Engine oil pump suitable for SD type, LD type, S type and ZH type diesel engine

A technology for oil pump and diesel engine, applied in the field of oil pump and diesel engine oil pump, can solve the problems of difficult to guarantee surface roughness and flatness, large area of high-pressure oil area, poor sealing performance, etc. Good oil absorption performance, not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

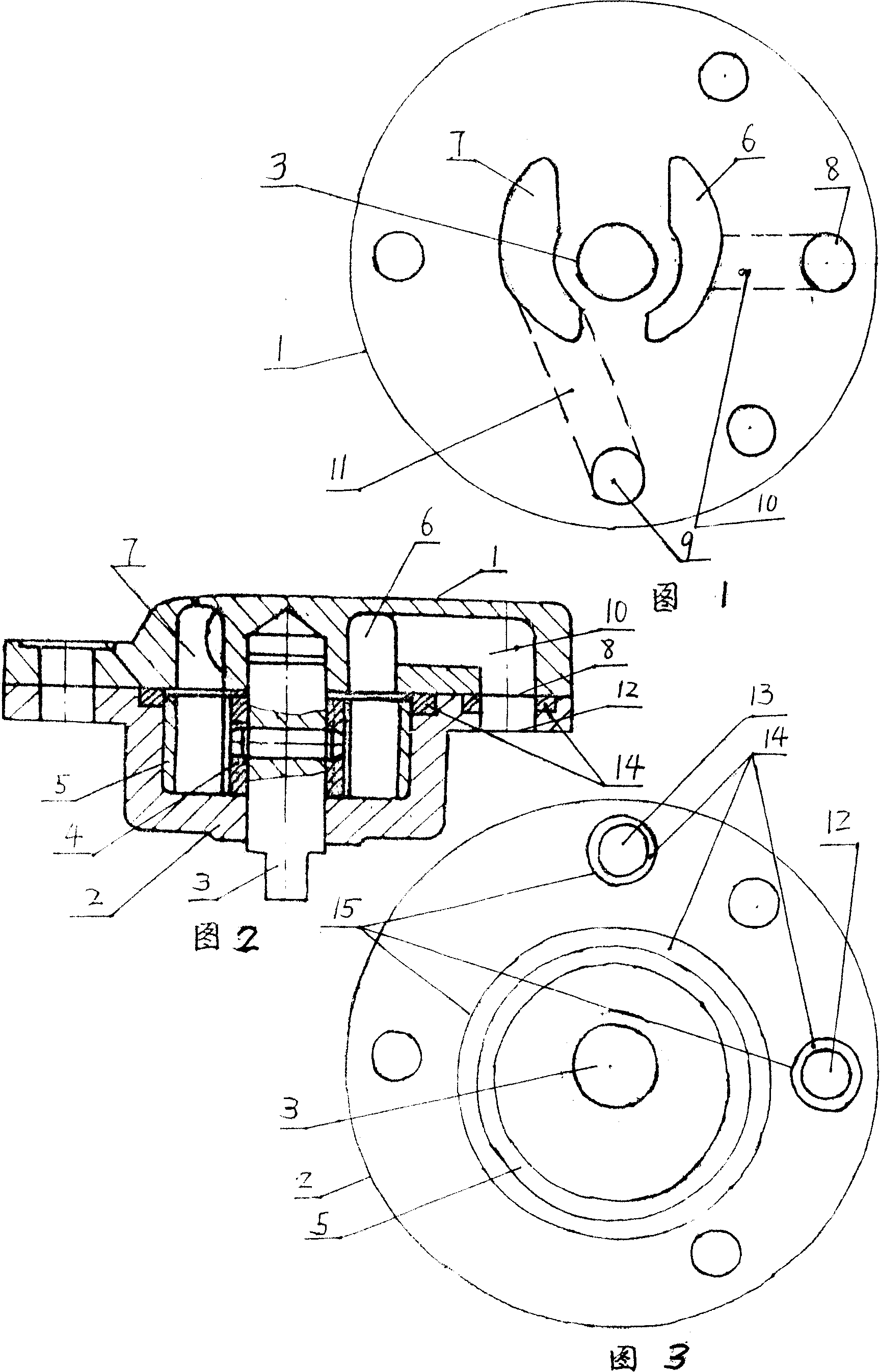

[0013] The best embodiments of the present invention are given below in conjunction with the accompanying drawings to further illustrate the technical solutions of the present invention.

[0014] Referring to Figures 1-3, it can be seen from the figure that the diesel engine oil pump of the present invention includes a pump cover 1 and a pump body 2 fastened together by fasteners, and a rotor passing through the pump cover 1 and the pump body 2 Shaft 3 is located in the inner rotor 4 and outer rotor 5 which are matched with the rotor shaft in the pump body. The pump cover is provided with the pump cover oil inlet and outlet holes 8 and 9, which are in communication with the pump body inlet and outlet oil chambers 12 and 13, and the pump cover for oil inlet and outlet. Cavities 6 and 7, the pump cover inlet and outlet oil passages 10 and 11 that connect the pump cover in and out of the oil cavity hole and the pump cover in and out of the oil cavity respectively; between the pump co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com