A combined gear oil stirring experimental device and method thereof

An experimental device, combined gear technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of installation errors, no exploration, no comparative analysis of gears and wheel discs, etc., to reduce installation errors, easy installation methods, and reduced installation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

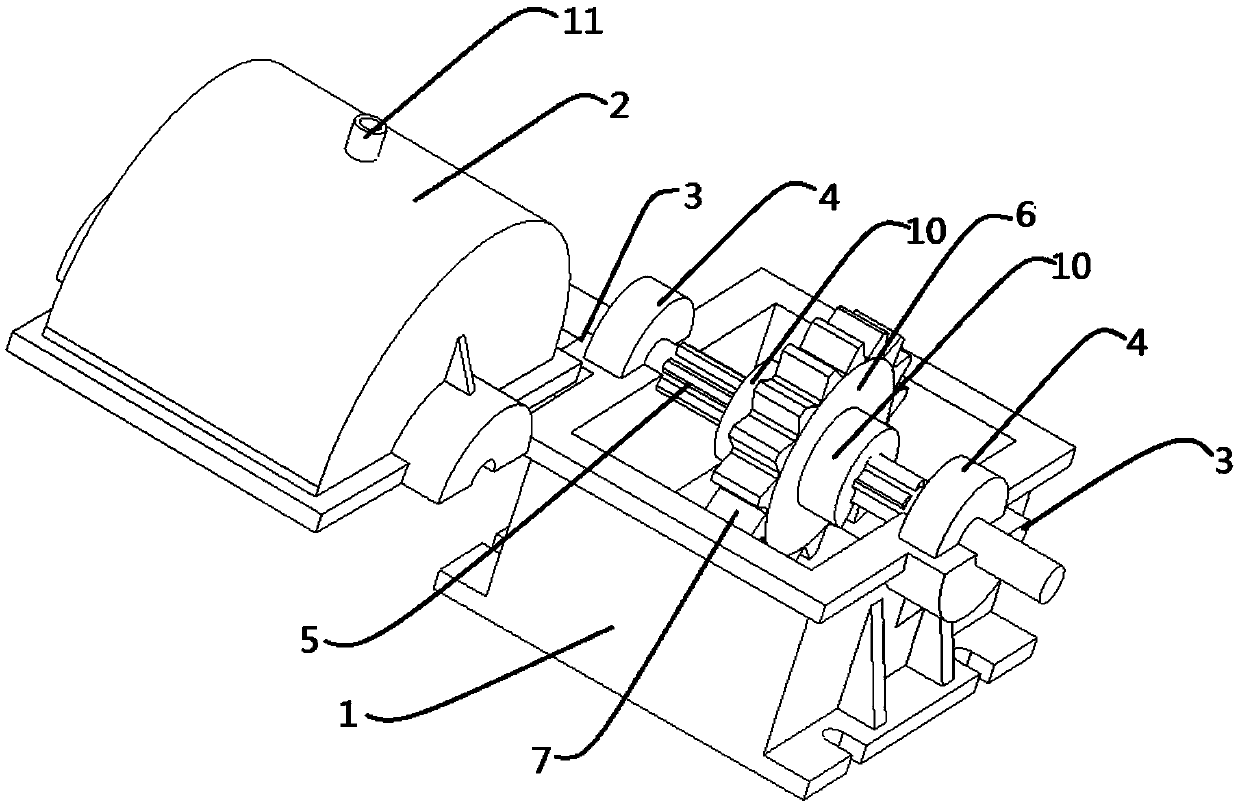

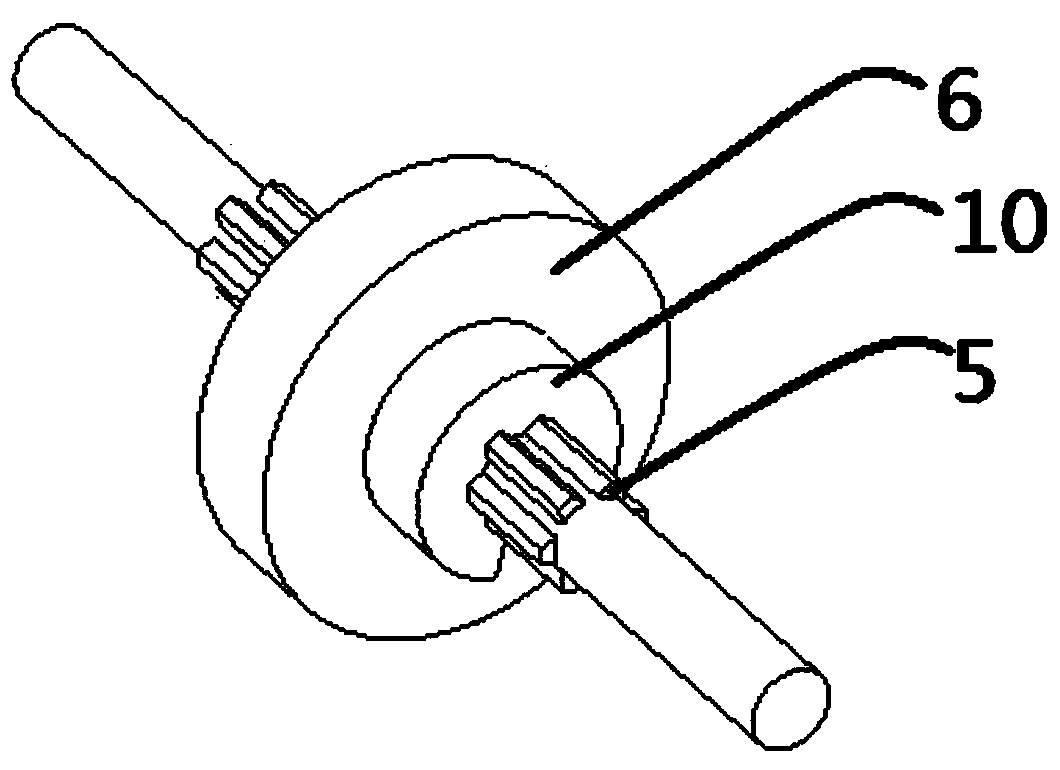

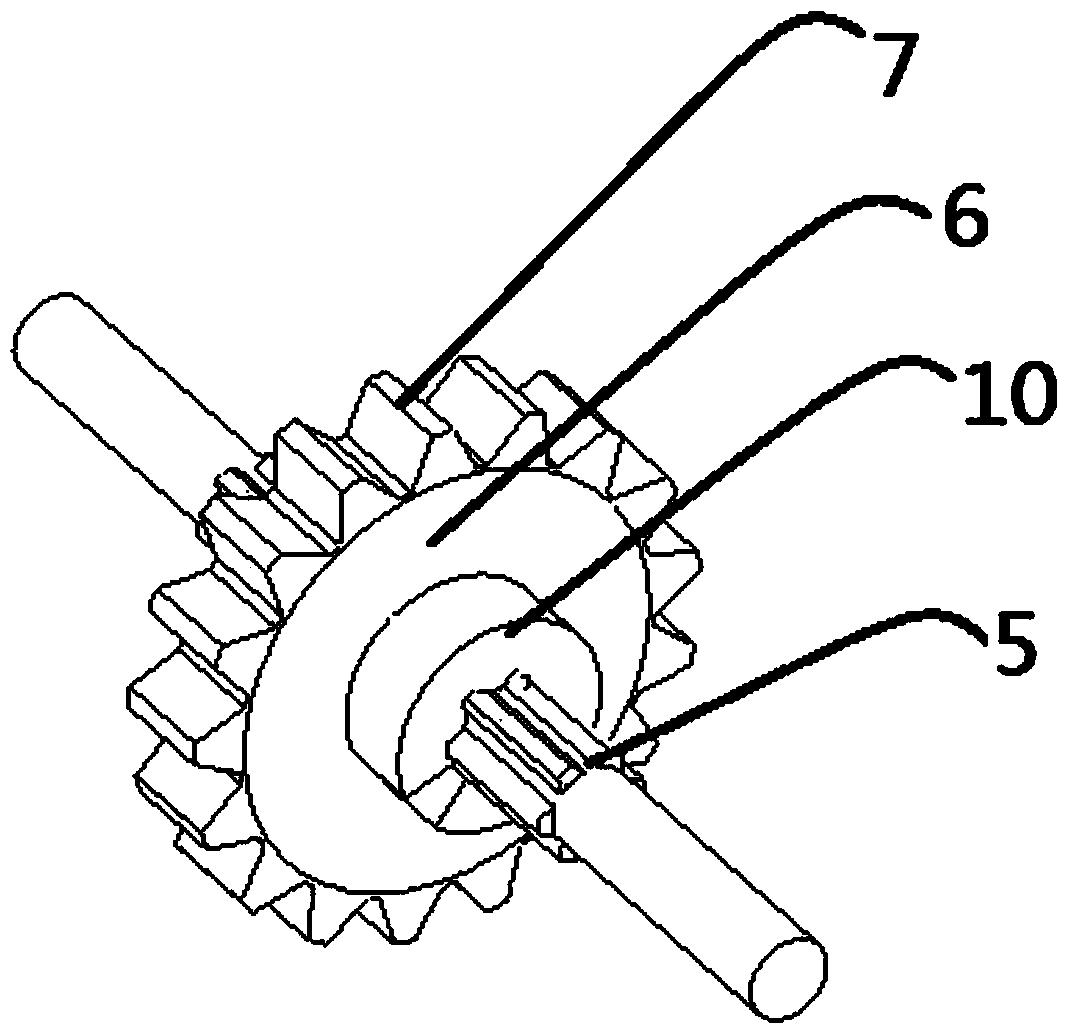

[0027] Embodiment 1: refer to Figure 1-6 As shown, a combined gear oil stirring experimental device includes a box body 1, a box cover 2 arranged on the box body 14, bearing seats 3 arranged on both sides of the box body 1, and fixed to the bearing seats by bearings 4 at both ends 3 on the spline stepped shaft 5, the spline stepped shaft 5 is set with a spline disc 6, and a spline gear assembly or a spline wheel assembly is set outside the spline disc 6; the spline gear assembly includes at least An external gear ring 7, when the number of external gear rings 7 is ≥ two, an internal gear ring 8 is set between two adjacent external gear rings 7; the spline wheel assembly includes at least one pair of external gear rings 7 and The inner gear ring 8, the outer gear ring 7 and the inner gear ring 8 are arranged at intervals from the inside to the outside; at the same time, one end of the spline stepped shaft 5 is connected to the speed torque sensor 1 and the drive motor, and the...

Embodiment 2

[0036] Embodiment 2: for different diameters, different modulus and the combined gear oil stirring experimental method of different number of teeth gears or roulette, its concrete method is as follows:

[0037] (1) One end of the splined stepped shaft 5 is connected with a rotational speed torque sensor one and a drive motor, and the other end is connected with a rotational speed torque sensor two and a dynamometer motor, and the splined disk 6 is moved to a certain position, and used Circlips 10 on both sides are axially fixed, and a plastic rack of a certain type is selected to be bent into an outer gear ring 7, which is set on the spline disc 6, and the box cover 2 is covered. If it is necessary to measure gears with different modulus and different numbers of teeth , replace different types of plastic racks to complete;

[0038] (2) Exploration of oil churning loss of gears and discs. Experimental testing is a discontinuous process. It is necessary to determine the output s...

Embodiment 3

[0040] Embodiment 3: For the combined gear churning test method of gears or wheel discs at different axial positions, its specific method is as follows:

[0041] (1) One end of the splined stepped shaft 5 is connected with the speed torque sensor one and the drive motor, and the other end is connected with the speed torque sensor two and the dynamometer motor, and the speed and torque at different axial positions on the splined stepped shaft 5 are detected. Oil churning loss, and the influence of the distance between the gear and the inner wall on the oil churning loss;

[0042] (2) This exploratory experiment test is a discontinuous process, and the axial position test points need to be set according to the length of the splined stepped shaft 5: s 1 …s i …s n , determine the range of drive motor output speed and torque according to the peak power of the drive motor, and set the speed of the drive motor to be: n 1 …n j …n m , move the splined disc 6 to the axial position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com