Normal temperature high efficient remover for hydrogen sulfide and its preparation method and application

A hydrogen sulfide and removal agent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of slow desulfurization speed at room temperature, high desulfurization temperature, vanadium limitation, etc., and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

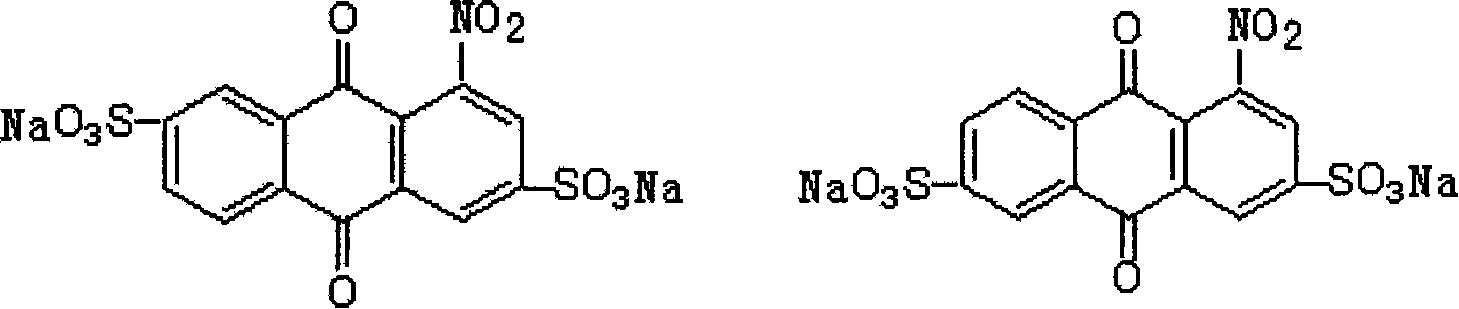

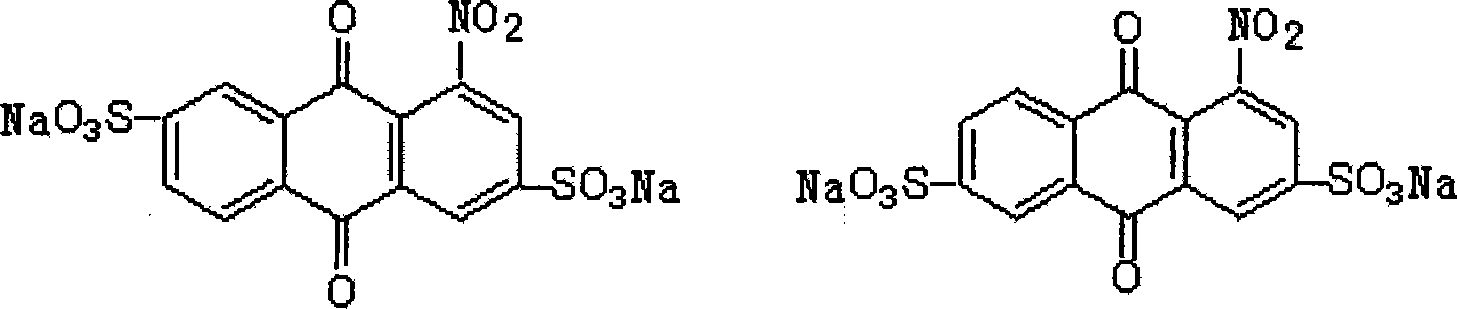

[0034] Example 1: A high-efficiency remover of hydrogen sulfide at room temperature 1-sodium nitroanthraquinone disulfonate and its preparation method

[0035] (1) Mix 1 kg of 1-aminoanthraquinone with 2 kg of fuming sulfuric acid, heat up to 150° C. and react for 6 hours under stirring conditions, and lower to normal temperature to obtain 1-aminoanthraquinone disulfonic acid solution;

[0036] (2) Slowly add the 1-aminoanthraquinone disulfonic acid solution dropwise to 2 kg of water, then slowly add 2 mol parts of the oxidizing agent potassium persulfate and stir for 2 hours to obtain the 1-nitroanthraquinone disulfonic acid solution;

[0037] (3) Slowly add sodium carbonate to the 1-nitroanthraquinone disulfonic acid solution, and neutralize to pH=8 to obtain a 1-nitroanthraquinone disulfonic acid sodium solution;

[0038] (4) Heat the 1-nitroanthraquinone disulfonate sodium solution to 60°C, filter it while it is hot, and dehydrate the filtrate under reduced pressure to 20%...

Embodiment 2

[0040] Example 2: A high-efficiency remover of hydrogen sulfide at room temperature 1-sodium nitroanthraquinone disulfonate and its preparation method

[0041] (1) Mix 1 kg of 1-aminoanthraquinone with 2.5 kg of fuming sulfuric acid, heat up to 120° C. and react for 8 hours under stirring conditions, and lower to normal temperature to obtain 1-aminoanthraquinone disulfonic acid solution;

[0042] (2) Slowly add the 1-aminoanthraquinone disulfonic acid solution dropwise to 2.5 kg of water, then slowly add 2 mol parts of the oxidizing agent potassium persulfate and stir for 3 hours to obtain the 1-nitroanthraquinone disulfonic acid solution ;

[0043] (3) Slowly add sodium carbonate to the 1-nitroanthraquinone disulfonic acid solution, and neutralize to pH=9 to obtain a 1-nitroanthraquinone disulfonic acid sodium solution;

[0044] (4) 1-Nitroanthraquinone sodium disulfonate solution is formulated into a 10% solution, and the pH value of the solution adjusted with sodium carbonat...

Embodiment 3

[0045] Example 3: A high-efficiency remover of hydrogen sulfide at room temperature 1-sodium nitroanthraquinone disulfonate and its preparation method

[0046] (1) Mix 1 kg of 1-aminoanthraquinone with 4.0 kg of fuming sulfuric acid, heat up to 120° C. and react for 16 hours under stirring conditions, and lower to normal temperature to obtain 1-aminoanthraquinone disulfonic acid solution;

[0047] (2) Slowly add 1-aminoanthraquinone disulfonic acid solution dropwise to 4.0 kg parts of water, then slowly add 4 mol parts of oxidant potassium permanganate and stir for 7 hours to obtain 1-nitroanthraquinone disulfonic acid solution;

[0048] (3) Slowly add sodium carbonate to the 1-nitroanthraquinone disulfonic acid solution, and neutralize to pH=8 to obtain a 1-nitroanthraquinone disulfonic acid sodium solution;

[0049] (4) Prepare 1-nitroanthraquinone disulfonate sodium solution into an 8% solution, then dissolve it into about 0.5% sodium vanadate, and adjust the pH value of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap