Optical lens for imaging

An optical mirror and imaging technology, applied in the field of optical mirror groups, can solve the problems of reduced lens thickness, poor lens uniformity, and difficulty in placing three lenses in this space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

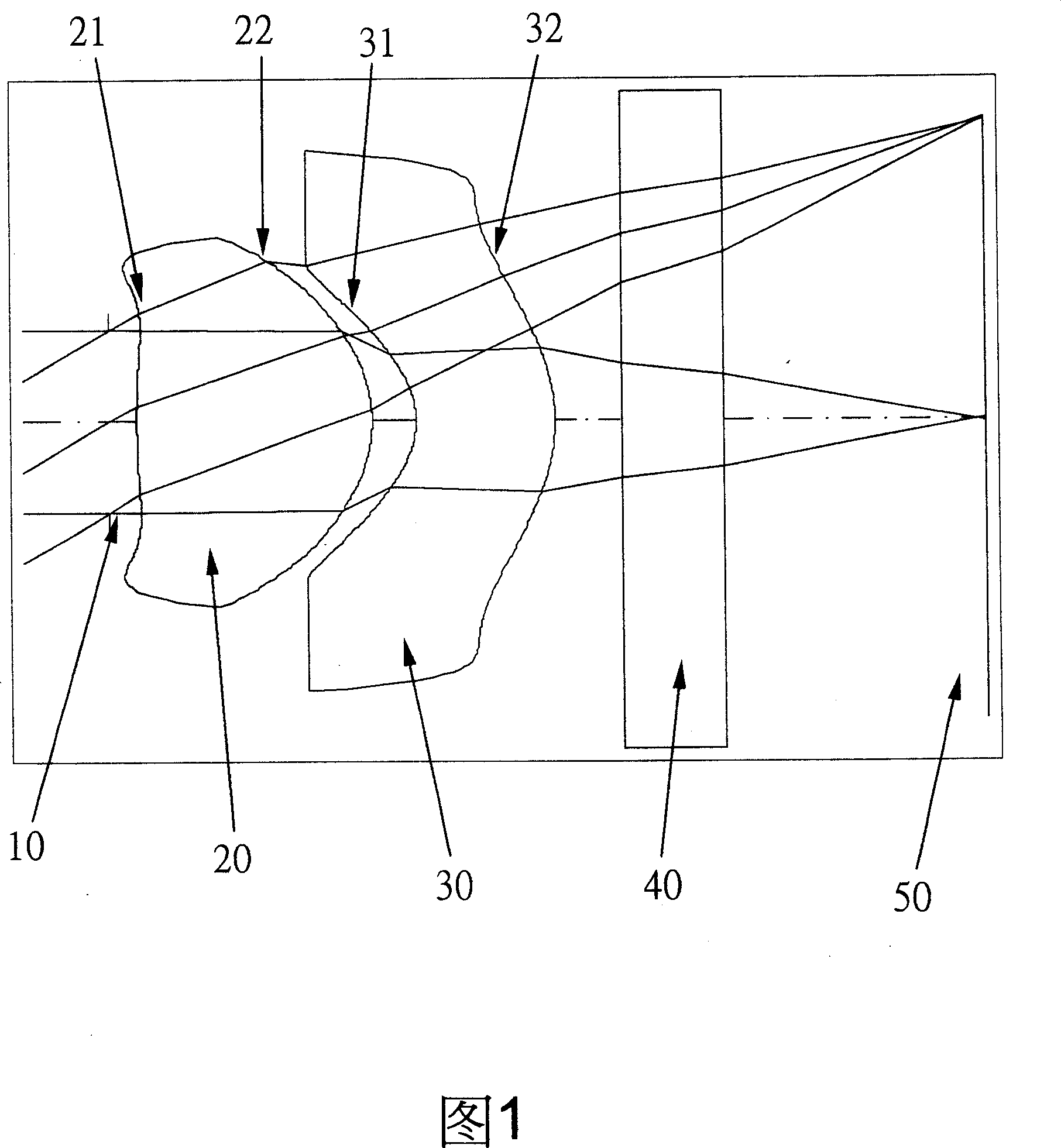

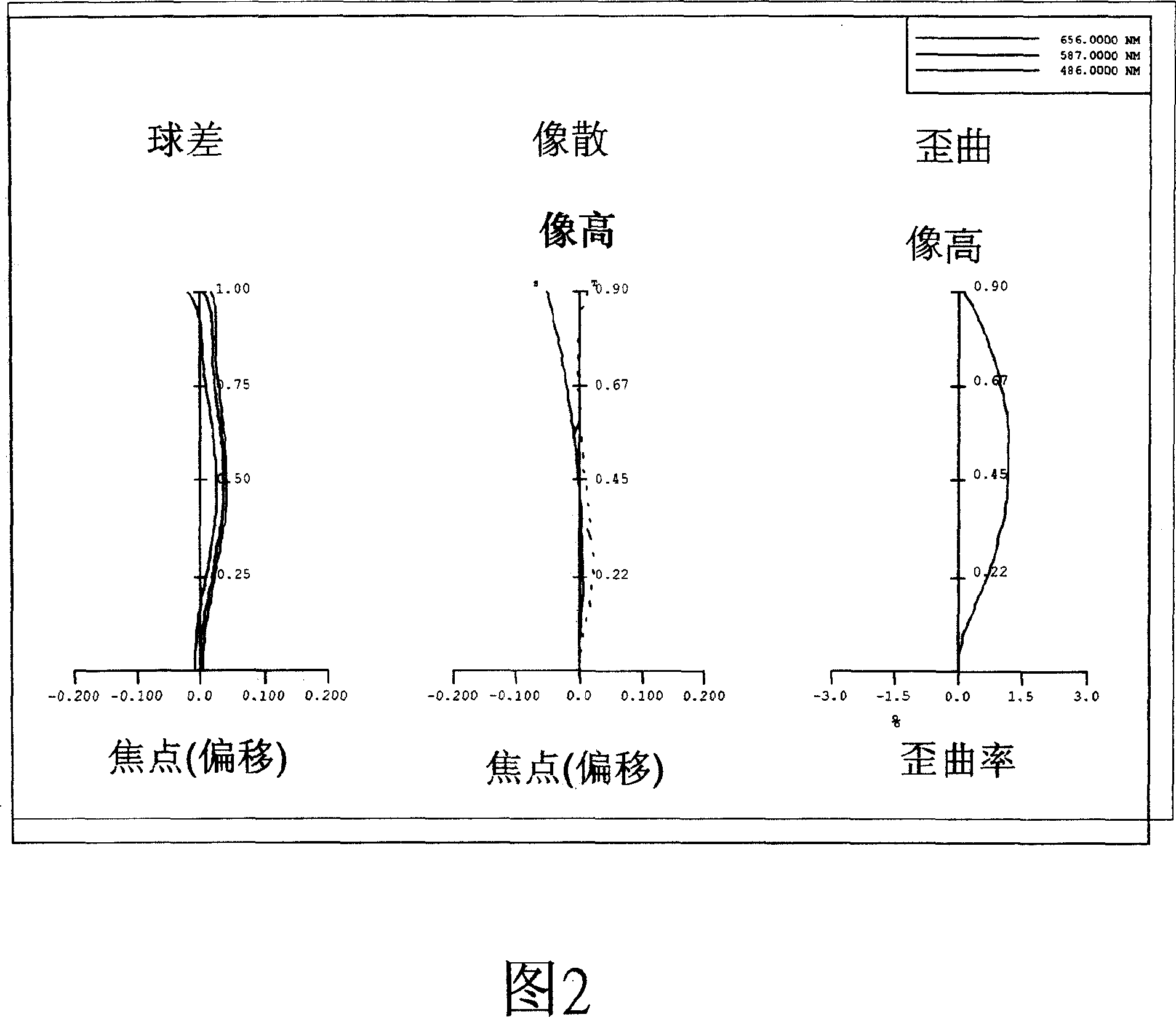

Embodiment 1

[0066] f (focal length) = 1.53mm Fno = 2.8, HFOV (half angle of view) = 30.2deg.

[0067]

[0068] Table 1

[0069] Aspheric coefficient

[0070] Table 2

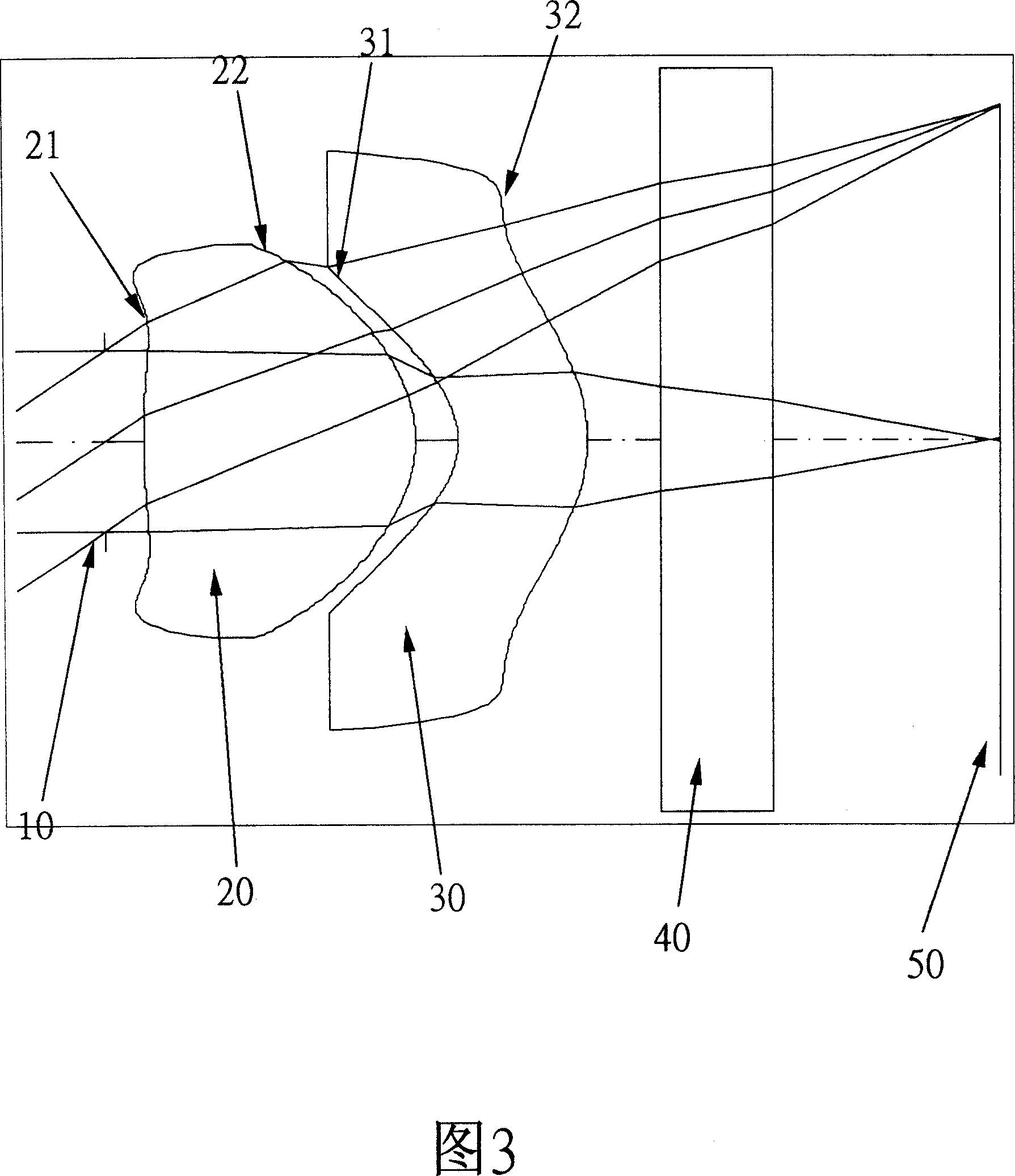

[0071] (Embodiment 2 Implementation 2)

[0072] F (focal length) = 1.38mm, Fno = 2.8, HFOV (half angle of view) = 33.0deg.

[0073]

[0074] table 3

[0075] Aspheric coefficient

[0076] Table 4

[0077] Embodiment one

[0078] table 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com