Automatic double-clutch engine gear arm

A dual-clutch and engine technology, applied in the field of shifting arms, can solve the problems of inability to operate the clutch, damage to the engine, difficult operation, etc., and achieve the effects of stable and reliable work, low manufacturing cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

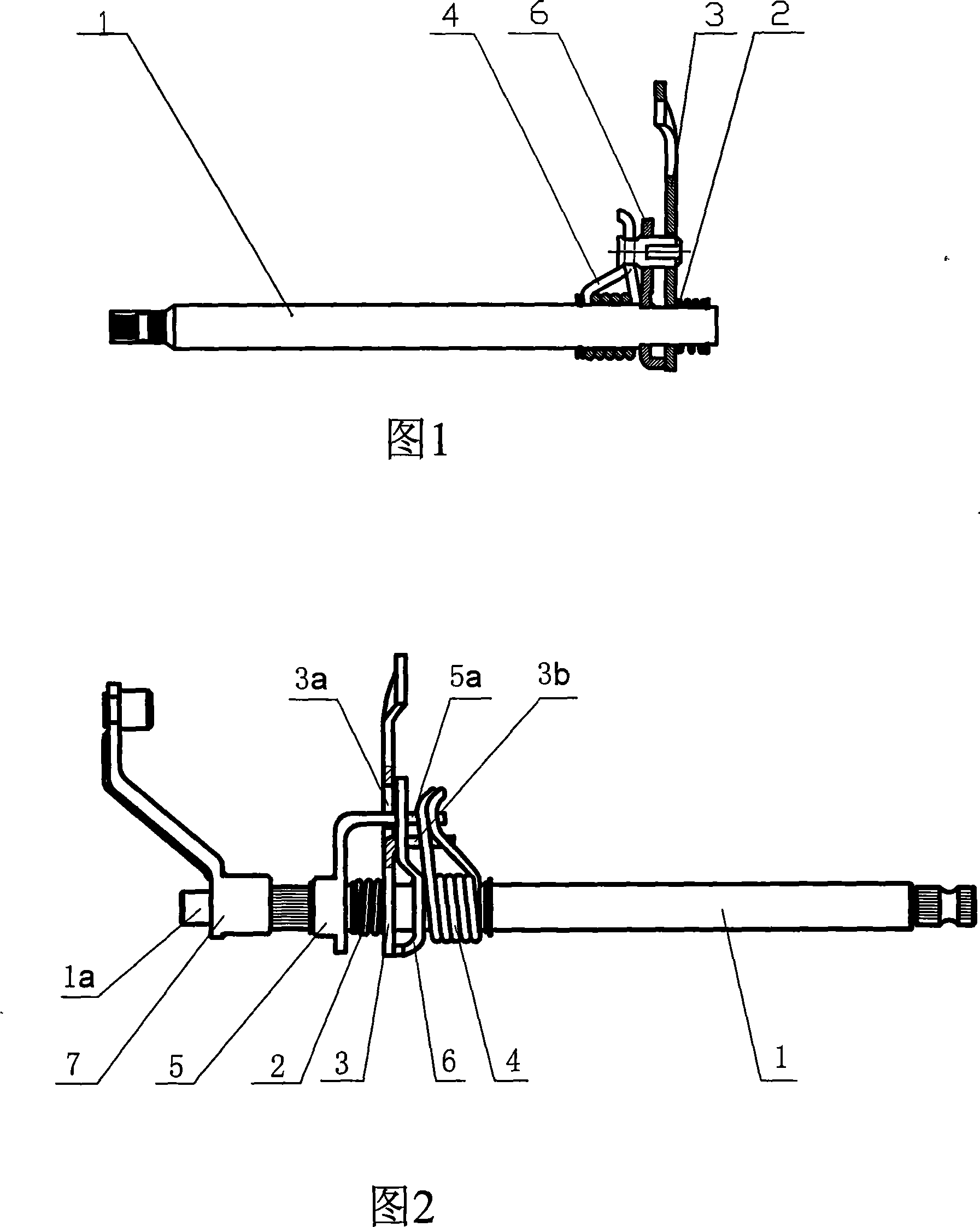

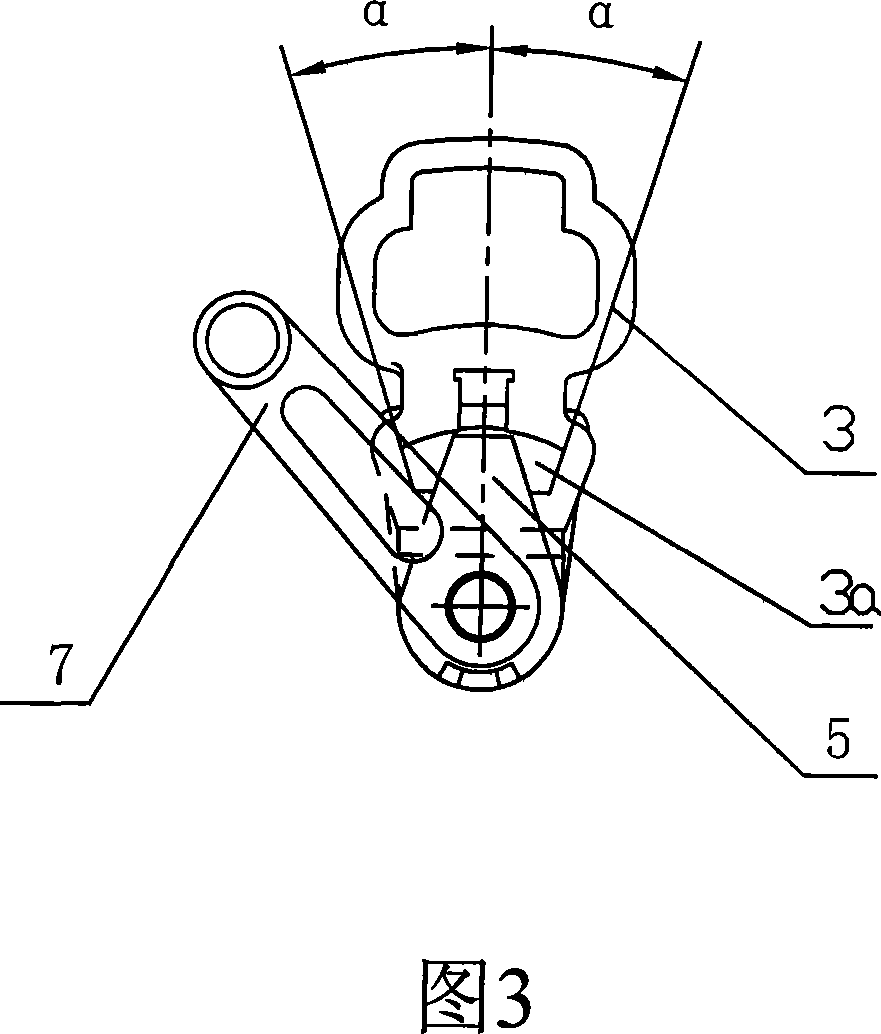

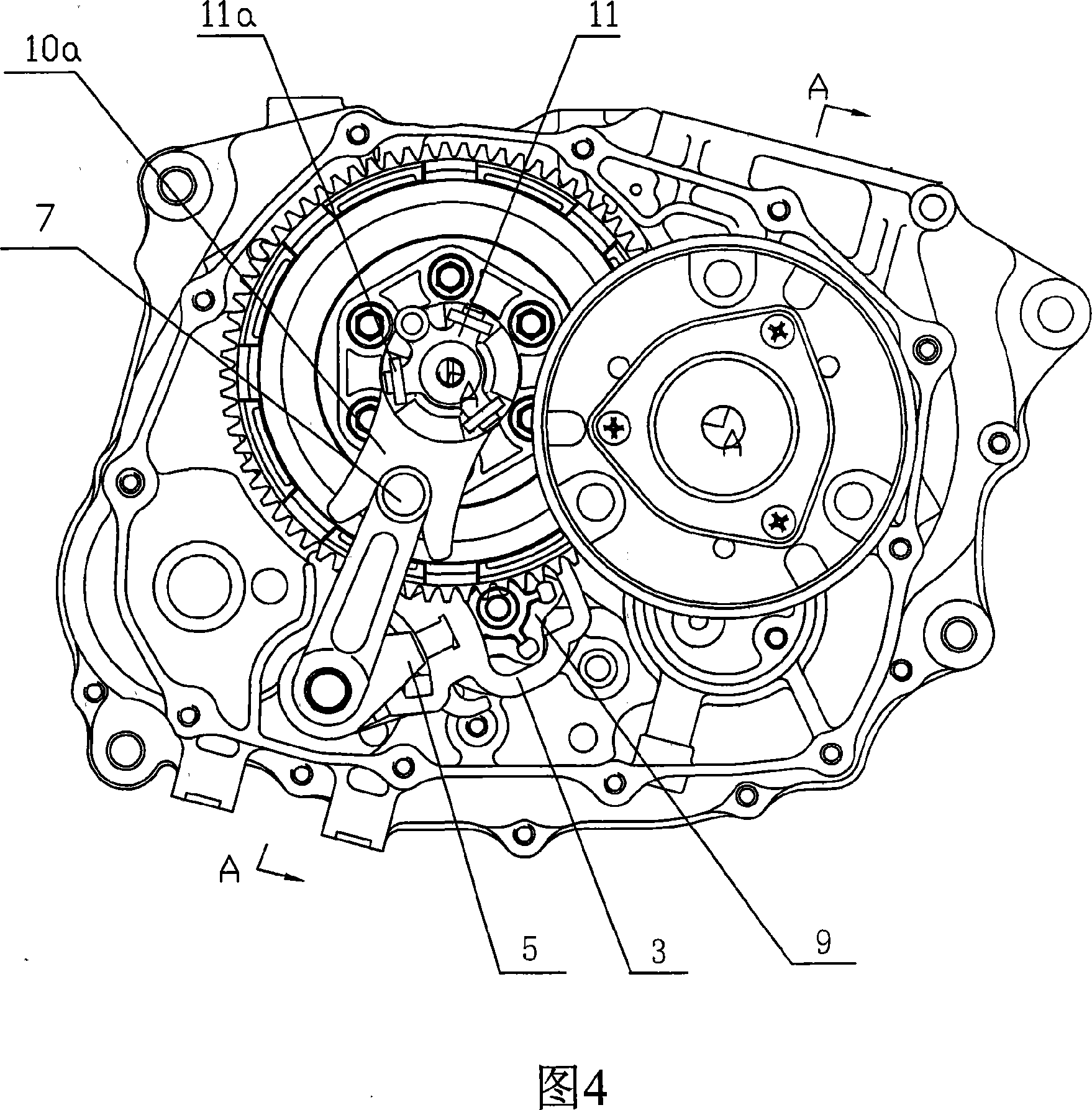

[0016] As shown in Figure 2, the present invention is mainly composed of a shift shaft 1, an operating arm 7, a second dial 5, a positioning spring 2, a first dial 3, a limit plate 6, a return spring 4, a washer and a snap ring. The first shifting plate 3 and the shift shaft 1 are looped, and the middle part is provided with a slot hole 3a with a folding arm 3b on the lower edge, and the folding arm 3b provided by the first shifting plate 3 extends between the two clamping feet of the return spring 4 , the return spring 4 is locked by a snap ring; the second dial 5 has an "L"-shaped folding arm 5a and is welded and fixed to the shift shaft 1, and the folding arm 5a of the second dial 5 passes through the first dial 3 The slot hole 3a of the reset spring 4 extends between the two clamping feet, the positioning spring 2 is pressed between the second shift plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com