Method for preparing ellipse-like hole honeycomb web plate

An elliptical hole and ellipse-like technology is applied in the field of preparation of elliptical hole honeycomb beam webs, which can solve the problems of complex production process, low production efficiency, waste of steel and other problems, and achieve the effects of reducing production cost, improving production efficiency and saving steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention is described below with specific examples, but protection scope of the present invention is not limited thereto:

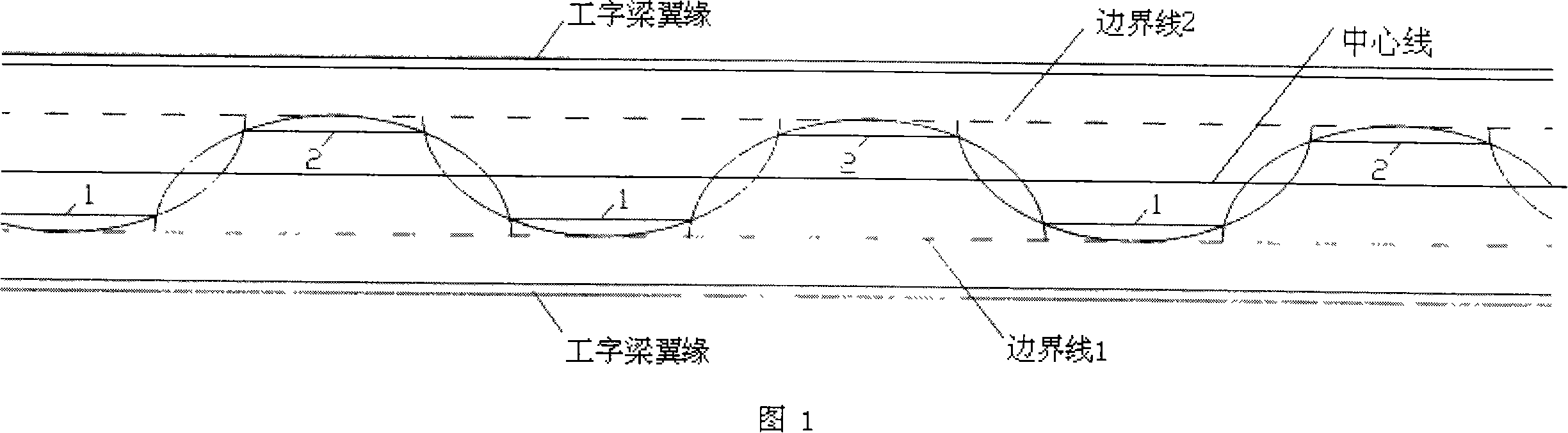

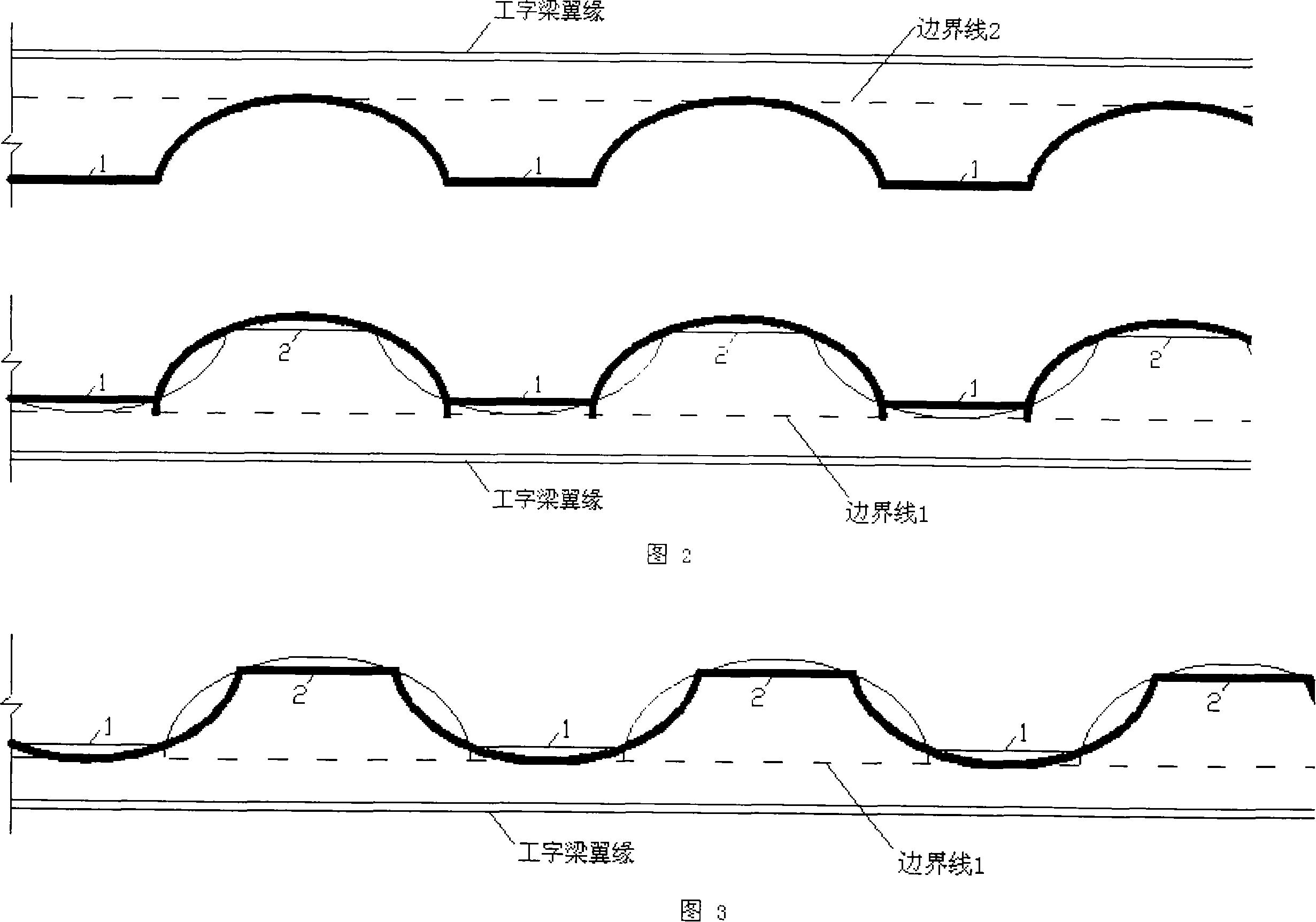

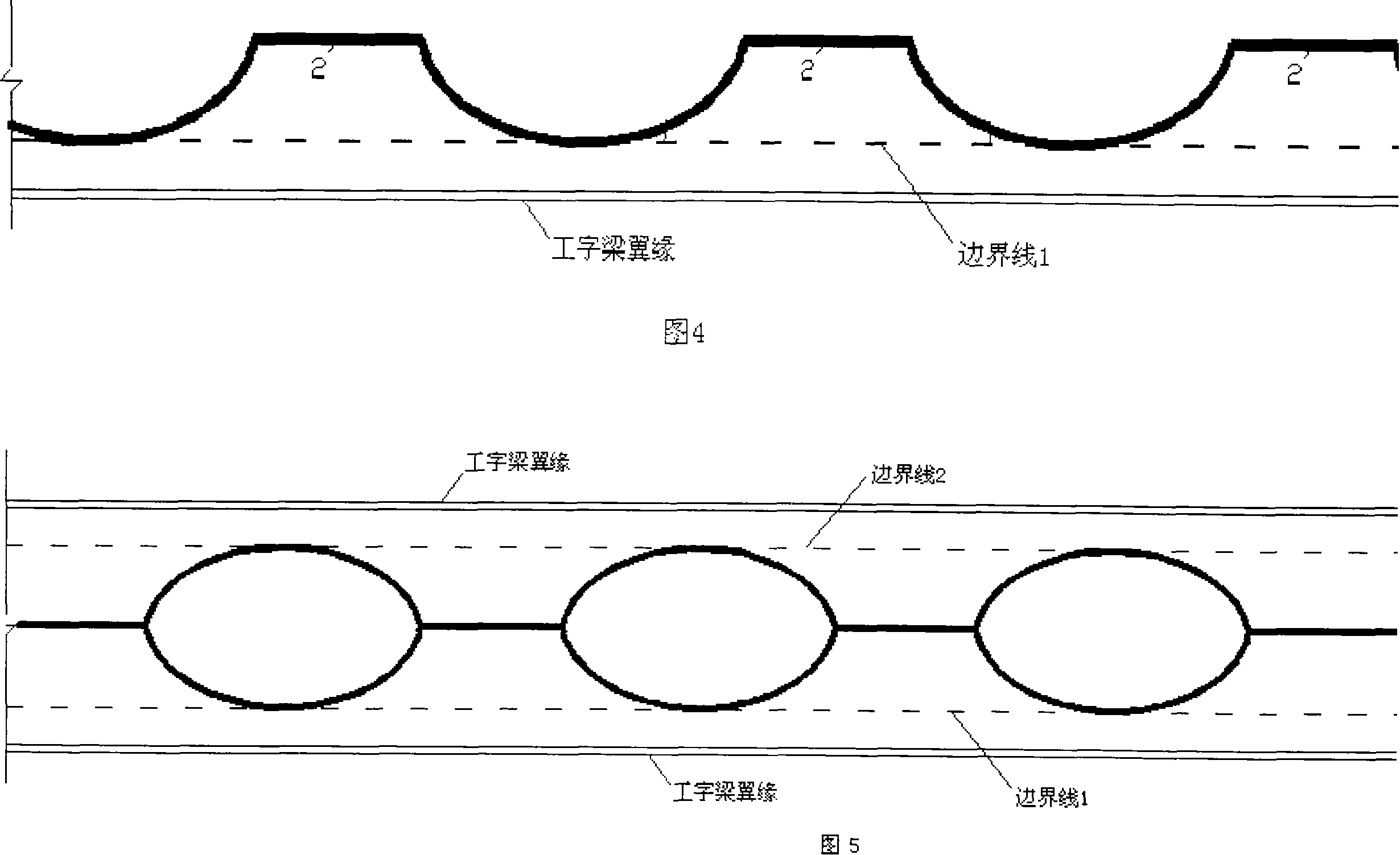

[0028] To produce a honeycomb beam with similar elliptical holes, the length of the major semi-axis a' of the similar elliptical hole opening on the web is 400 mm, the length of the minor semi-axis b' is 300 mm, and the distance L between the centers of adjacent similar elliptical holes is 1000 mm.

[0029] Adopt the preparation method of a kind of oval-hole honeycomb beam web of the present invention, carry out according to the following steps: 1) according to aforementioned formula (1), (2) determine the length of the major and minor semiaxes a, b of lofting ellipse to be respectively: a=400.2 mm, b=309.8mm;

[0030] 2) On both sides of the center line of the I-beam web, determine a parallel line with a distance of b / 2 from the center line, which are respectively recorded as boundary lines 1 and 2;

[0031] 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap