Wiper for cleaning sampling needle

A technology of sampling needles and swabs, which is applied in the field of blood cell analysis equipment, can solve the problems of difficult production and achieve the effects of convenient pipeline layout, gas saving, and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

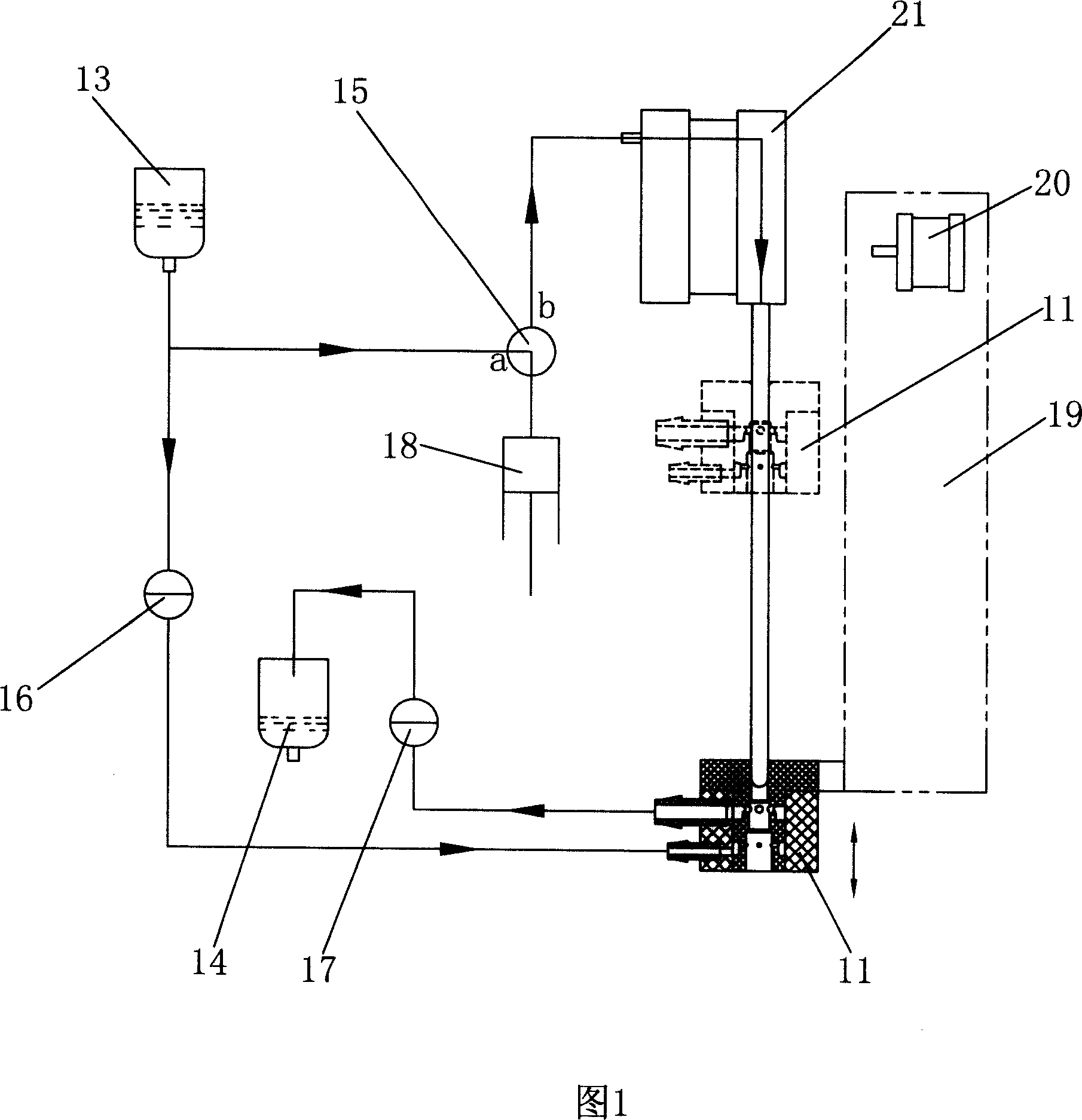

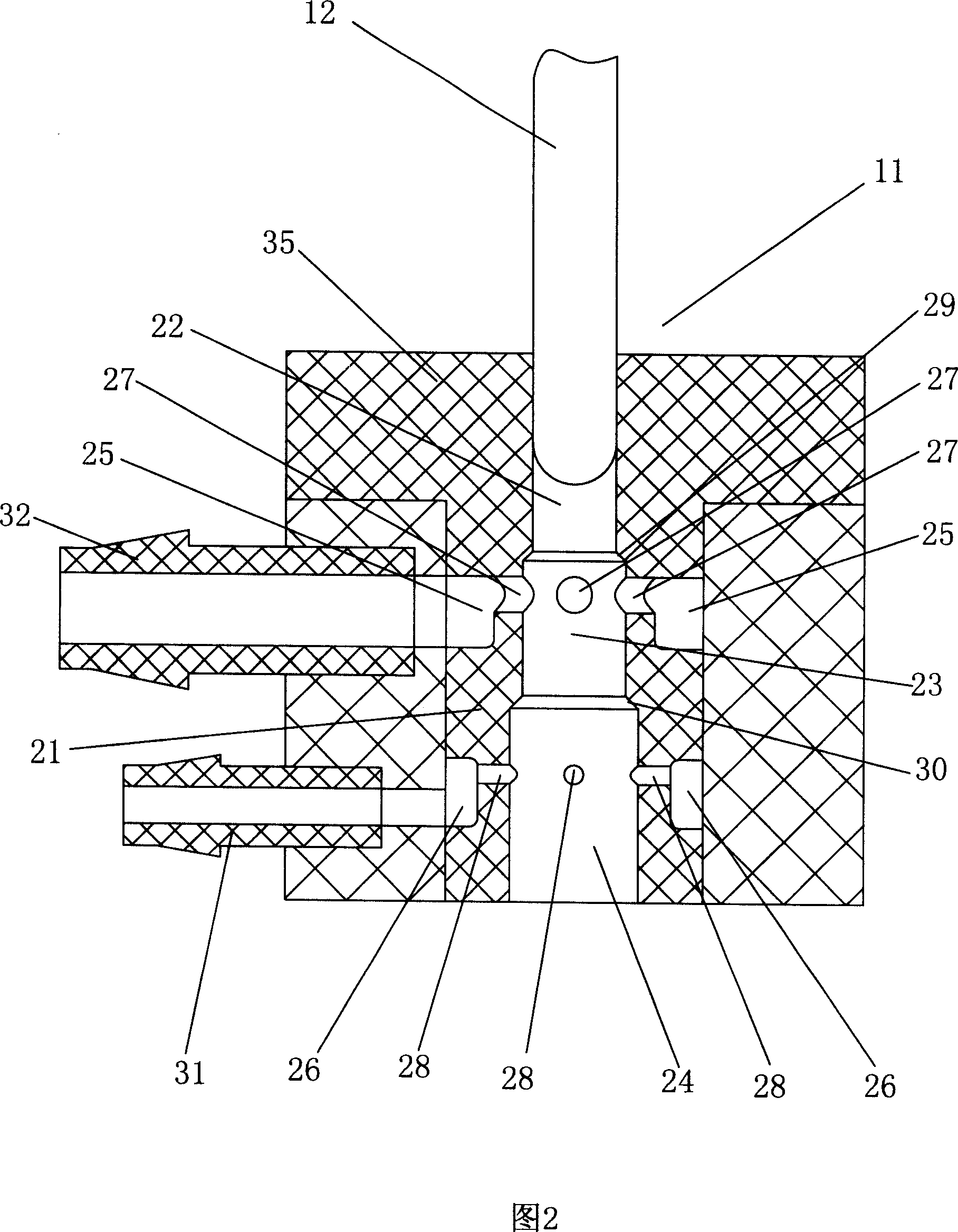

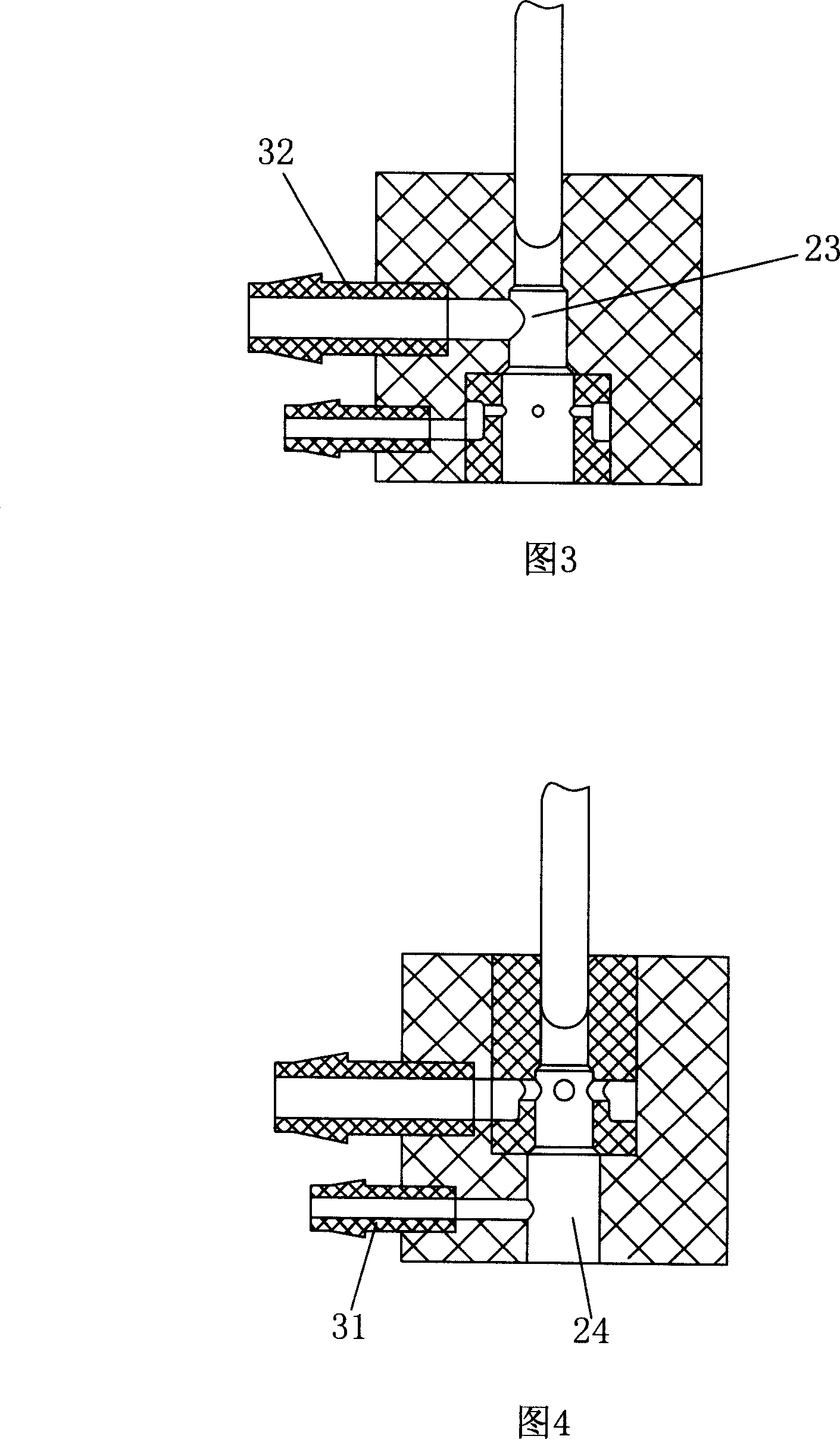

[0038] Please refer to FIG. 1 to FIG. 2 , the swab 11 for cleaning the sampling needle of the present invention includes a swab body 35 , a first liquid flow tube 31 and a second liquid flow tube 32 . The central position of the swab body 35 axially penetrates to form a cavity, the first liquid flow pipe 31 is the liquid inlet pipe 31 for the cleaning liquid to flow in, and the second liquid flow pipe 32 is used for discharging the waste liquid after cleaning The discharge pipe 32, the cross-sectional area of the liquid inlet pipe 31 is smaller than the cross-sectional area of the liquid discharge pipe 32, and the liquid inlet pipe 31 and the liquid discharge pipe 32 are installed on the swab body horizontally (that is, the radial direction of the swab body) 35 and communicate with the cavity, and in the direction of gravity, the liquid inlet pipe 31 is located below the liquid discharge pipe 32 . Certainly, the central cavity axis of the swab 11 is not limited to be place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com