Emergency braking device for a lift cabin

A technology of emergency braking and elevator car, which is applied in the direction of transportation and packaging, elevators, etc., and can solve the problems of insufficient safety and reliability of elevators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

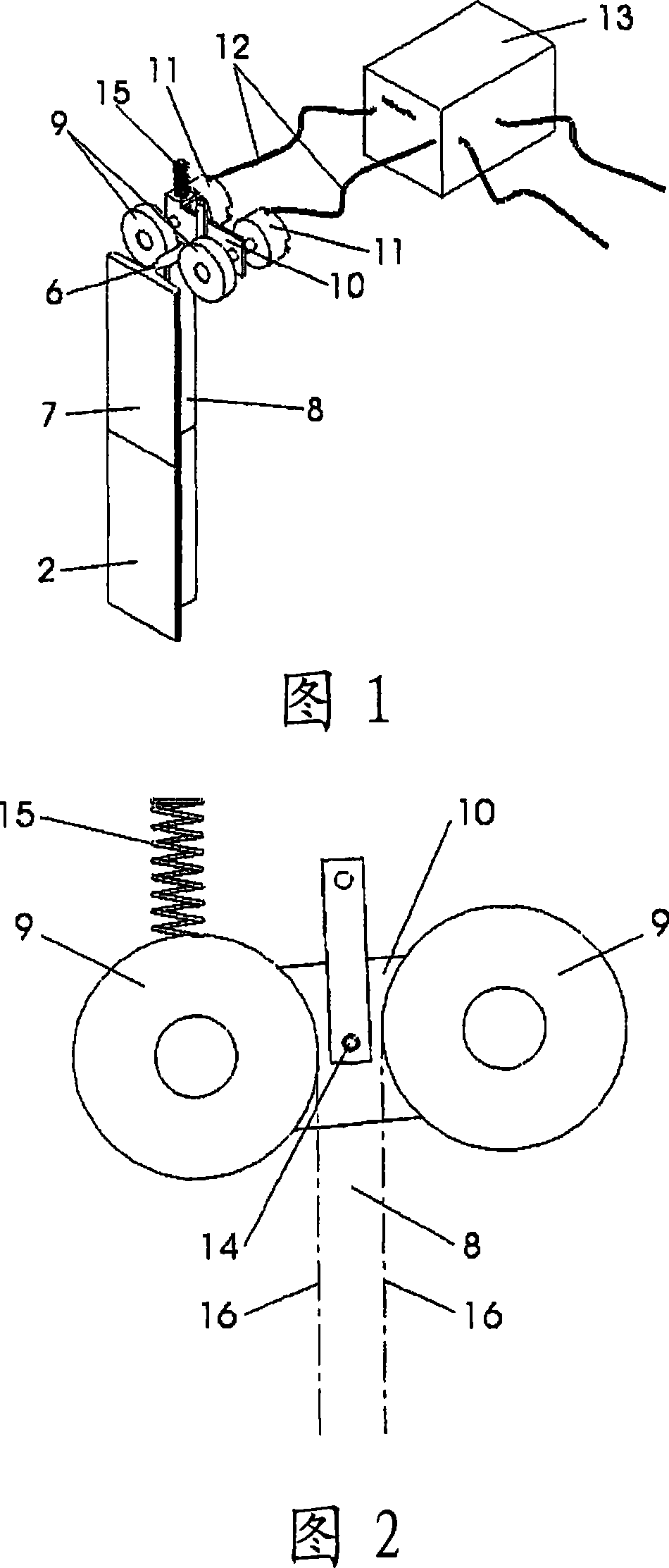

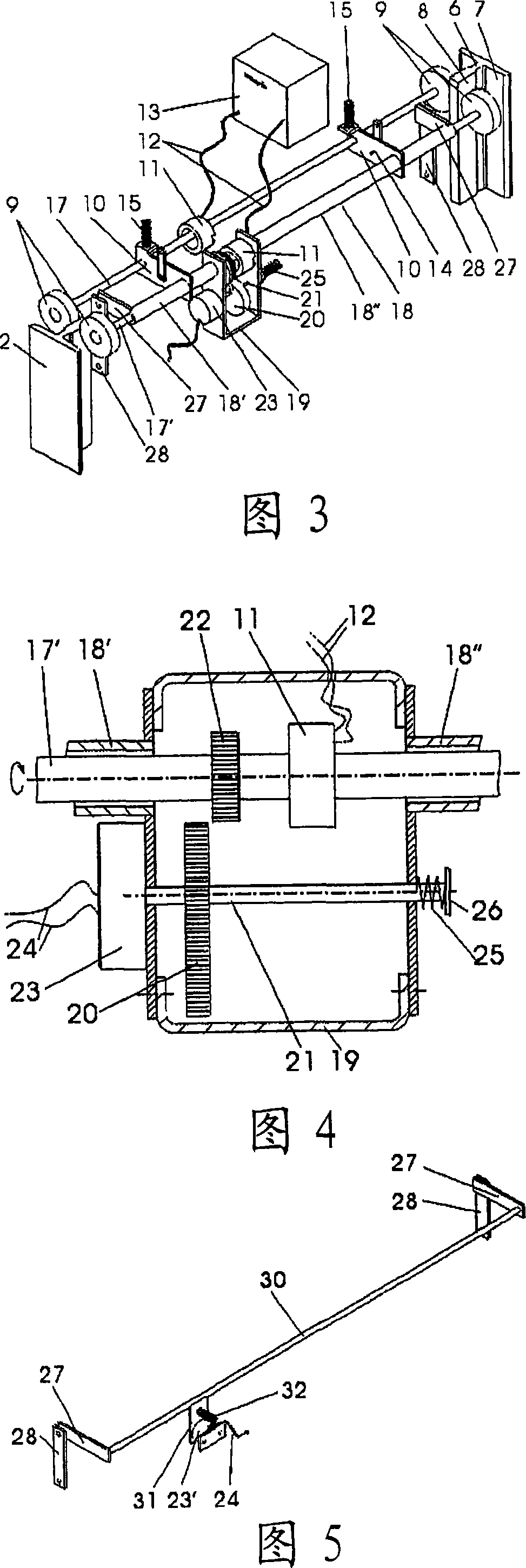

[0027] As shown in FIG. 1 , the guide rail 2 has a rail head 8 connected via a web 6 to a rail base 7 .

[0028] The wheels 9 rest against the sides of the rail head 8 , are held rotatably in a rocker 10 (see also FIG. 2 ), and are connected in a rotationally fixed manner to a sensor 11 . The sensor 11 is connected via a signal line 12 to a mechanism 13 for detecting excessive speed.

[0029] As shown in FIG. 2 , the rocker 10 is pivotably arranged about an axis 14 between two wheels 9 and is under the force of a spring 15 , which is supported on a not-shown support and serves to rotate the rocker 10 , and then the wheel 9 is pressed tightly on the two side surfaces 16 of the rail head 8 . Since the net distance between the two wheels 9 is only slightly smaller than the width of the rail head 8 and the point of application of the spring 15 is far away from the axle 14 of the fork 10, a corresponding leverage is produced, even if the spring 15 is relatively weak. High wheel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com