Rod electronic shifter and car

An electronic shifter, lever-type technology, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc., can solve the problems of increasing cost, not being simple and beautiful, and increasing the volume of electronic shifters. , to achieve the effect of convenient operation, reduced volume and development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

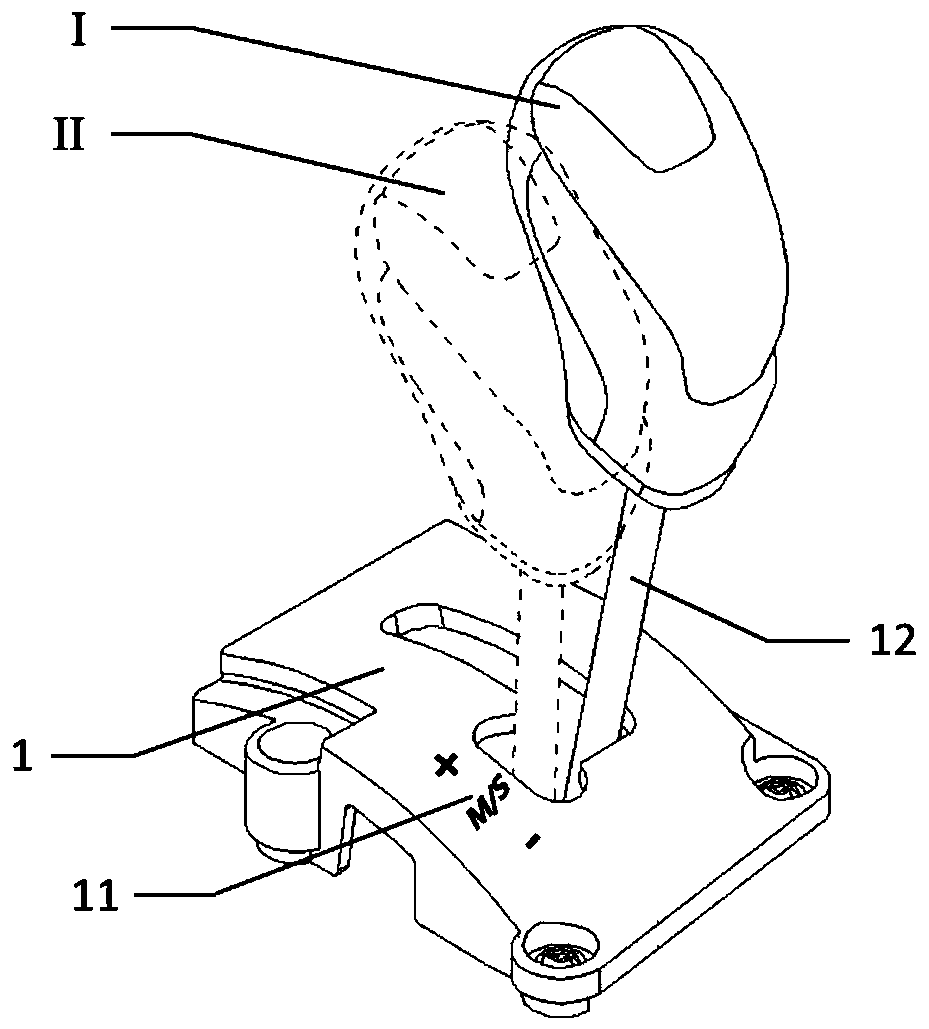

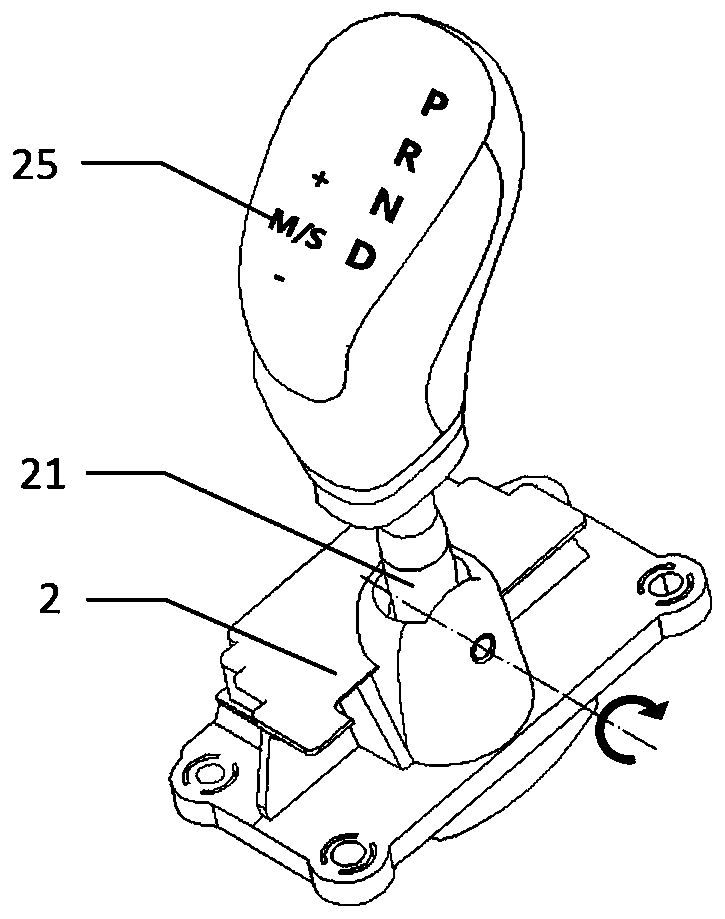

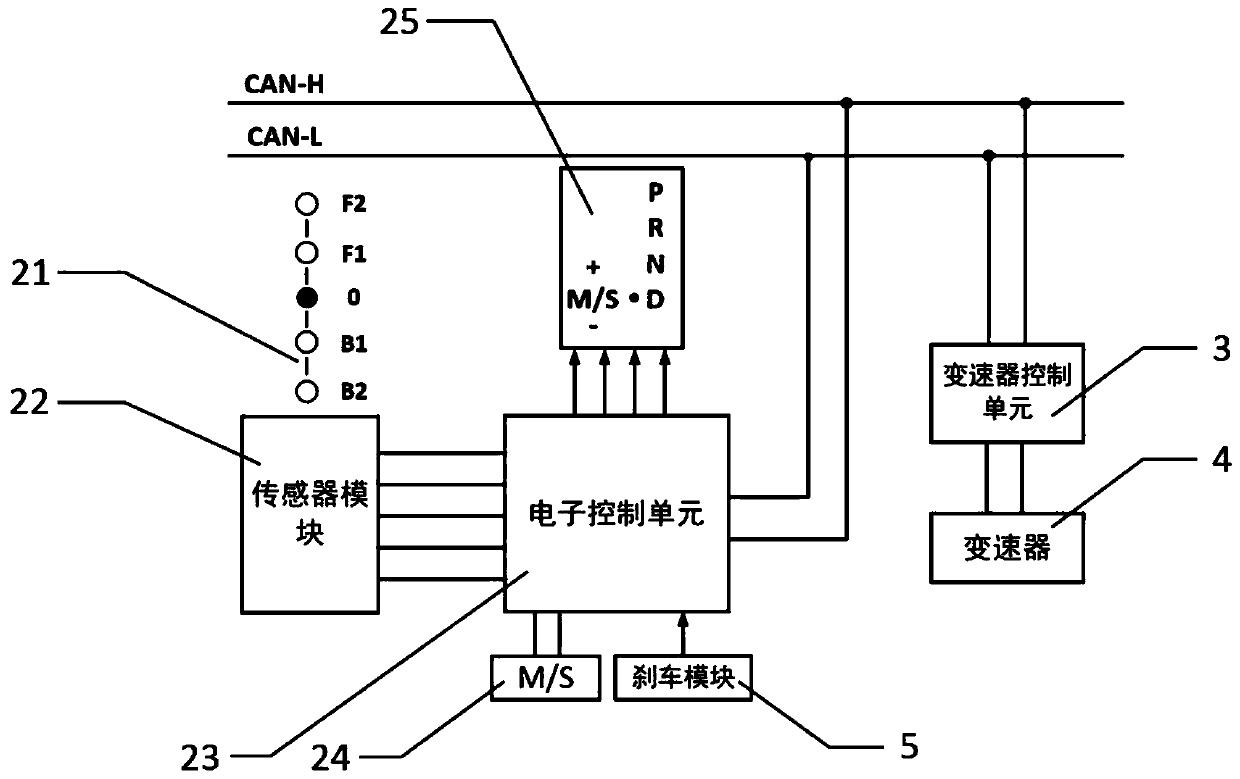

[0023] Such as figure 2 and image 3 As shown, the lever-type electronic shifter of the present invention includes: a shift lever assembly 21 , a sensor module 22 , an electronic control unit 23 , an M / S gear button 24 and a gear display panel 25 . Wherein, the sensor module 22 , the M / S gear button 24 and the gear display panel 25 are respectively connected with the electronic control unit 23 .

[0024] Such as Figure 2 to Figure 4 As shown, the shift lever assembly 21 is in the form of a five-position monostable, and has five mechanical positions of F2, F1, 0, B1 and B2. Position 0 is a steady state position, and F2, F1, B1, and B2 are all unsteady state positions. After the shift lever assembly 21 is rotated from the 0 position to the unsteady state position and let go, it can automatically return to the 0 position.

[0025] In this embodiment, the sensor module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com