Plasma display manufacturing method

The technology of a plasma display and its manufacturing method is applied in the direction of discharge tube/lamp manufacturing, cold cathode manufacturing, electrode system manufacturing, etc. It can solve the problems of unit board pollution, flying out of glass powder, easy damage of plasma display, etc., and achieve reduction Pollution, Intensity-Increasing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

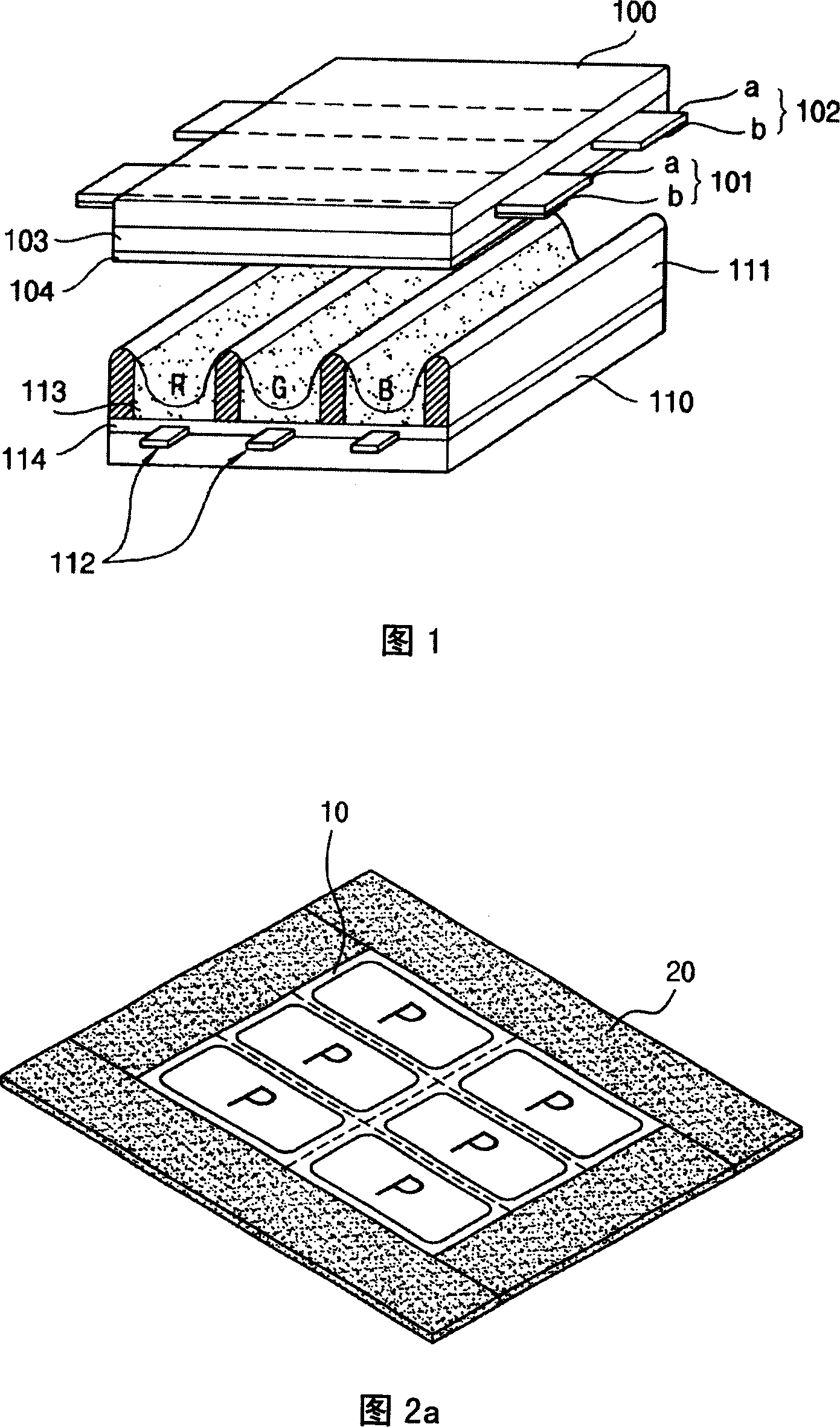

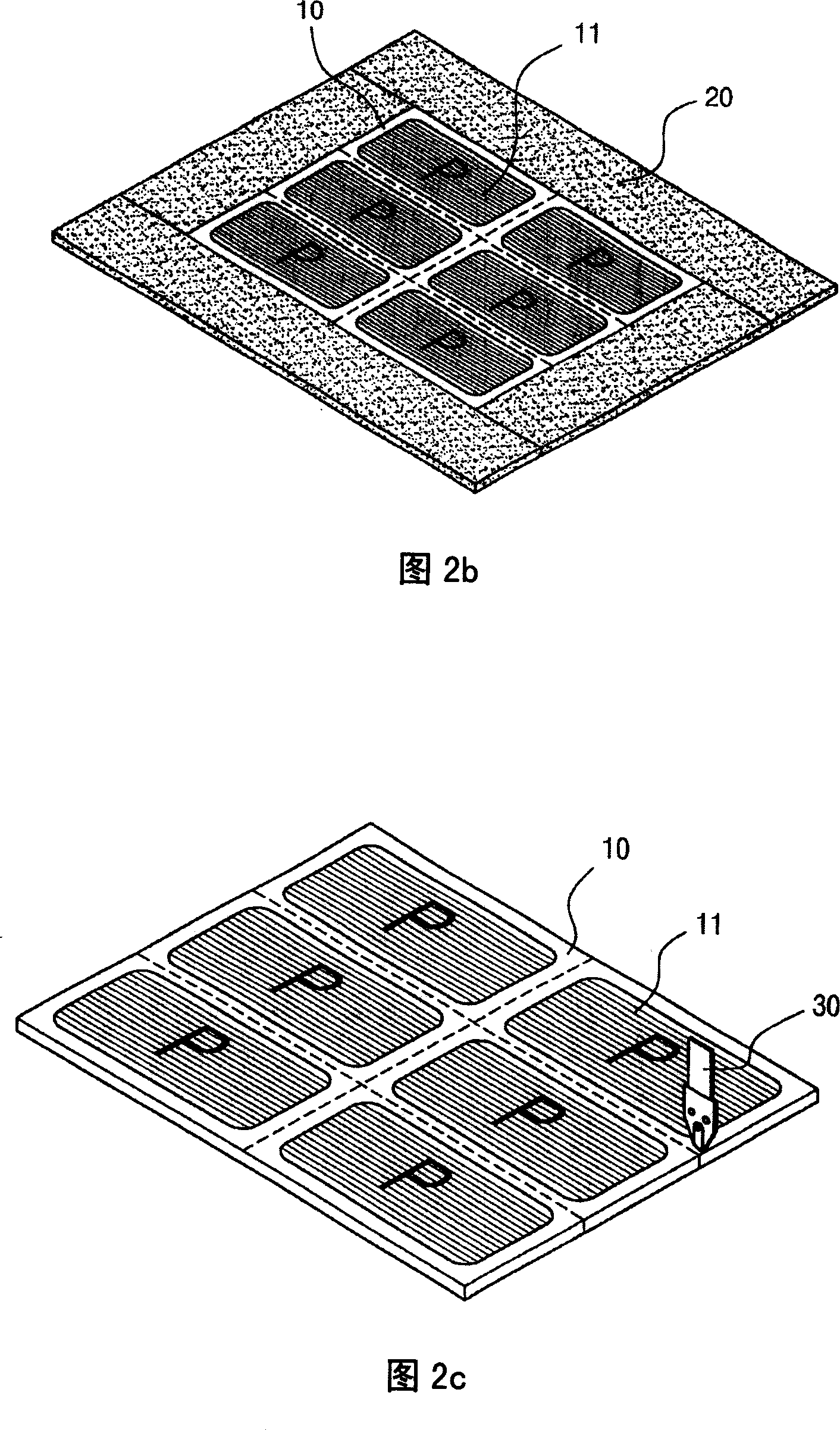

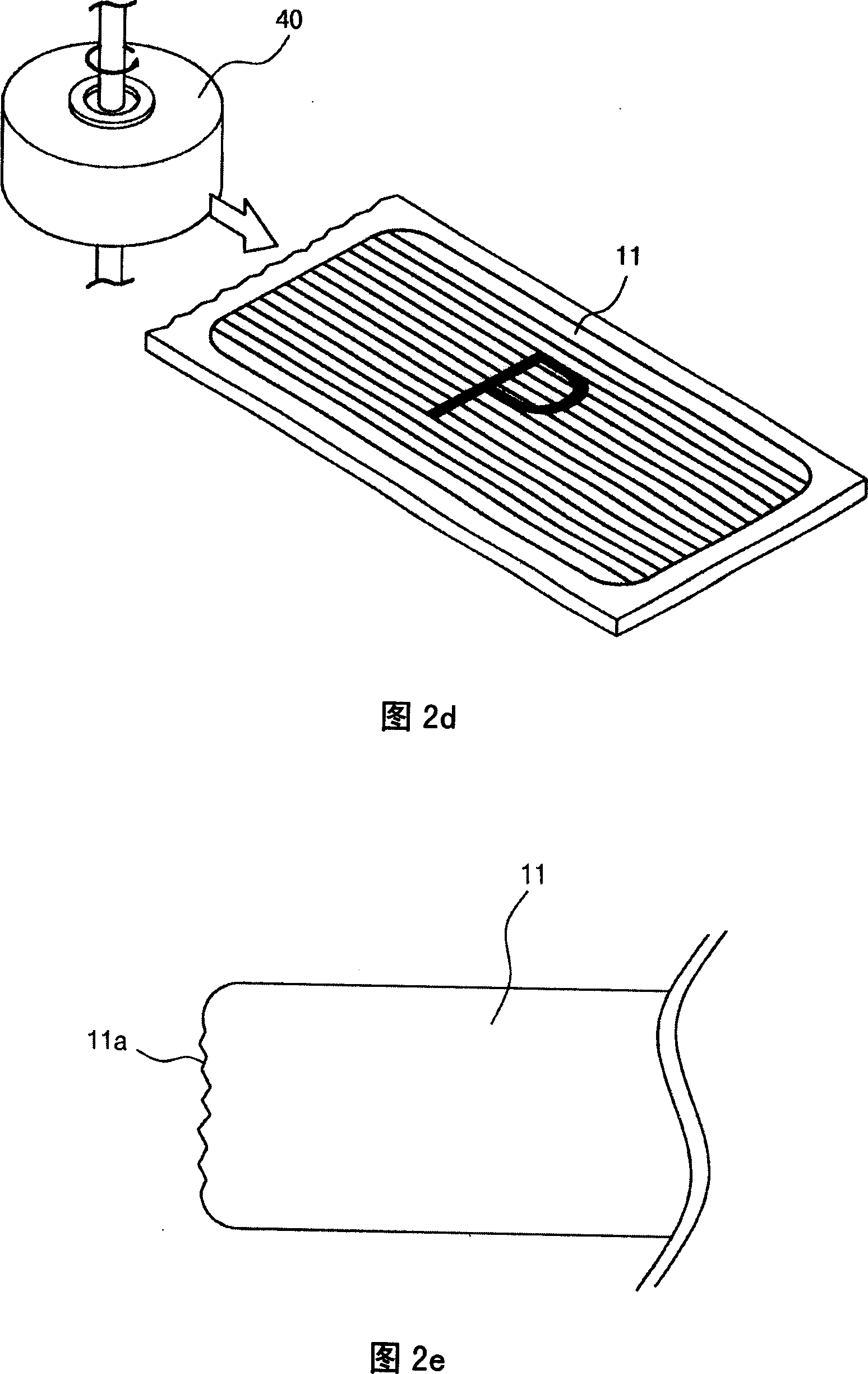

[0031] FIG. 3 is a schematic diagram of the multi-facet acquisition process in the manufacturing method of the plasma display according to the present invention.

[0032] As shown in Figure 3, according to the multi-face-taking process of the plasma display of the present invention, it consists of several steps: the step of fixing and arranging the mother glass substrate with a guide plate (S10); after fixing and arranging the mother glass substrate, The step of forming a unit panel on the glass substrate (S20); after the unit panel is formed, the step of cutting the mother glass substrate according to the unit panel by a cutter (S30); and the step of heating and polishing the cut surface of the unit panel (S40 ).

[0033] The step of fixing and arranging the mother glass substrate by using the guide plate (S10) is to install the electrode, the dielectr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap