Method and device for processing electric hammer drill shank

A processing method, the technology of electric hammer drilling, applied in the direction of metal processing equipment, manufacturing tools, metal rolling, etc., can solve the problems of difficult guarantee of processing accuracy and long working hours, so as to improve production efficiency, ensure consistency and processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

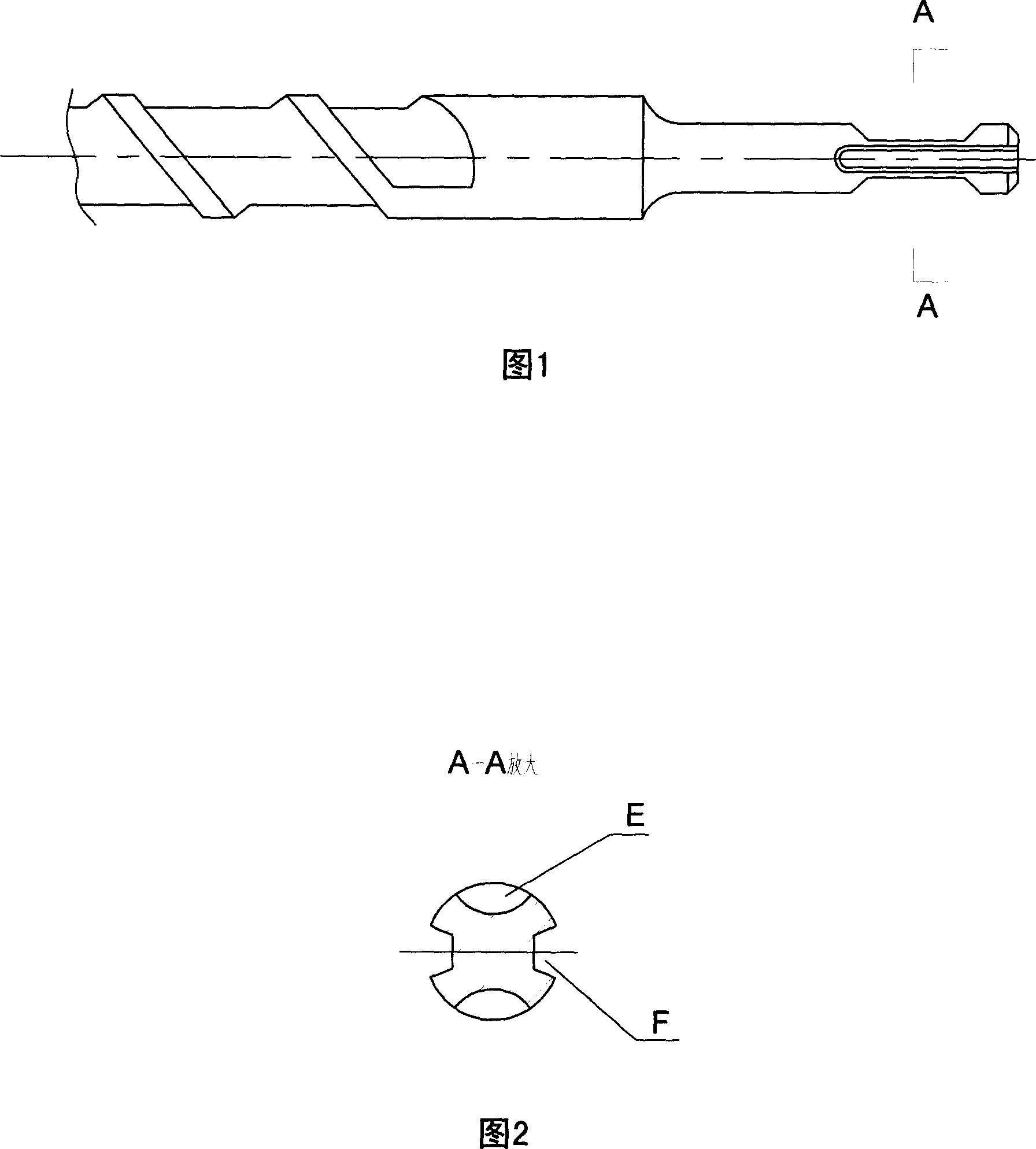

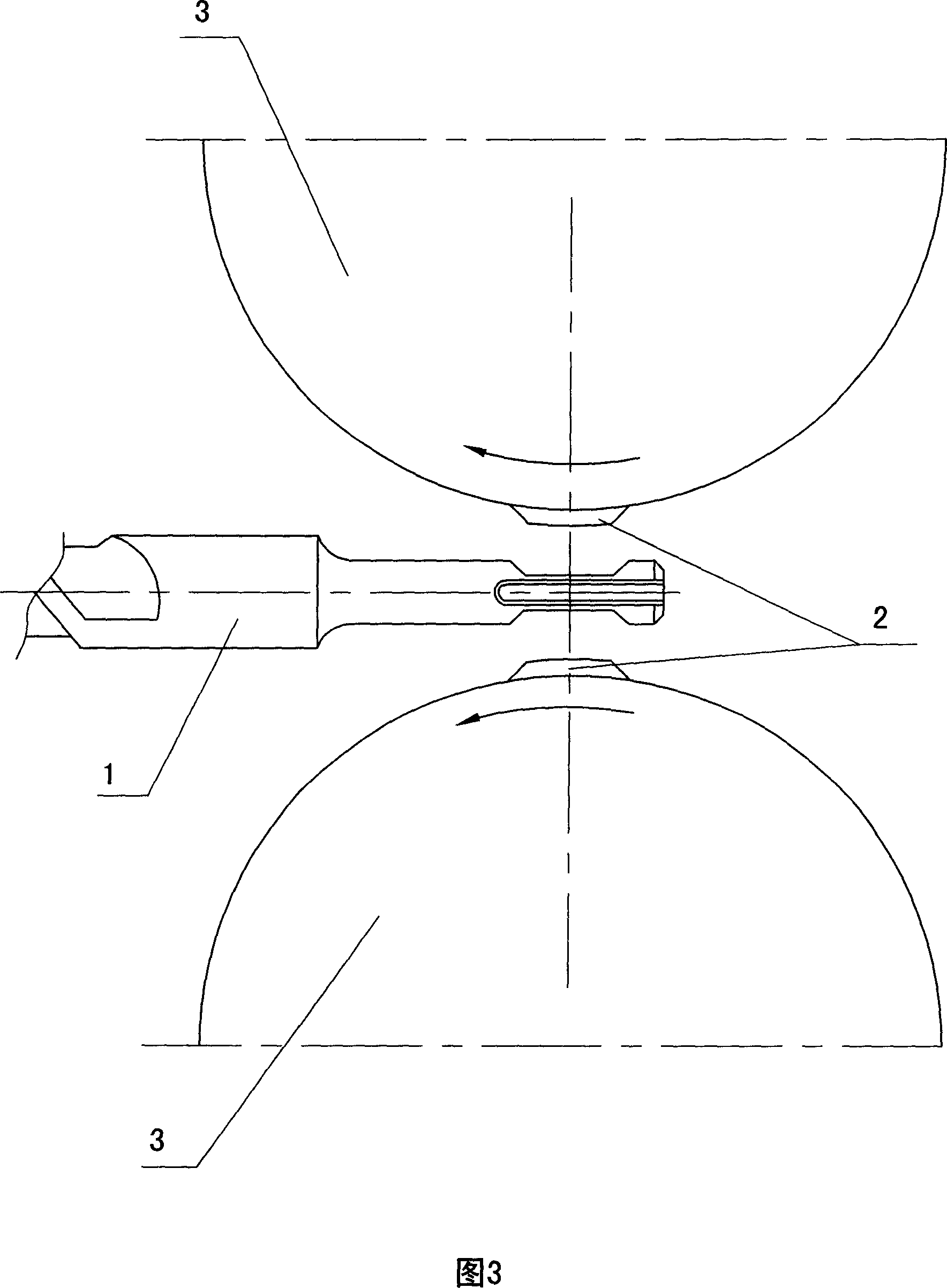

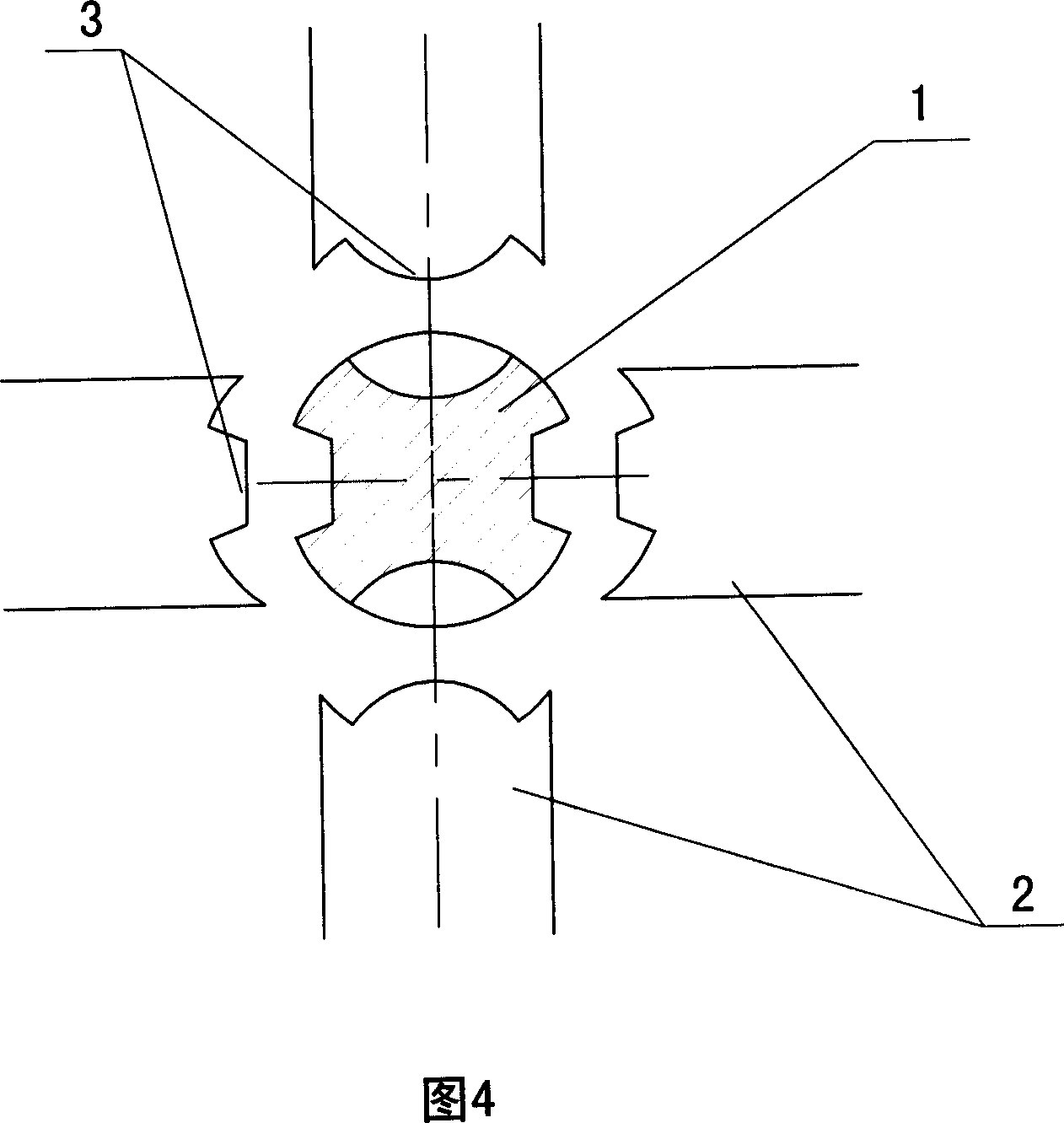

[0015] A specific processing process of the present invention is: machining the bar blank to obtain the outer circle; heating the workpiece blank to 850°C and sending it to the rolling equipment including the structure in Figure 3 and Figure 4, and clamping and fixing the blank 1 , set four fan-shaped templates 2 whose rotation axes are perpendicular to the axis of the blank in four directions at intervals of 90° on the periphery of the handle of the blank, and set a protruding die 3 at the center of the outer edge of the fan-shaped template, and the center of the die is facing the axis of the blank. The depth of the die head corresponds to the pit or groove to be processed, and the rotating shafts of the four fan-shaped templates rotate synchronously, extruding the shank of the blank from four directions, forming a pair of pits and a pair of grooves at one time; rolling After forming, the blank is turned again to remove the deformation protrusions caused by rolling on the pits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com