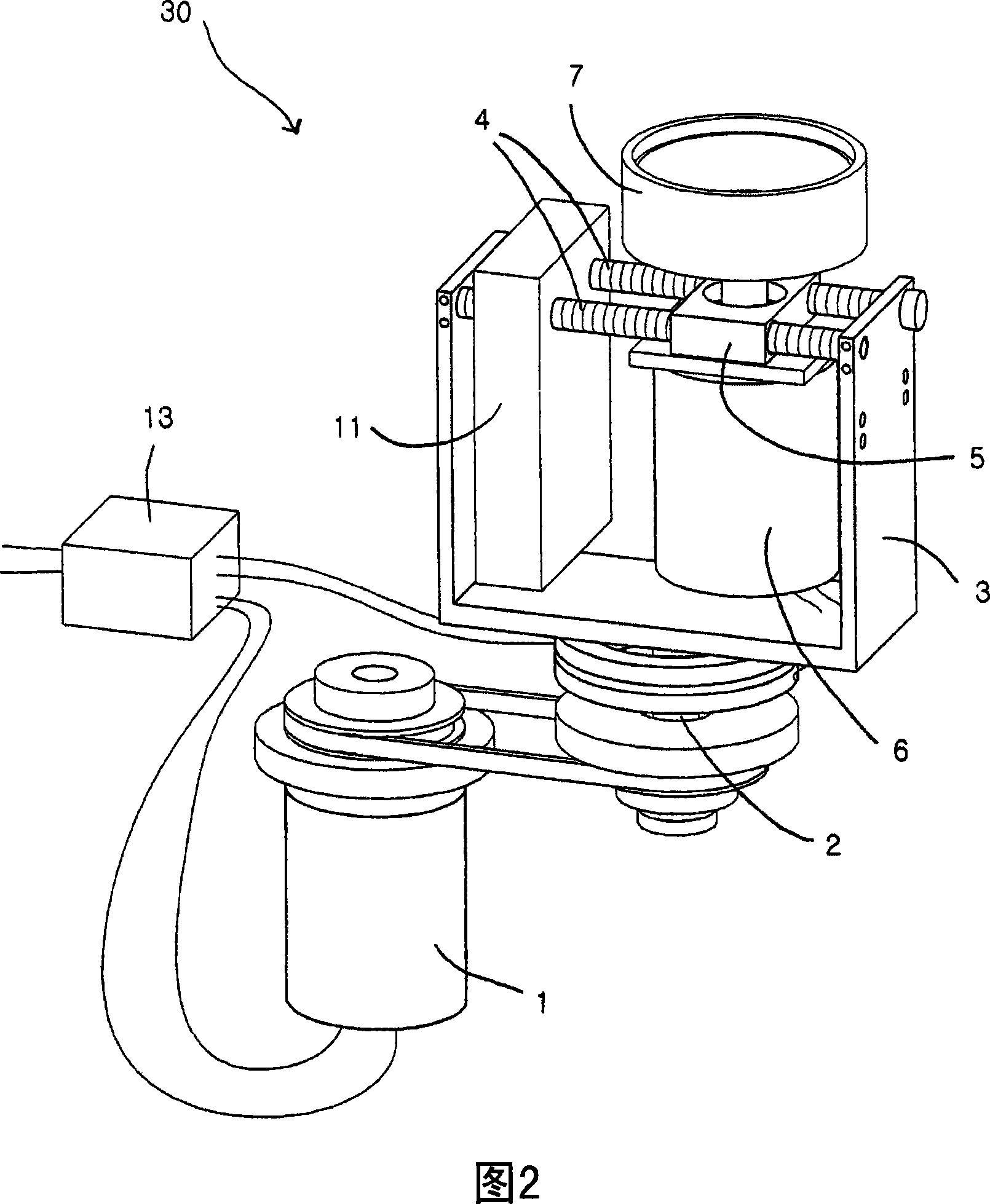

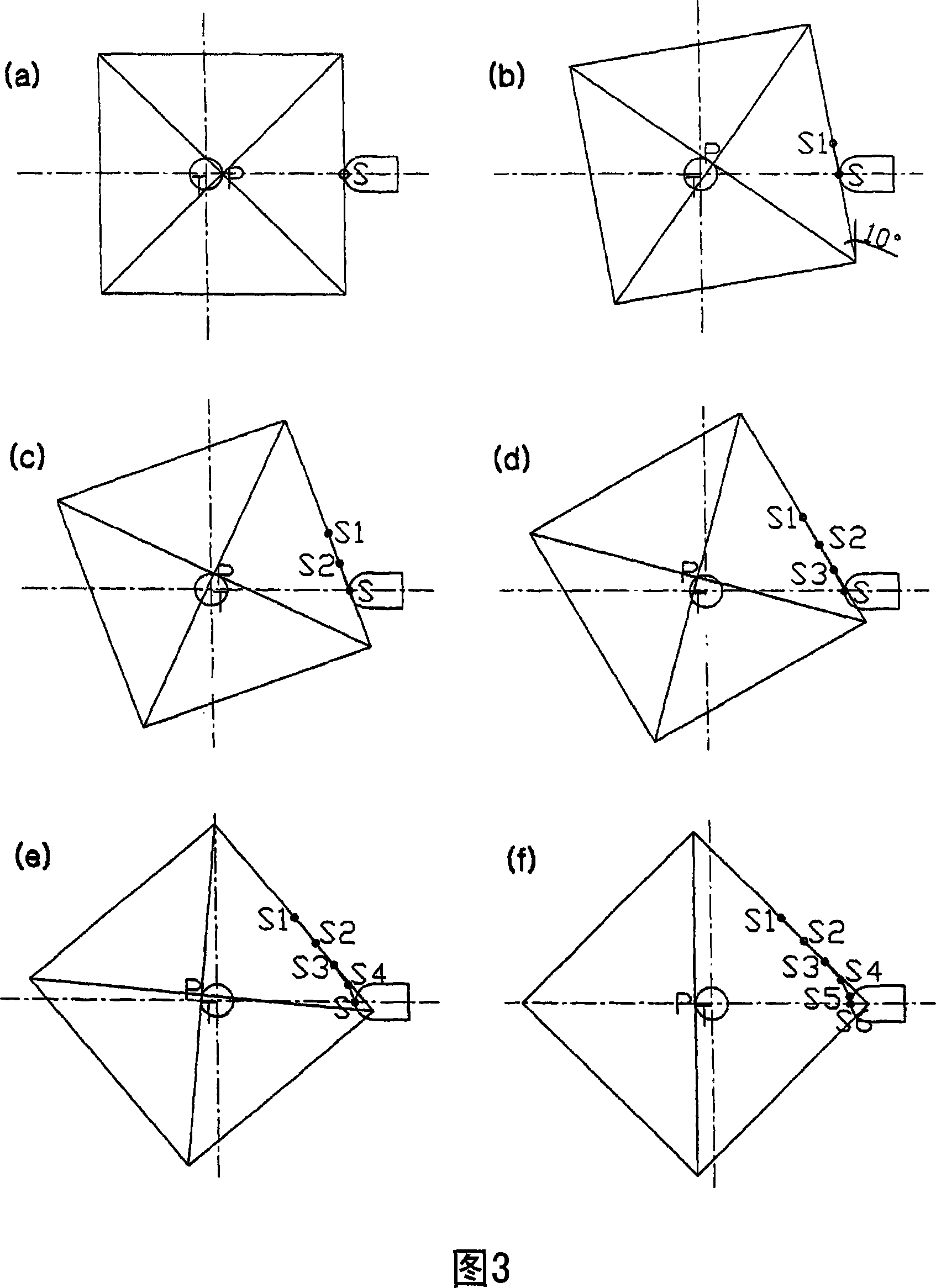

[0054] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0055] 1-8(b) show a first embodiment of the present invention. Referring to FIGS. 1 and 2 , a ceramic wheel 20 for a lathe table includes a support frame 14 , a revolution-rotation drive device 30 and a tool support 40 . The revolution-rotation driving device 30 and the tool support 40 are mounted on the support frame 14 . The revolution-rotation drive device 30 includes a first drive motor 1 , a sun shaft 2 , a revolution frame 3 , a revolution radius adjuster 50 , a second drive motor 6 , a planetary shaft 38 , a controller 13 and an electric bridge 12 . The driving force of the first driving motor 1 is transmitted to the sun shaft 2 using a pulley. However, the invention is not limited to pulleys and other power transmission means such as gears may be used. Alternatively, the shaft of the first drive motor 1 may be directly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com