Driving device fr calendering roller

A transmission device and calender roll technology, applied in textiles and papermaking, winding mechanisms, fiber processing, etc., can solve problems such as gear wear, unfavorable for low-noise equipment, and dirty gear transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

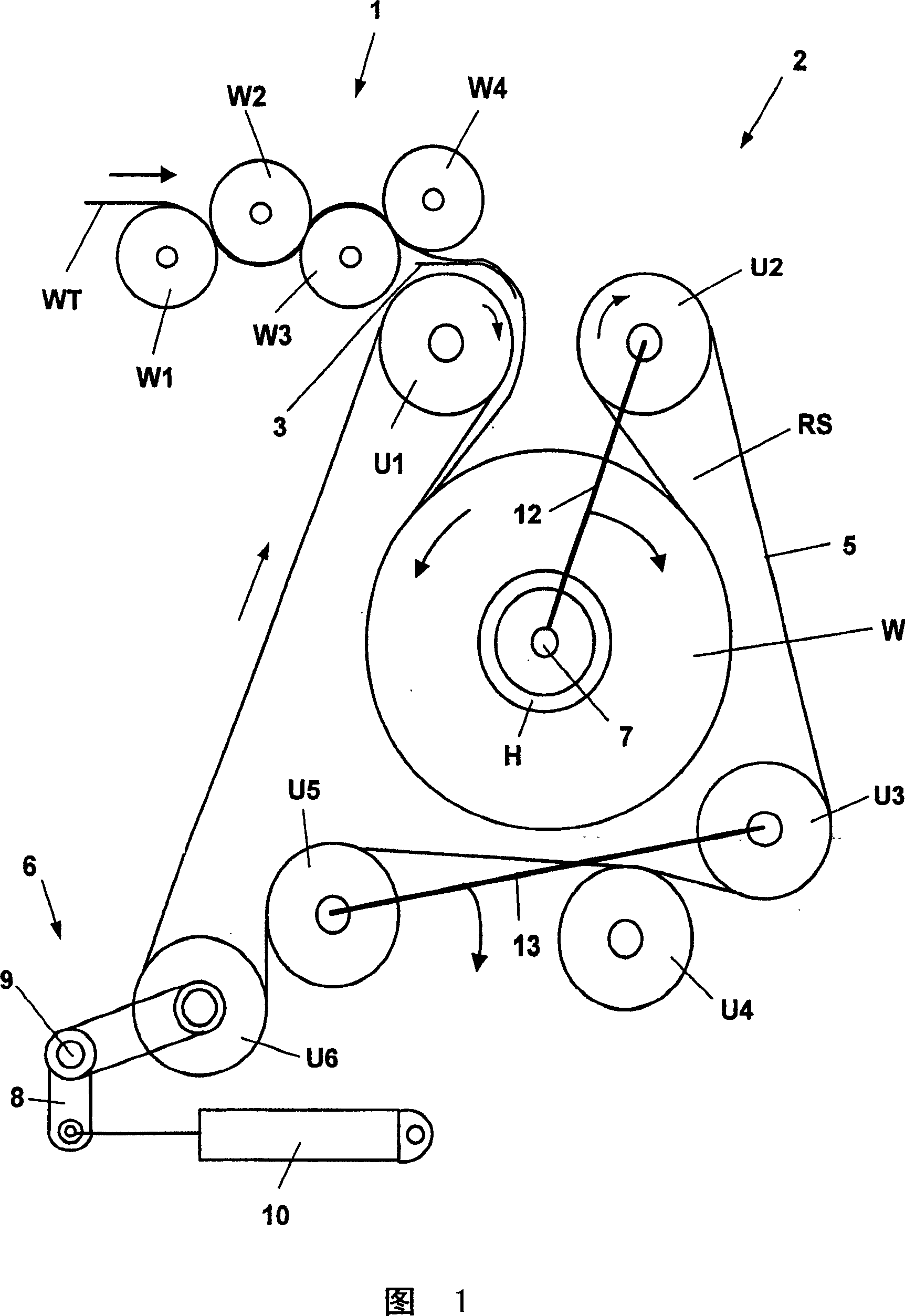

[0025] FIG. 1 shows a set of calender rolls 1 , which set consists of four calender rolls W1 - W4 arranged one behind the other. The calender rolls are arranged slightly offset front and back, between which the cotton WT is transported meanderingly to a subsequent lapping device 2 . Furthermore, the cotton WT passes through a ramp 3 between two deflection rollers U1 and U2, below which there is a belt loop RS of a belt 5 which is guided by other deflection rollers U3, U4, U5 and U6. A small roll W is formed in the belt loop RS, in which the cotton WT is wound on a sleeve H. The sleeve H is supported rotatably about an axis 7 by means of a transverse bearing not shown in detail. Tensioning of the belt 5 of the lap forming device 2 takes place by means of deflection rollers U6 which are arranged rotatable via a double-arm lever 8 in relation to a rotational axis 9 . Double arm lever 8 bears the active force of a cylinder 10 installed in the frame.

[0026] After the small rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com