Opposite infrared rays detector

A technology of infrared radiation and detectors, applied in the direction of optical device exploration, etc., can solve the problems of increasing the difficulty of installation work, inconvenient installation, impact of walls, etc., and achieve the requirements of reducing the difficulty of installation, increasing the distance, and avoiding re-rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

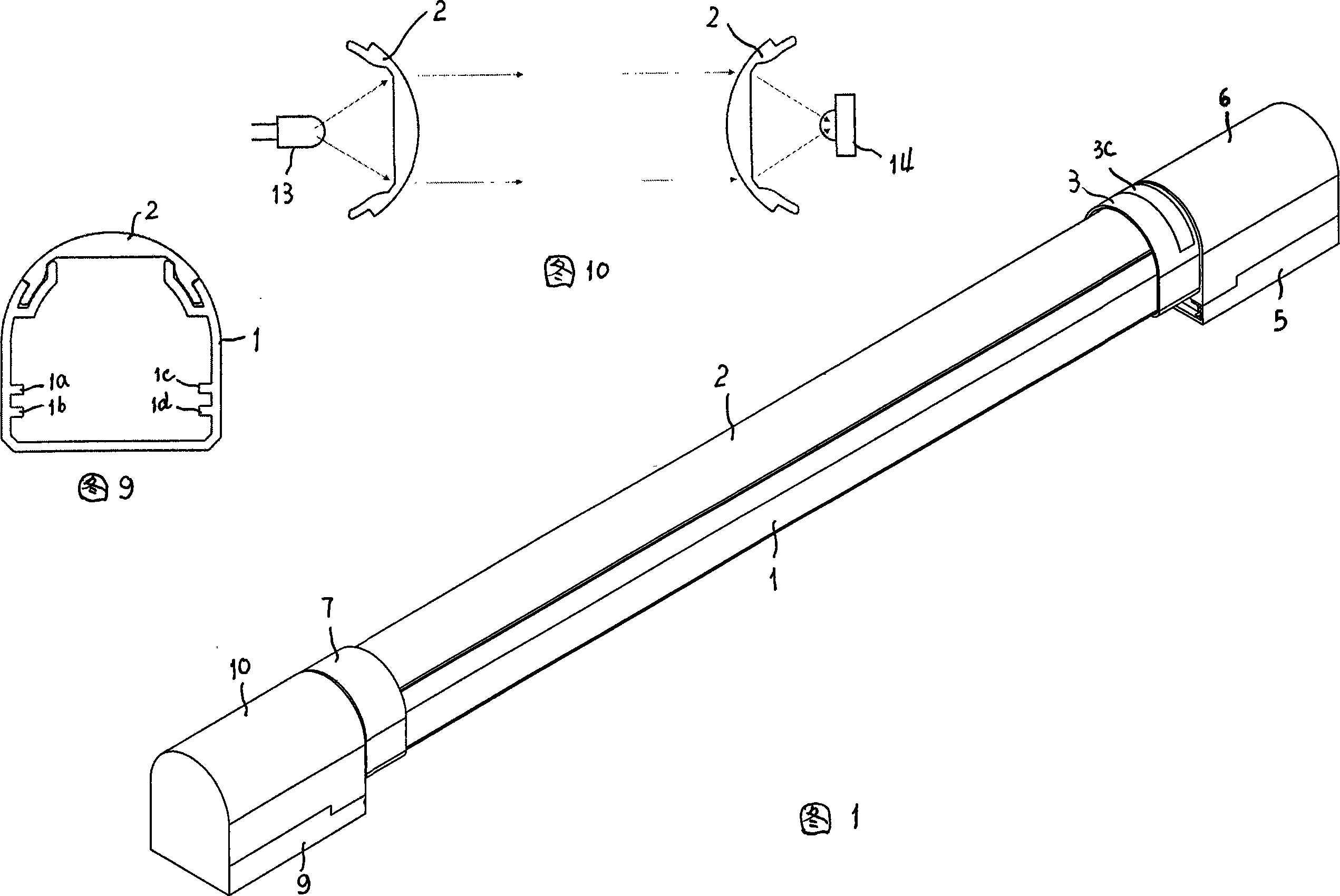

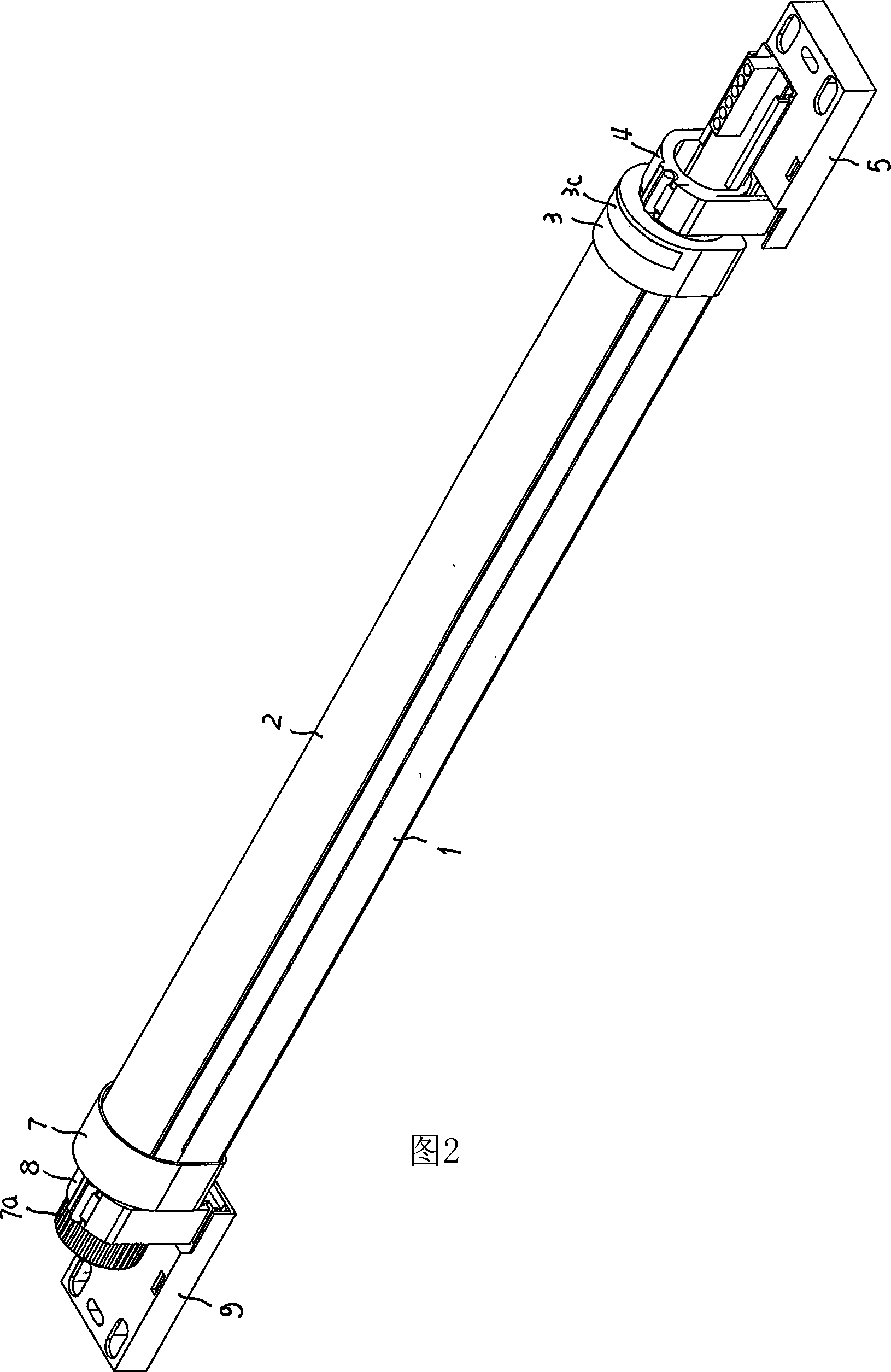

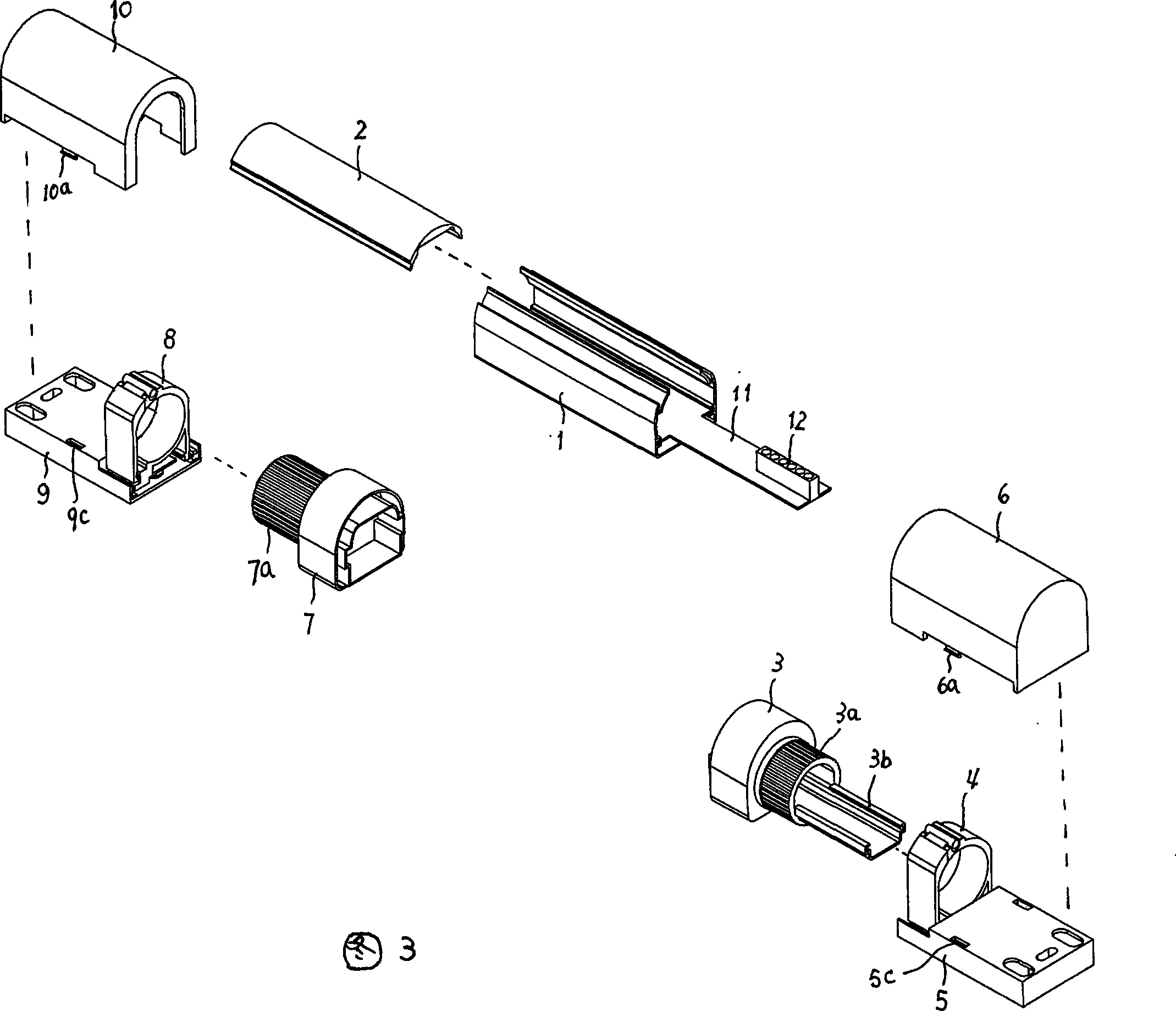

[0030] Figure 1, Figure 2 and Figure 3 show that the pipe body 1 is an aluminum alloy profile, its cross-sectional shape is composed of a rectangle and an arc shape, and its top is open, and there are symmetrical Y-shaped grooves on the left and right sides, and the left and right sides of the pipe body 1 The side inner walls are respectively provided with two longitudinal strips 1a, 1b, 1c, 1d for placing circuit boards 11 (Fig. 9). Referring to FIG. 3 , the circuit board 11 is used for installing an infrared transmitting circuit or an infrared receiving circuit, and its outer end is provided with a terminal block 12 for circuit connection. The vertical height of the inner side of the Y-shaped groove on the pipe body is higher than that of the outer side (see FIG. 9 ). The sectional shape of (infrared) filter plate 2 is made up of outwardly convex arc-shaped surface and arc-shaped tabs on the left and right sides, and the two arc-shaped tabs are matched with the Y-shaped groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com