Patents

Literature

33results about How to "Gear shifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

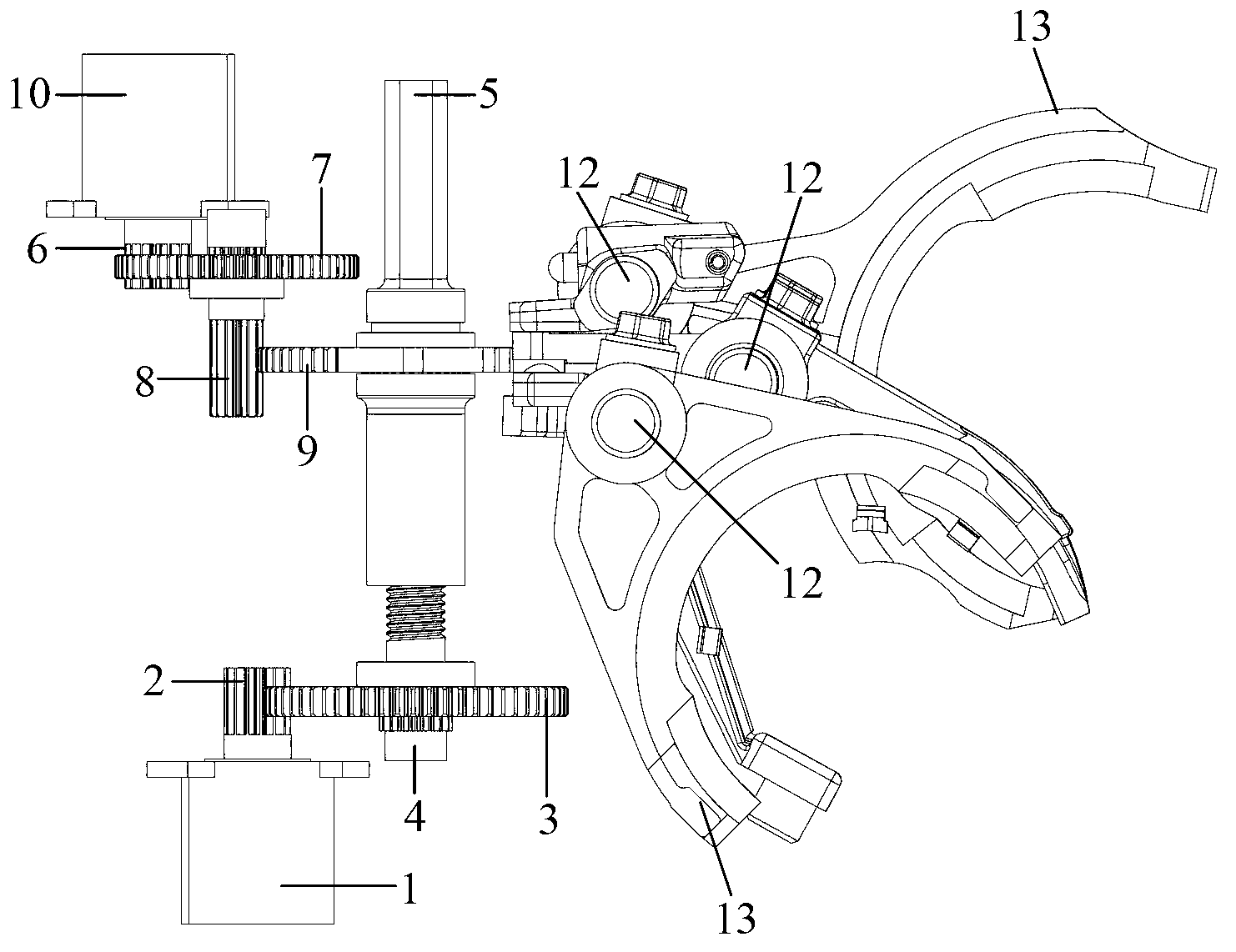

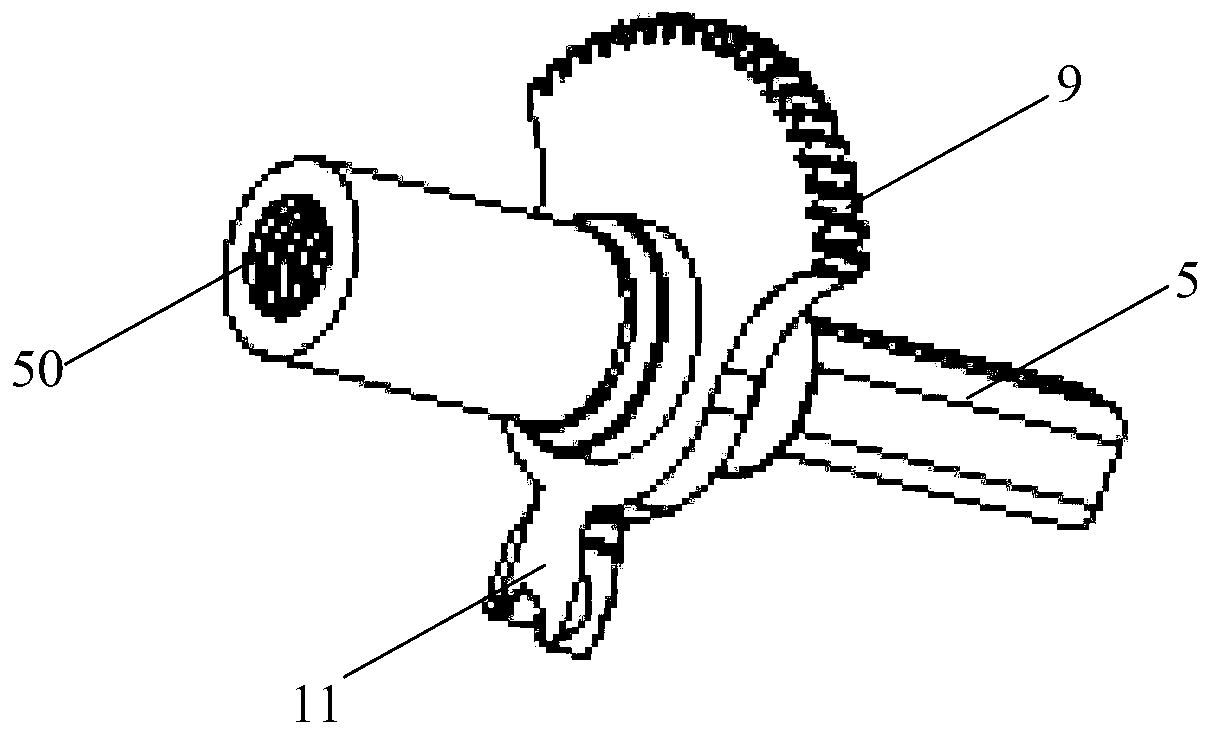

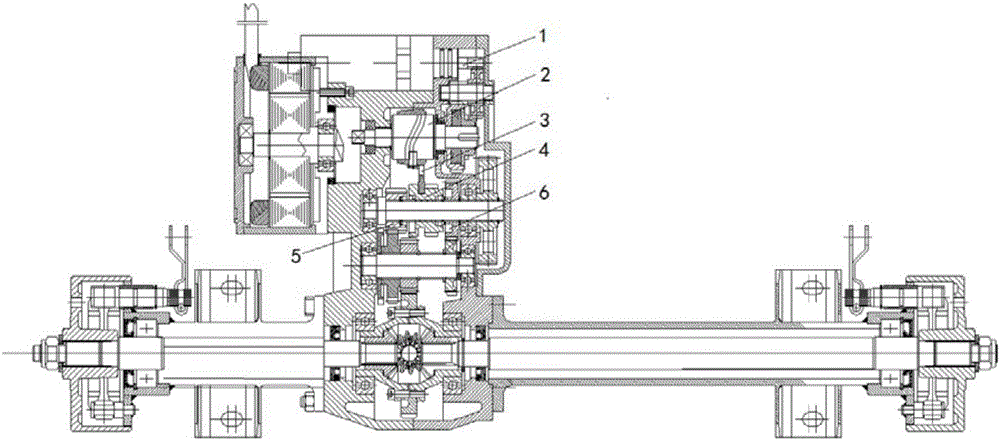

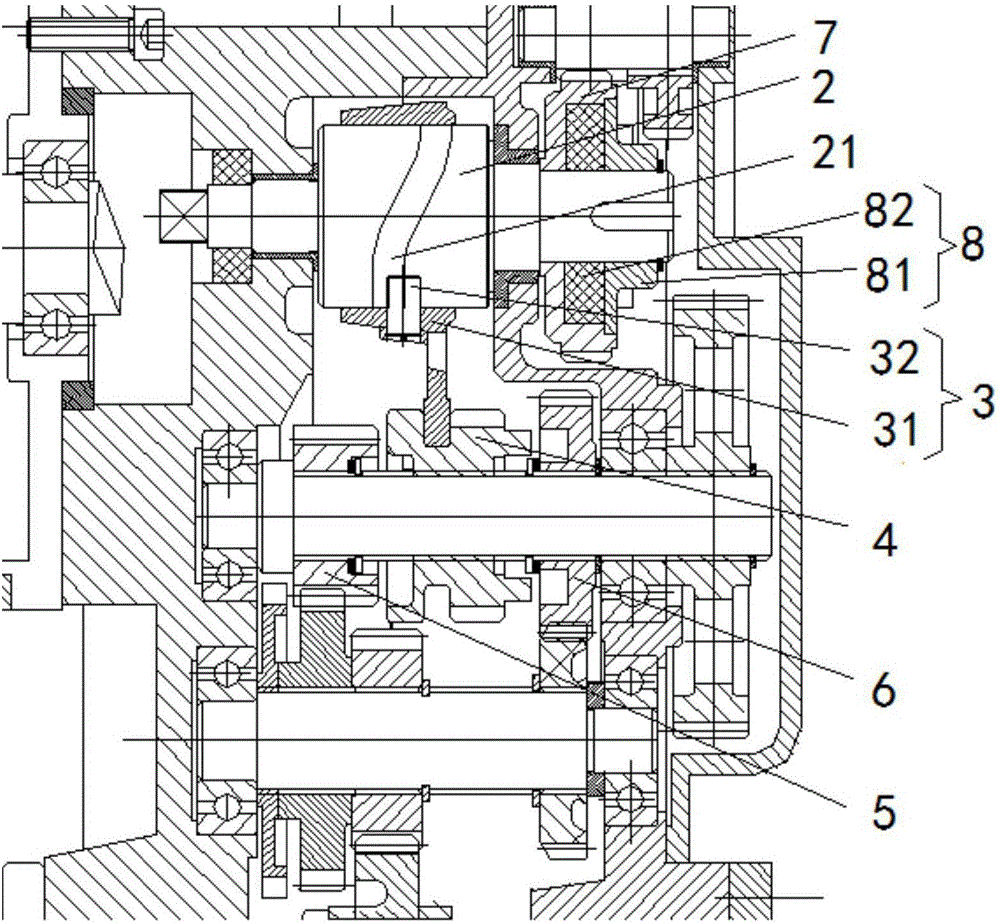

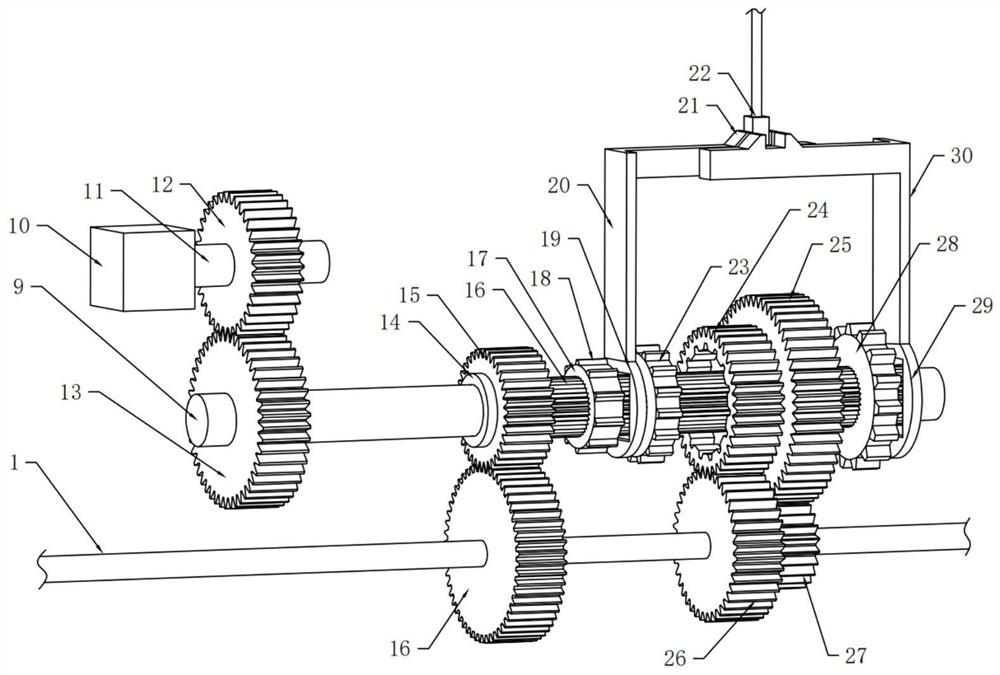

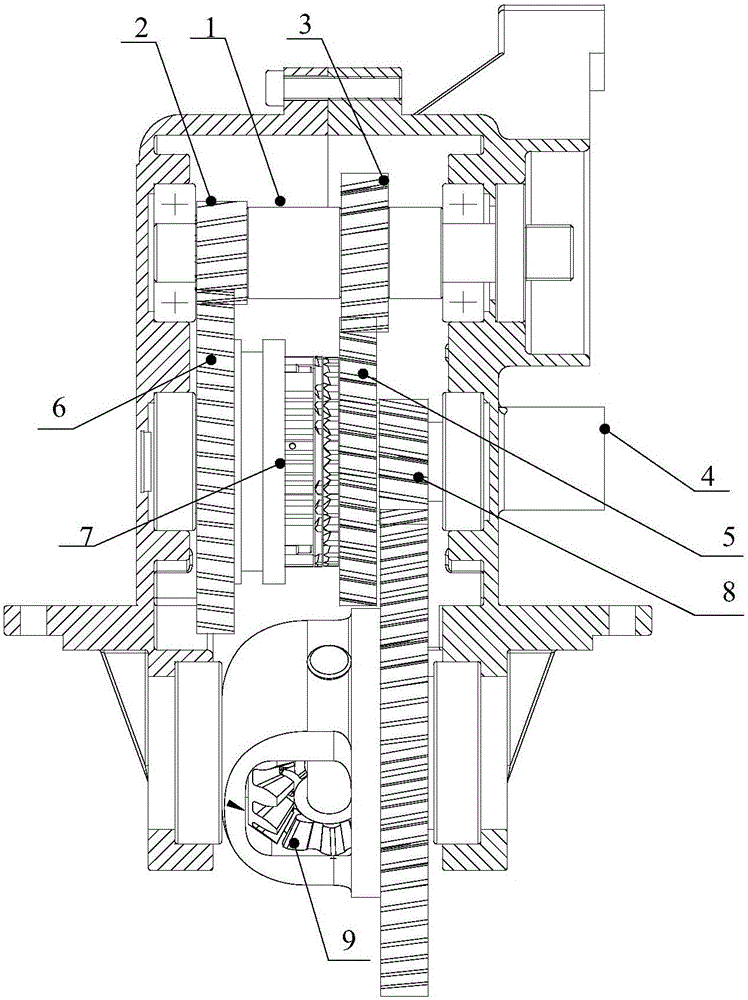

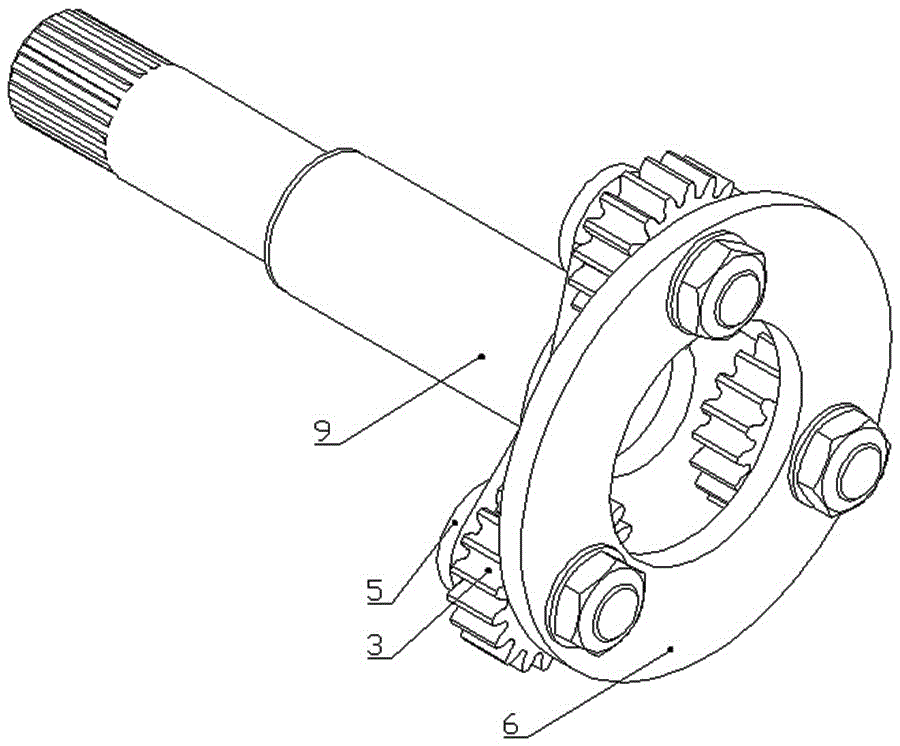

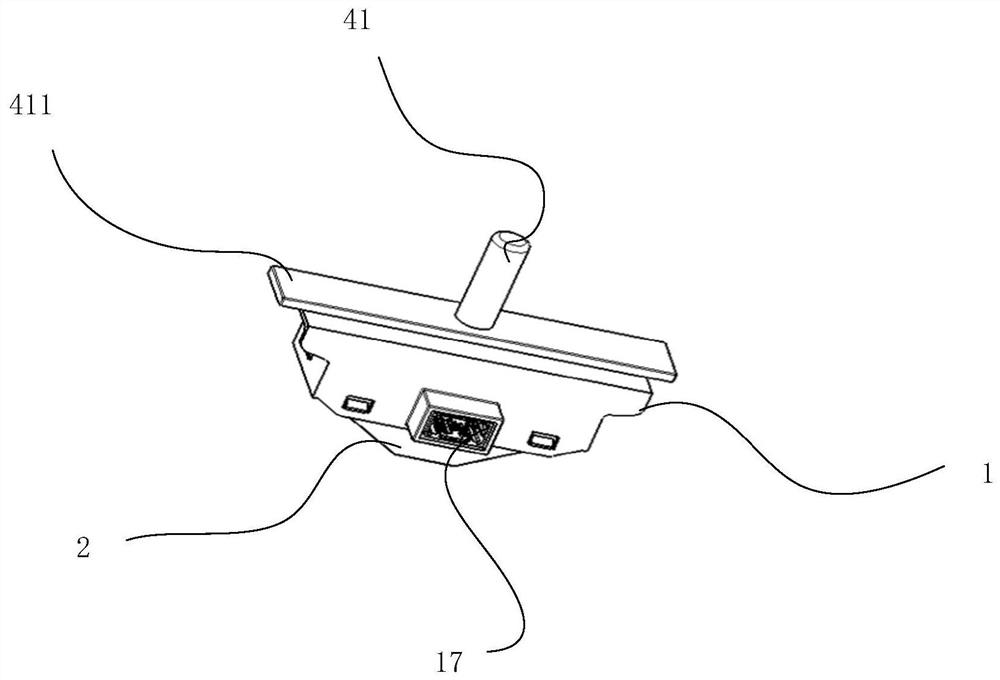

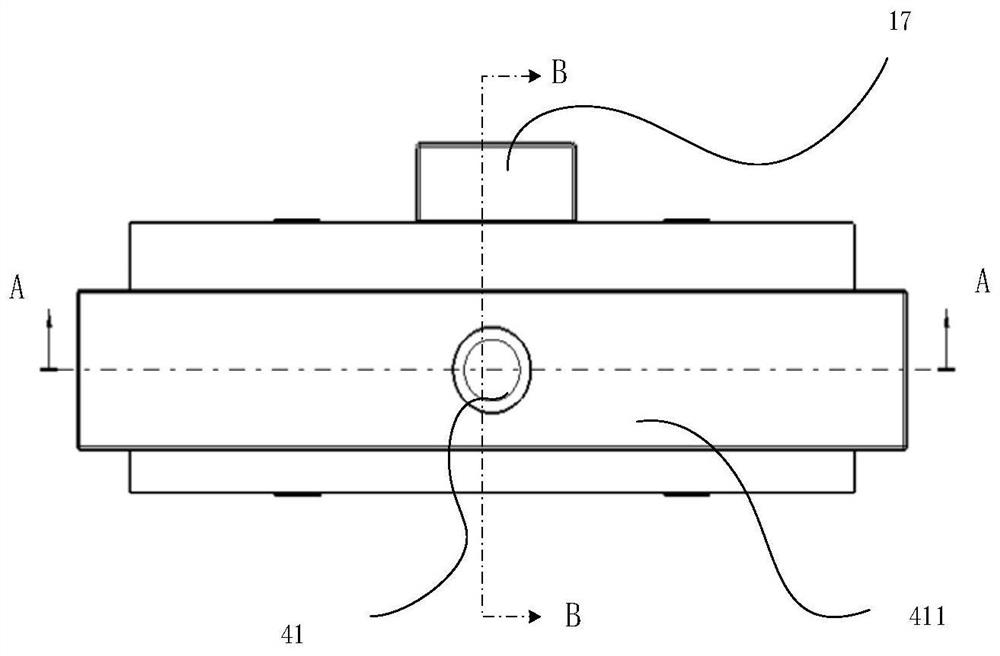

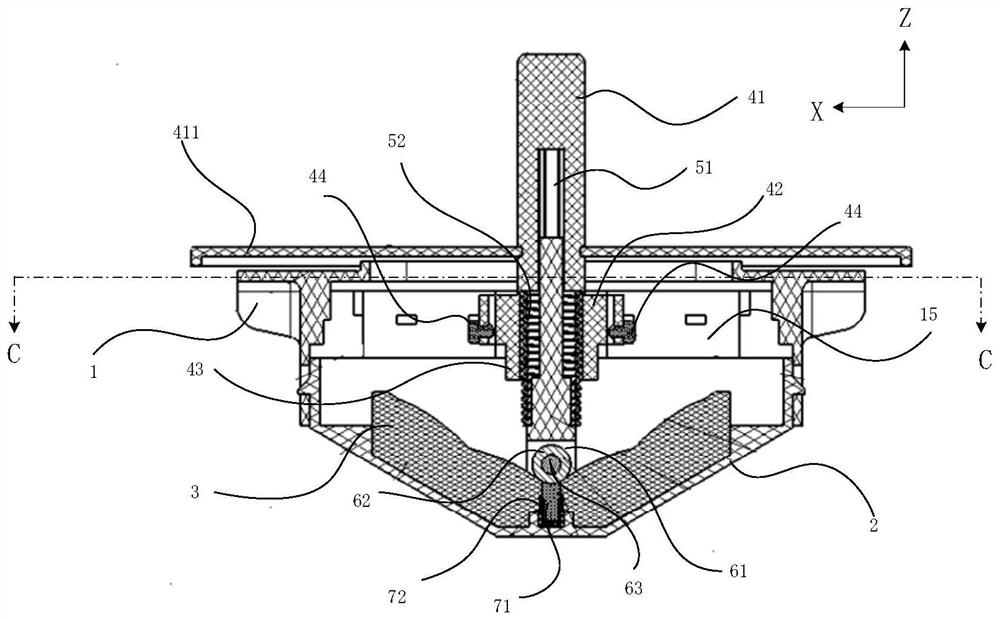

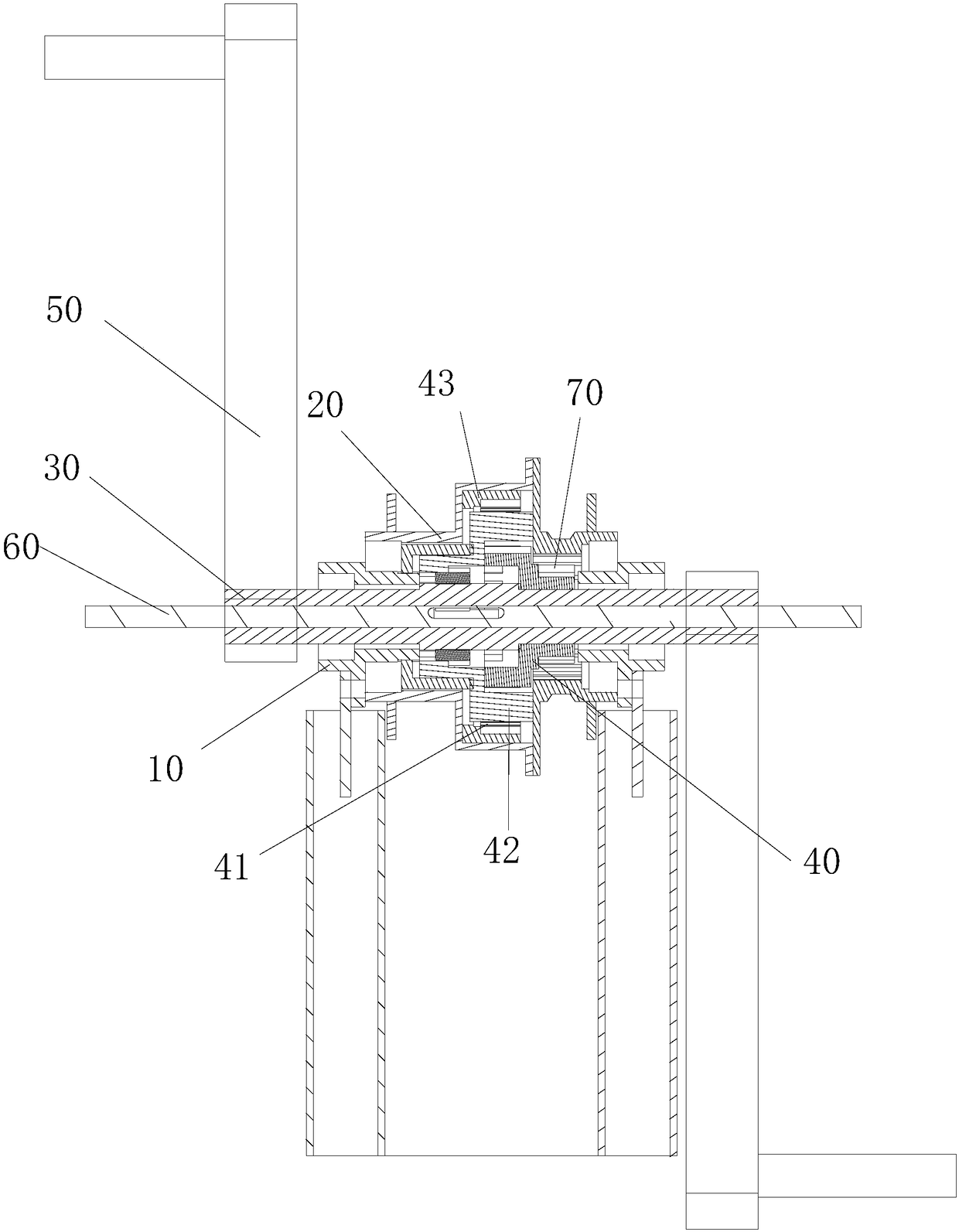

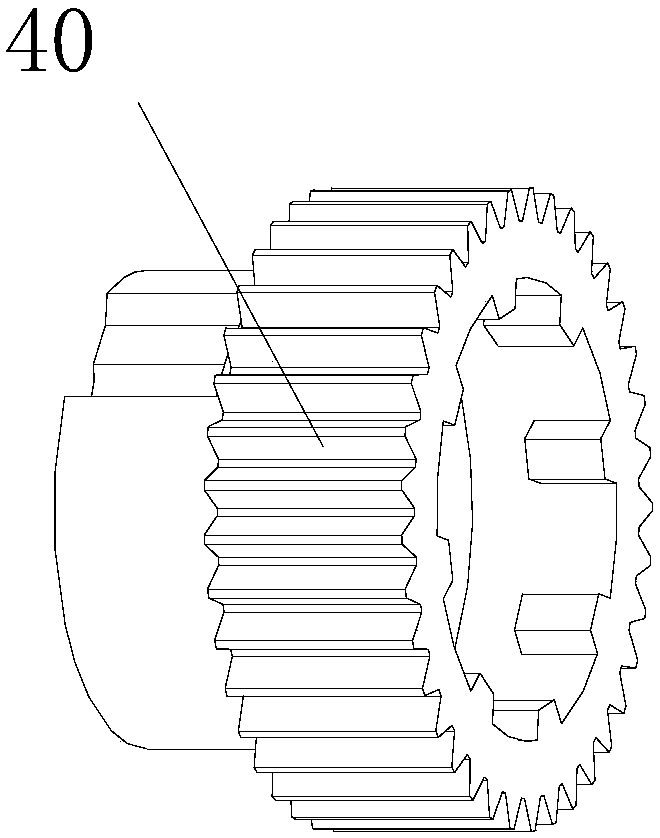

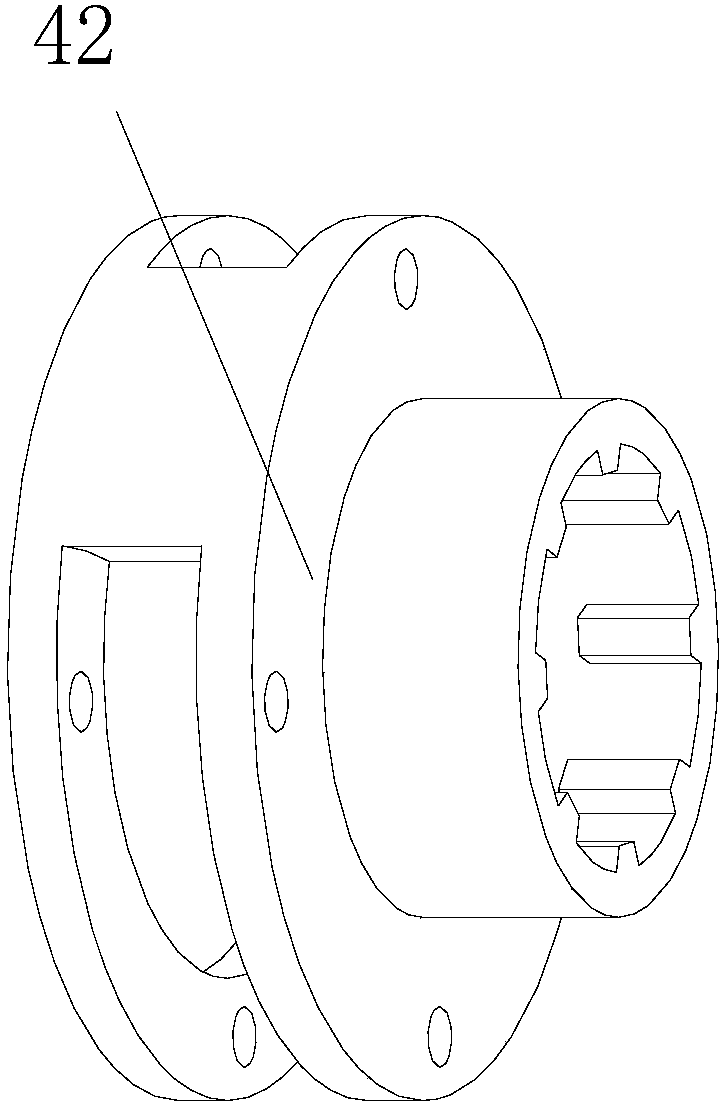

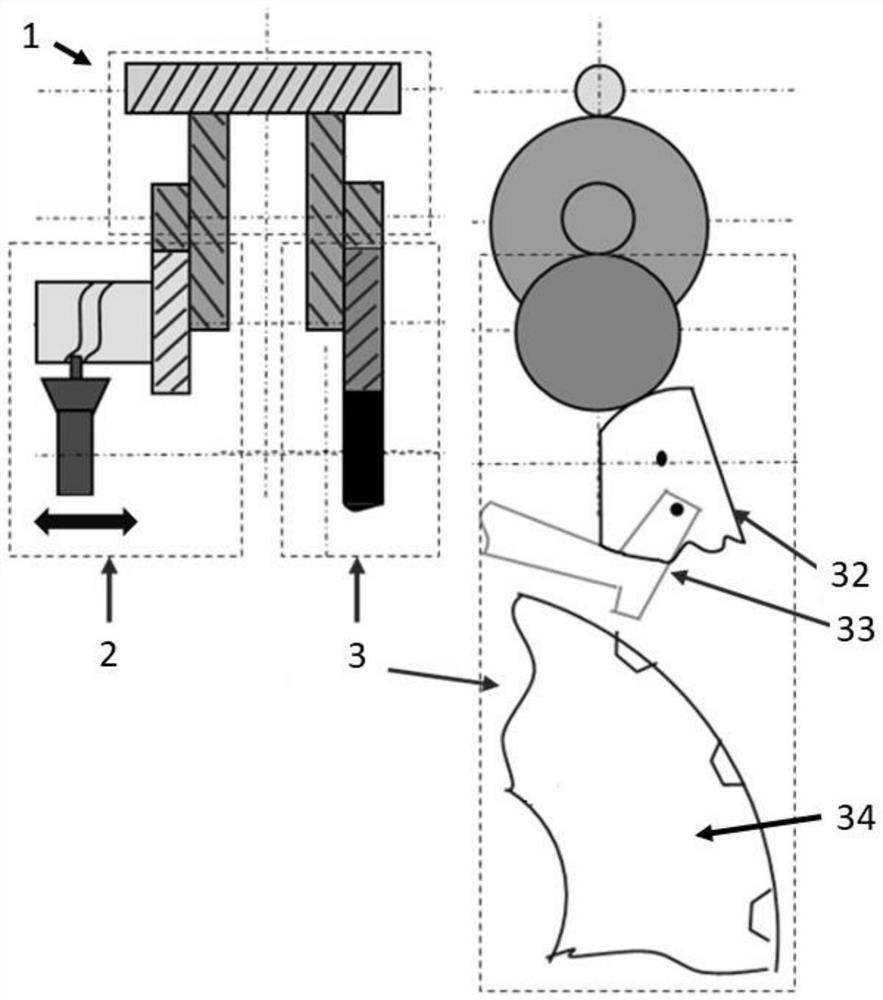

Motor-driven planetary gear train gear shifting mechanism

ActiveCN104329455ASimple internal structureSimple installation structureRoad transportGearing controlCircular discBall screw drive

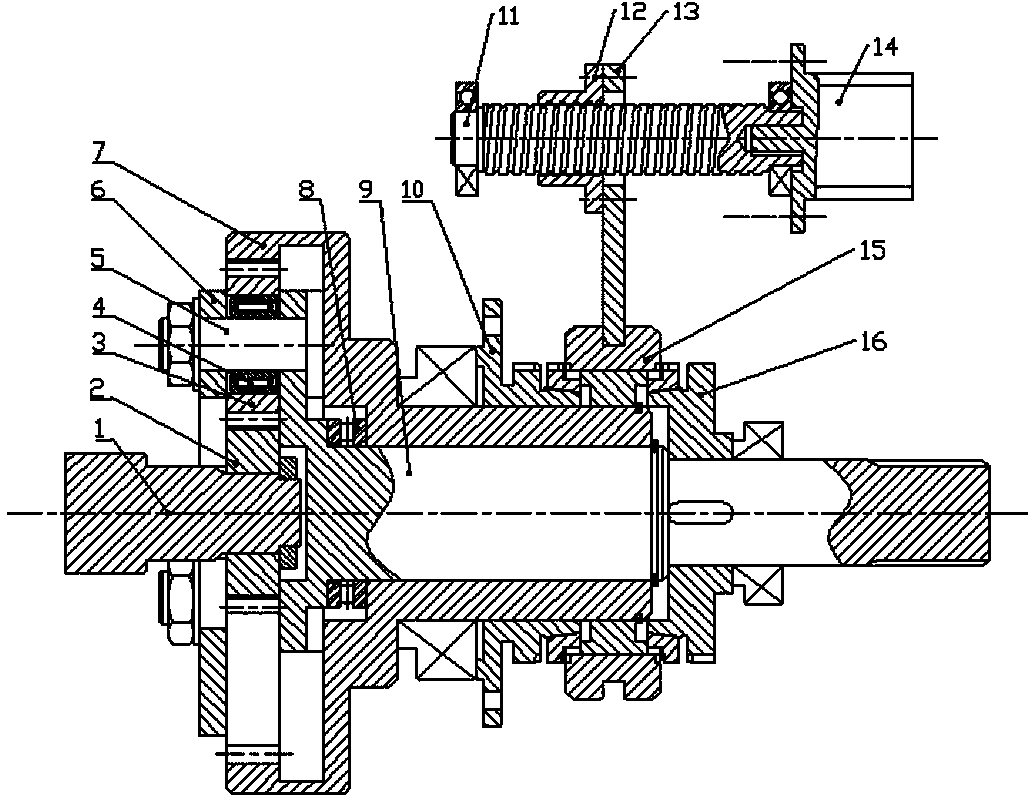

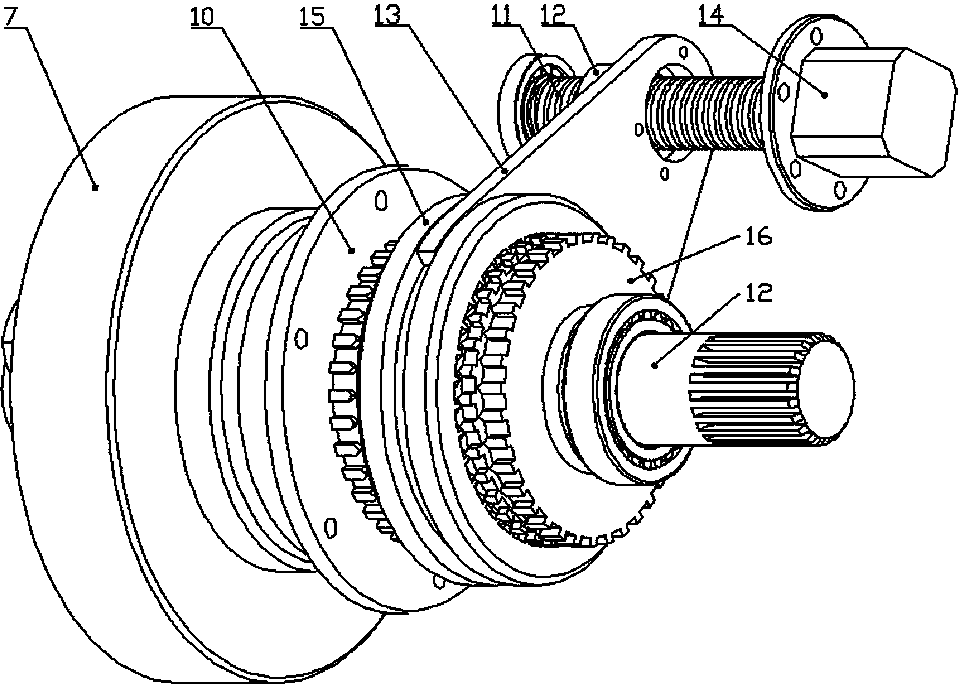

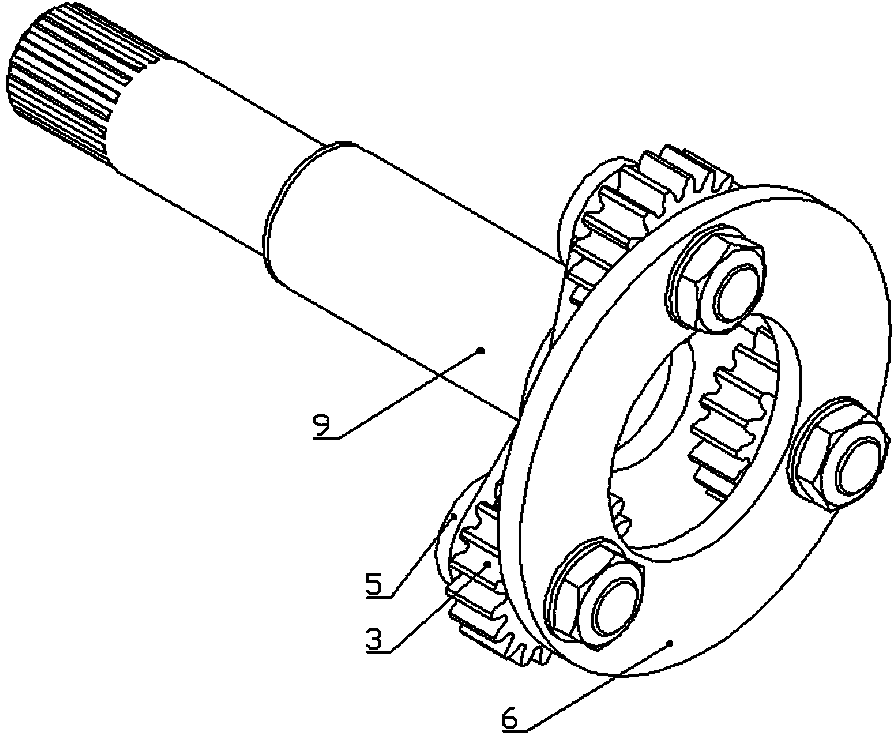

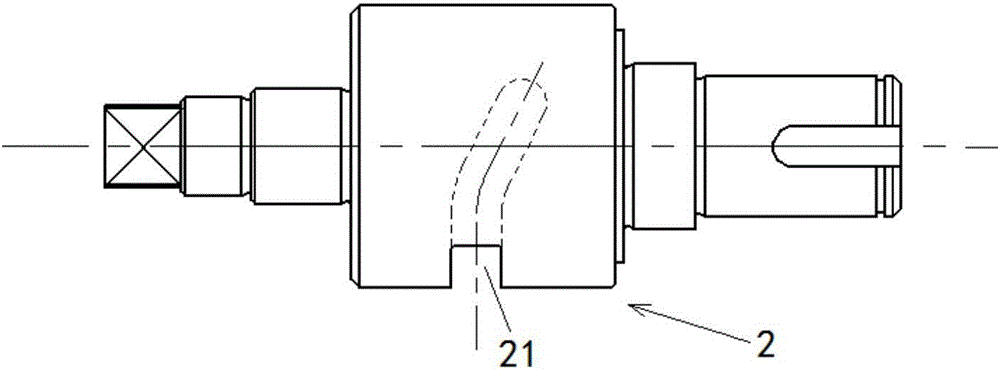

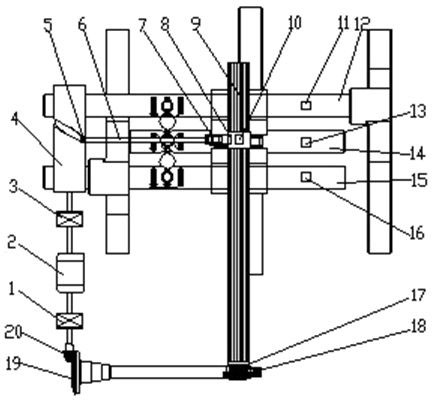

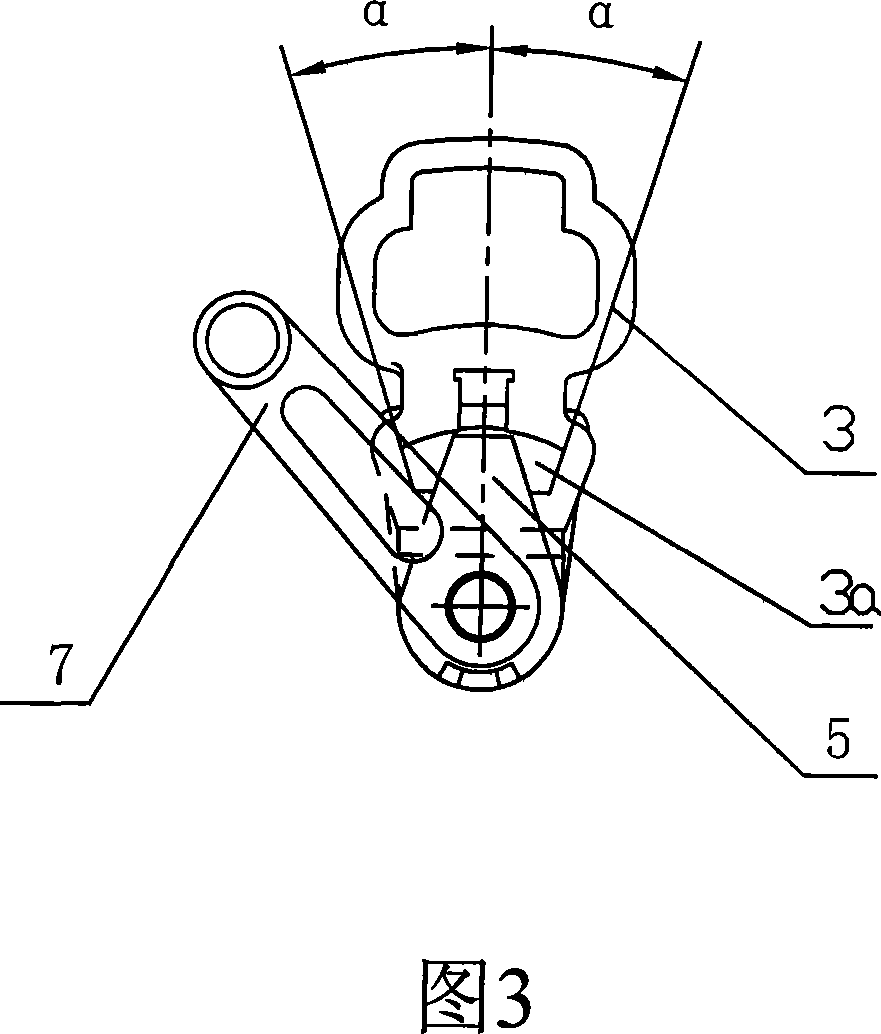

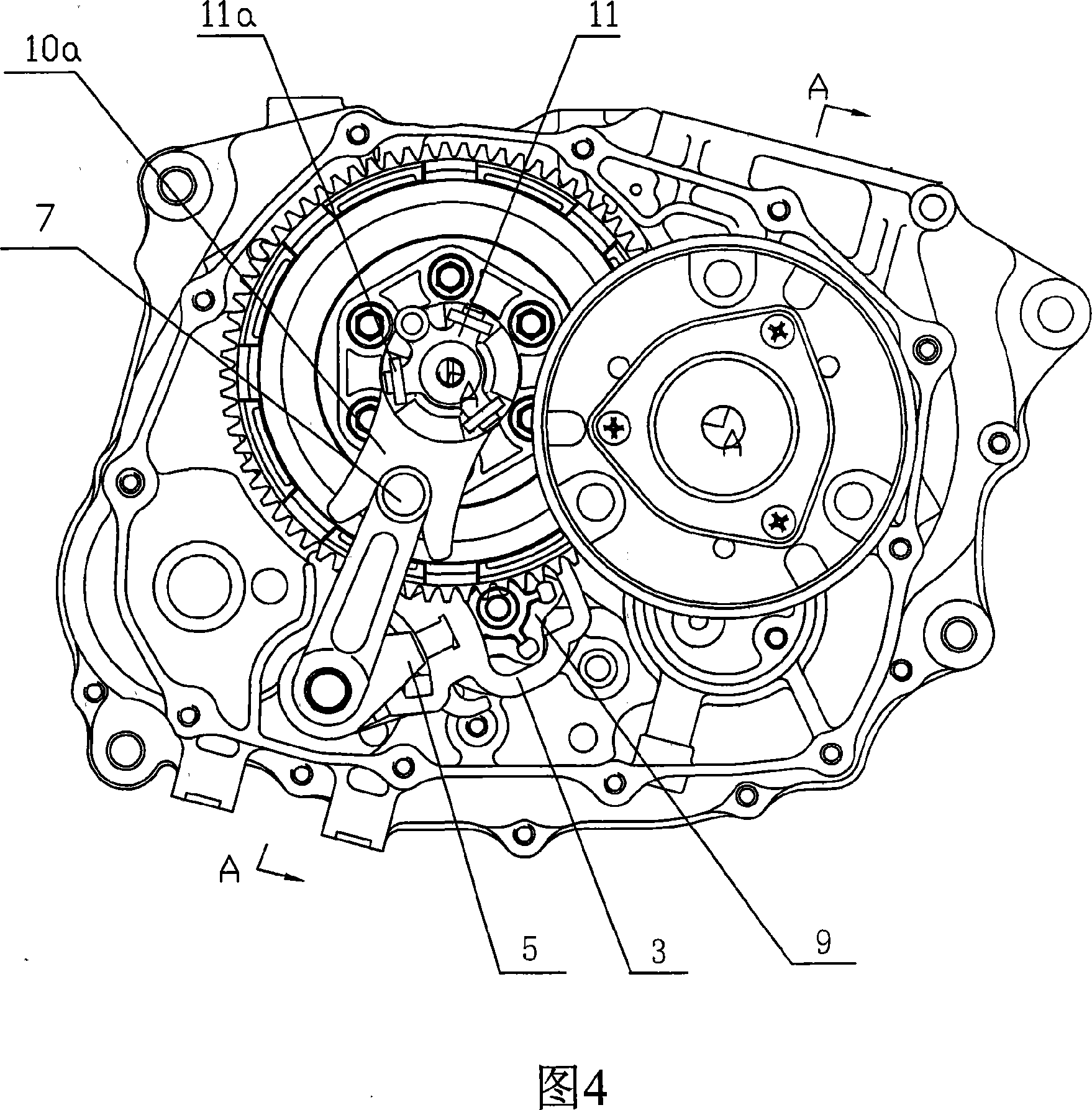

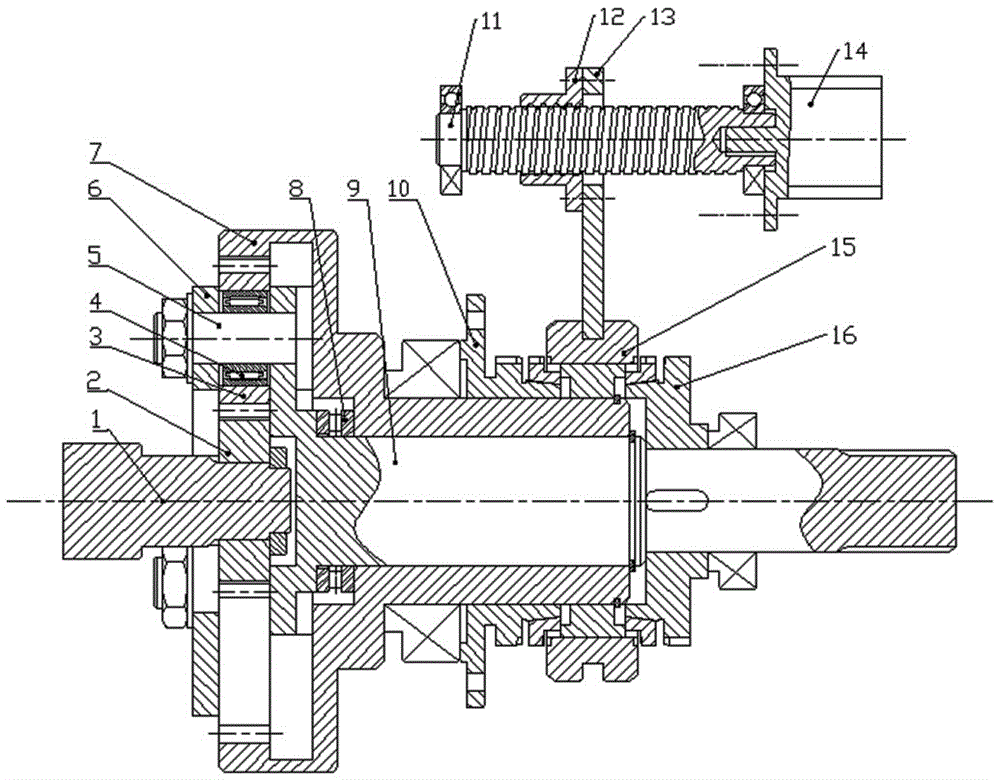

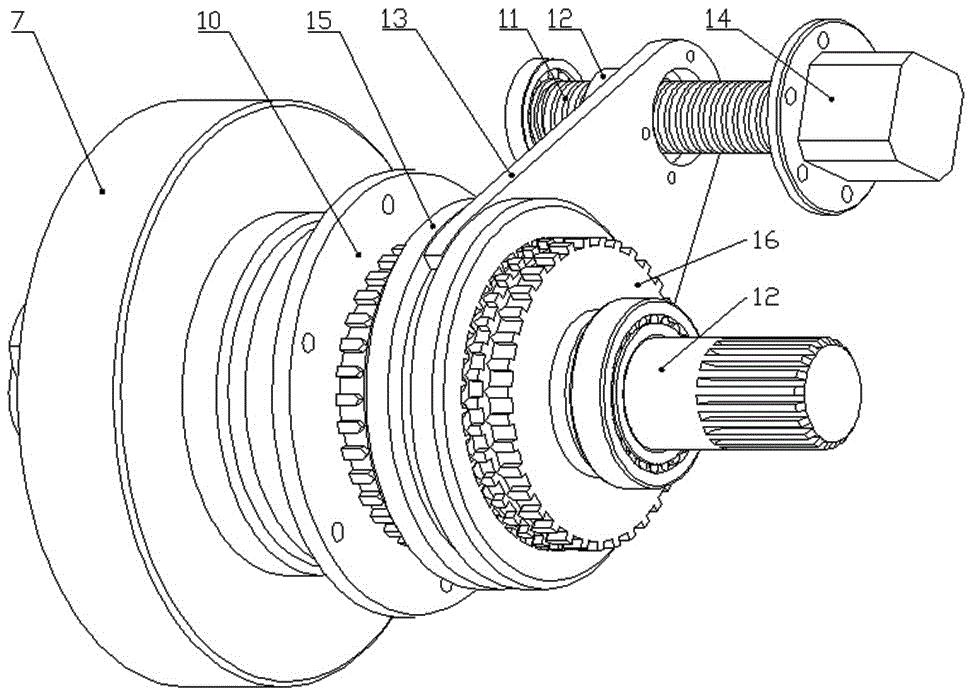

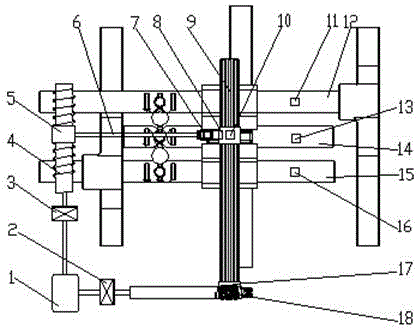

The invention relates to a motor-driven planetary gear train gear shifting mechanism, which consists of a planetary gear train mechanism, a synchronizer and a gear shifting transmission fork mechanism, wherein the planetary gear train mechanism comprises a center wheel, an inner gear ring, a planetary carrier and three planetary gears; the planetary carrier is formed by the fact that a disk is coaxially connected with one spindle; the three planetary gears are evenly distributed on the disk and are respectively meshed with the center wheel and the inner gear ring; one side of the inner gear ring is connected with a tubular shaft sleeve; the shaft sleeve sheathes the spindle of the planetary carrier; one side of the synchronizer sheathes the shaft sleeve of the inner gear ring, and the other side of the synchronizer sheathes the spindle of the planetary carrier; the gear shifting transmission fork mechanism comprises a transmission fork, a ball screw and a servo motor. According to the motor-driven planetary gear train gear shifting mechanism, the ball screw driven by the servo motor is used for driving a gear shifting transmission fork to realize gear shifting, so that gear shifting impact is small, and gear shifting smoothness and service life are improved and prolonged. Since the servo motor is supplied with power by an automobile battery instead of directly consuming the kinetic energy of an engine, the efficiency of the engine is effectively improved.

Owner:HEFEI UNIV OF TECH

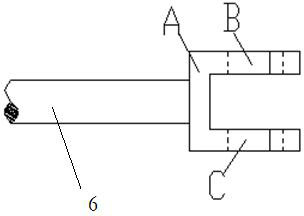

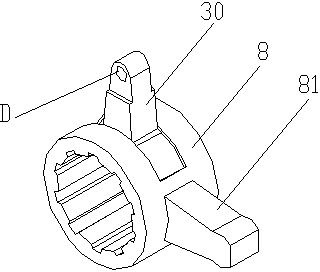

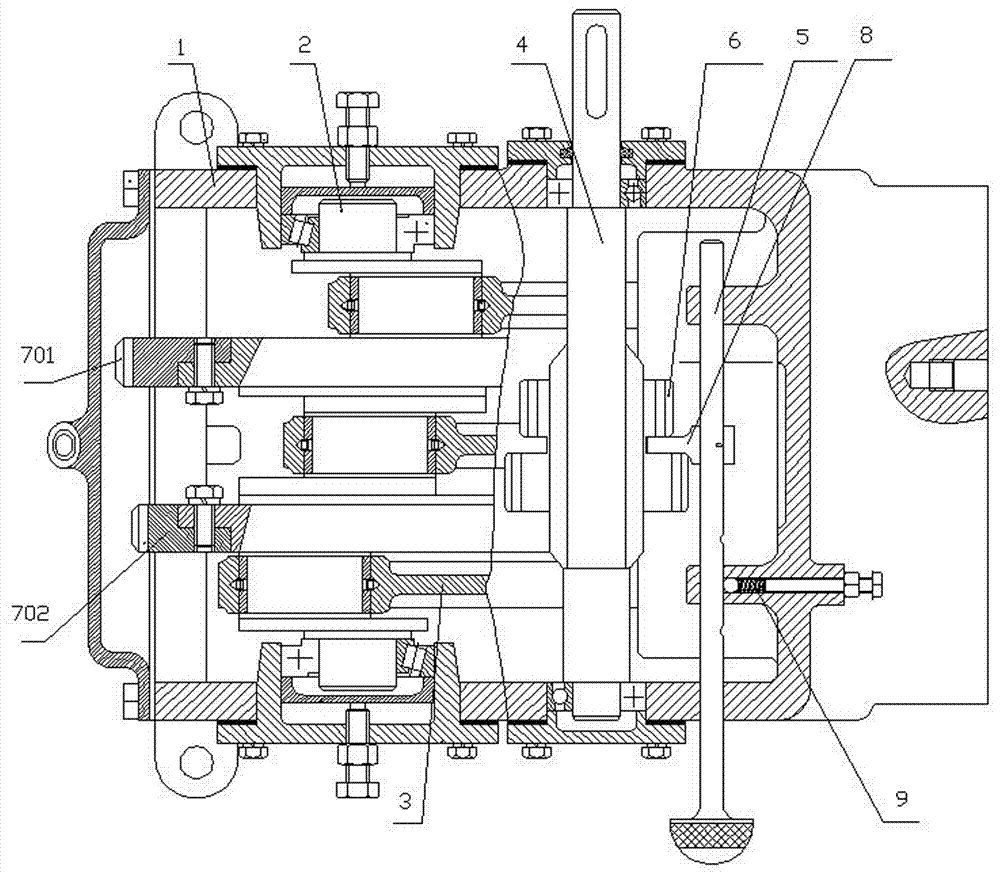

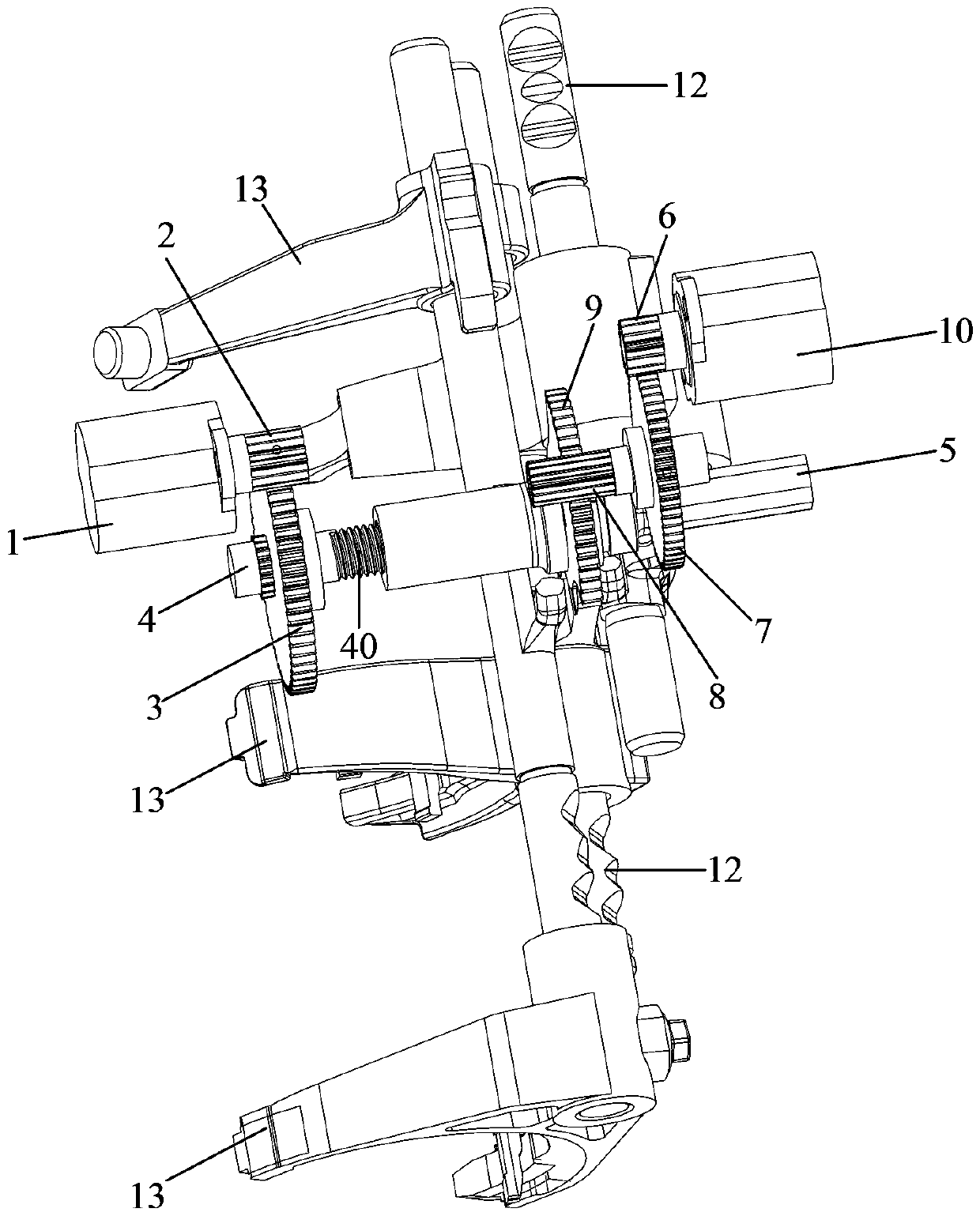

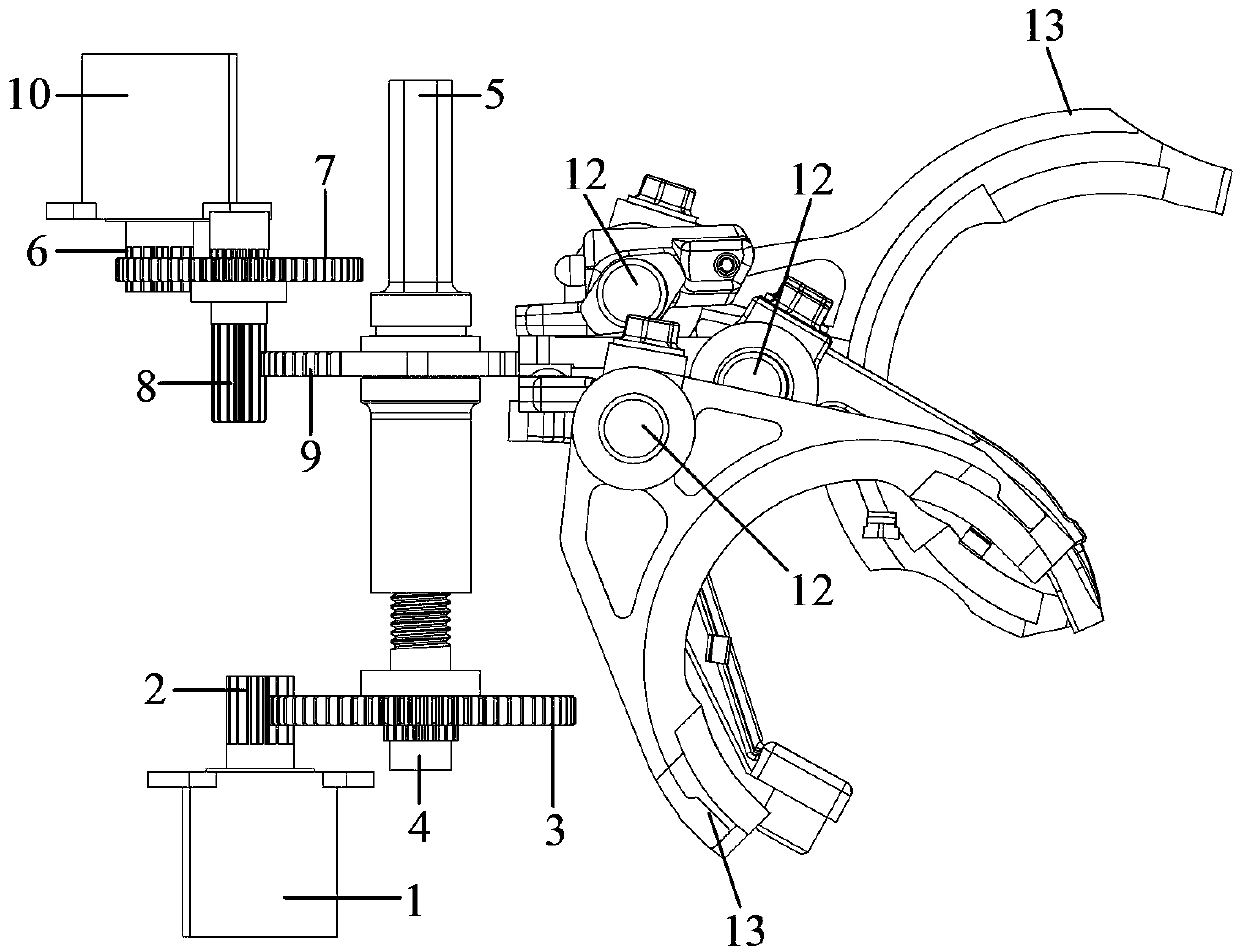

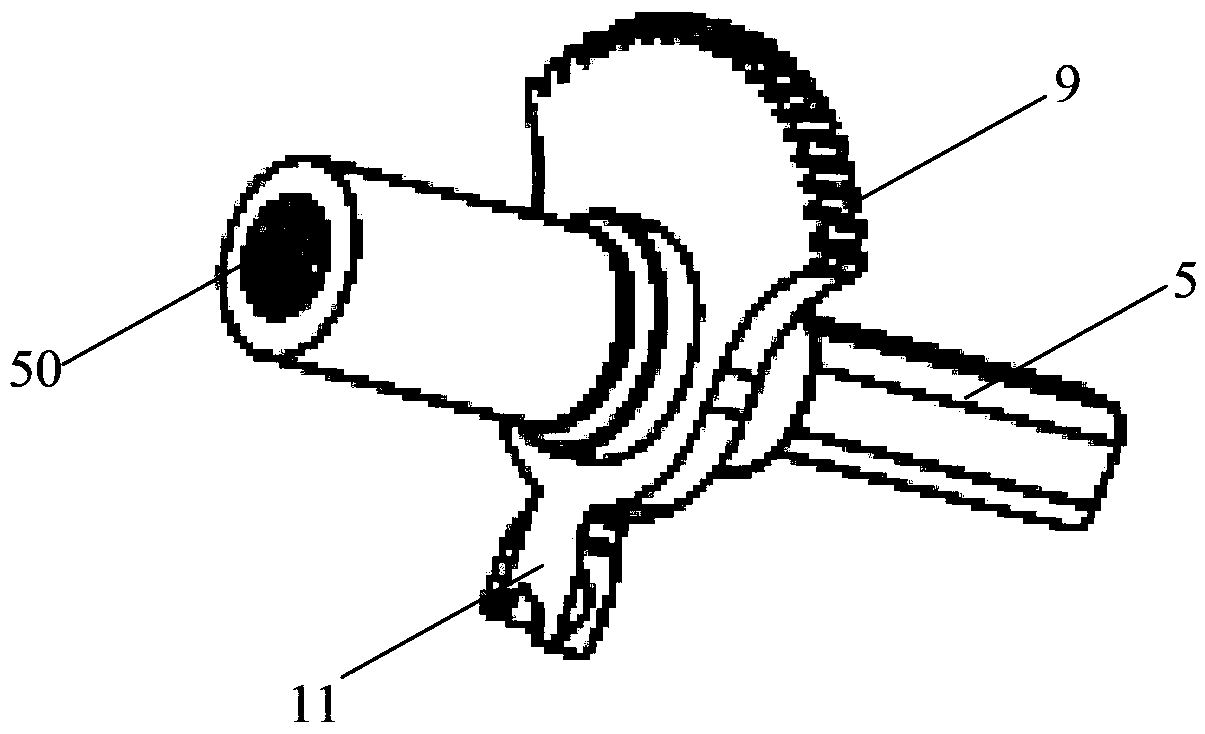

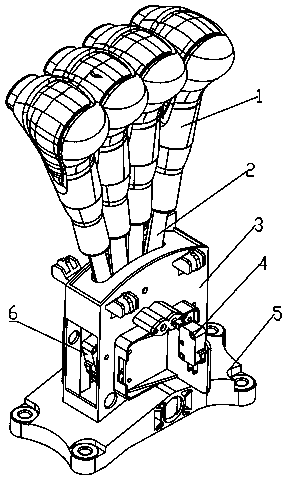

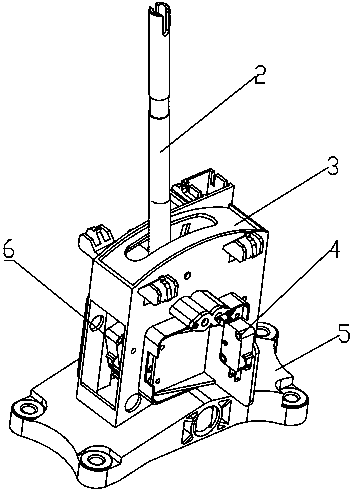

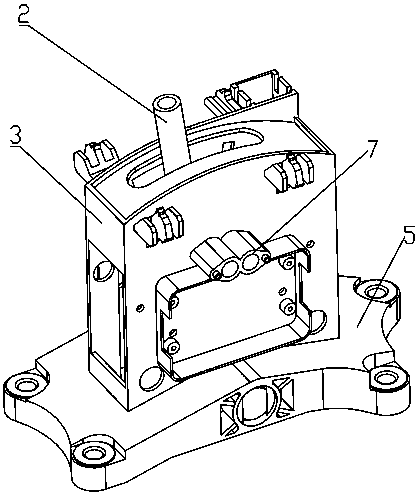

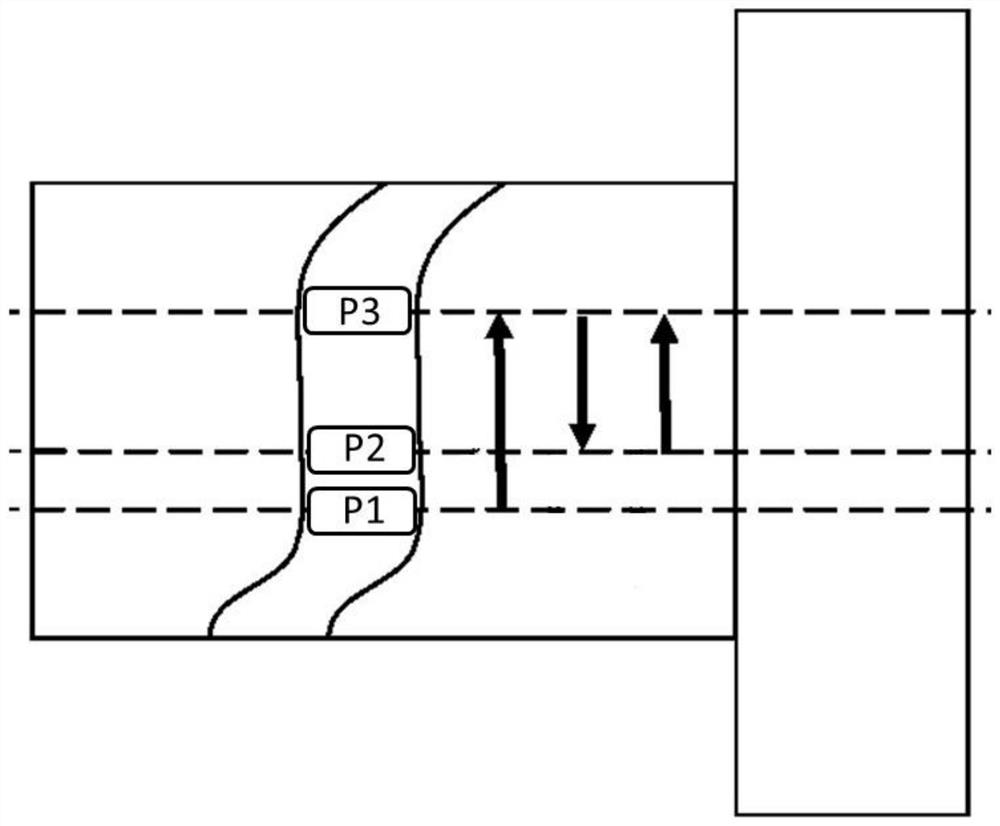

Gear selecting and shifting actuating mechanism and automatic transmission

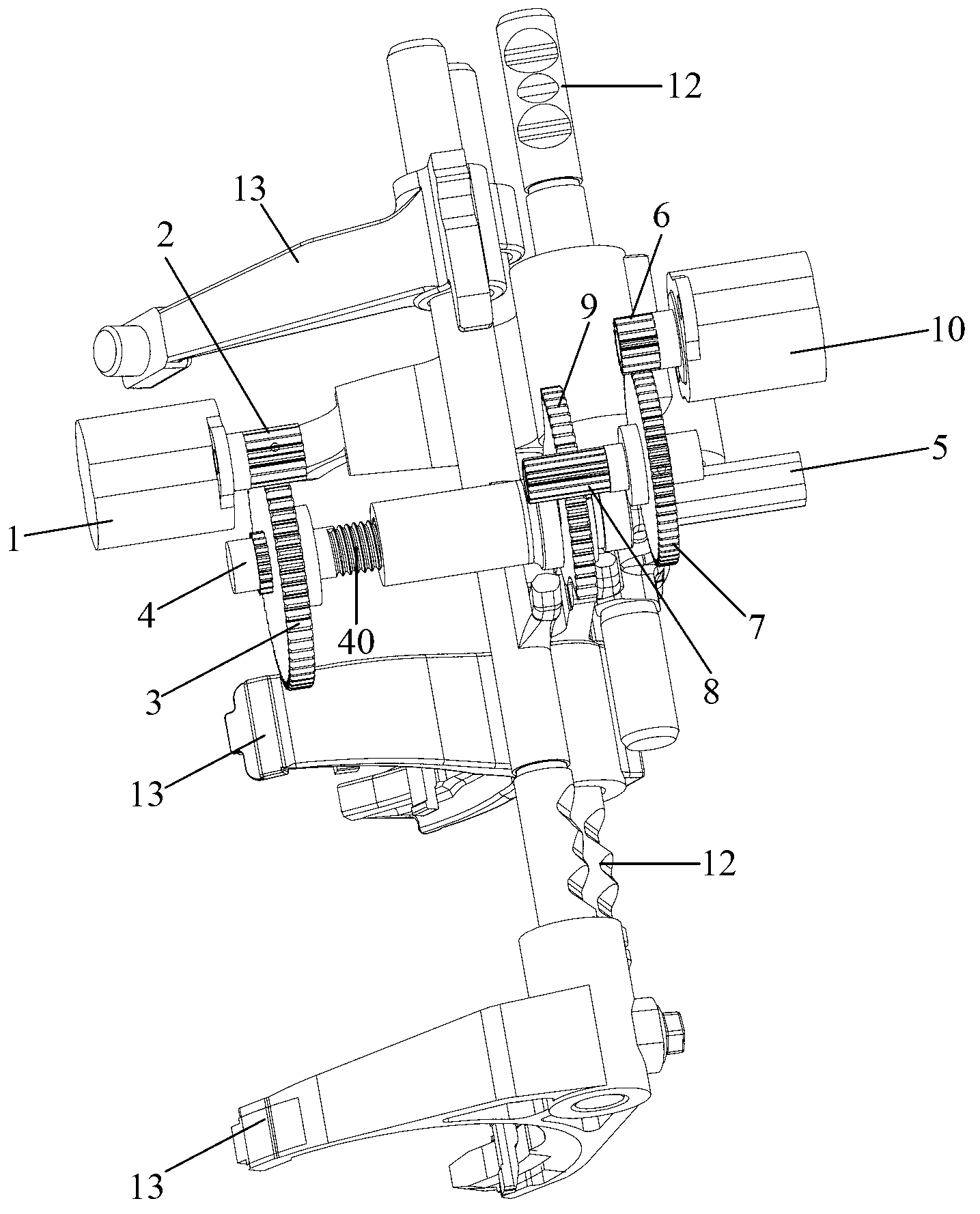

InactiveCN103016711AAvoid the risk of tooth collisionGear shiftingControlled membersGearing controlAutomatic transmissionEngineering

The invention discloses a gear selecting and shifting actuating mechanism and an automatic transmission and relates to the technical field of transmissions, aiming at preventing the situation that gears collide with each other from occurring during gear selection of the transmission. The gear selecting and shifting actuating mechanism comprises a gear selecting motor, a gear selecting shaft, a gear shifting motor, a gear shifting shaft, a gear shifting block, shifting fork shafts and shifting forks, wherein the gear selecting motor is connected with the gear selecting shaft in a driving way, the gear shifting motor is connected with the gear shifting shaft in a driving way, the gear selecting shaft is connected with the gear shifting shaft through a thread pair, the gear shifting block which can rotate along the circumferential direction of the gear shifting shaft is sheathed on the gear shifting shaft, the shifting fork shafts are arranged below the gear shifting block and are arranged at intervals in parallel along the axial direction of the gear shifting shaft, and a shifting fork is fixedly arranged on each shifting fork shaft. When the gear shifting block rotates along the circumferential direction of the gear shifting shaft, one shifting fork shaft is driven to move along the axial direction of the shifting fork shaft. The gear selecting and shifting actuating mechanism is mainly used in automobile transmissions.

Owner:GREAT WALL MOTOR CO LTD

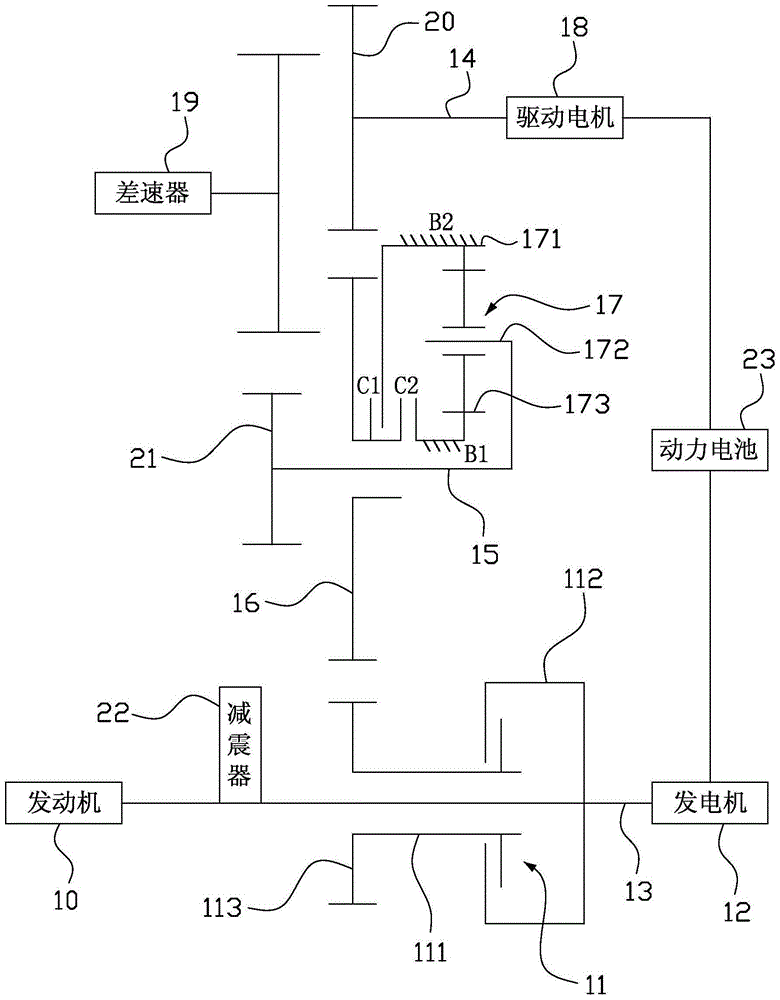

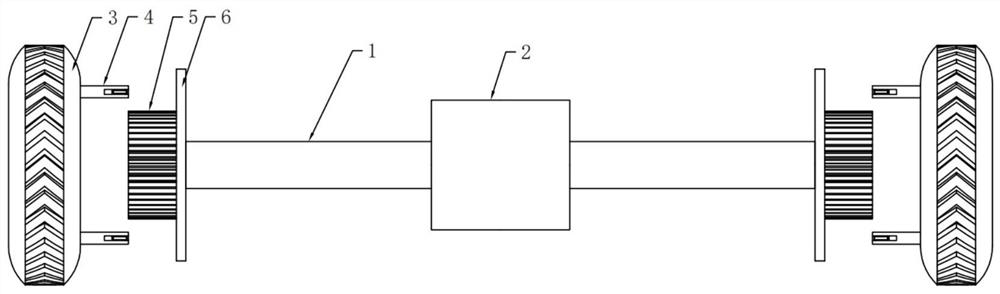

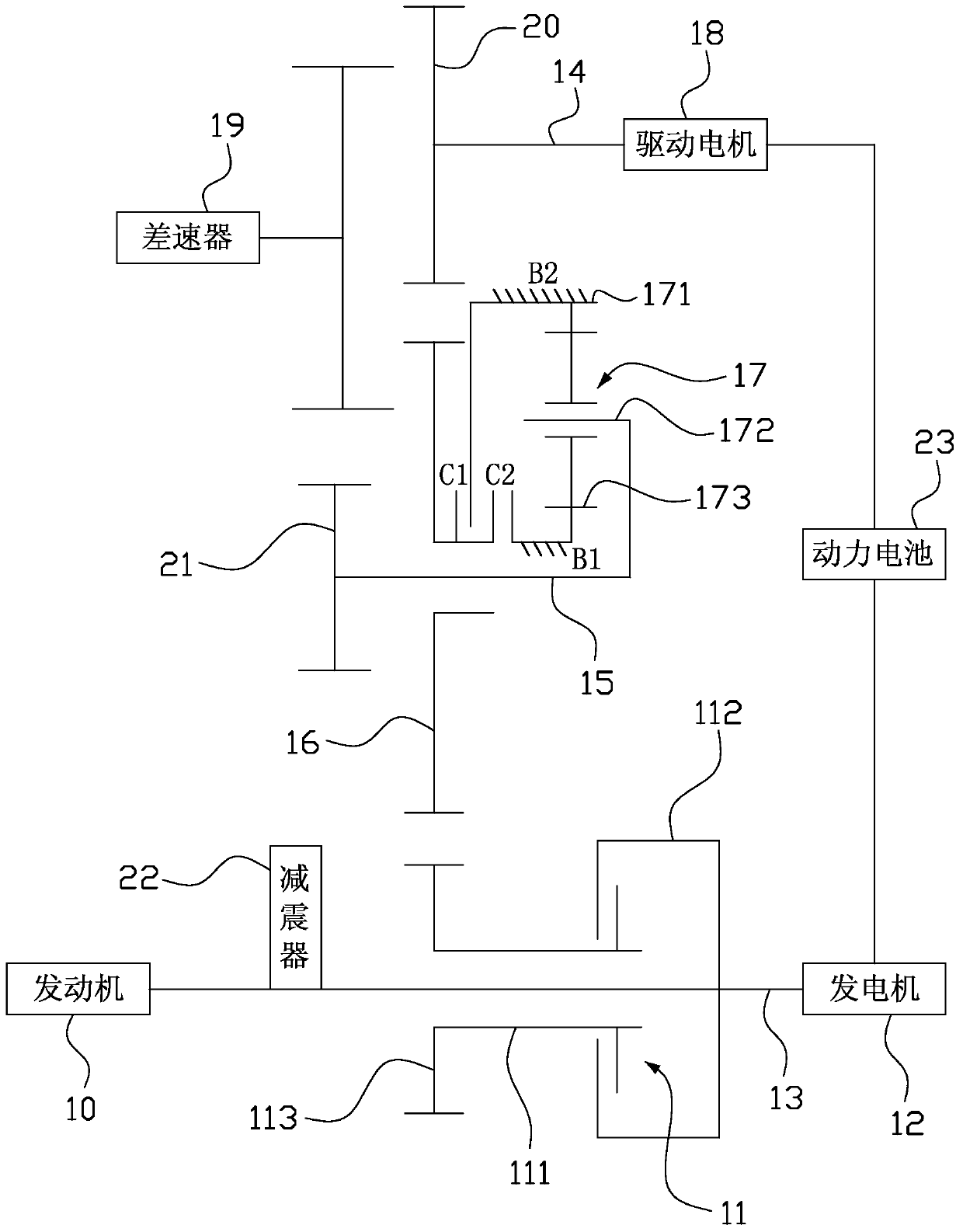

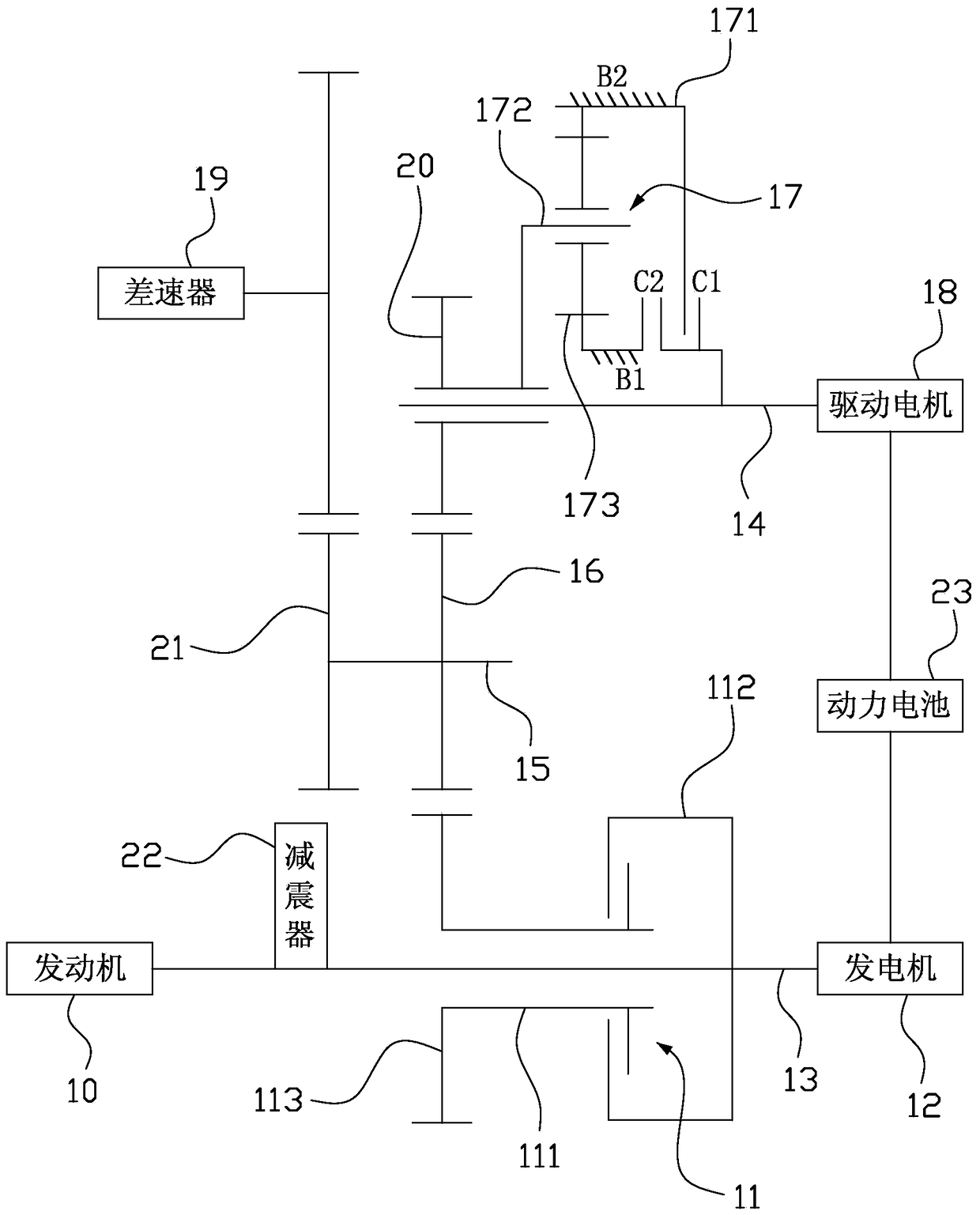

Hybrid two-gear gearbox transmission system and hybrid electric vehicle

ActiveCN106585359AShorten the axial lengthFew partsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelDrive motor

The invention relates to a hybrid two-shift gearbox transmission system. An engine is connected with an input shaft I, a clutch is provided with a driven end and a driving end, the driving end is fixed to the input shaft I, and the driven end is provided with a driven end gear which is meshed with a shift gear; an output shaft gear is fixed to an output shaft and is meshed with a differential mechanism; the shift gear sleeves the output shaft in a hollow manner; a planetary gear unit is mounted on the output shaft, and is provided with a gear ring, a planet carrier, a sun gear, a first clutch, a second clutch, a first brake and a second brake; the planet carrier is fixed to the output shaft, and the first clutch is arranged between the shift gear and the gear ring; the second clutch is arranged between the shift gear and the sun gear; and the first brake is used for locking the sun gear, the second brake is used for locking gear ring, a driving motor is connected with the input shaft II, the gear of the input shaft II is fixed to the input shaft II, and the gear of the input shaft II is meshed with the shift gear. The invention further provides a hybrid electric vehicle with the transmission system.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

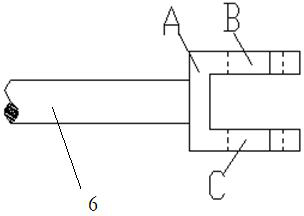

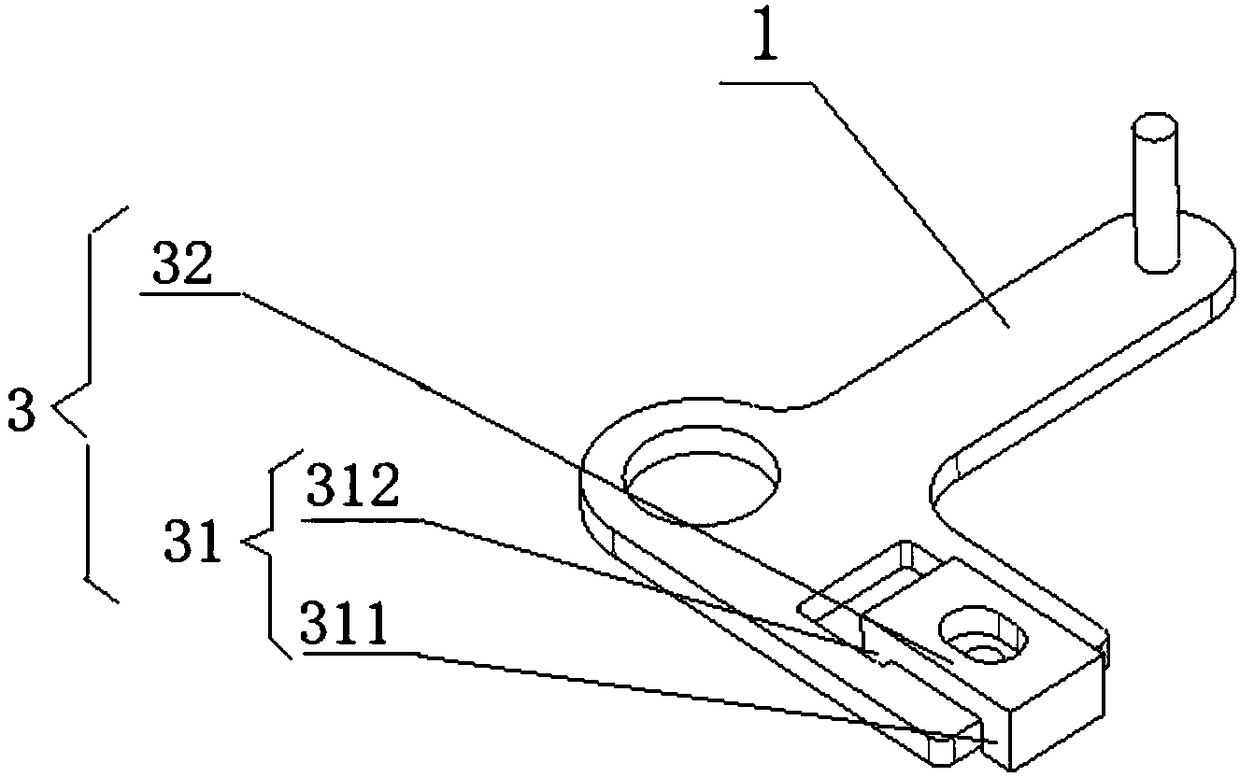

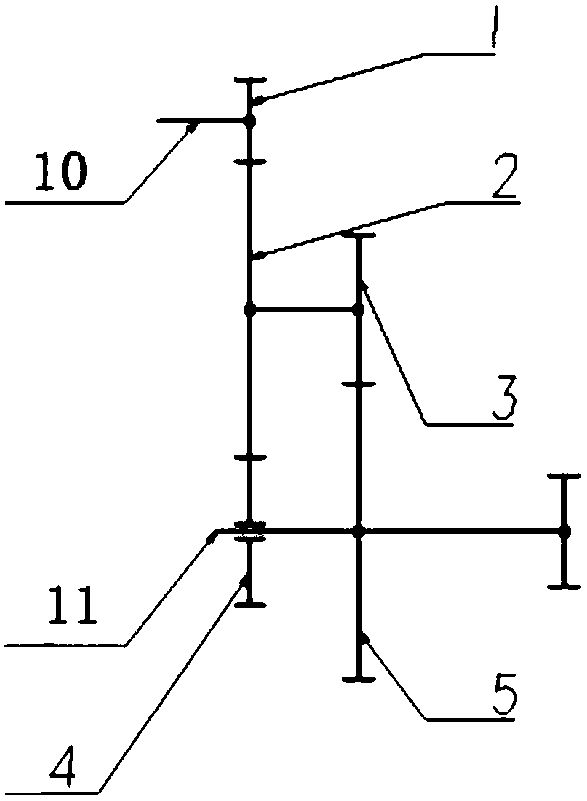

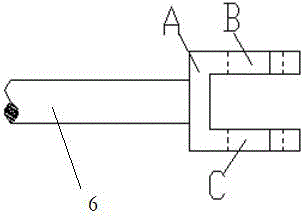

Screw rod gear selecting and gear shifting mechanism

The invention relates to a screw rod gear selecting and gear shifting mechanism, comprising a gear selecting mechanism and a gear shifting mechanism. The gear selecting mechanism is a screw rod gear selecting mechanism, and comprises a screw rod with the rotating axis parallel with a gear shifting shaft; a nut making linear motion along the rotating axis when the screw rod rotates is assembled on the screw rod, the nut is in transmission connection with a gear shifting fingerstall through a driven rod fixed with the nut, and the gear shifting fingerstall is axially assembled on a gear shifting finger along the gear shifting shaft in a limiting and rotating mode. The gear selecting mechanism is a screw rod-nut mechanism, wherein the nut is driven to make linear motion through driving the screw rod to rotate, the nut drives the gear shifting finger to slide along the gear shifting shaft through the driven rod, and the gear shifting finger glides to a position corresponding to a shifting fork shaft, therefore, gear selecting is realized. The gear shifting mechanism comprises a gear shifting shaft and a gear shifting finger matched with the gear shifting shaft through a spline. When the gear shifting shaft rotates, the gear shifting finger is driven to rotate so as to drive a shifting fork, and the corresponding shifting fork shaft is turned to move to a proper gear so that gear shifting is realized.

Owner:HENAN UNIV OF SCI & TECH

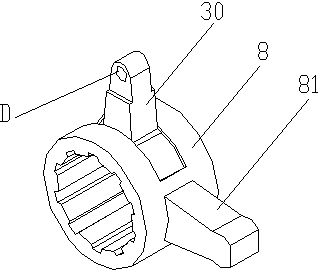

Gearshift mechanism, gearbox and electric vehicle

InactiveCN106609842ASimple and efficient operationIncreased Convenience and ComfortControlled membersGearing controlElectric vehicleEngineering

The invention provides a gearshift mechanism, a gearbox and an electric vehicle. The gearshift mechanism comprises a gearshift motor, a shifting fork shaft and a shifting fork. The gearshift motor is connected with the shifting fork shaft and used for driving the shifting fork shaft to rotate around the axis of the shifting fork shaft. The shifting fork is installed on the shifting fork shaft, and the shifting fork shaft can drive the shifting fork to move along the extension direction of the shifting fork shaft when the shifting fork shaft rotates around the axis of the shifting fork shaft. The shifting fork shaft is driven to rotate by using the gearshift motor in gearshifting, and the shifting fork shaft can drive the shifting fork to move along the extension direction of the shifting fork shaft when the shifting fork shaft rotates around the axis of the shifting fork shaft so as to realize gearshifting. Manual operation of a driver is not required in the gearshift process so that the gearshift operation is enabled to be easy and convenient, and the use comfortableness and convenience can be enhanced.

Owner:SOUTHWEST UNIVERSITY

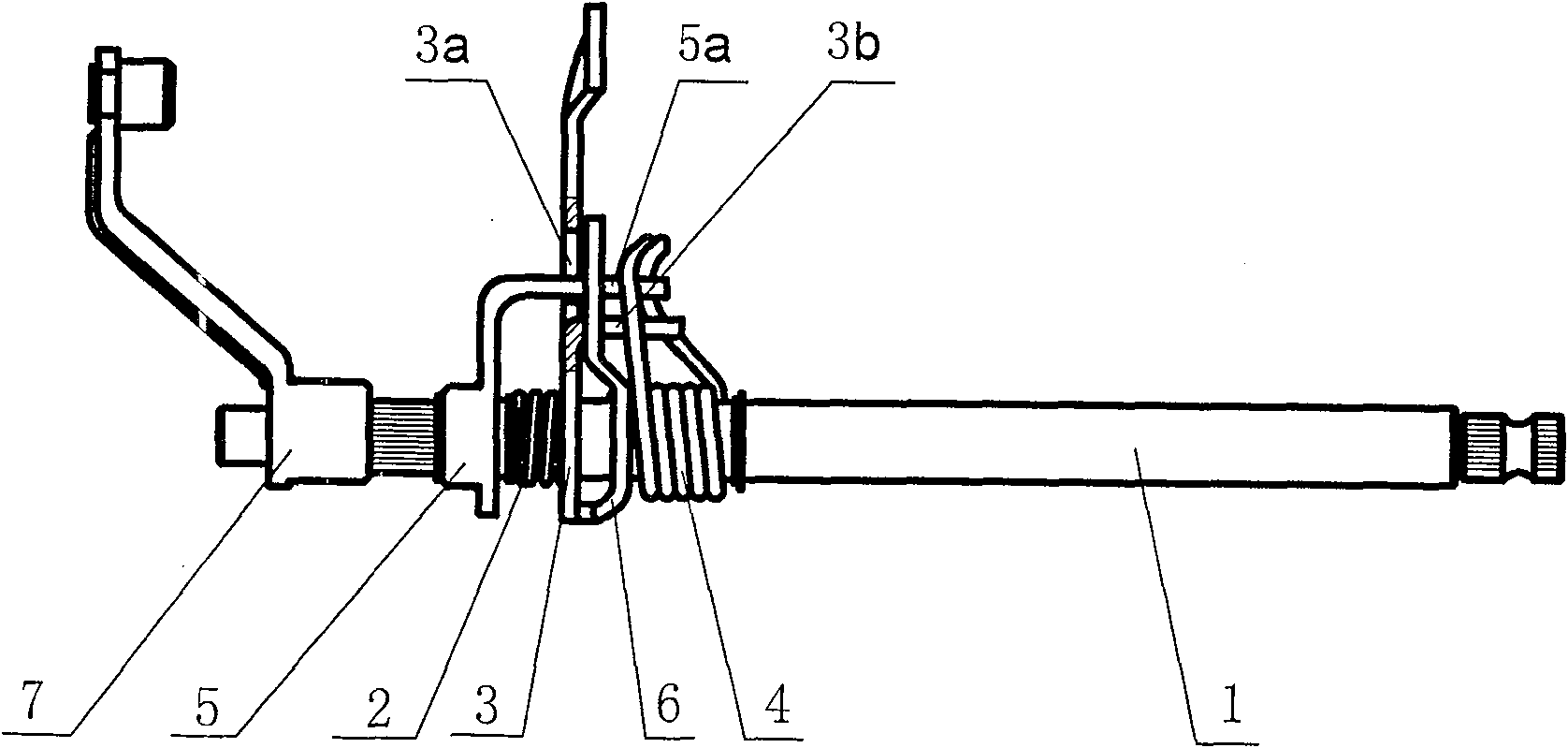

Gear selecting and shifting mechanism for cam

The invention relates to a gear selecting and shifting mechanism for a cam. The gear selecting and shifting mechanism comprises a gear selecting mechanism, a gear shifting mechanism and a double-shaft motor, wherein the gear selecting mechanism is a cam gear selecting mechanism and comprises a cylinder rotary cam, a rotation axis of the cylinder rotary cam and a gear shifting shaft are parellelly arranged, a driven roller is assembled in a rotary groove of the cylinder rotary cam in a guide sliding mode and linearly moves along the rotation axis when the cylinder rotary cam rotates, the driven roller is in transmission connection with a finger stall through a driven rod which is fixedly connected with the driven roller, the gear shifting finger stall is rotatingly assembled on a gear shifting finger in a limiting mode along the axial direction of the gear shifting shaft, and two output shafts of the double-shaft motor are connected with the cam and the gear shifting shaft in a driving mode through clutches which correspond to the two output shafts. The gear selecting mechanism is a transmission mechanism of the cylinder rotary cam, the gear selecting mechanism is used for driving the cylinder cam to rotate so as to drive the roller to move along a groove line of the surface of the cylinder cam, and the driven rod is enabled to drive the gear shifting finger to slide to a position of a corresponding fork shaft along the gear shifting shaft, so that gear selection is achieved.

Owner:HENAN UNIV OF SCI & TECH

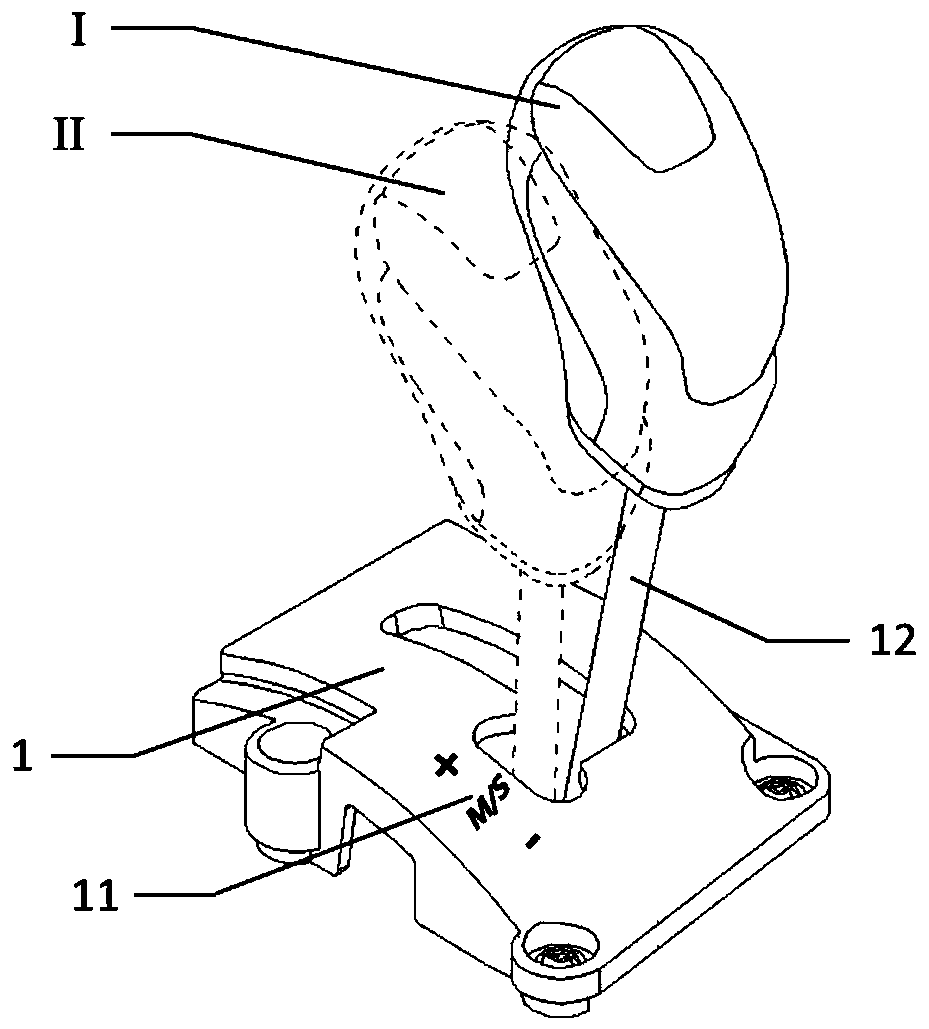

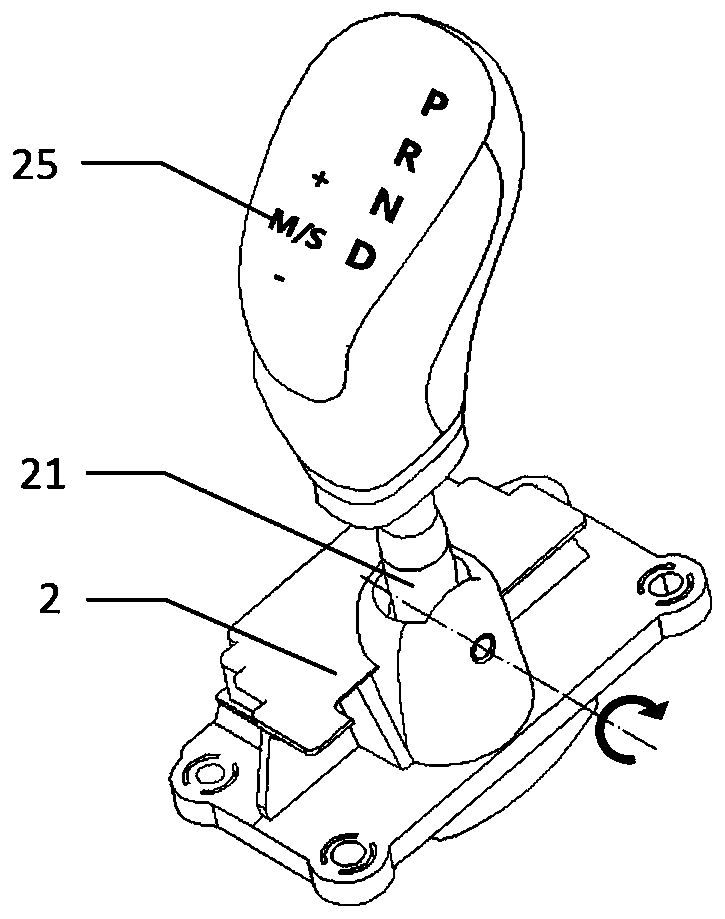

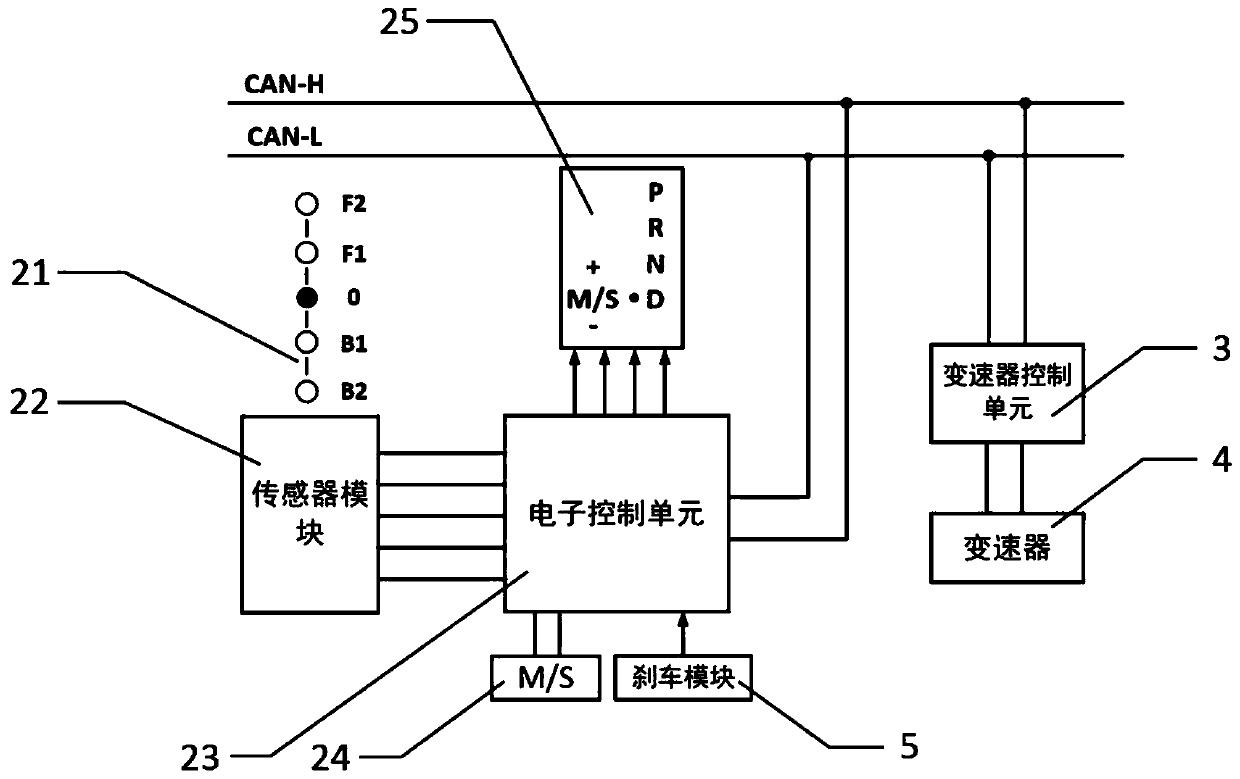

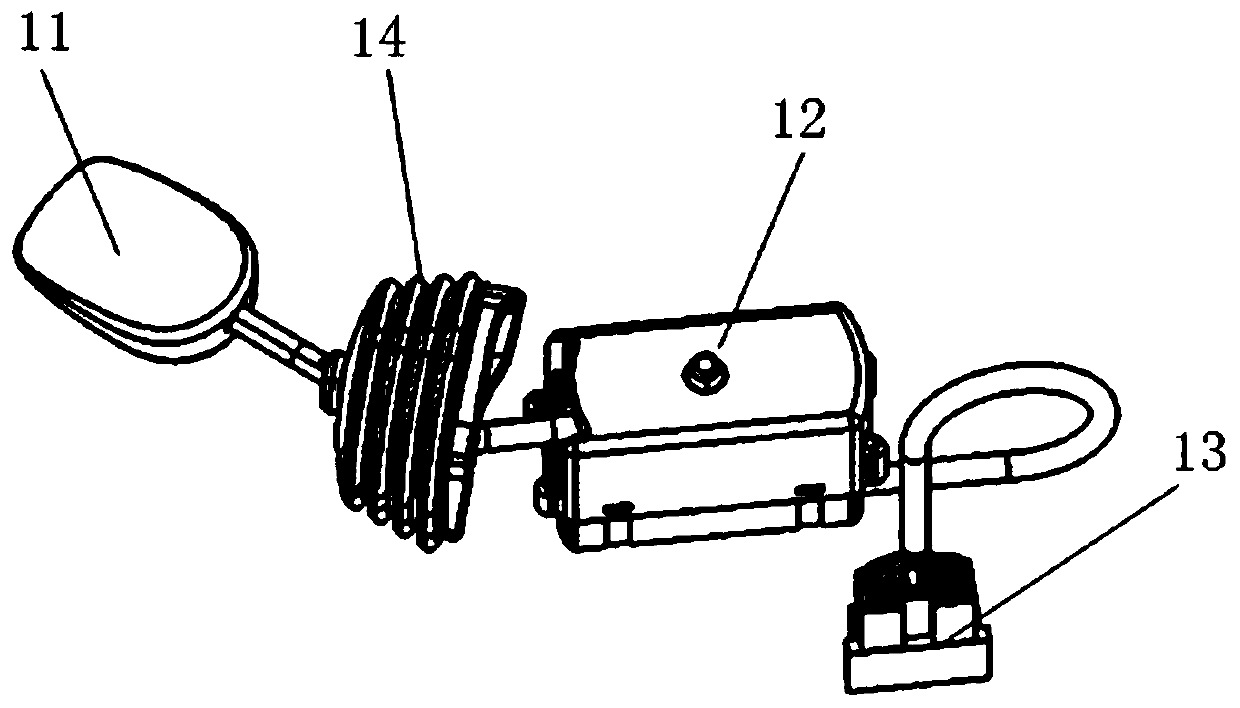

Rod electronic shifter and car

ActiveCN109812574BReduce volumeReduce development costsGearing controlDriver/operatorControl engineering

The invention discloses a rod type electronic gear shifter and an automobile. The rod type electronic gear shifter comprises a shifting rod component, a sensor module, an electronic control unit and M / S gear buttons; the shifting rod component is in a five-position mono-stability form; when the shifting rod component is pulled to a non-stable position and is released, the shifting rod component can be automatically returned to a stable position; the sensor module is used for detecting the pulling angle or position of the shifting rod component and transmitting the pulling angle or position tothe electronic control unit; the electronic control unit is used for acquiring a current gear signal of the overall automobile from a transmission control unit, acquiring a braking signal from a brakemodule, acquiring an input signal of a driver from the sensor module and the M / S gear buttons and calculating a target gear and sending the target gear to the transmission control unit according to preset rules and based on the acquired signals; and the transmission control unit is used for driving a transmission to be pulled to the target gear. The rod type electronic gear shifter disclosed by the invention can realize shifting of the M / S gears without additionally arranging a mechanical structure.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

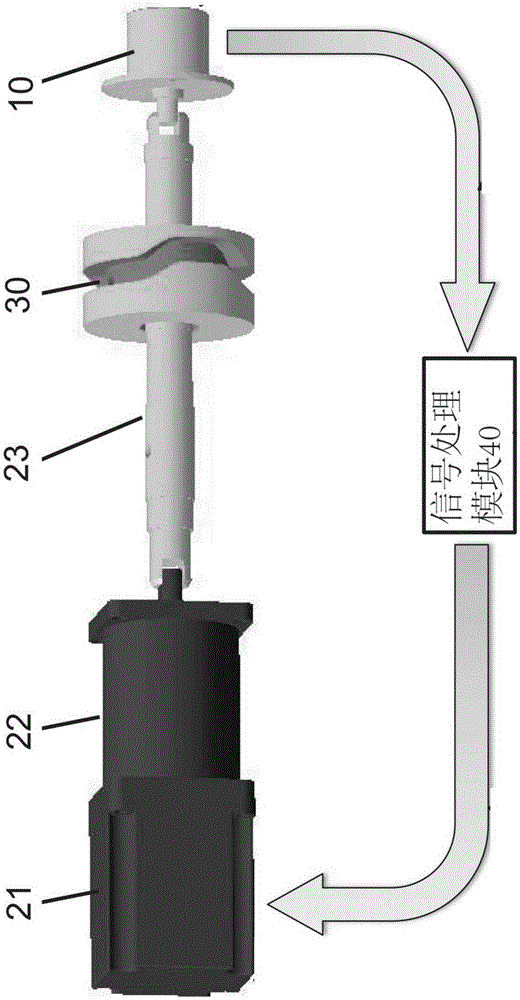

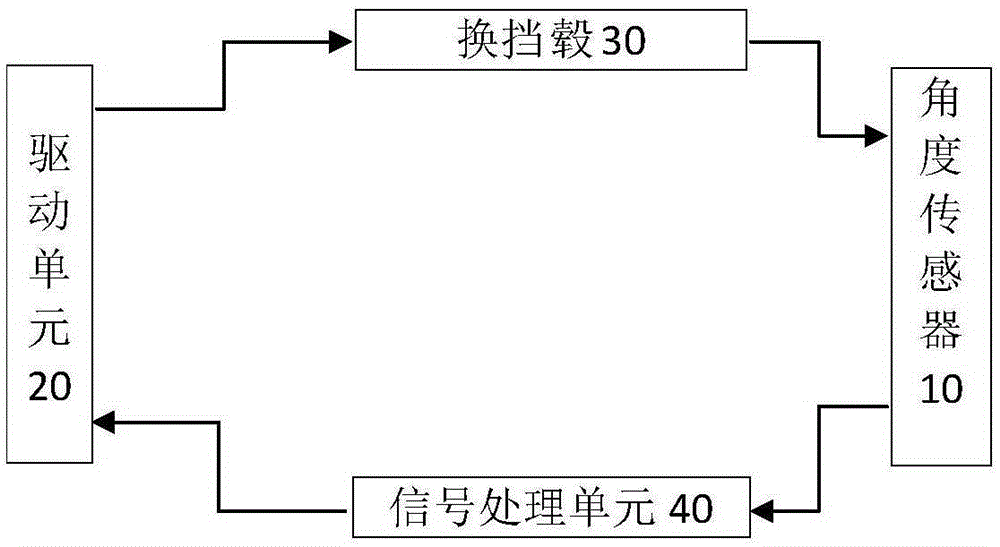

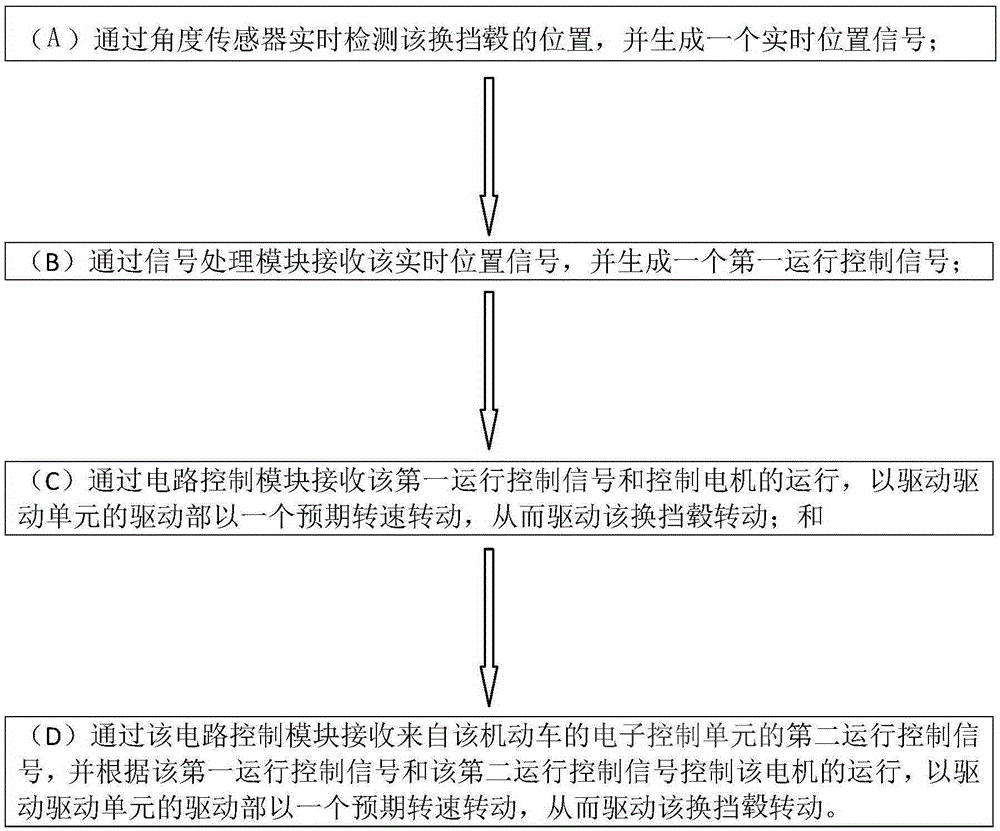

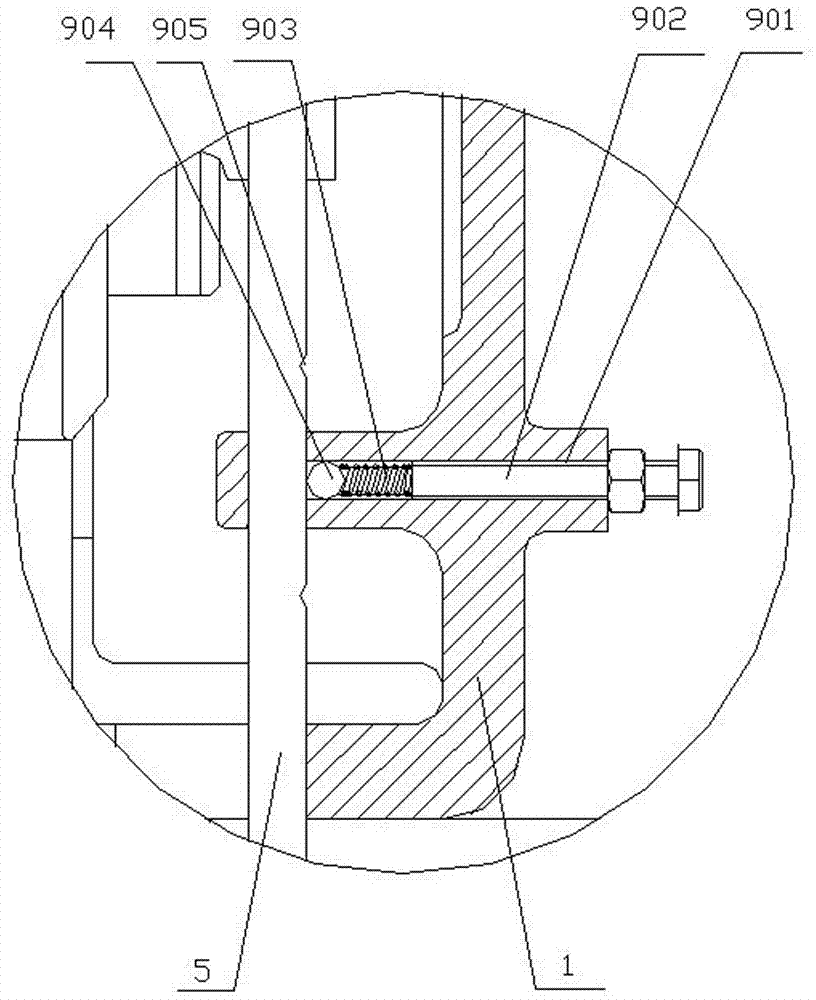

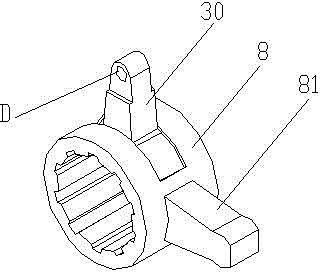

Gear shifting device for motor vehicle

InactiveCN105422838AStable and fast shiftingRealize closed-loop shift controlGearing controlControl signalControl theory

The invention discloses a gear shifting device for a motor vehicle. The gear shifting device comprises an angle sensor, a driving unit and a gear shifting hub. The angle sensor is arranged to face towards the gear shifting hub so as to detect the real-time position of the gear shifting hub and generate a real-time position signal and a signal processing module. The angle sensor is electrically connected with the signal processing module. The signal processing module can receive the real-time position signal from the angle sensor and generate a first operation control signal according to the real-time position signal. The signal processing module is electrically connected with the driving unit. The driving unit can receive the first operation control signal from the signal processing module and operate according to the first operation control signal so as to drive the gear shifting hub to rotate.

Owner:SHANGHAI ECOTORC VEHICLE TECH INC

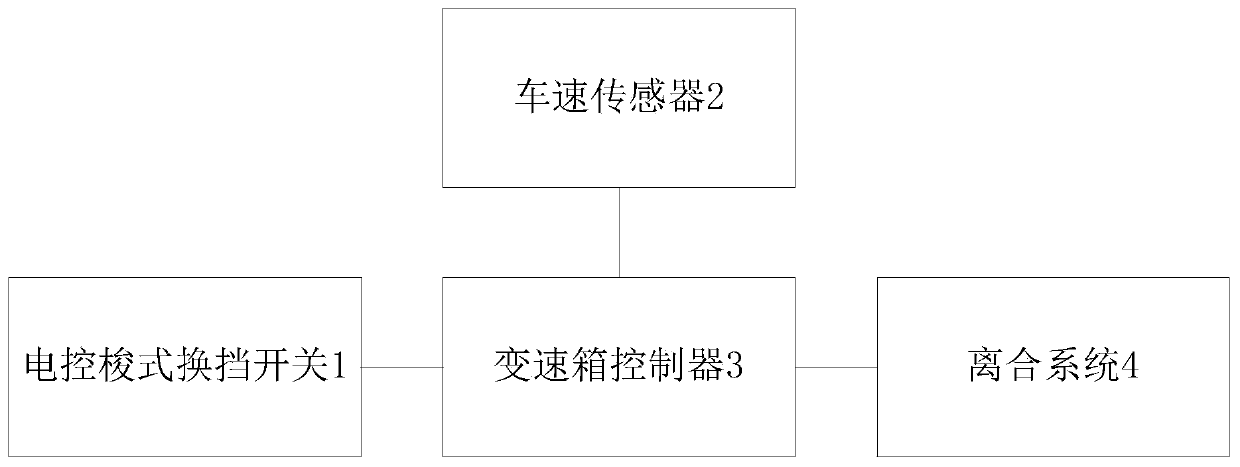

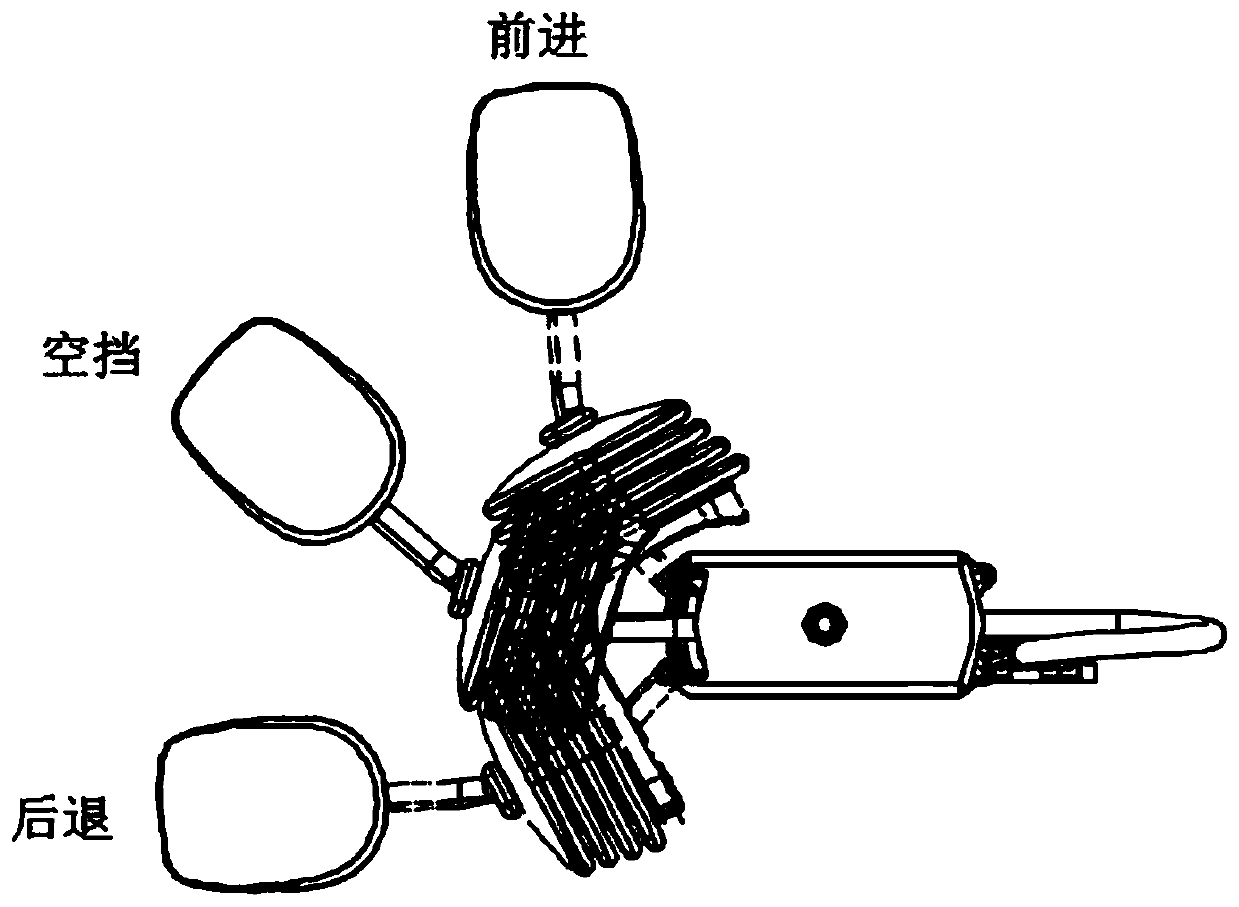

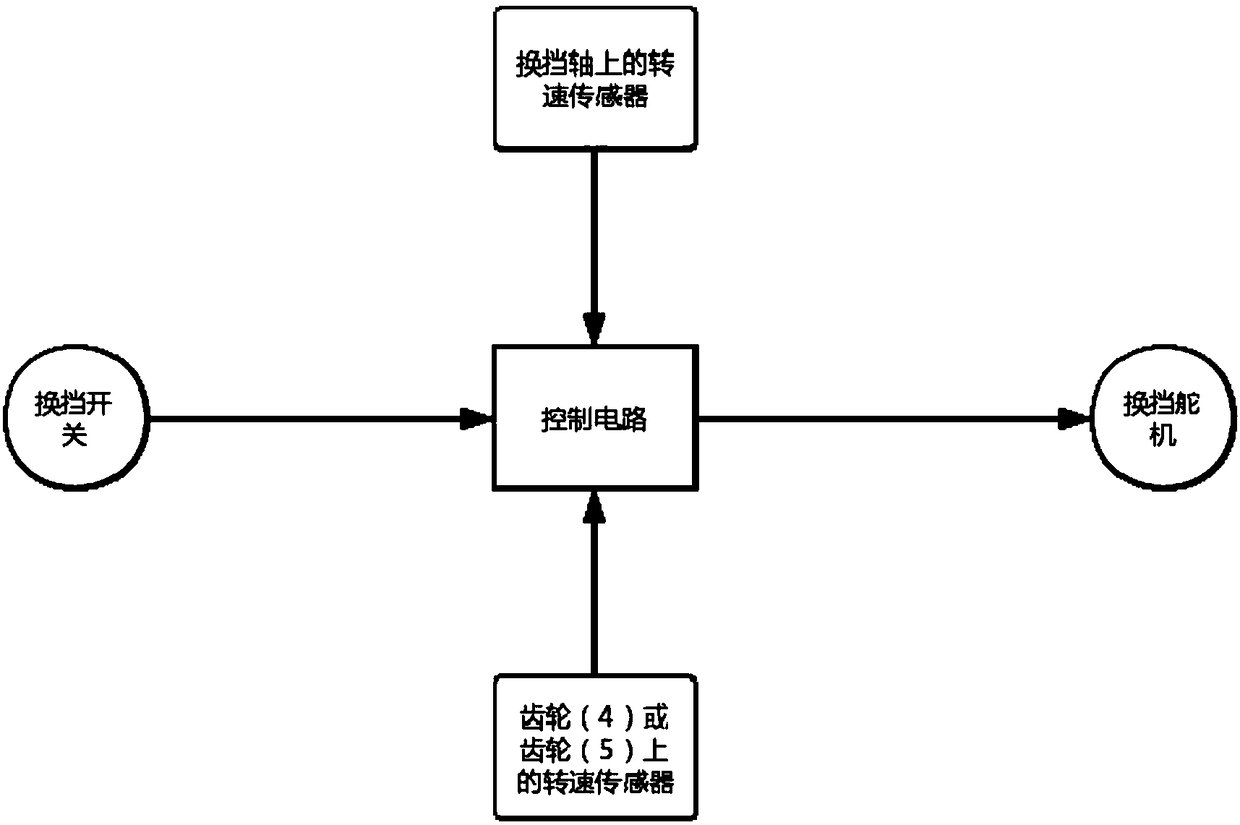

Electronically-controlled shuttle type gear shifting system and method

InactiveCN109764129AGear shiftingSolve the problem of reduced gear shift accuracyGearing controlControl theoryTractor

The invention discloses an electronically-controlled shuttle type gear shifting system and method, and relates to the field of tractors. The system includes an electronically-controlled shuttle type gear shifting switch, a vehicle speed sensor and a speed changing box controller; the electronically-controlled shuttle type gear shifting switch is used for generating a gear shifting signal accordingto gear shifting operation of a user; the vehicle speed sensor is used for acquiring the vehicle speed of a vehicle and generating a vehicle speed signal; and the speed changing box controller is used for judging whether the vehicle is in neutral or not according to the gear shifting signal, if the vehicle is not in neutral, whether the vehicle speed of the vehicle is 0 or not is judged accordingto the vehicle speed signal, if the vehicle speed of the vehicle is 0, separation and reunion of a clutch system are controlled according to the gear shifting signal, and gear shifting is achieved. According to the electronically-controlled shuttle type gear shifting system and method, electronically-controlled shuttle type gear shifting of the tractor is achieved, the problem that the gear shifting precision is low due to the fact that a pull line is used for a long time during pull-type gear shifting used by the tractor at present is solved, and the advantages that the gear shifting precision is high, and the gear shifting precision cannot be decreased after long-term use are achieved.

Owner:LOVOL HEAVY IND CO LTD

Electric vehicle driving system with stepless speed changing function

PendingCN112431904AChange tram speedChange speedControlled membersElectric propulsion mountingAutomotive engineeringElectric vehicle

The invention discloses an electric vehicle driving system with a stepless speed changing function. The electric vehicle driving system comprises a driving shaft and tires. A gearbox is arranged on the driving shaft and rotatably connected with the driving shaft, and a first-gear driven gear, a second-gear driven gear and a third-gear driven gear are fixedly installed on the portion, in the gearbox, of the driving shaft in sequence from left to right. A first rotating shaft is rotatably connected to the gearbox, a bearing is fixedly installed on the first rotating shaft, and a first-gear driving gear, a second-gear driving gear and a third-gear driving gear are rotatably connected to the bearing on the first rotating shaft in sequence from left to right. The first-gear driving gear, the second-gear driving gear and the third-gear driving gear are engaged with the first-gear driven gear, the second-gear driven gear and the third-gear driven gear in sequence. The speed of an electric vehicle is changed by arranging the gearbox.

Owner:SUPERSOCO INTELLIGENT TECHNOLOGY (SHANGHAI) CO LTD

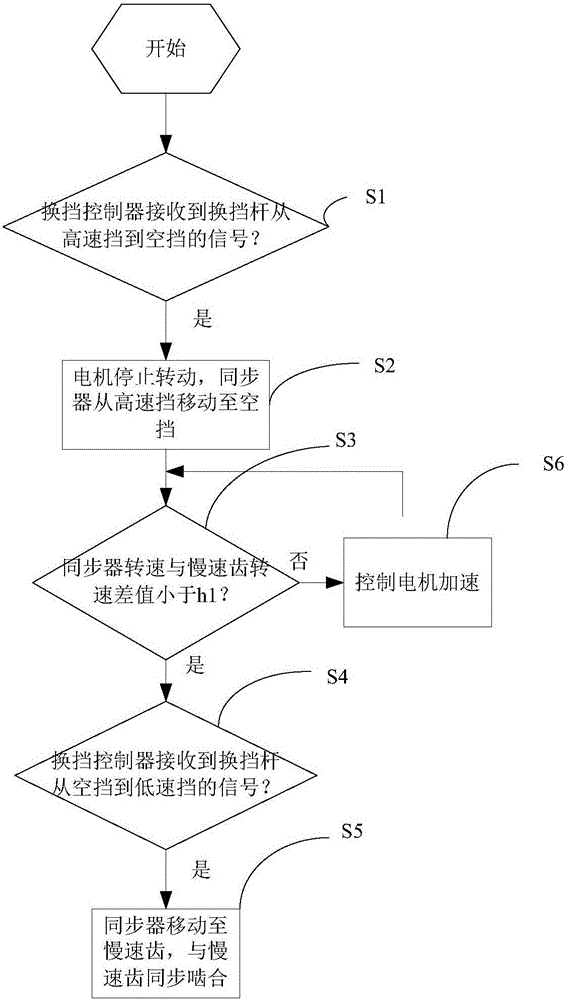

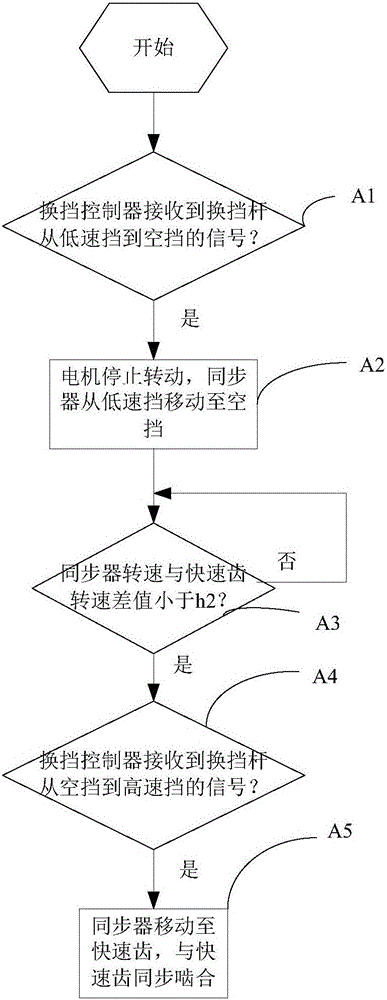

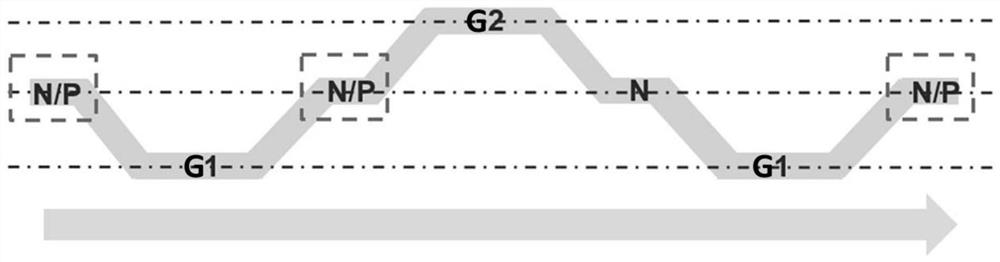

Manual gear shifting device of two-gear speed changing box

The invention discloses a manual gear shifting device of a two-gear speed changing box. In the process that an electric automobile is switched to a low-speed gear from a high-speed gear, after a synchronizer is moved to a neutral gear from the high-speed gear, a gear shifting controller firstly detects whether the difference value of the rotation speed of the synchronizer and the rotation speed of a low-speed tooth is smaller than the set value h1 or not, if the difference value of the rotation speed of the synchronizer and the rotation speed of the low-speed tooth is larger than the set value h1, it is shown that the rotation speed difference value of a synchronous tooth and the low-speed tooth is too large, gear shifting cannot be conducted, then the gear shifting controller controls a motor to accelerate so that the rotation speed of the low-speed tooth can be increased till the rotation speed difference value of the low-speed tooth and the synchronizer is smaller than h1, then the synchronizer is stirred to the low-speed tooth position, synchronous engagement is achieved, and gear shifting is achieved. By utilization of the method, any switchover from the high-speed gear to the low-speed gear can be achieved for the electric automobile.

Owner:重庆瑞阳鑫驰新能源汽车有限责任公司

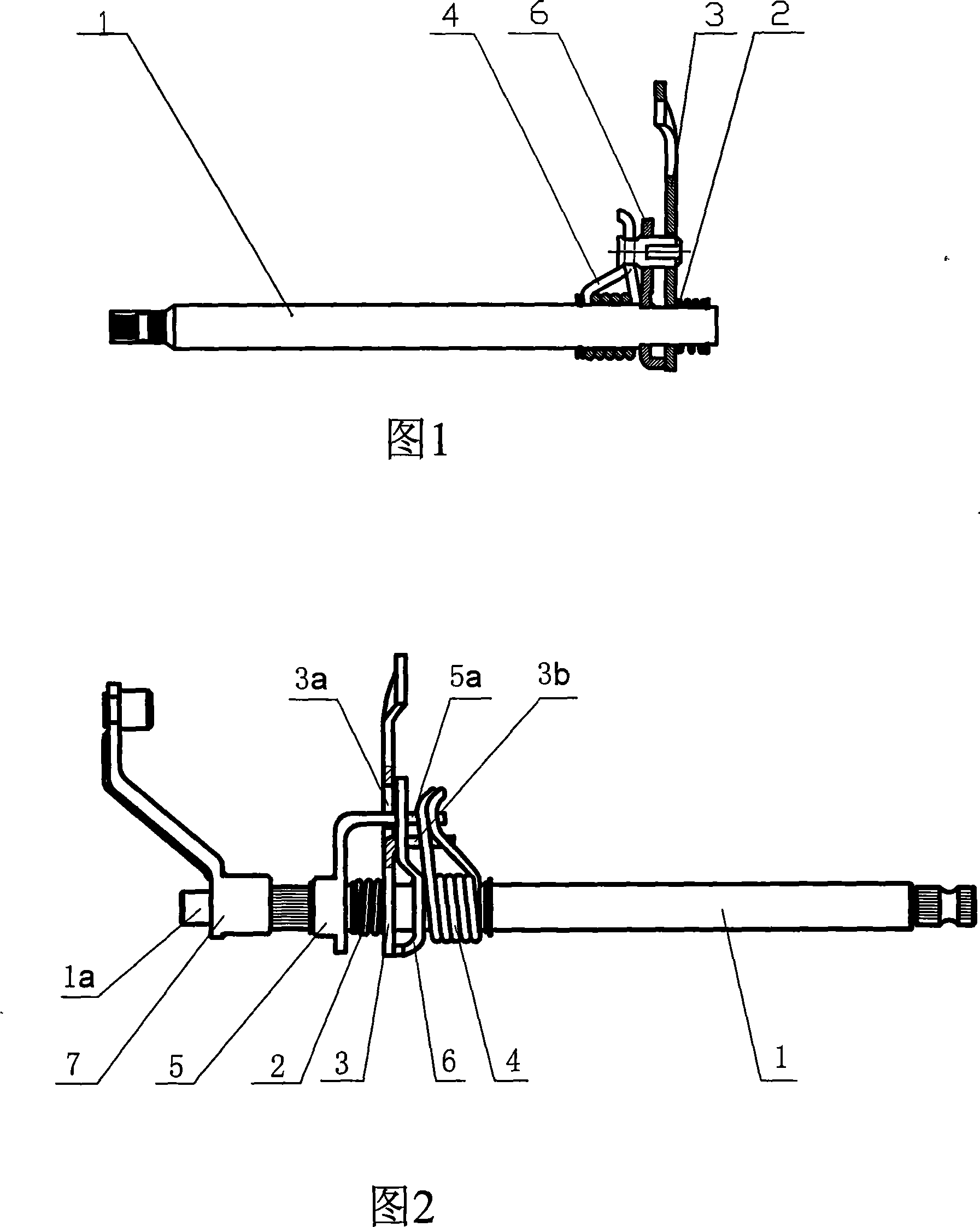

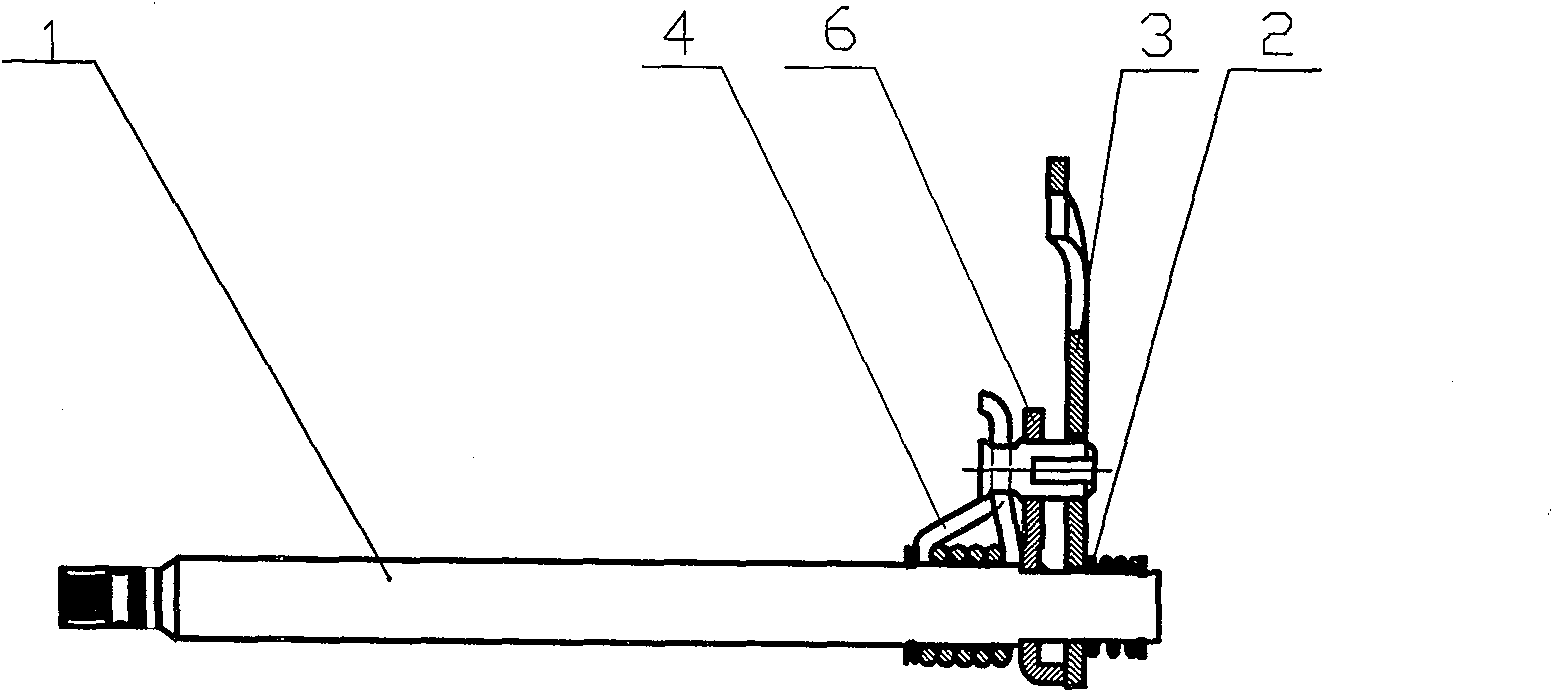

Automatic double-clutch engine gear arm

This invention is automatic double clutches engine gear change arm. There are locating reed, first driving board, spacing board, reset reed, gasket and clasp on the gear changing shaft. The said first driving board is active cased on the gear changing shaft. The spacing board and gear changing shaft are welded together. The slot, which bottom edge has bend arm, is set on the middle part of the said first driving board. The bend arm is set between the two clamping feet of reset reed. The reset reed is locked by clasp. The 'L' shaped second driving board is welded on the gear changing shaft outside locating reed. The bend arm of second driving board passes through slot and extends into two clamping feet of reset reed. The reset reed is arranged between first and second driving boards. The gear changing shaft outside the second driving board is arranged with operating arm through spline. This invention can automatically separate the clutch when changing gear.

Owner:胡光宇

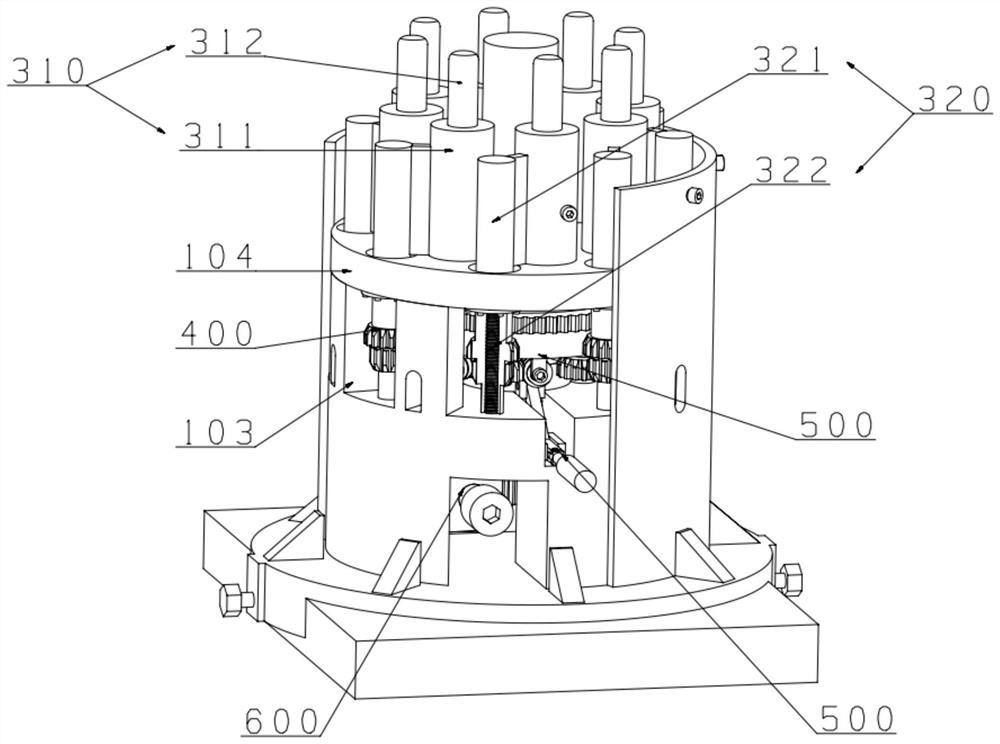

A planetary gear shift mechanism driven by a motor

ActiveCN104329455BSimple internal structureSimple installation structureRoad transportGearing controlCircular discBall screw drive

The invention relates to a planetary gear shifting mechanism driven by a motor. The shifting mechanism is composed of a planetary gear mechanism, a synchronizer and a shift fork mechanism; the planetary gear mechanism includes a sun gear, an inner ring gear, a planetary carrier and three planetary gears; the planetary carrier is coaxially connected by a disc Formed around a rotating shaft, three planetary gears are evenly distributed on the disc, and the three planetary gears mesh with the center wheel and the ring gear at the same time; one side of the ring gear is connected with a tubular bushing, and the bushing is set on the On the rotating shaft of the carrier; one side of the synchronizer is sleeved on the shaft sleeve of the inner ring gear, and the other side of the synchronizer is sleeved on the rotating shaft of the planetary carrier; the shift fork mechanism includes a shift fork, a ball screw and a servo motor. The present invention adopts the ball screw driven by the servo motor to drive the shift fork to realize the shifting; the shifting impact is relatively small, and the smoothness and service life of the shifting are improved; the servo motor is powered by the car battery, which does not directly consume the kinetic energy of the engine, effectively improving the the efficiency of the engine.

Owner:HEFEI UNIV OF TECH

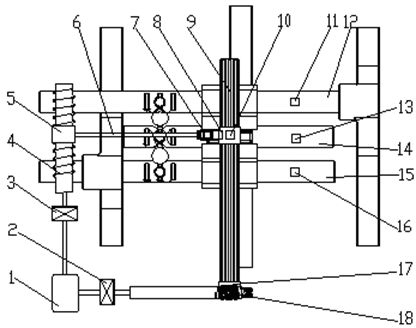

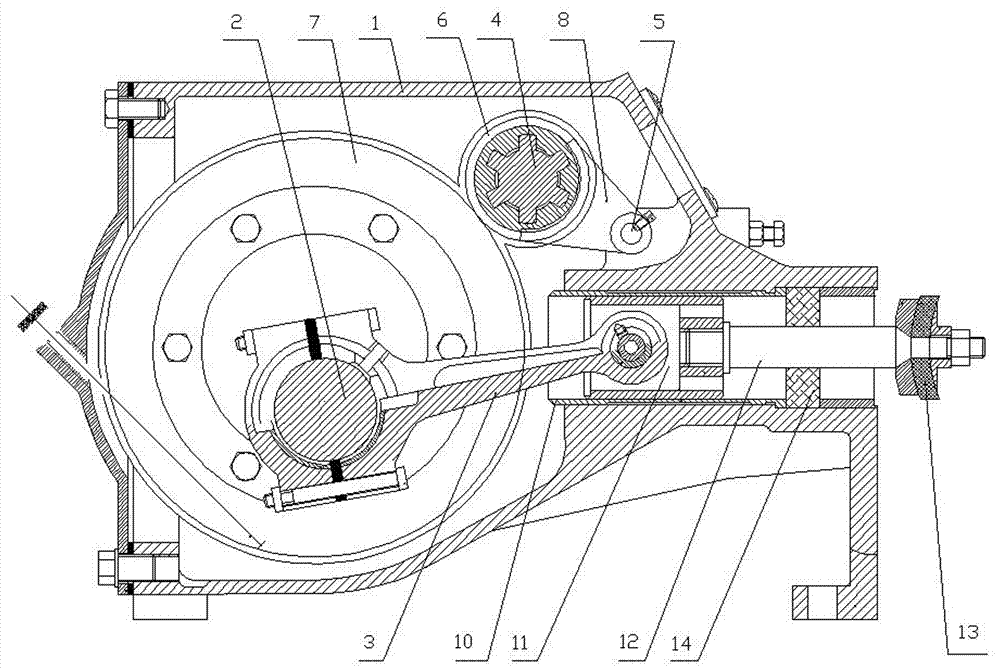

Power box for reciprocating drilling mud pump

InactiveCN107529588AReduce size and weightCombined volume is smallPositive displacement pump componentsPiston pumpsReduction driveDrive shaft

The invention relates to the field of drilling equipment and in particular relates to a power box for a reciprocating drilling mud pump. The power box comprises a box body, wherein a crankshaft is rotationally arranged in the box body; a connecting rod is arranged on the crankshaft in a matched manner; a driving shaft and a gear-shifting shaft parallel to the crankshaft are arranged in the box body; a gear-shifting driving gear set capable of axially sliding along the driving shaft is arranged at a part, which is positioned in the box body, of the driving shaft in a sleeving manner; a gear-shifting driven gear set corresponding to the gear-shifting driving gear set is arranged on the crankshaft; and a shifting fork used for shifting the gear-shifting driving gear set and the gear-shiftingdriven gear set to be in corresponding meshed connection is arranged at a part, which is positioned in the box body, on the gear-shifting shaft. The power box disclosed by the invention is compact instructure and stable in performance and has a speed control gear-shifting function, and the quantity of gears of a reducer matched with the power box can be reduced under the condition that the size is basically invariable, so that the mud pump reducer assembly has small spacing size and multiple gear options and has a wide application range under the well.

Owner:LUOYANG INST OF SCI & TECH

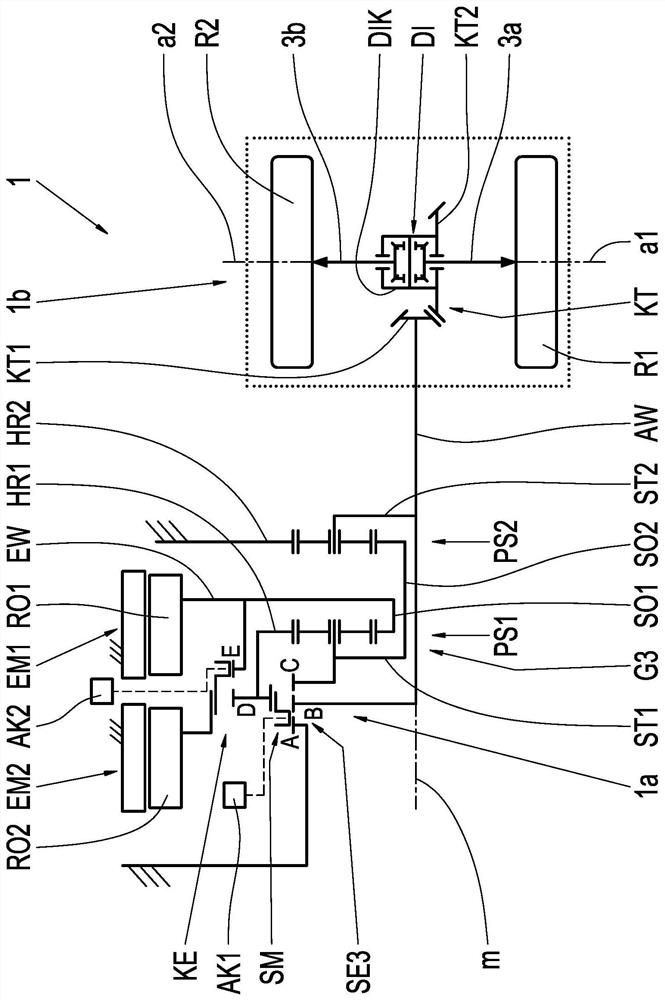

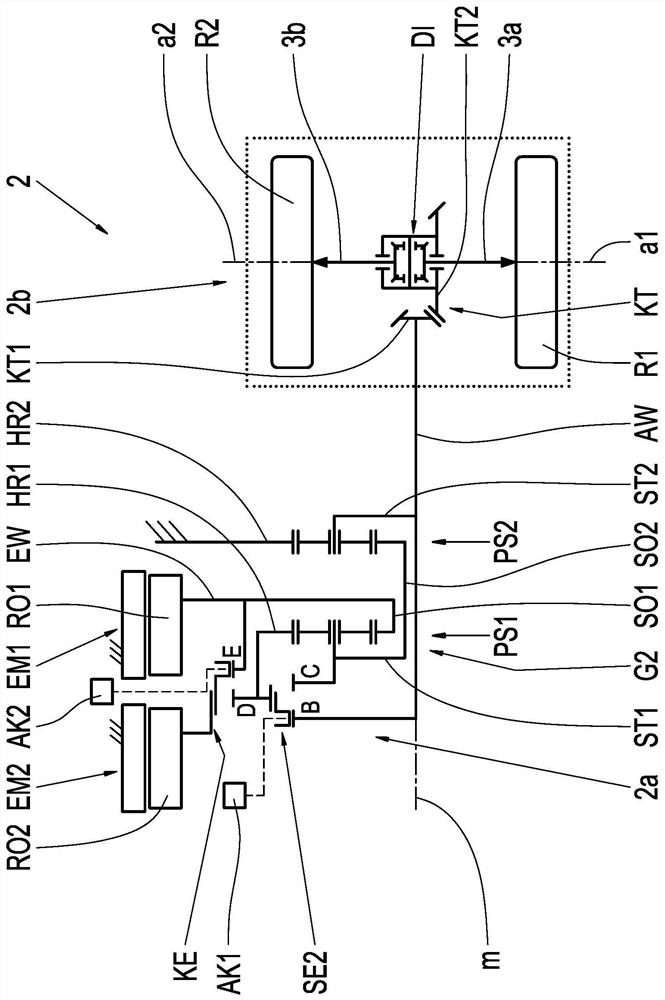

Drive arrangement for electric vehicle and method for power shifting

PendingCN112728023AIncrease drive powerTraction interruptionElectric propulsion mountingToothed gearingsRotational axisDrive wheel

Owner:ZF FIEDRICHSHAFEN AG

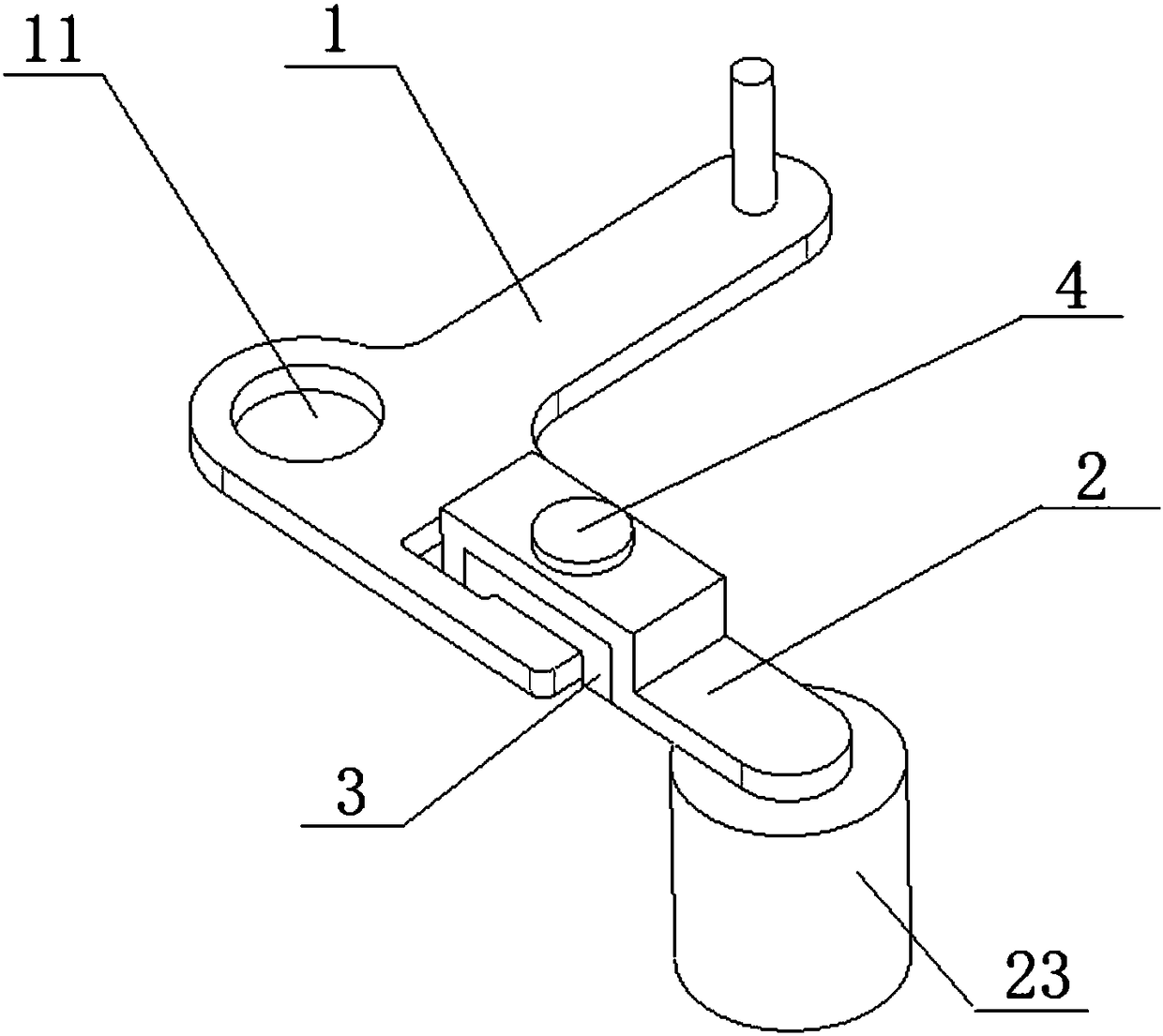

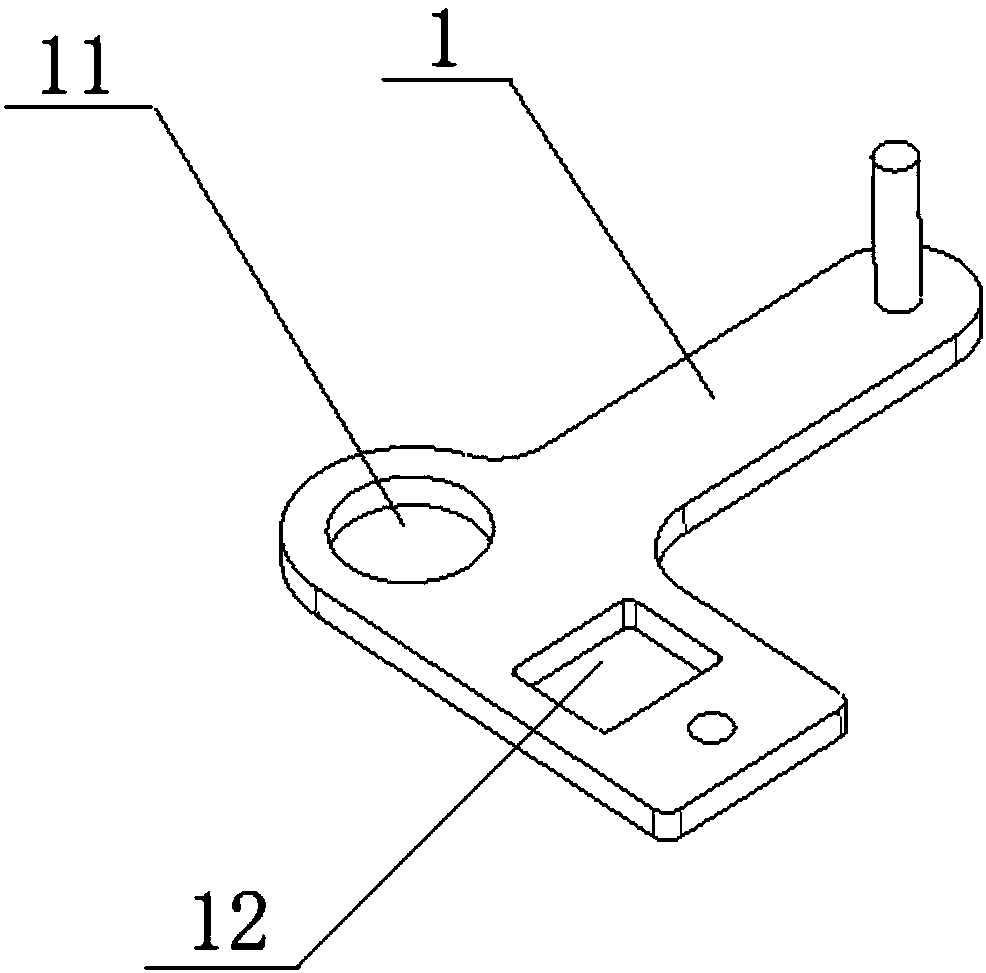

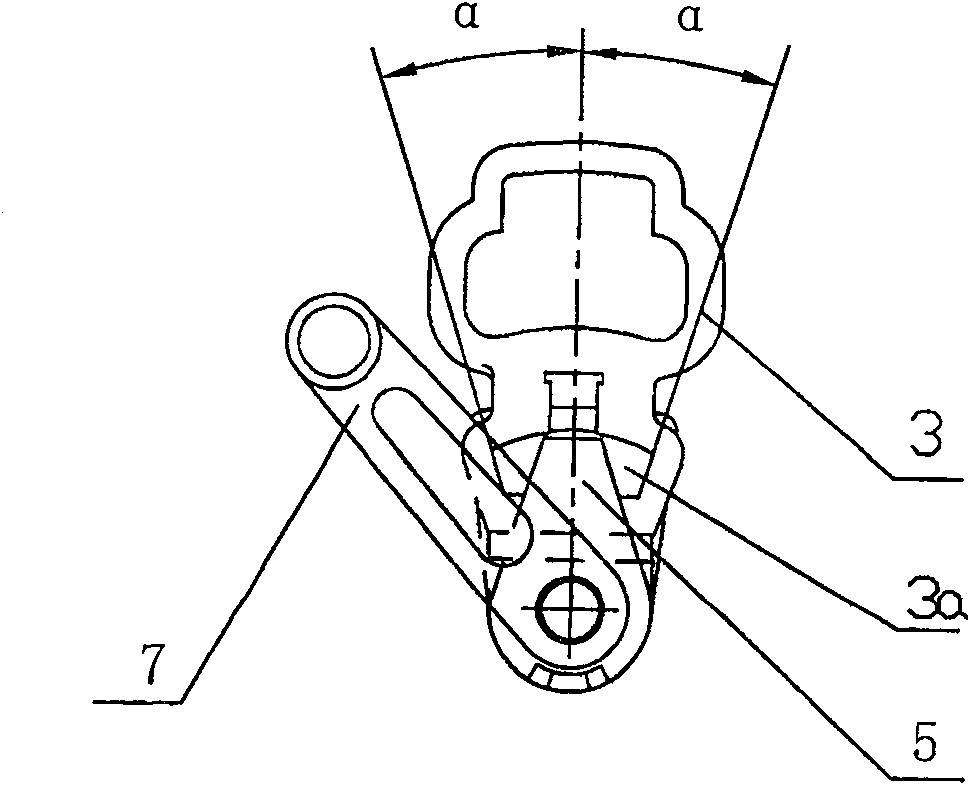

Gear selection and shift control mechanism and gear shift rocker arm assembly thereof

InactiveCN108612842AMinimize the impact of comfortIncrease the moment of inertiaGearing controlEngineeringRocker arm

The embodiment of the invention provides a gear selection and shift control mechanism and a gear shift rocker arm assembly thereof. The gear shift rocker arm assembly comprises a gear shift rocker arm, a balance weight device connected to the gear shift rocker arm and a damping device arranged between the gear shift rocker arm and the balance weight device and used for isolating the gear shift rocker arm from the balance weight device. According to the gear selection and shift control mechanism and the gear shift rocker arm assembly thereof, vibration transmitted by an engine to a gear shift handle can be reduced.

Owner:SCHAEFFLER TECH AG & CO KG

A gear selection actuator and automatic transmission

InactiveCN103016711BAvoid the risk of tooth collisionGear shiftingControlled membersGearing controlAutomatic transmissionEngineering

The invention discloses a gear selecting and shifting actuating mechanism and an automatic transmission and relates to the technical field of transmissions, aiming at preventing the situation that gears collide with each other from occurring during gear selection of the transmission. The gear selecting and shifting actuating mechanism comprises a gear selecting motor, a gear selecting shaft, a gear shifting motor, a gear shifting shaft, a gear shifting block, shifting fork shafts and shifting forks, wherein the gear selecting motor is connected with the gear selecting shaft in a driving way, the gear shifting motor is connected with the gear shifting shaft in a driving way, the gear selecting shaft is connected with the gear shifting shaft through a thread pair, the gear shifting block which can rotate along the circumferential direction of the gear shifting shaft is sheathed on the gear shifting shaft, the shifting fork shafts are arranged below the gear shifting block and are arranged at intervals in parallel along the axial direction of the gear shifting shaft, and a shifting fork is fixedly arranged on each shifting fork shaft. When the gear shifting block rotates along the circumferential direction of the gear shifting shaft, one shifting fork shaft is driven to move along the axial direction of the shifting fork shaft. The gear selecting and shifting actuating mechanism is mainly used in automobile transmissions.

Owner:GREAT WALL MOTOR CO LTD

Electronic gear shifting device

The invention discloses an electronic gear shifting device which comprises an upper support, a lower support, a gear shifting return mechanism and an induction mechanism. The upper support and the lower support are matched to form a containing cavity, a sliding groove is formed in the upper support, and a gear block is assembled on the lower support; the gear shifting return mechanism is assembled in the containing cavity, extends out of the containing cavity through the sliding groove and is used for moving along the sliding groove and the gear block to achieve gear shifting and automatic return; and the induction mechanism is arranged on the upper support and used for forming a gear signal according to the movement position of the gear shifting return mechanism. The electronic gear shifting device does not need to be manually returned by a user, effectively improves the gear shifting efficiency, and meanwhile has the advantages of being simple in structure and effectively saving cost.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

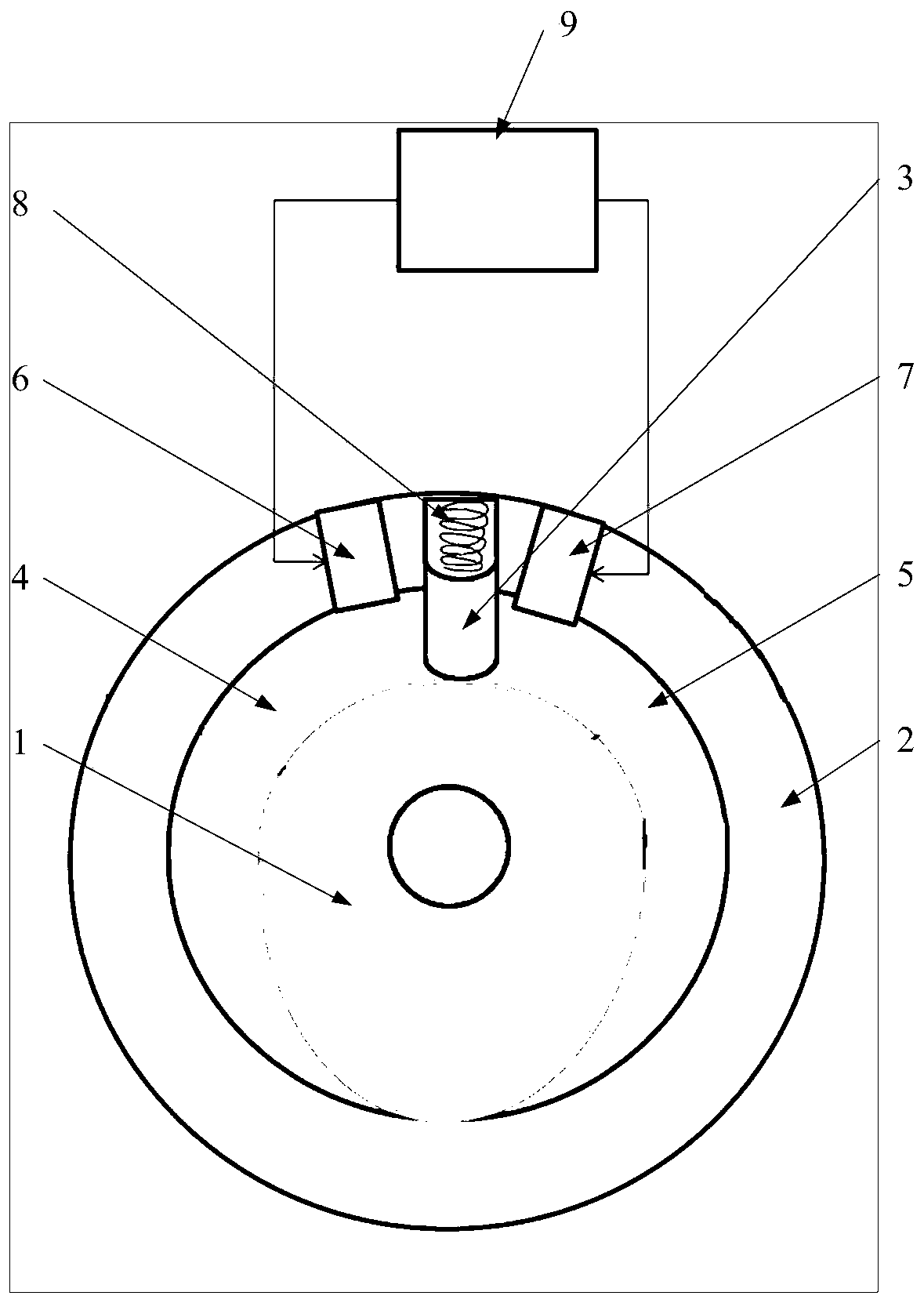

A clutch and a vehicle with the clutch

ActiveCN107489708BExtended service lifeRealize automatic controlFluid actuated clutchesAutomatic controlDrive shaft

The invention discloses a clutch. The clutch comprises a driving shaft, a driven shaft, and a transmission part static relative to the peripheral direction of the driven shaft or the driving shaft; the driven shaft and the driving shaft are embedded, and a closed first inner cavity is defined by the driving shaft, the driven shaft and the transmission part; the first inner cavity is provided with a first valve; in a closed state of the first valve, the driving shaft is rotated to compress a medium in the first inner cavity to push the driven shaft to rotate; and in an open state of the first valve, when the driving shaft rotates, the driven shaft can be kept static. The clutch realizes the engaging and disengaging function through gentle motion of the medium in the first inner cavity; and acute friction heating cannot be generated in the engaging and disengaging process, so that the friction ablation problem is prevented, the service life of the clutch is effectively prolonged, and the energy loss is reduced. Meanwhile, the clutch needs no special clutching hydraulic mechanism, can realize automatic control of a harness, and is simple and reliable in structure. The invention further discloses a vehicle comprising the clutch; and the same technical effects are achieved.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

Electric vehicle four gear manipulator

ActiveCN105946566BPrevent affecting driving safetyGear shiftingGearing controlControl devicesElectric machineSteering control

The invention discloses an electromobile four-gear manipulator which comprises a base, a shell, a spindle, a gear rod, a handle and a gear shift signal generating device. The shell is fixedly mounted on the top surface of the base, a rectangular notch is formed in the middle of the base, the spindle is horizontally arranged in the rectangular notch penetratingly and fixedly connected with the base, an arc-shaped long slotted hole is formed in the top surface of the shell, an rotation axis of the arc-shaped long slotted hole is parallel to an axis of the spindle, the gear rod penetrates the long slotted hole in the top surface of the shell, a shaft sleeve arranged at the lower end of the gear rod is mounted on the outer side of the spindle in a sleeved manner, the handle is fixedly mounted at the top end of the gear rod, and the gear shift signal generating device is mounted between the gear rod and the shell. The electromobile four-gear manipulator is used for realizing gear shift of an electromobile; the gear shift signal generating device is mounted between the shell and the gear rod, a gear shift signal is triggered solely by swinging the gear rod, and a gear shift signal output end is connected with an electromobile driving motor to realize control on rotating speed and steering. Compared with existing manipulators, the electromobile four-gear manipulator is more compact in structure and convenient to mount.

Owner:河北科超汽车配件有限公司

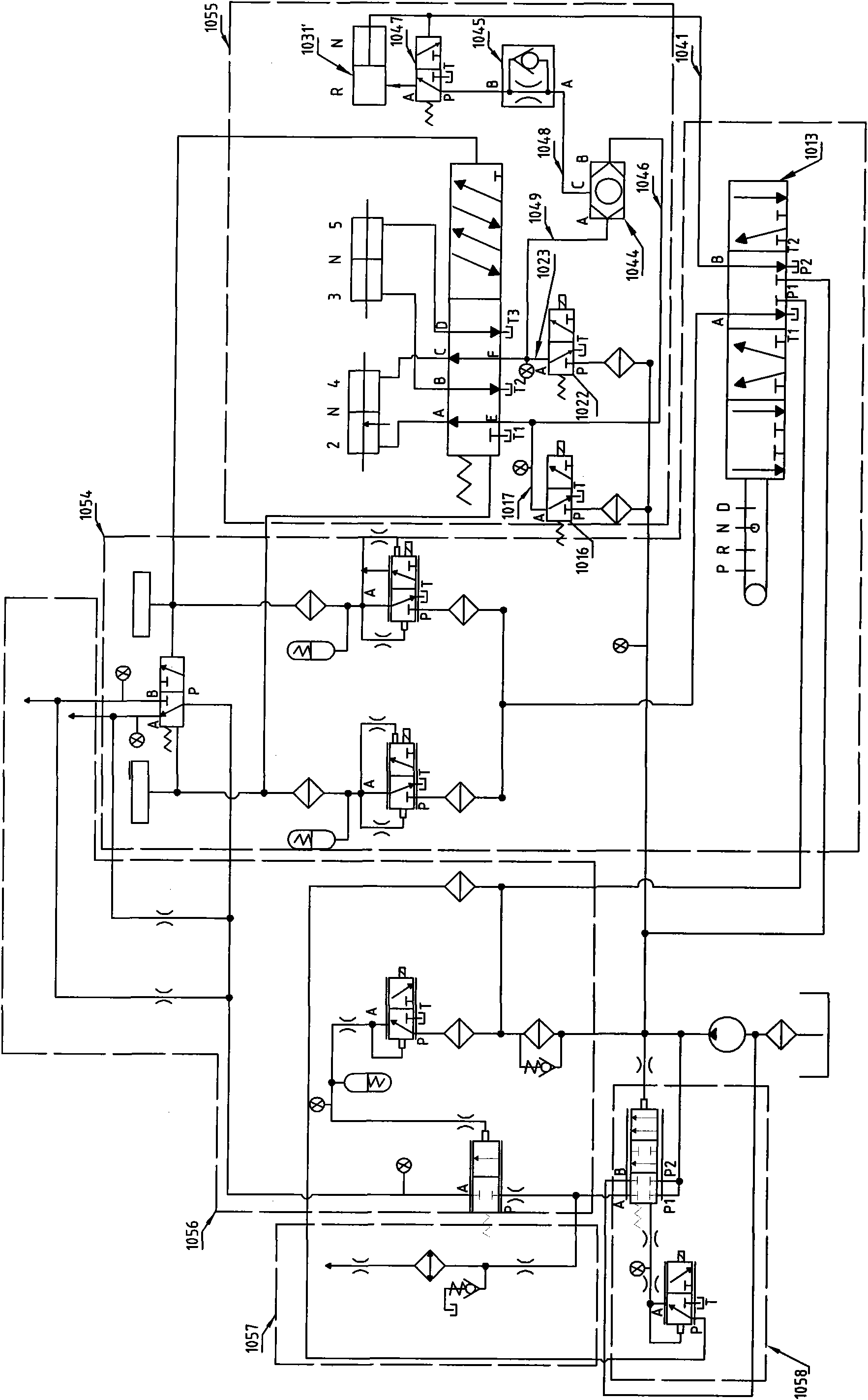

Hydraulic control system of dual-clutch automatic transmission

ActiveCN101943261BGear shiftingReduce stiffnessGearing controlFluid gearingsClutch controlAutomatic transmission

The invention relates to a hydraulic control system of a dual-clutch automatic transmission. The system comprises a clutch control module, a shift control module, a clutch cooling module, a shafting cooling module and a main pressure-regulating module, wherein two shift electromagnetic valves and an R-gear shift cylinder are arranged inside the shift control module; a shift valve is arranged in the clutch control module; the R-gear shift cylinder is communicated with the shift valve through an R-gear shift oil way; an R-gear empty oil way is respectively extracted in parallel from output oil ways of the two shift electromagnetic valves; the two R-gear empty oil ways are connected with two input ends of a shuttle valve respectively; and an output end of the shuttle valve is communicated with the spring chamber of the R-gear shift cylinder through an empty output oil way. The hydraulic control system effectively solves the technical problem of unreliable return of an R gear of the dual clutch, makes the return of the R gear of the dual clutch more reliable and improves the working reliability of the hydraulic control system of the dual-clutch automatic transmission.

Owner:CHONGQING TSINGSHAN IND

A bicycle transmission mechanism with a built-in planetary transmission

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

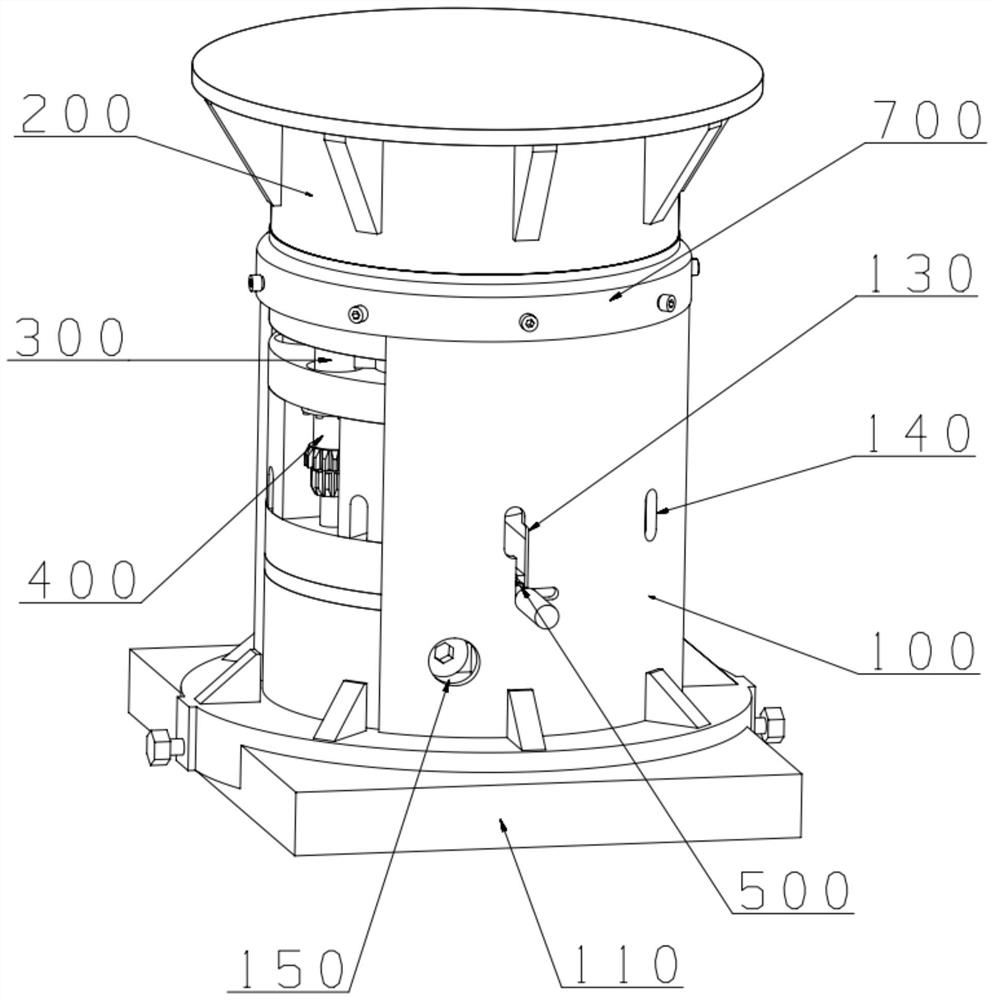

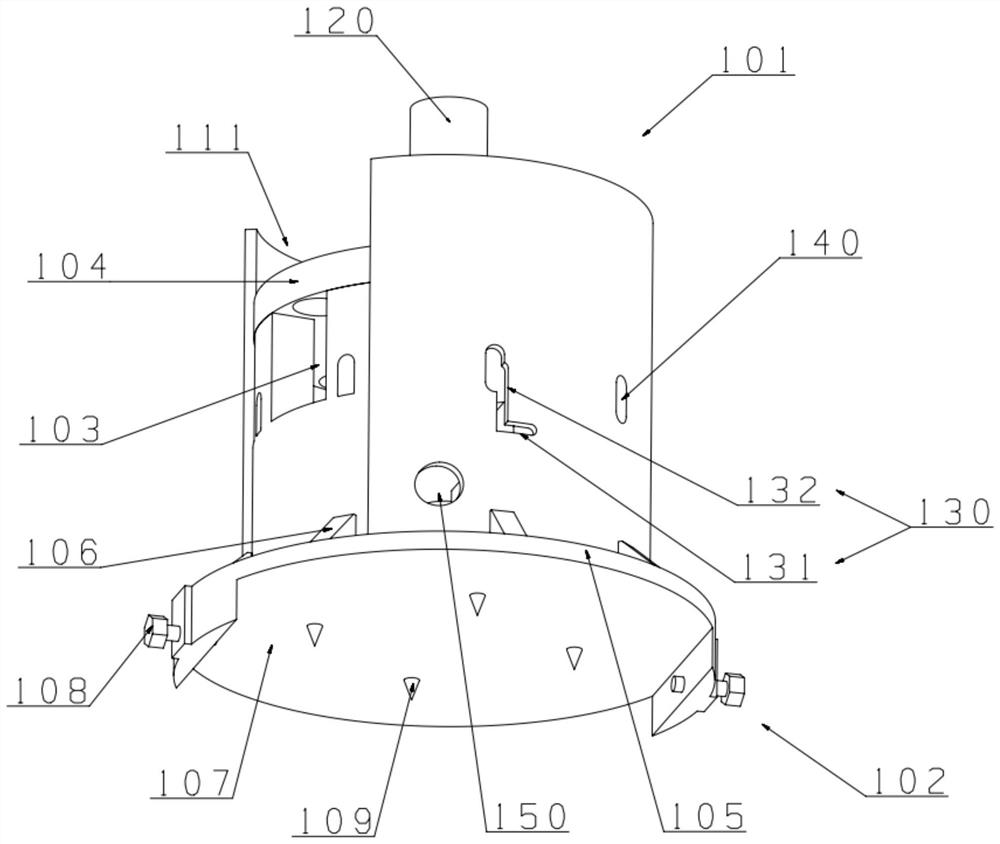

A support device for outriggers of a bridge erecting machine

The invention relates to the field of bridge erecting machine auxiliary devices, and specifically discloses a bridge erecting machine leg support device, comprising: a base with a bottom plate, a bottom plate with sleeper grooves and nails, a sleeper board, and a mobile seat with a top plate , a lifting assembly consisting of the first hydraulic cylinder and the second hydraulic cylinder, a rotating bushing, a shift assembly with a shift shaft and a shift lever assembly, an adjustment assembly and a dust shield. The invention can be welded or fixedly connected on the traverse track of the bridge erecting machine, can replace the traditional sleeper pier, is durable, and has better safety, and the sleeper board on the fixed seat can increase the friction force of the fixed surface of the support device, The overall height can be adjusted through the internal lifting components, and local fine-tuning in various directions in the horizontal plane can also be realized through the shifting components.

Owner:广西北投交通养护科技集团有限公司

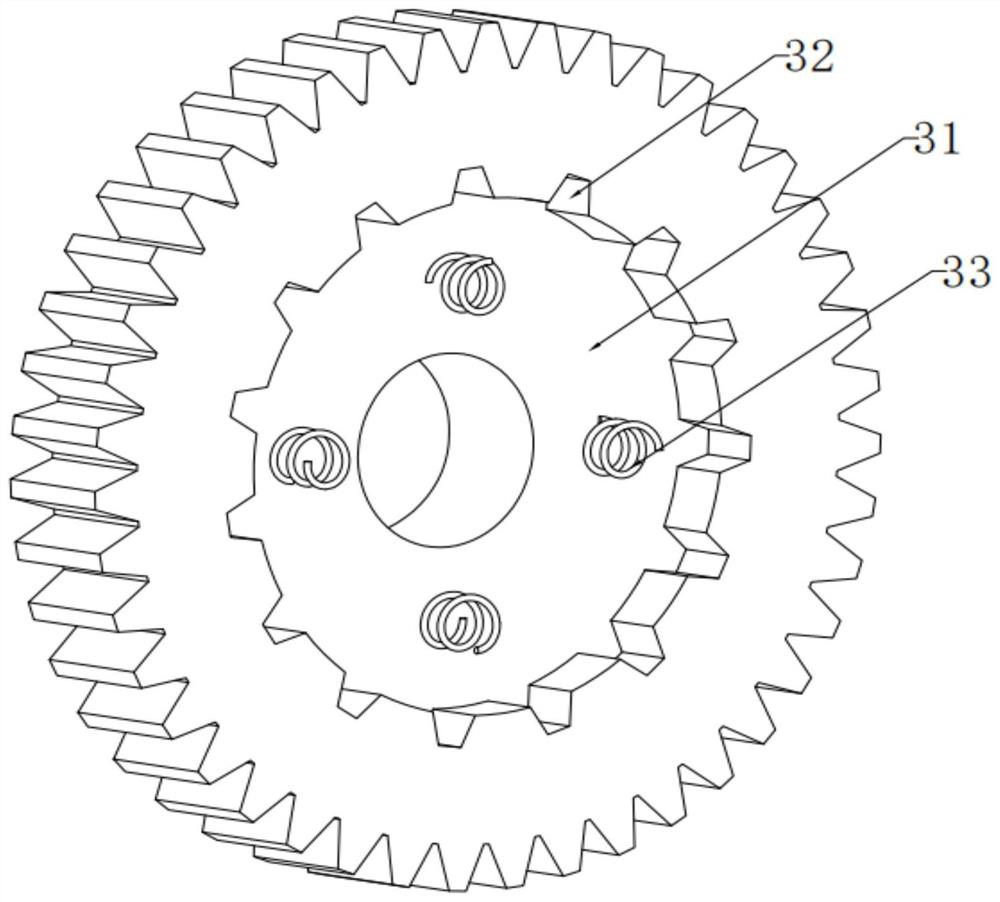

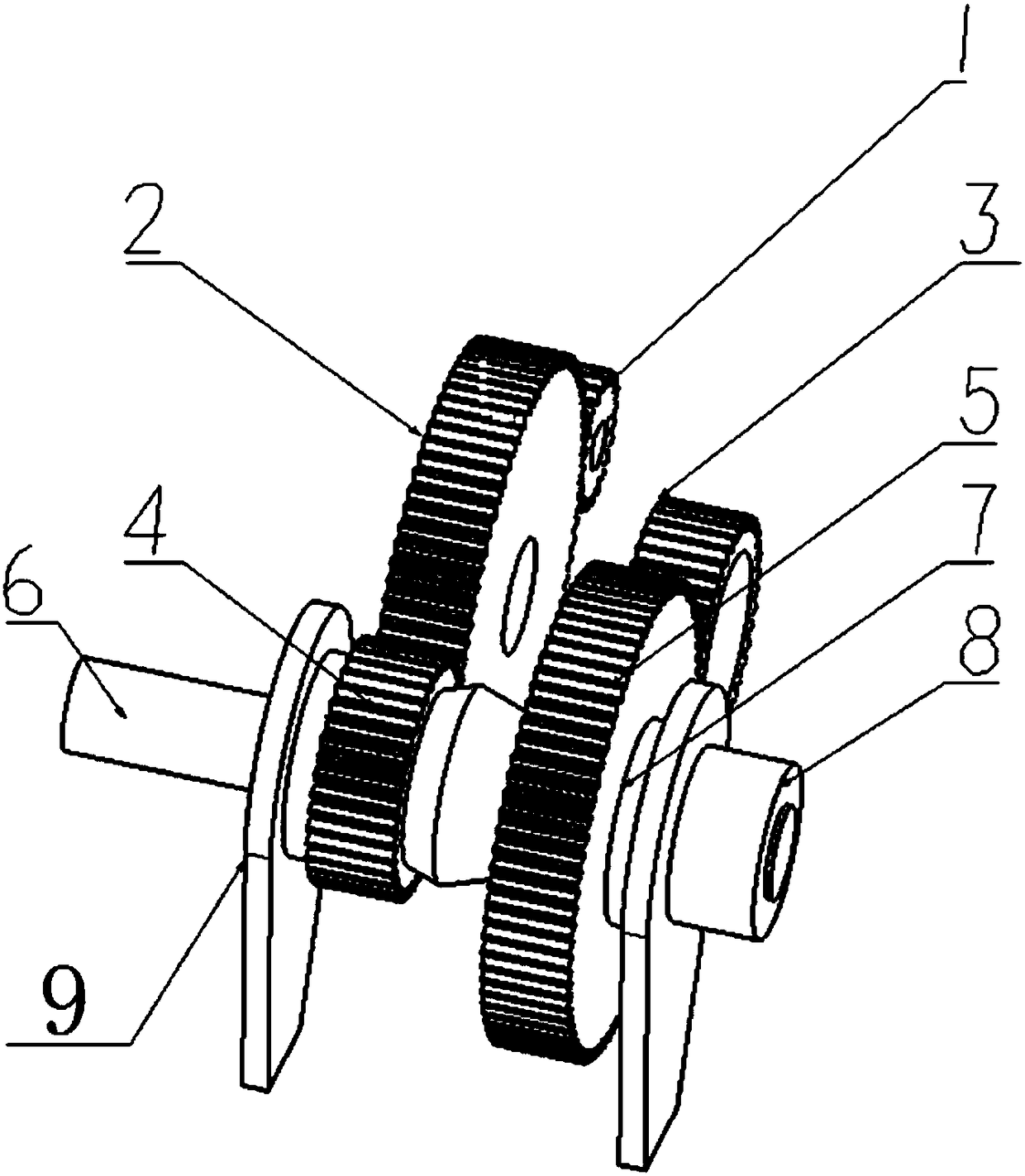

Gear speed reducer capable of achieving flexible impact

PendingCN108518455AReduce disadvantagesAvoid disadvantagesToothed gearingsGearing controlGear wheelReducer

The invention discloses a gear speed reducer capable of achieving flexible impact. The device comprises a gear shifting shaft arranged on two racks, two conical faces are symmetrically arranged at theposition, between the two racks, of the gear shifting shaft, the sides, with the large area, of the two conical faces are tightly attached, the two conical faces are provided with a third constant mesh gear and a fourth constant mesh gear correspondingly, the third constant mesh gear and the fourth constant mesh gear are matched with the two conical faces, a first constant mesh gear is engaged with the third constant mesh gear, the first constant mesh gear is engaged with an input gear, a second constant mesh gear is engaged with the fourth constant mesh gear, the first constant mesh gear andthe second constant mesh gear are fixedly connected through a shaft, one free end of the gear shifting shaft serves as an output shaft, and an output wheel is connected to the output shaft. Disengaging and engaging of the gear shifting shaft and the gear are used for gear shifting, gear shifting in the motion can be achieved, the structure of a speed change mechanism is simplified, impact in thegear shifting process can be greatly reduced, and the defect of the traditional speed change mechanism can be effectively overcome.

Owner:CHANGAN UNIV

Automatic double-clutch engine gear arm

This invention is automatic double clutches engine gear change arm. There are locating reed, first driving board, spacing board, reset reed, gasket and clasp on the gear changing shaft. The said firstdriving board is active cased on the gear changing shaft. The spacing board and gear changing shaft are welded together. The slot, which bottom edge has bend arm, is set on the middle part of the said first driving board. The bend arm is set between the two clamping feet of reset reed. The reset reed is locked by clasp. The 'L' shaped second driving board is welded on the gear changing shaft outside locating reed. The bend arm of second driving board passes through slot and extends into two clamping feet of reset reed. The reset reed is arranged between first and second driving boards. The gear changing shaft outside the second driving board is arranged with operating arm through spline. This invention can automatically separate the clutch when changing gear.

Owner:胡光宇

A screw selector shift mechanism

The invention relates to a screw rod gear selecting and gear shifting mechanism, comprising a gear selecting mechanism and a gear shifting mechanism. The gear selecting mechanism is a screw rod gear selecting mechanism, and comprises a screw rod with the rotating axis parallel with a gear shifting shaft; a nut making linear motion along the rotating axis when the screw rod rotates is assembled on the screw rod, the nut is in transmission connection with a gear shifting fingerstall through a driven rod fixed with the nut, and the gear shifting fingerstall is axially assembled on a gear shifting finger along the gear shifting shaft in a limiting and rotating mode. The gear selecting mechanism is a screw rod-nut mechanism, wherein the nut is driven to make linear motion through driving the screw rod to rotate, the nut drives the gear shifting finger to slide along the gear shifting shaft through the driven rod, and the gear shifting finger glides to a position corresponding to a shifting fork shaft, therefore, gear selecting is realized. The gear shifting mechanism comprises a gear shifting shaft and a gear shifting finger matched with the gear shifting shaft through a spline. When the gear shifting shaft rotates, the gear shifting finger is driven to rotate so as to drive a shifting fork, and the corresponding shifting fork shaft is turned to move to a proper gear so that gear shifting is realized.

Owner:HENAN UNIV OF SCI & TECH

Hybrid two-speed transmission transmission system and hybrid electric vehicle

ActiveCN106585359BShorten the axial lengthFew partsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive motorEngineering

The invention relates to a hybrid two-shift gearbox transmission system. An engine is connected with an input shaft I, a clutch is provided with a driven end and a driving end, the driving end is fixed to the input shaft I, and the driven end is provided with a driven end gear which is meshed with a shift gear; an output shaft gear is fixed to an output shaft and is meshed with a differential mechanism; the shift gear sleeves the output shaft in a hollow manner; a planetary gear unit is mounted on the output shaft, and is provided with a gear ring, a planet carrier, a sun gear, a first clutch, a second clutch, a first brake and a second brake; the planet carrier is fixed to the output shaft, and the first clutch is arranged between the shift gear and the gear ring; the second clutch is arranged between the shift gear and the sun gear; and the first brake is used for locking the sun gear, the second brake is used for locking gear ring, a driving motor is connected with the input shaft II, the gear of the input shaft II is fixed to the input shaft II, and the gear of the input shaft II is meshed with the shift gear. The invention further provides a hybrid electric vehicle with the transmission system.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Hybrid two-speed transmission transmission system and hybrid electric vehicle

ActiveCN106585360BShorten the axial lengthFew partsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringElectric vehicle

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Gear shifting and parking braking system, vehicle and control method

ActiveCN111609126AGear shiftingControlled membersGearing controlControl theoryMechanical engineering

The invention relates to a gear shifting and parking braking system, a vehicle and a control method. The gear shifting and parking braking system involves an actuating mechanism, a gear shifting mechanism and a parking mechanism, wherein the gear shifting mechanism and the parking mechanism are in transmission connection with the actuating mechanism, and the actuating mechanism drives the gear shifting mechanism to rotate forwards or reversely and drives the parking mechanism to be switched between a non-braking state and a braking state; the gear shifting mechanism is provided with a first gear, a second gear and a neutral gear, the parking mechanism is in a non-braking state when the actuating mechanism drives the gear shifting mechanism to rotate forwards, and the actuating mechanism drives the parking mechanism to enter a braking state at the same time when the actuating mechanism drives the gear shifting mechanism to rotate reversely from the neutral gear. According to the gear shifting and parking braking system, the vehicle and the control method, the integration level of the gear shifting and parking braking system is improved, the layout space is saved, and meanwhile the cost is reduced.

Owner:SCHAEFFLER TECH AG & CO KG

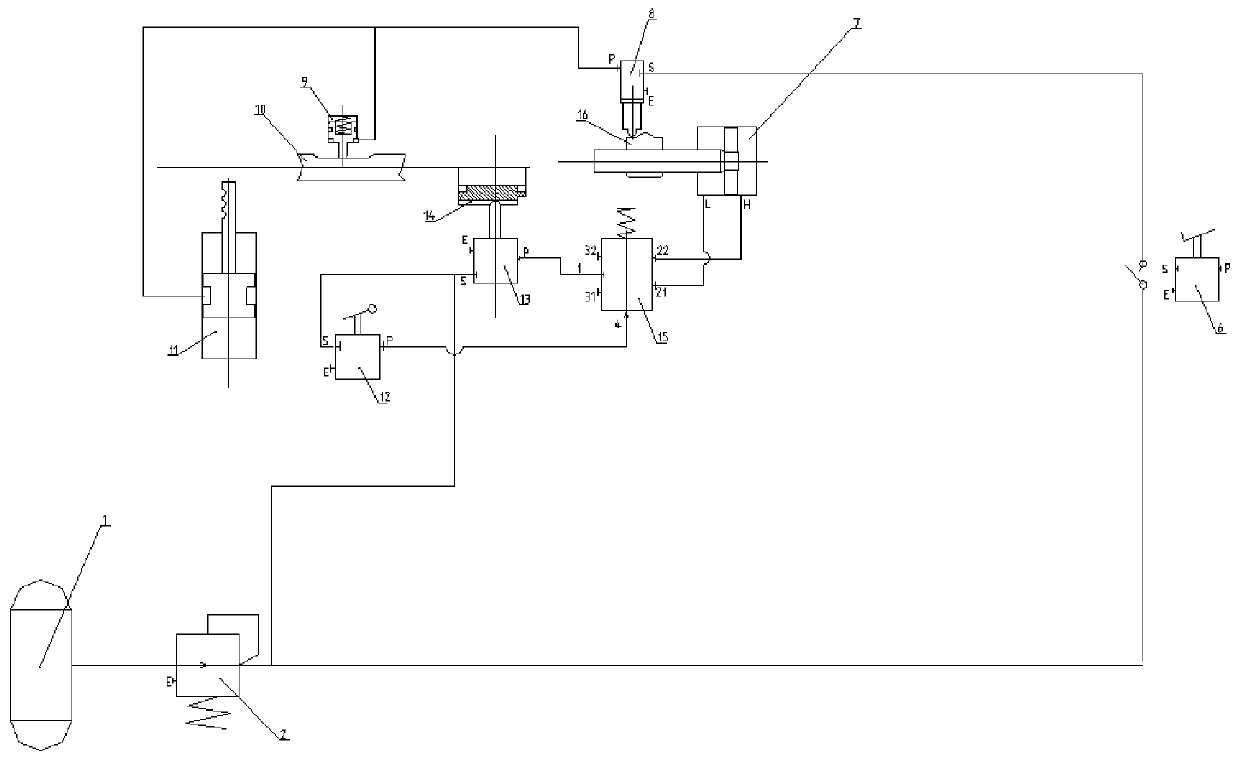

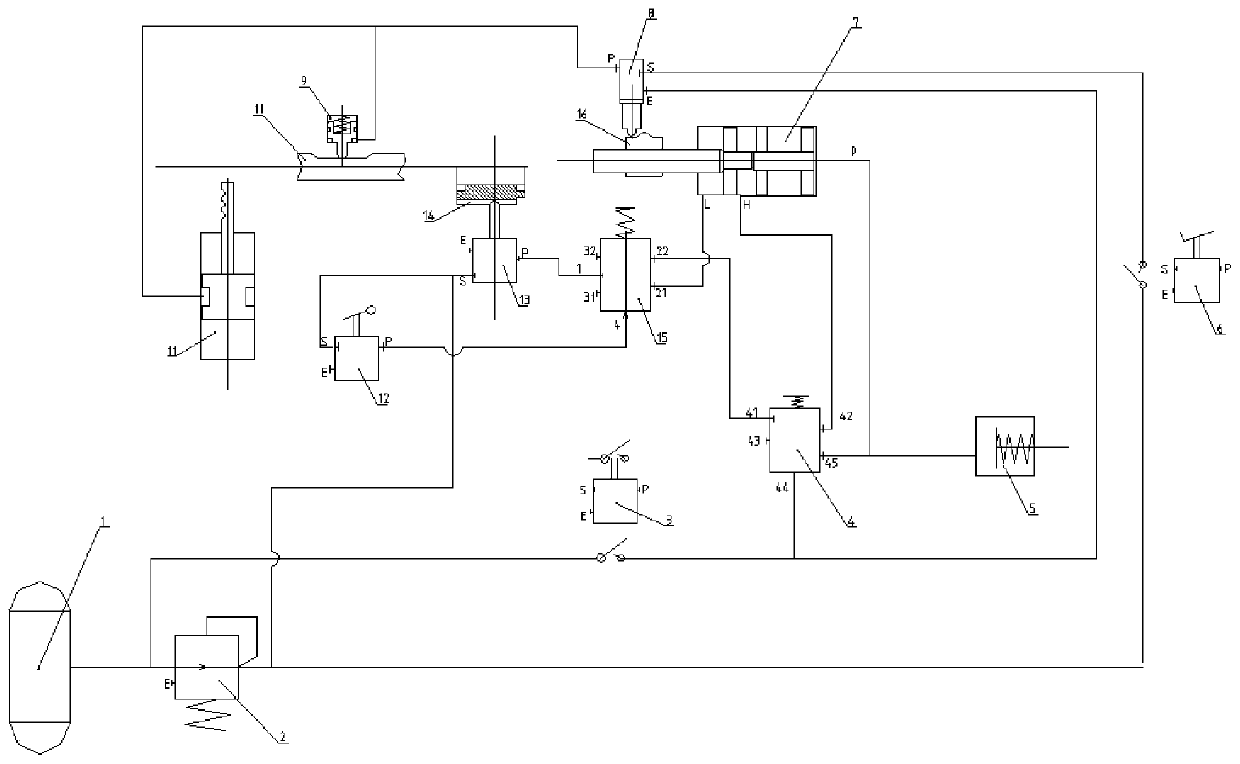

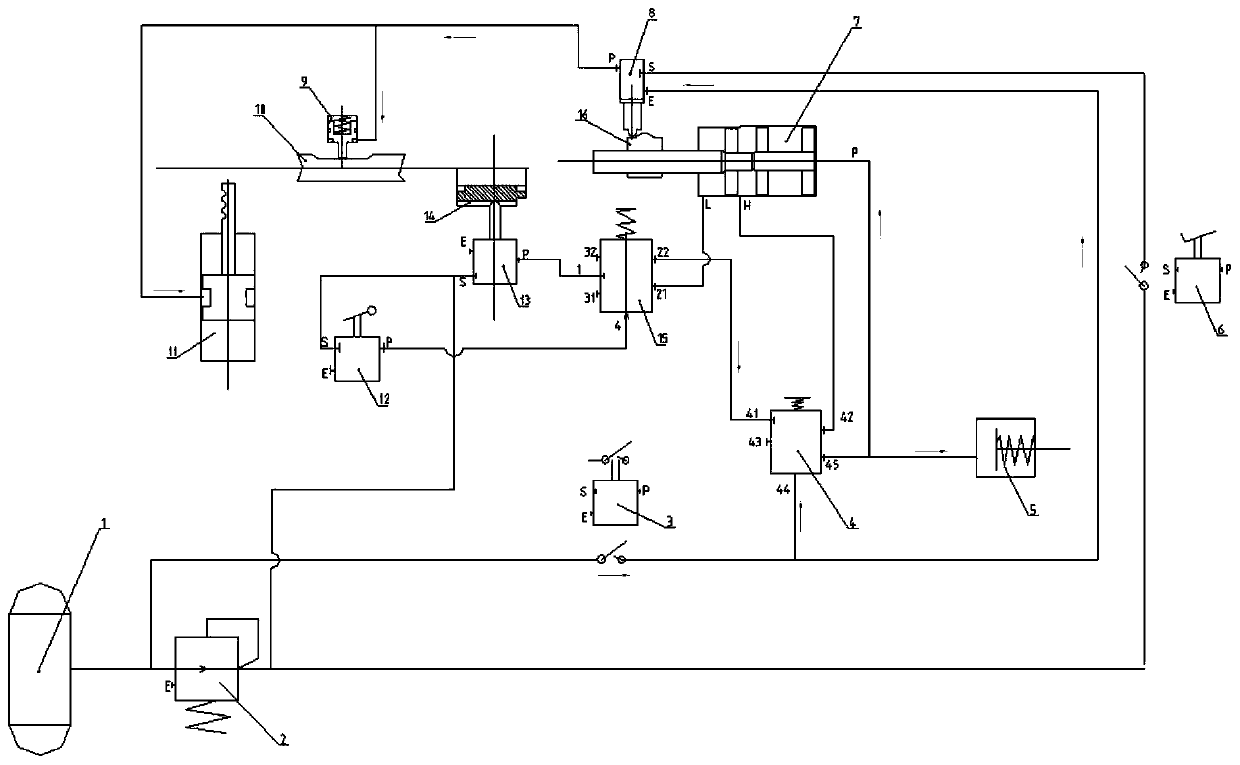

Multi-gear transmission operating system

The invention belongs to the field of transmissions, and discloses a multi-gear transmission operating system. The multi-gear transmission operating system comprises an air reservoir, a middle position air cylinder assembly, a gear shifting rod, an operation hand ball, an air path control valve, a gear change shifting block, a single H valve, an auxiliary box shifting fork shaft and an air reservoir air outlet which are sequentially connected with a pressure regulating valve, a clutch separating pump switch, an interlocking valve and a backset cylinder; the air inlets of the operation hand ball and the air path control valve are connected with an air outlet of the pressure regulating valve correspondingly; the operation hand ball and the air path control valve are connected with the singleH valve, an air outlet of the single H valve is connected with a low gear side of the middle position air cylinder assembly and an air inlet at a high gear side, and a high-low gear pre-selection switch connected with the single H valve is arranged on the operation hand ball; one end of the auxiliary box shifting fork shaft is connected with the middle position air cylinder assembly, an interlocking control block is arranged on the other end of the auxiliary box shifting fork shaft, and a radial protruding block is arranged on the interlocking control block; one end of the gear change shifting block is connected with the air path control valve, and the other end of the gear change shifting block is connected with the gear shifting rod. According to the operating system, the damage to a synchronizer by misoperation is effectively prevented, the failure rate of the synchronizer is reduced, the vehicle is guaranteed to operate well, and the maintenance service cost is saved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com