Variable speed-change gearbox

A technology for transmissions and gearshift clutches, which is applied to vehicle gearboxes, transmissions, transportation and packaging, etc. It can solve the problem of no advantage in installation length and achieve the effect of reducing bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

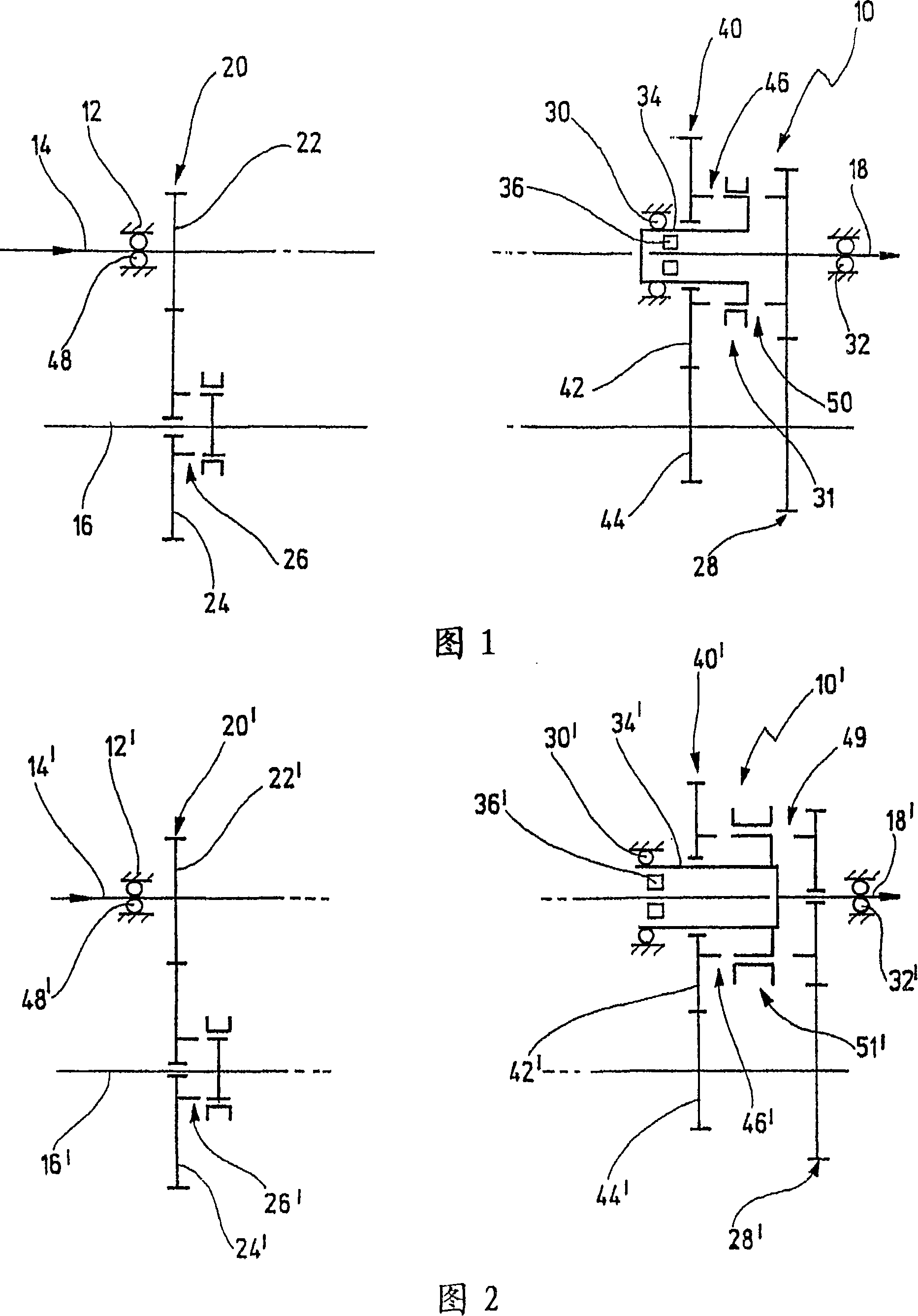

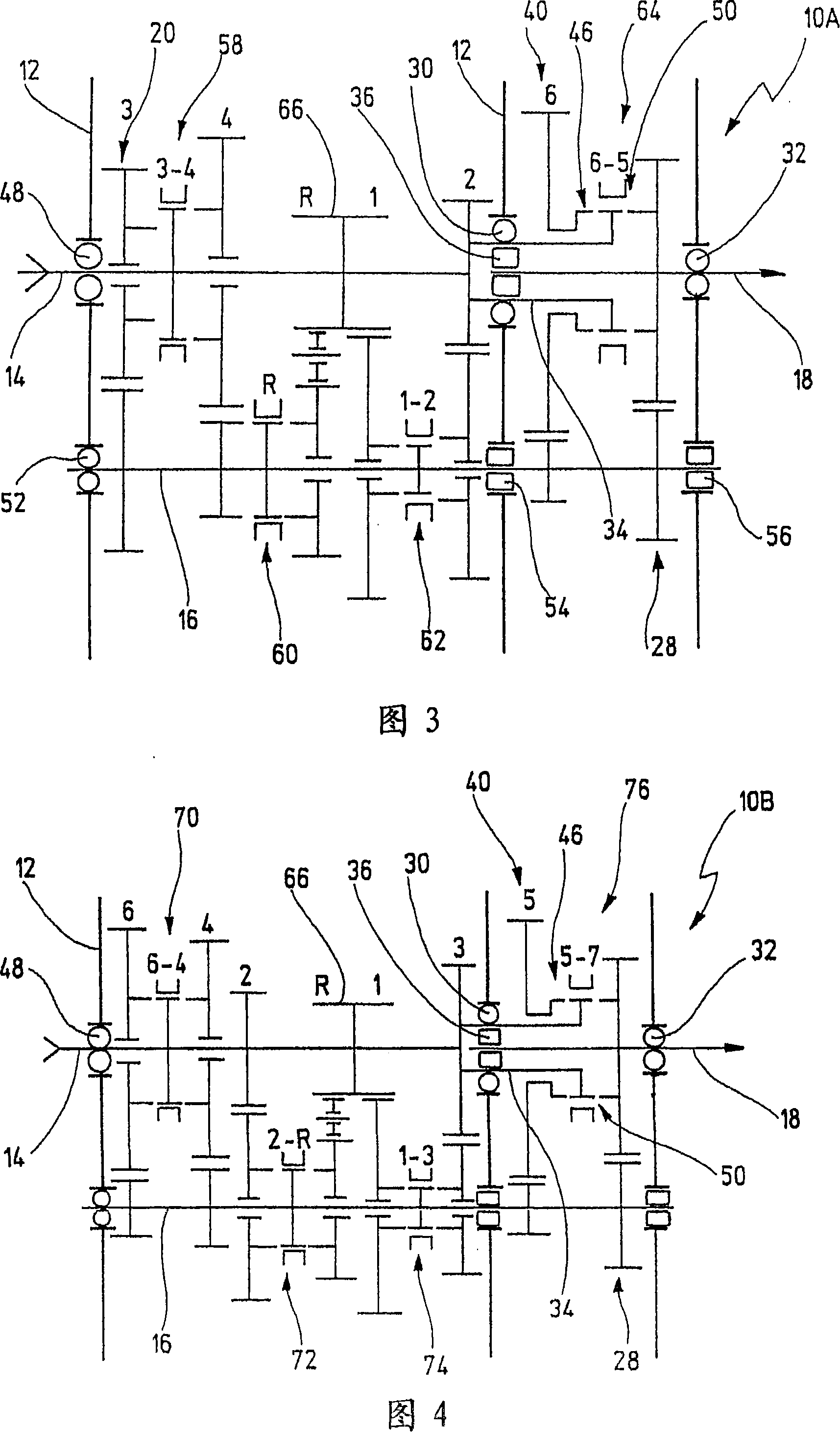

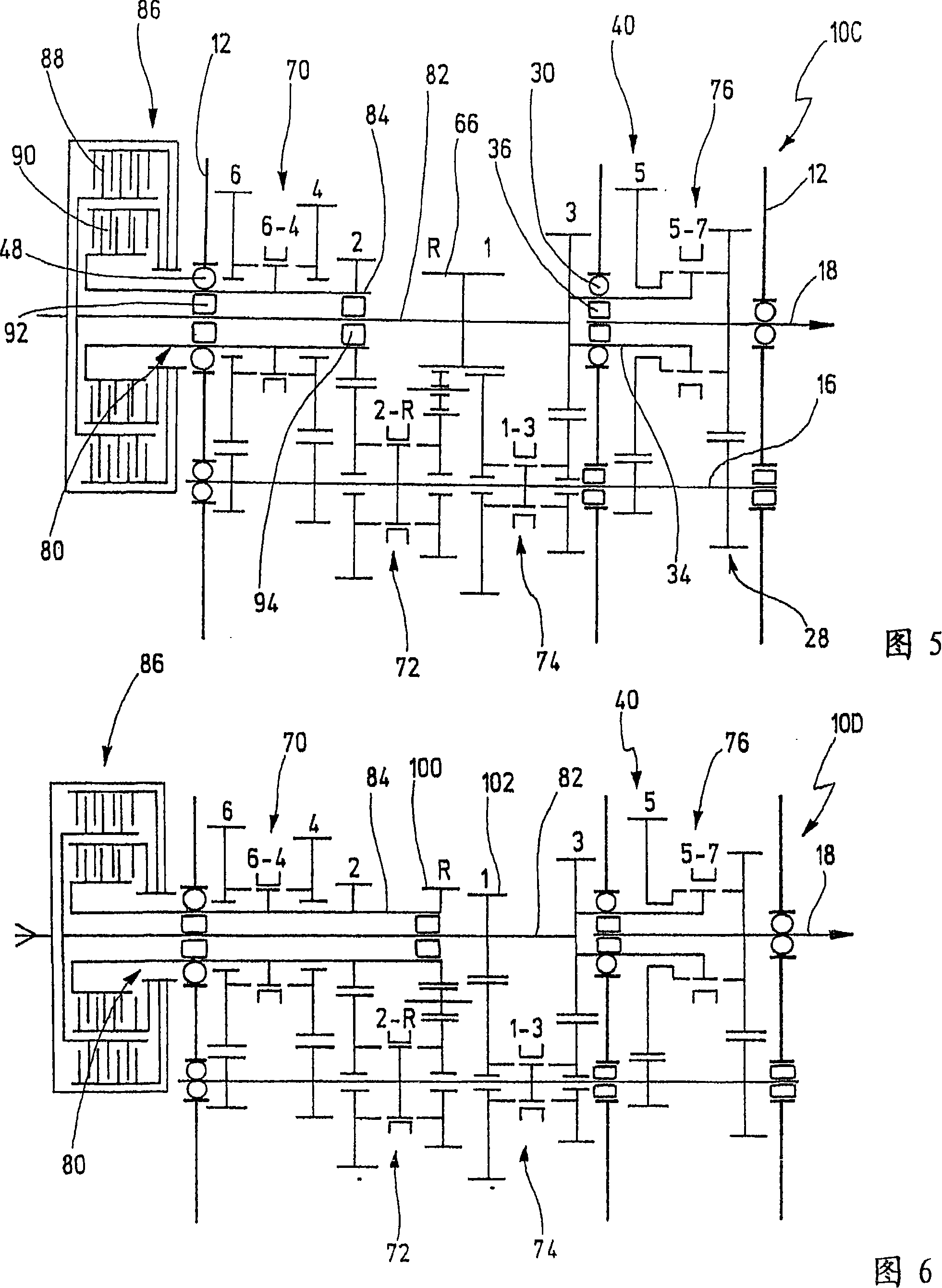

[0055] In FIG. 1 , a first embodiment of a multi-stage transmission according to the invention is generally designated 10 .

[0056] The multi-stage transmission 10 is designed as an in-line transmission, that is to say a transmission for longitudinal installation in a vehicle, in particular a passenger vehicle.

[0057] The multi-speed transmission 10 has a housing generally designed to accommodate multiple components. For ease of illustration, the housing 12 shown in FIG. 1 and subsequent figures is shown in its non-separated state. The housing 12 can accommodate only the necessary functional elements of the multi-stage transmission. However, the housing 12 can also be formed as part of an adjacent housing and comprise, for example, a partition wall between the gear sets of the multi-stage transmission 10 and / or between the input-side starting and separating clutches or the like.

[0058] The multi-stage transmission 10 also has a power input shaft arrangement in the form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com