Drive arrangement for electric vehicle and method for power shifting

A driving mechanism, a technology for electric vehicles, applied in the direction of electric power units, power units, vehicle components, etc., can solve problems such as the inability to realize power shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

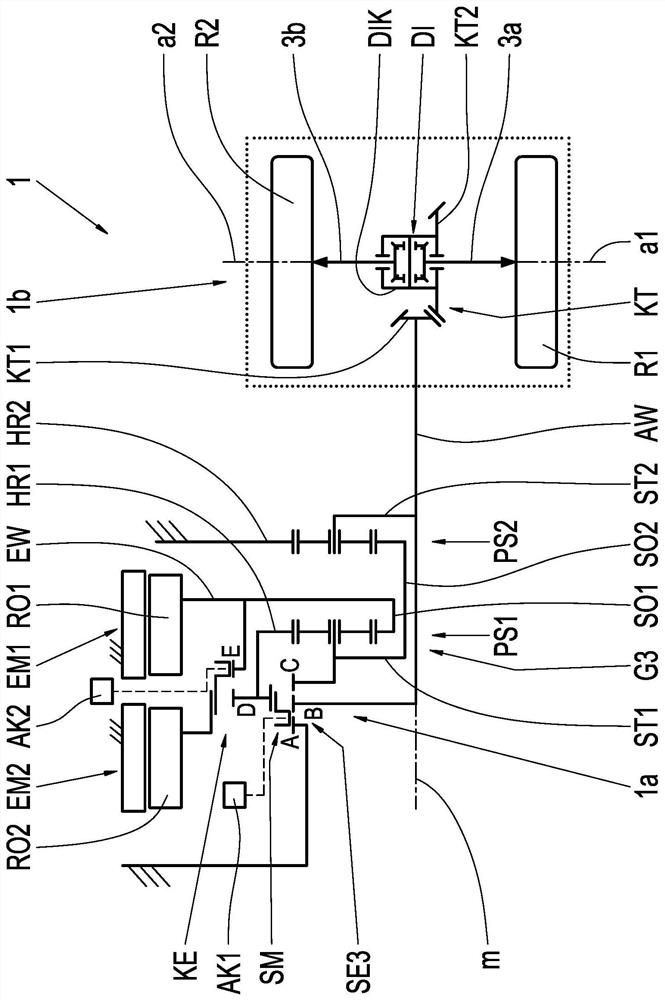

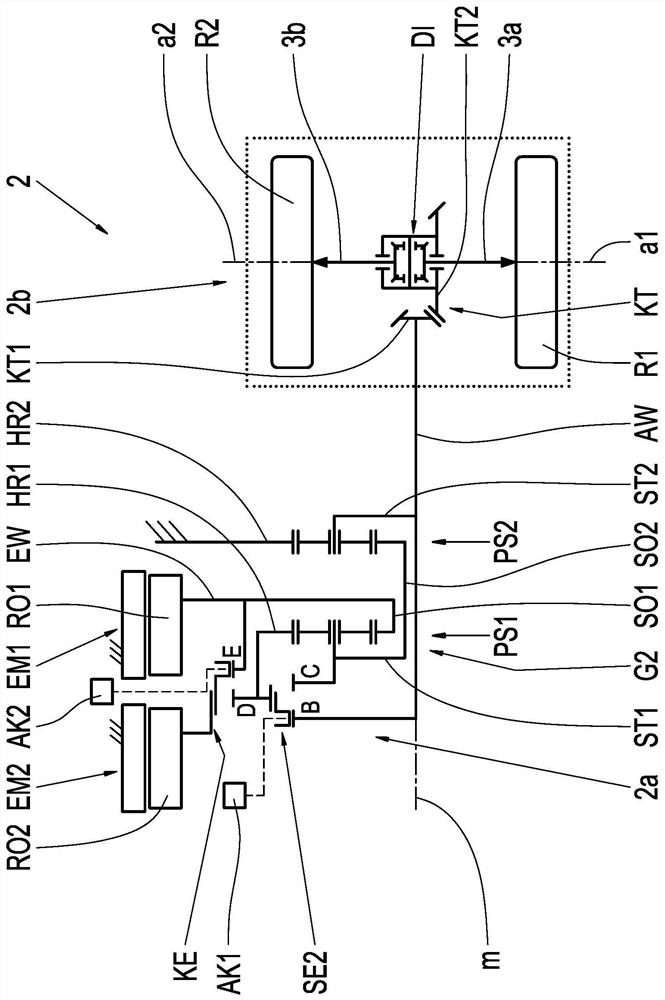

[0023] figure 1 As a first exemplary embodiment of the invention, a first drive mechanism 1 of an electrically driveable vehicle (hereinafter referred to simply as an electric vehicle) is shown as a so-called central drive. The drive mechanism 1 comprises, on the one hand, a drive unit 1a consisting of a first electric machine EM1 with a first rotor RO1, a second electric machine EM2 with a second rotor RO2, a third gear with a shifting device SE3 and a coupling device KE. The shift transmission G3 constitutes. The electric machines EM1 , EM2 have a common axis of rotation m which extends in the longitudinal direction of the electric vehicle. The axis of rotation m is at the same time the axis of symmetry of the shift transmission G3, only the upper half of which is shown. The drive train 1 also includes a conventional axle 1b with a first drive wheel R1 and a second drive wheel R2 with associated wheel axes a1, a2, an axle differential DI, and two differentials Output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com