Punch

A punching machine and hole-containing technology, which is applied in the field of punching machines, can solve the problems of cumbersome production of integral components and limited labor-saving effect, and achieve the effect of simple structure and fast punching action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

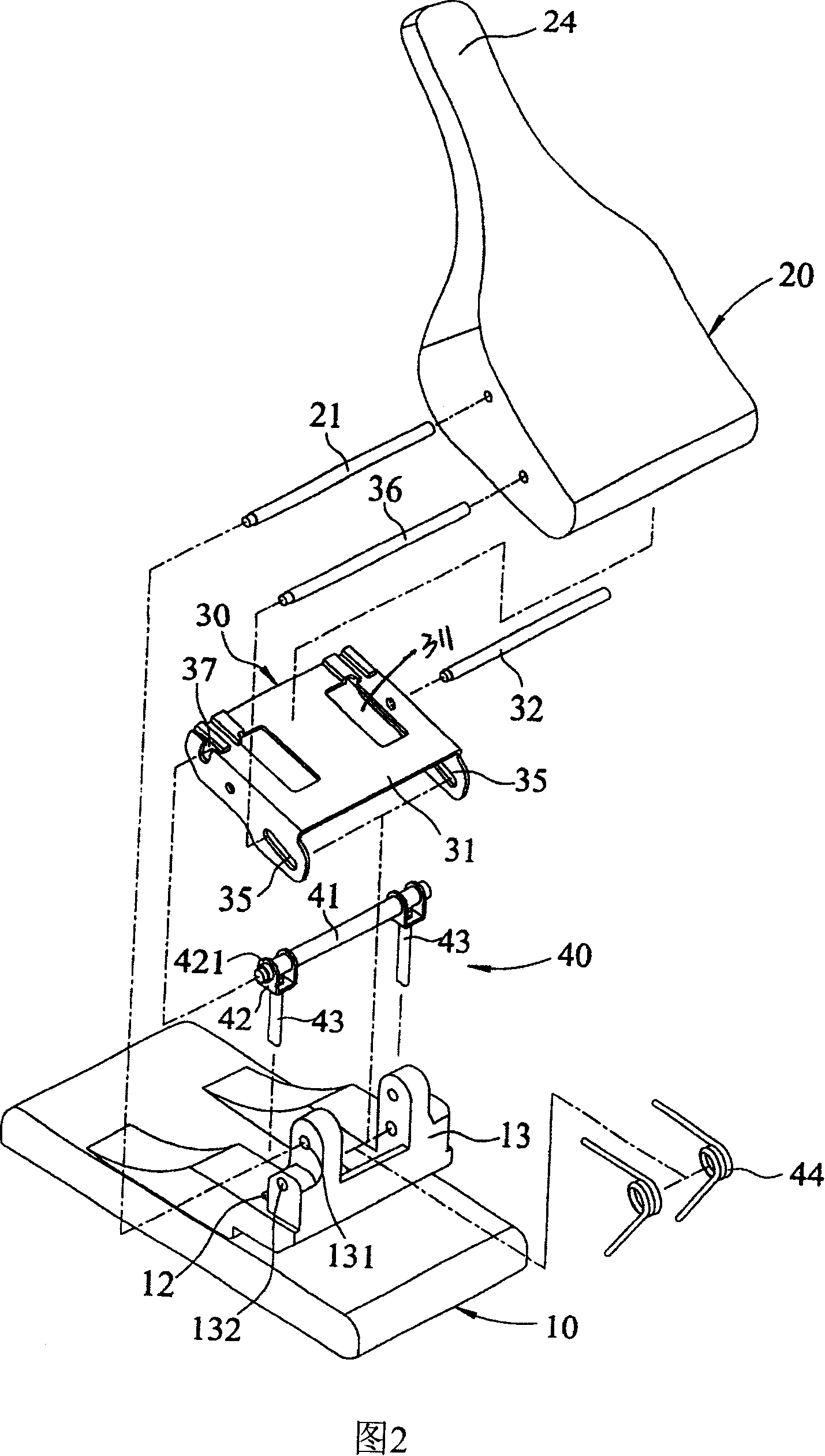

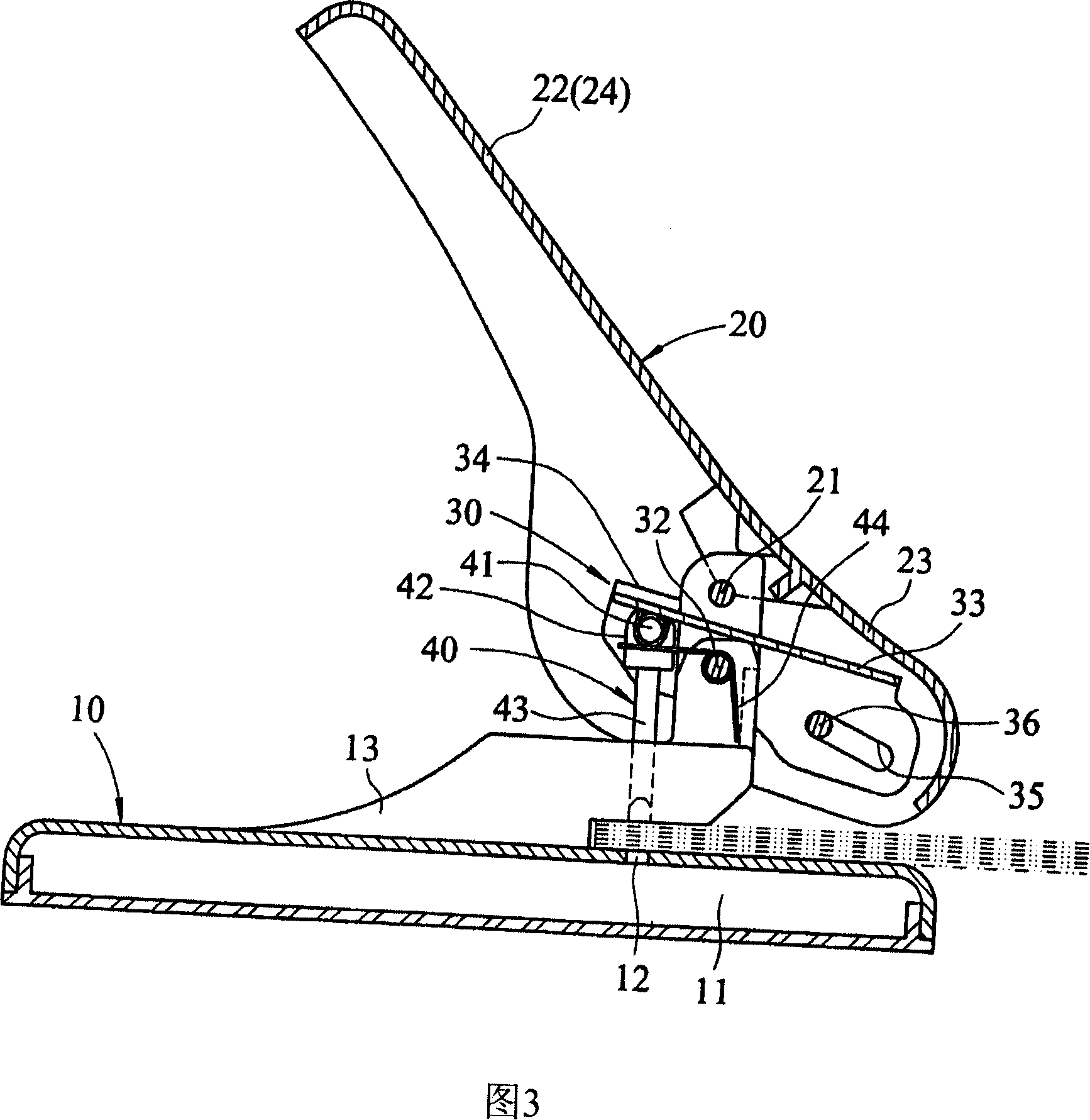

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

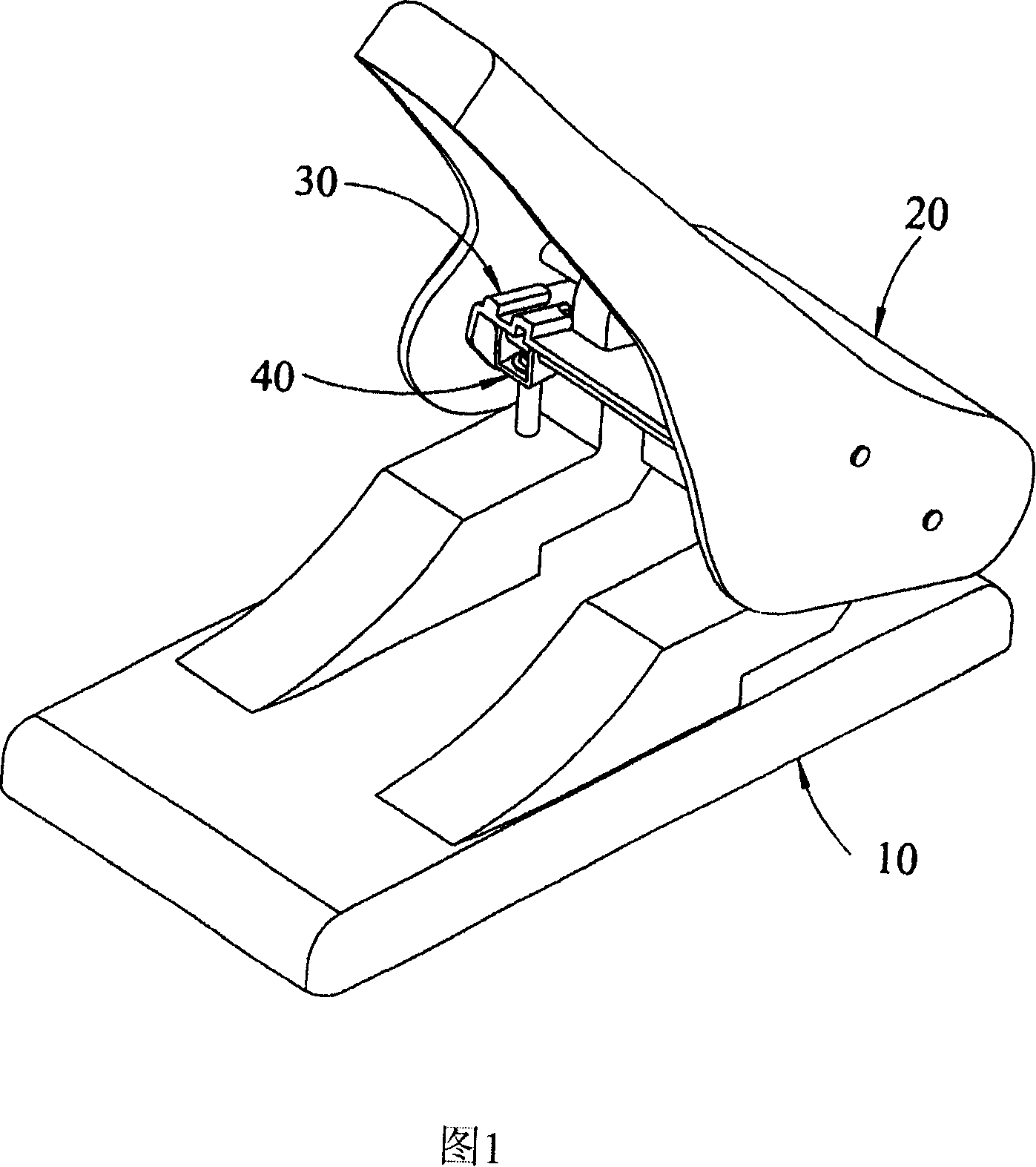

[0018] It can be seen from Fig. 1, Fig. 2 and Fig. 3 that the present invention includes: a base 10, an upper cover 20, a linkage group 30 and a punching part 40, wherein;

[0019] The base 10 is a pedestal body with a chamber 11 below, and two holes 12 are arranged above it, and two fixing seats 13 which are aligned side by side with each of the holes 12 are fixed on its top surface, the fixing seats 13 There are upper and lower pivot holes 131, 132 for pivot connection;

[0020] The upper cover 20 is pivoted through the pivot hole 131 on each of the fixing bases 13 with a first pivot rod 21, which can be rotated at a preset angle, and a first pivot is formed at both ends of the pivot point. The force application arm 22 and a first force resistance arm 23 which is linked, and the first force application arm 22 is set as a pressing part 24;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com