Bicycle suspension system

一种悬挂系统、自行车的技术,应用在自行车弹簧、自行车附件、车轴悬挂装置等方向,能够解决短操纵管、增大管长度、叉不能应付前/后加载等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

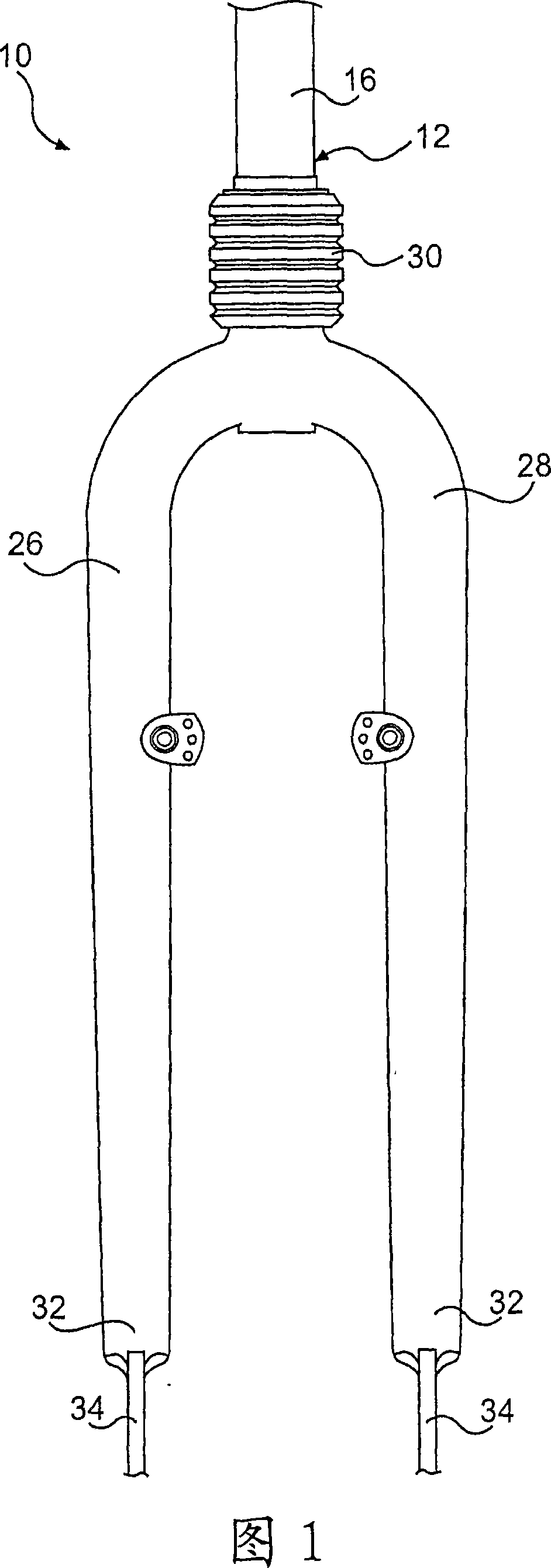

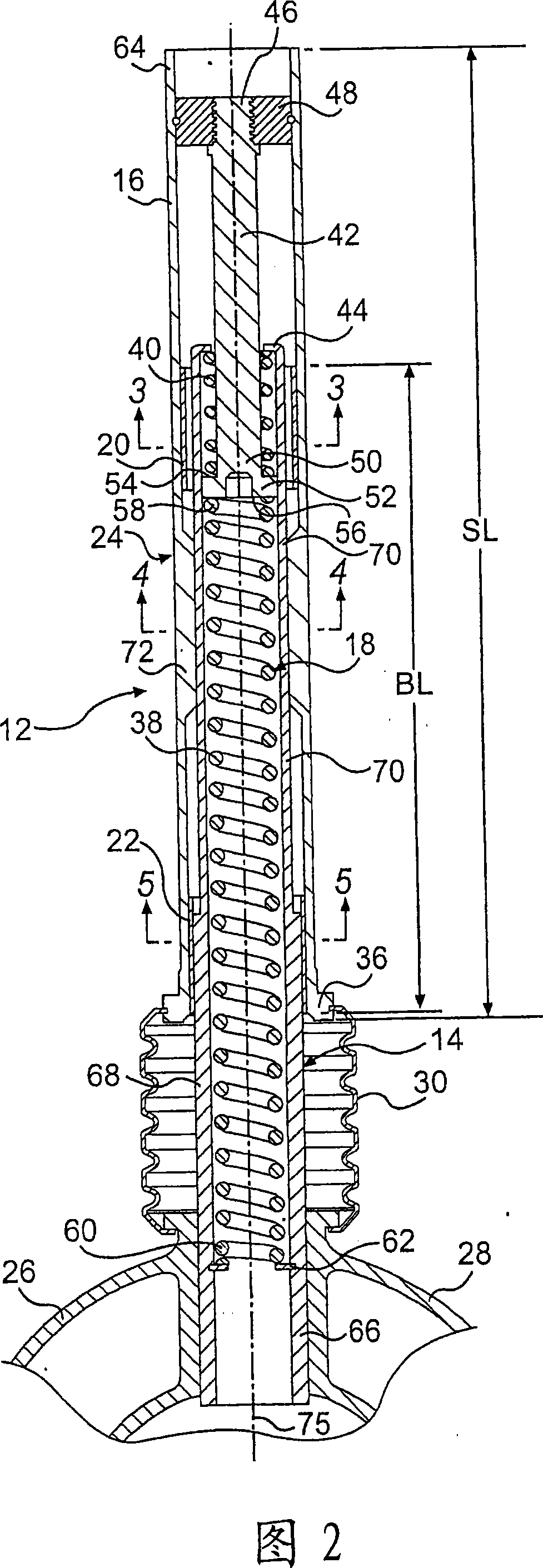

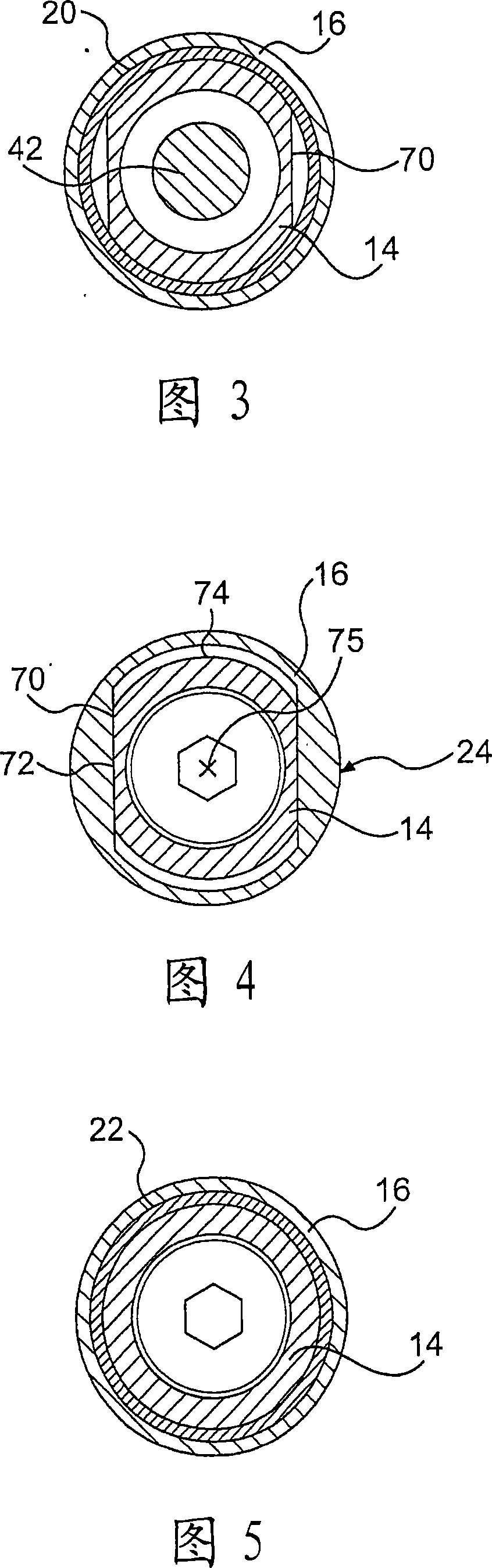

[0015] 1 to 5 illustrate a bicycle front fork 10 having a suspension system 12 associated with a head tube (not shown) of a bicycle frame, according to one embodiment of the present invention. The suspension system 12 generally includes an inner tube 14 , an outer tube 16 , a shock absorbing mechanism 18 , a first bushing 20 , a second bushing 22 and a steering control mechanism 24 . Referring to FIG. 1 , the fork 10 includes a first leg 26 , a second leg 28 , a bellows 30 and an outer tube 16 mountable to the head tube, the bellows being disposed between the outer tube 16 and the legs 26 , 28 To seal and protect the suspension system 12 from foreign objects. An end 36 of the outer tube 16 is connected to a bellows 30 connected to the legs 26, 28 of the fork 10 (see FIG. 2 ). First leg 26 and second leg 28 are connected at their distal ends 32 by dropouts 34 to an axle (not shown). The first and second legs 26 , 28 and the inner tube 14 move axially or slidingly relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com