Engine cooling apparatus and engine cooling method

A cooling device and engine technology, applied in the direction of engine cooling, cooling device control device, engine components, etc., can solve the problems of increased fuel consumption, and achieve the effects of reducing effective utilization, avoiding large-scale, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described below based on the drawings.

[0042] In the present embodiment, the engine cooling device 2 and the method of cooling the engine are applied to a vehicle equipped with an engine 4 (here, a diesel engine) that responds to trucks or automobile exhaust gas restrictions with a large-capacity EGR system or the like. .

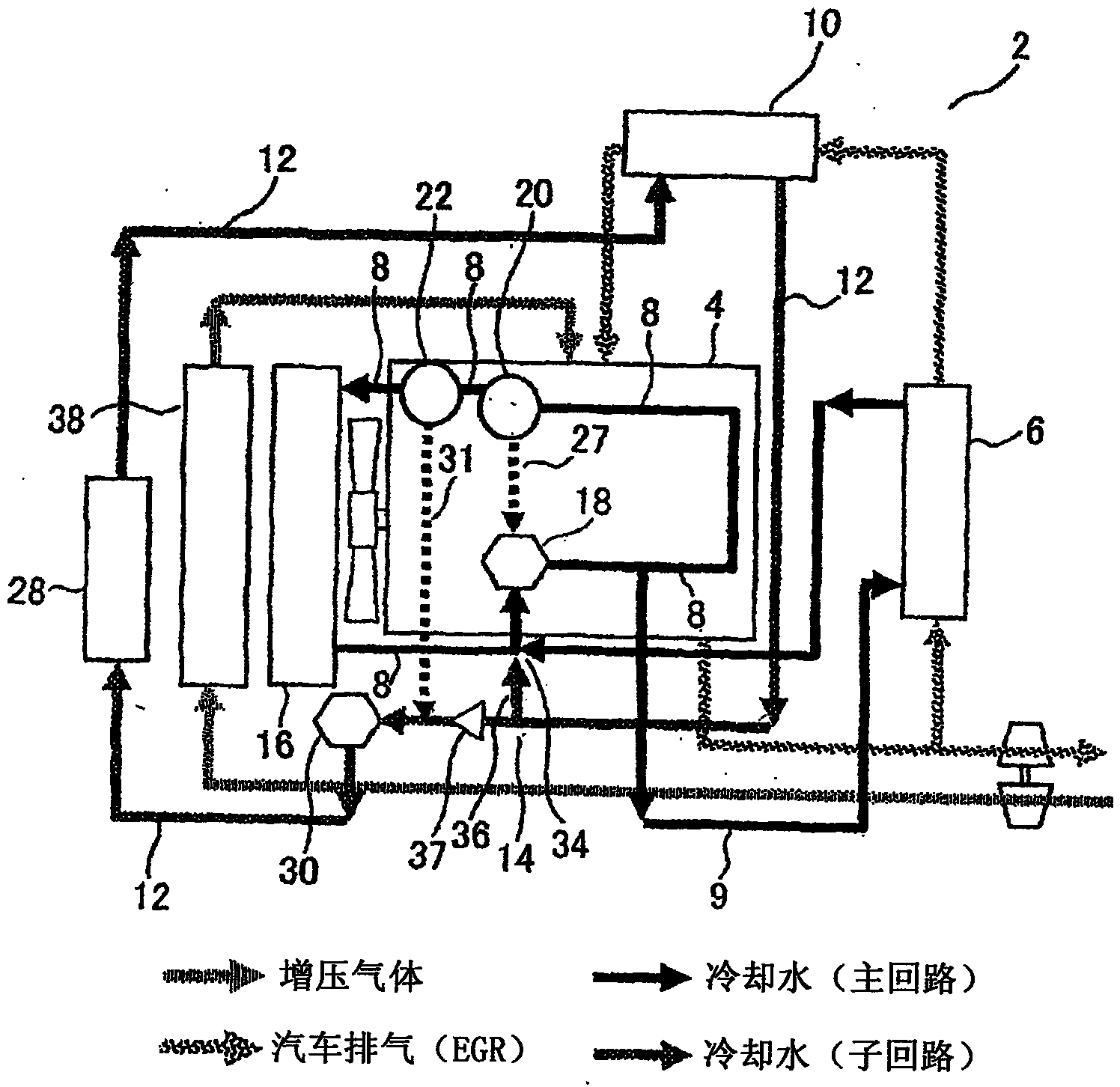

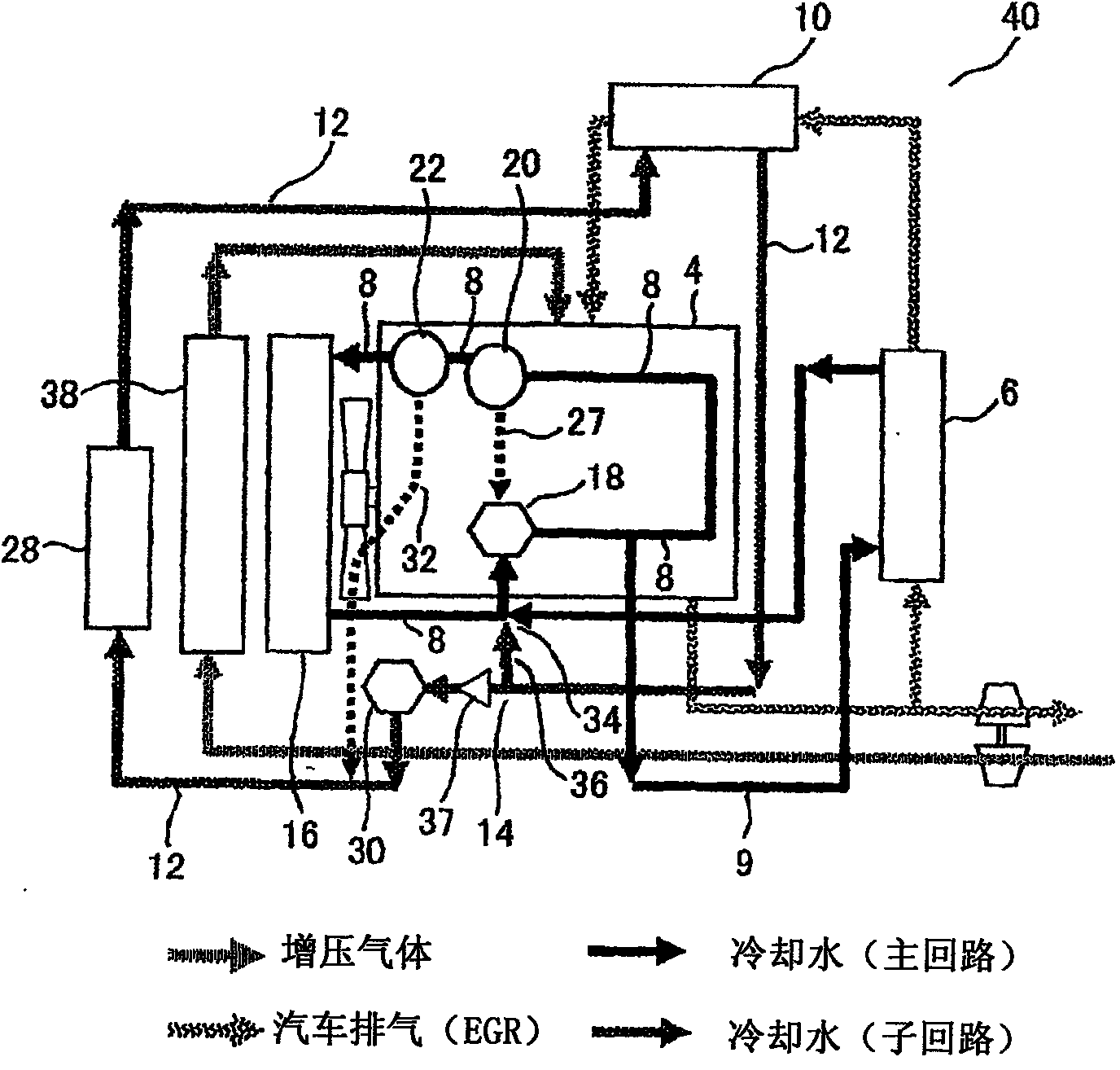

[0043] figure 1 It is a block diagram showing the configuration of the engine cooling device 2 according to the first embodiment.

[0044] The cooling device 2 of the engine has the following two circuits: the main circuit 8 of cooling water, which uses the main radiator 16 to cool the engine 4 and the first EGR cooler 6; The low-temperature cooling water cools the second EGR cooler 10 .

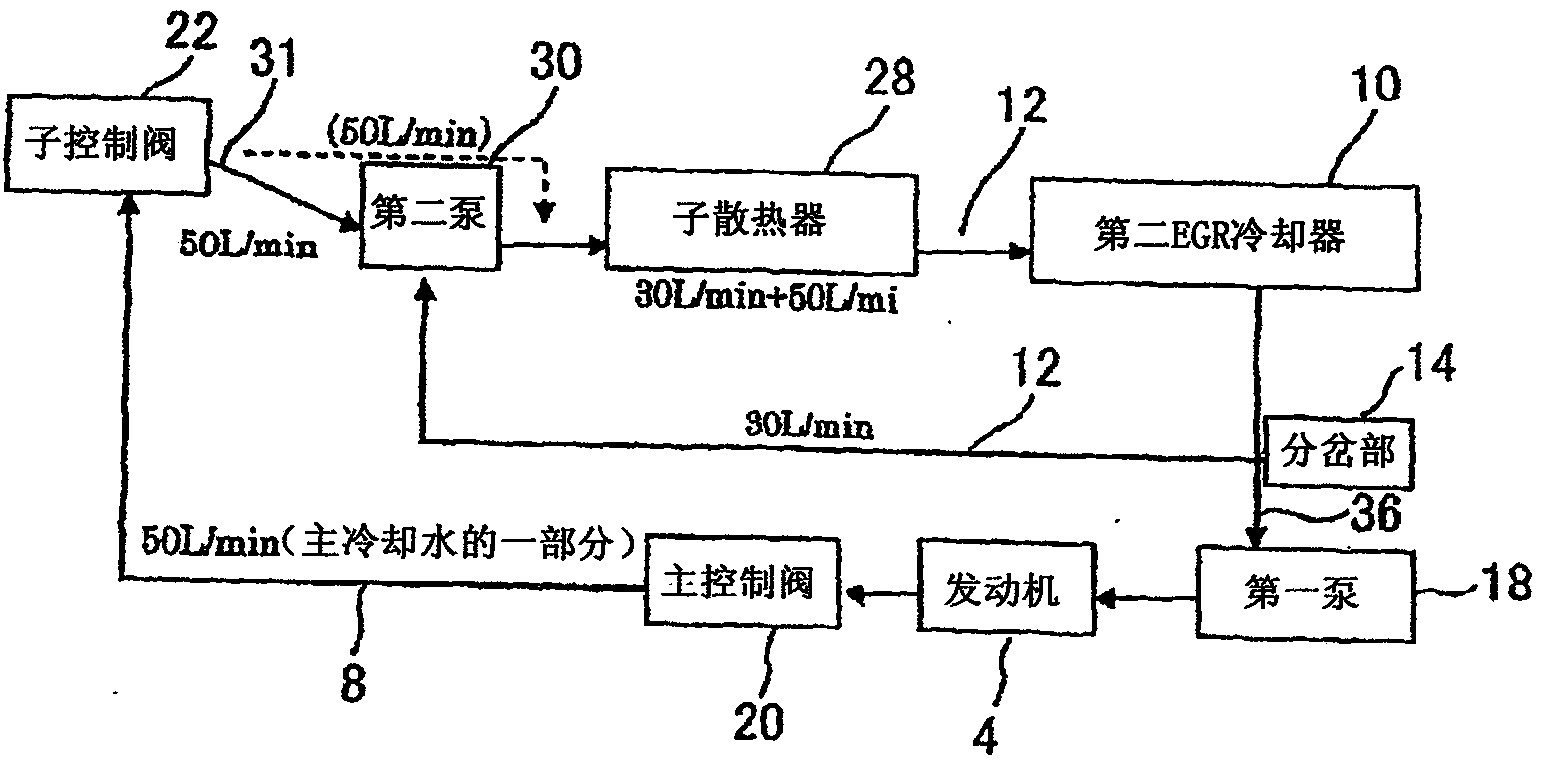

[0045] In addition, a branch portion 14 is provided on the above-mentioned sub-circuit 12. According to predetermined conditions, the cooling water circulating in the sub-circuit 12 flows into the main circuit 8 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com