Optical scanner, and mechanism for cleaning optical scanner cover glass

A light scanning device, image technology, applied in the direction of optics, optical components, instruments, etc., can solve problems such as differences in exit angles, curved scanning line traces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] Hereinafter, the principle and embodiments of the optical scanning device of the present invention will be described in detail based on the drawings.

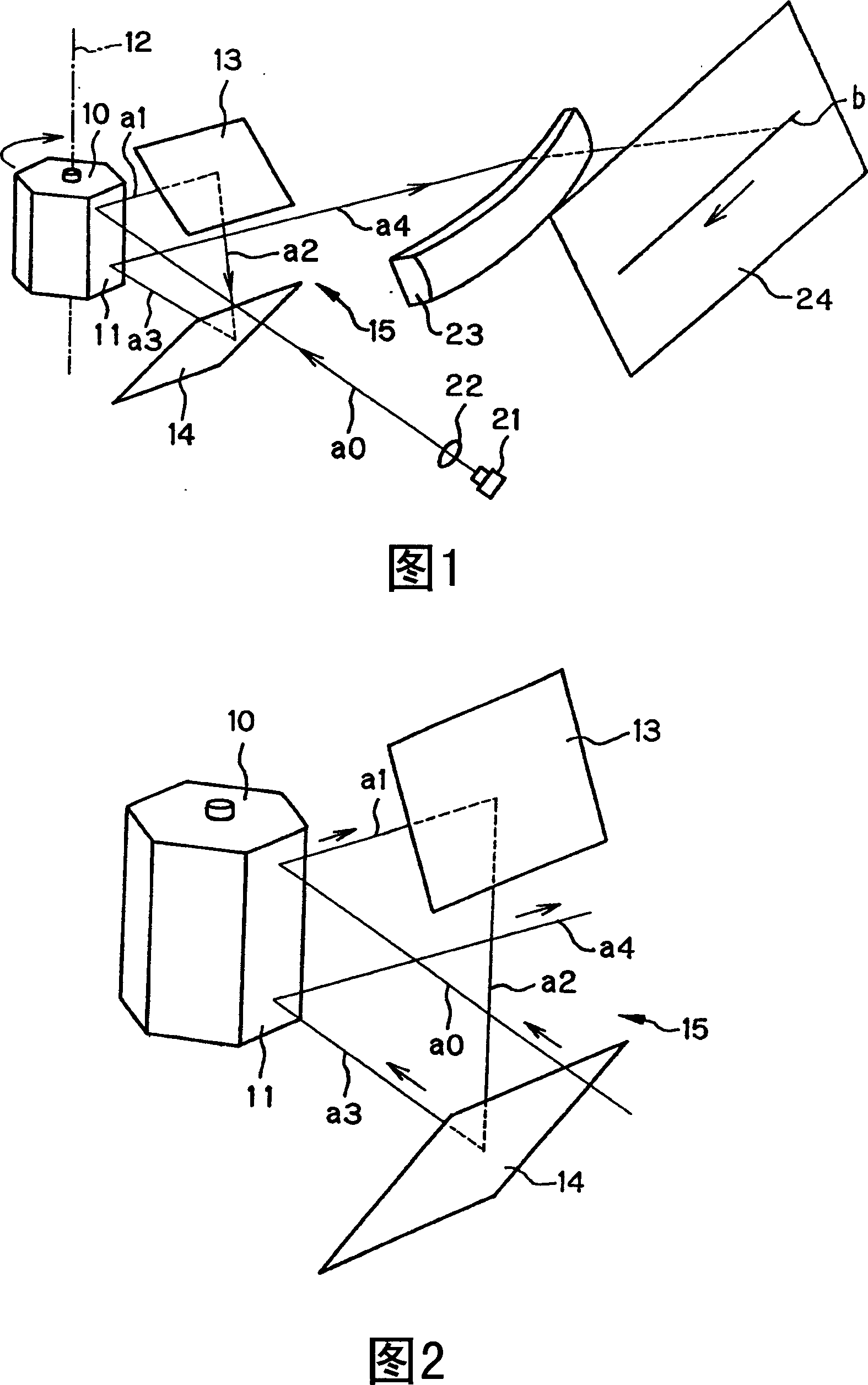

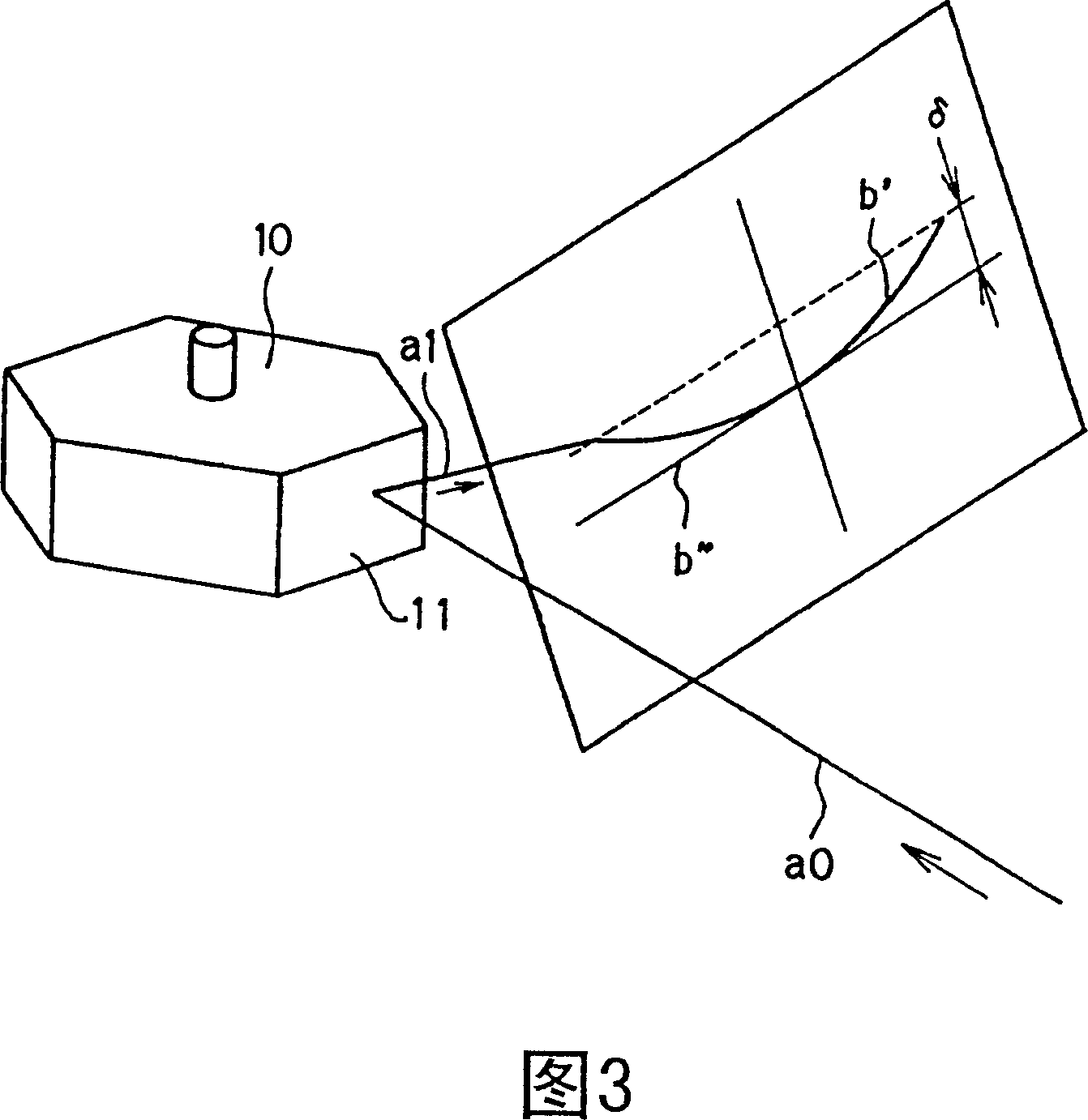

[0117] FIG. 1 is a perspective view of the overall structure of an optical scanning device according to a first embodiment of the present invention, and FIG. 2 is a perspective view of a light deflection optical system of its main part.

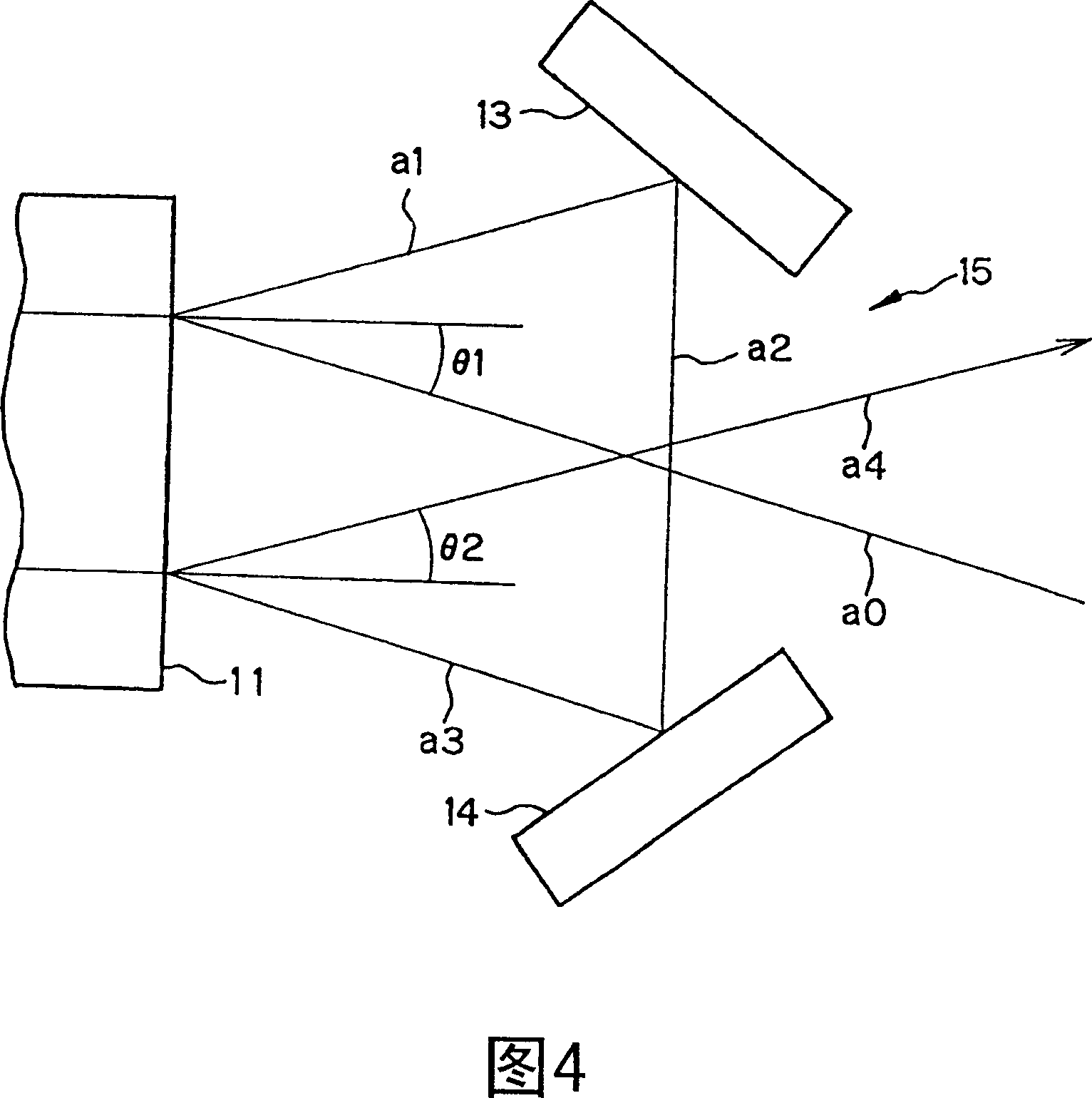

[0118] In the structure, the light deflecting portion is constituted by an optical polyhedron 10 having a plurality (six in the figure) of deflecting reflective surfaces 11 on the sides of the polyhedral column, which rotate about their rotation axes 12 . And, facing the deflection reflective surface 11 participating in the light deflection, two fixed plane mirrors 13, 14 are arranged, said fixed plane mirrors 13, 14 are at a certain angle to each other with a gap 15 between them.

[0119] Furthermore, the light from the light source 21 passes through the lens 22 into a parallel light b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com