Drum-type material loosening and temperature-increasing moisturizing device

A temperature-increasing, humidifying, drum-type technology, applied in the field of drum-type processing device structure, can solve the problems of low heat-moisture exchange intensity, insufficient material tearing strength, and loose materials that are difficult to agglomerate, so as to improve the loosening effect and save installation space , to avoid the effect of material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

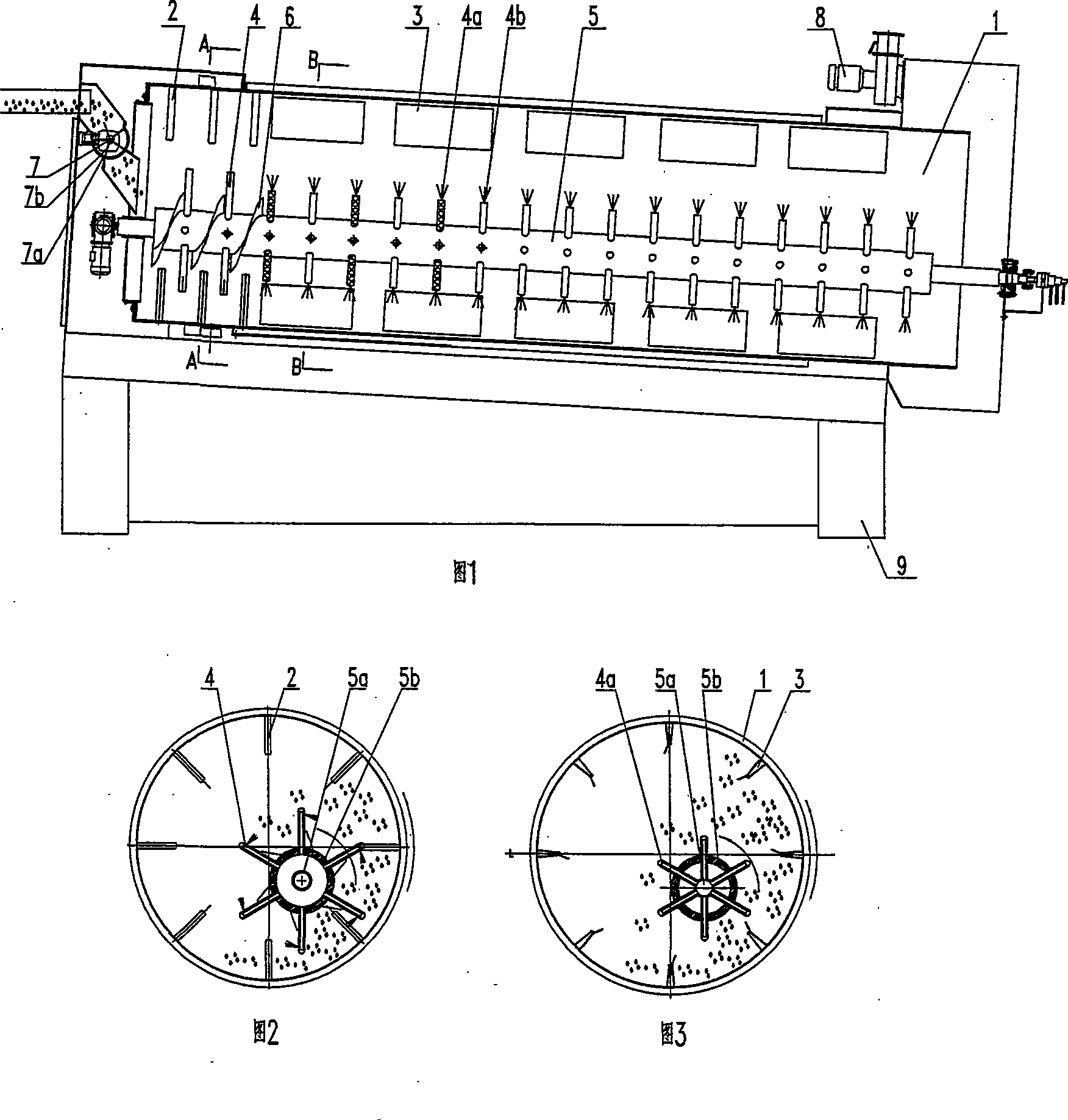

[0014] As shown in the figure, the present invention includes a drum 1 horizontally installed on a frame 9, loose rake nails 2 and a copying plate 3 arranged on the inner wall of the drum, and a rotating shaft 5 with outer rake nails 4 is arranged axially in the drum , the rotation shaft 5 is set to rotate in the same direction as the drum 1, and the rotation speed of the rotation shaft 5 is greater than the rotation speed of the drum 1. The rake 4 on the rotating shaft 5 can be a rake that only plays a loose role, or a rake 4a with a water spray hole that can spray water mist on the material, or a rake with an air spray hole that can spray water on the material Hot steam rake 4b. According to actual needs, loose rake nails can be set on the front section of the rotating shaft 5, and rake nails 4a with water spray holes or rake nails 4b with air jet holes can be set at the rear section, or the rake nails 4a with water spray holes and the rake nails with air jet holes The rake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com